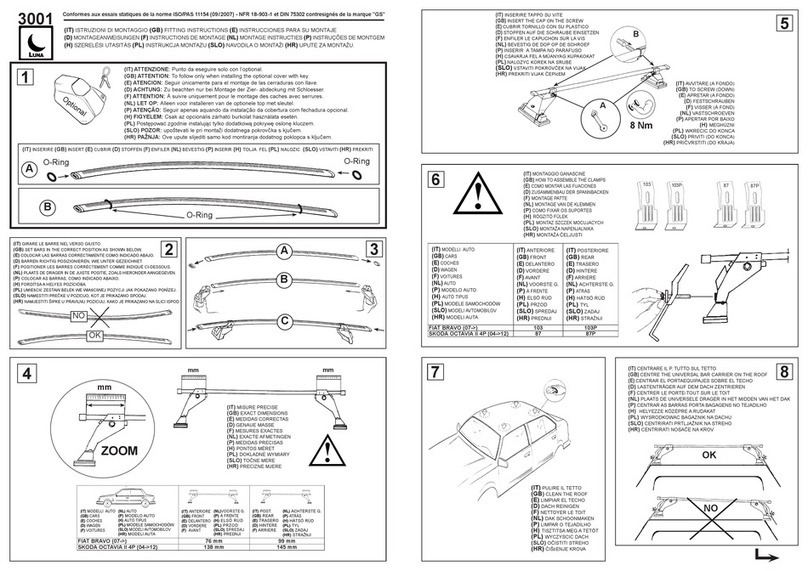

Actron Global OBD II Scan Tool 9620 User manual

9620 Global

OBD II Scan Tool

©2002 Actron Manufacturing Co.

Printed in USA

0002-002-2361

ACTRON MANUFACTURING CO.

15825 Industria Parkway

C eve and, Ohio 44135-9946

USA

Internet and e-mail - http://www.actron.com

SFI or SEFI:

Sequentia Fue Injection or Sequentia E ectronic Fue Injection. A fue injection system

that uses one or more injectors for each cy inder. The injectors are mounted in the

intake manifo d and are fired individua y.

ST:

Short Term fue trim.

TBI:

Thrott e Body Injection. A fue injection system having one or more injectors mounted in a

centra y ocated thrott e body, as opposed to positioning the injectors c ose to an intake

va ve port. TBI is a so ca ed Centra Fue Injection (CFI) in some vehic es.

TDC:

Top Dead Center. When a piston is at its uppermost position in the cy inder.

Throttle Body:

A device which performs the same function as a carburetor in a fue injection system. On a

thrott e body injection (TBI) system, the thrott e body is both the air door and the ocation of

the fue injectors. On port fue injection systems (PFI, MPFI, SFI, etc.), the thrott e body is

simp y an air door. Fue is not added unti the injectors at each intake port are activated. In

each case, the thrott e body is attached to the acce erator peda .

TPS:

Thrott e Position Sensor. Potentiometer-type sensor connected to the thrott e shaft. Its vo tage

signa output increases as the thrott e is opened. The PCM uses this signa to contro many

systems such as id e speed, spark advance, fue de ivery, etc.

TTS:

Transmission Temperature Sensor. A resistance sensor mounted in the transmission

housing in contact with the transmission f uid. It sends a vo tage signa to the PCM indicating

the temperature of the transmission.

VECI:

Vehic e Emission Contro Information. A deca ocated in the engine compartment containing

information about the emission contro systems found on the vehic e. The VECI is the

authoritative source for determining whether a vehic e is OBD II-comp iant.

VIN:

Vehic e Identification Number. This is the factory-assigned vehic e seria number. This

number is stamped on a number of ocations throughout the vehic e, but the most prominent

ocation is on top of the dashboard on the drivers side, visib e from outside the car. The VIN

inc udes information about the car, inc uding where it was bui t, body and engine codes,

options, and a sequentia bui d number.

VSS:

Vehic e Speed Sensor. Sends a frequency signa to the PCM. The frequency increases as

the vehic e moves faster to give the PCM vehic e speed information used to determine shift

points, engine oad, and cruise contro functions.

WOT:

Wide-Open Thrott e. The vehic e operating condition brought about when the thrott e is

comp ete y (or near y) open. The PCM wi typica y de iver extra fue to the engine and de-

energize the A/C compressor at this time for acce eration purposes. The PCM uses a

switch or the Thrott e Position Sensor to identify the WOT condition.

29620 Professional OBD II Scan Tool

Table of Contents

2.3.9 On-Board Systems ............... 17

2.3.10 Record Data .......................... 17

2.3.11 Vehicle Info ........................... 1

2.3.12 Modules Present ................... 19

2.3.13 Review Data .......................... 19

2.3.14 Print Data .............................. 20

Section 3: Diagnostic Trouble

Codes (DTC) ---- 22

3.1 DTC For at .................................. 22

3.2 Code Lookup ................................ 23

3.3 Diagnostic Trouble Code Ranges 24

Section 4: Help and Trouble-

shooting Tips ---- 25

4.1 How to Use Help ........................... 25

4.2 Scan Tool Proble s ..................... 25

4.2.1 Scan Tool does not powerup:

25

4.2.2 Scan Tool does not Link

withvehicle:........................... 25

4.2.3 One or more modules drops

the communication link: ...... 26

4.2.4 Keyboard does not function

properly: ................................ 26

4.3 Tool Self-Tests .............................. 26

4.3.1 Display Test ........................... 26

4.3.2 Keyboard Test ....................... 26

4.3.3 Memory Test .......................... 27

4.3.4 Printer Test ............................ 27

4.4 Technical Support ........................ 27

Appendi A: Global OBD II PID

List & Definitions 28

Appendi B: Glossary & Defini-

tions ---------------- 31

A information, i ustrations and specifications contained in this manua are based

on the atest information avai ab e from industry sources at the time of pub ication.

No warranty (expressed or imp ied) can be made for its accuracy or comp eteness,

nor is any responsibi ity assumed by Actron or anyone connected with it for oss or

damages suffered through re iance on any information contained in this manua or

misuse of accompanying product. Actron reserves the right to make changes at any

time to this manua or accompanying product without ob igation to notify any person

or organization of such changes.

Vehicle ServiceInformation ......3

Safety Precautions .....................4

Section 1: Vehicle Computer

Systems------------- 5

1.1 Introduction ..................................... 5

1.1.1 What The Computer Controls . 5

1.1.2 What Has Not Changed ..........5

1.1.3 Computer Control System ......5

1.2 Data Link ConnectorandLocation .6

1.3 OBD II Scan Tool Hookup ................6

1.3.1 Keyboard .................................7

1.3.2 Display .....................................7

1.3.3 Lists, Menus, and Questions ...7

1.4 Tool Setup ....................................... 8

1.4.1 Changing Measurement Units

1.4.2 Changing Display Contrast .....

1.4.3 Displaying Tool Information ....9

1.4.4 Program Mode .........................9

1.5 Personal Co puter (PC) and

PrinterInterface..............................9

1.6 Replacing the Battery .....................9

1.7 AC Adapter ......................................9

Section 2: Diagnosing with

theScan Tool ---- 10

2.1 Preli inary Checks ..................... 10

2.2 Connecting the Scan Tool ............ 10

2.3 OBD II Functions List ..................... 11

2.3.1 I/M Readiness ........................ 11

2.3.2 Read Codes .......................... 12

2.3.3 Pending Codes ..................... 12

2.3.4 Erase Codes ......................... 13

2.3.5 View Data .............................. 13

2.3.6 View Freeze Data ................. 15

2.3.7 O2 Monitor Test ..................... 15

2.3. Non-Continuous Tests .......... 16

9620 Professional OBD II Scan Tool 35

M/T:

Manua transmission or manua transax e.

MAF:

Mass Air F ow Sensor. Measures the amount and density of air entering the engine and

sends a frequency or vo tage signa to the PCM. The PCM uses this signa in its fue de ivery

ca cu ations.

MAP:

Manifo d Abso ute Pressure Sensor. Measures intake manifo d vacuum or pressure and

sends a frequency or vo tage signa (depending on sensor type) to the PCM. This gives the

PCM information on engine oad for contro of fue de ivery, spark advance, and EGR f ow.

MAT:

Manifo d Air Temperature sensor. A resistance sensor in the intake manifo d that sends a

vo tage signa to the PCM indicating the temperature of the incoming air. The PCM uses this

signa for fue de ivery ca cu ations.

MIL:

Ma function Indicator Lamp. The MIL is most common y known as the Check Engine or

Service Engine Soon ight. A required on-board indicator to a ert the driver of an emission-

re ated ma function.

Monitor:

A test performed by the on-board computer to verify proper operation of emission re ated

systems or components.

MPFI or MFI:

Mu ti-Port Fue Injection. MPFI is a fue injection system using one (or more) injector(s) for

each cy inder. The injectors are mounted in the intake manifo d, and fired in groups rather

than individua y.

NOx:

Oxides of Nitrogen. A po utant. The EGR system injects exhaust gases into the intake

manifo d to reduce these gases at the tai pipe.

O2S:

Oxygen Sensor. Generates a vo tage of 0.6 to 1.1 vo ts when the exhaust gas is rich ( ow

oxygen content). The vo tage changes to 0.4 vo ts or ess when the exhaust gas is ean

(high oxygen content). This sensor on y operates after it reaches a temperature of

approximate y 349°C (660°F). O2 sensors are usua y found both upstream and downstream

of the cata ytic converter. The PCM uses these sensors to fine tune the air-fue ratio and to

monitor the efficiency of the cata ytic converter. See Bank 1, Bank 2, Sensor 1, Sensor 2.

ODM:

Output Device Monitor.

OBD II:

On-Board Diagnostics, Second Generation. OBD II is a U.S. Government-mandated standard

requiring a cars and ight trucks to have a common data connector, connector ocation,

communication protoco , DTCs and code definitions.

Sensor:

Any device that reports information to the PCM. The job of the sensor is to convert a parameter

such as engine temperature into an e ectrica signa that the PCM can understand.

Sensor 1:

A standard term used to identify the ocation of oxygen sensors. Sensor 1 is ocated upstream

of the cata ytic converter. See O2S, Bank 1, Bank 2.

Sensor 2:

A standard term used to identify the ocation of oxygen sensors. Sensor 2 is ocated

downstream of the cata ytic converter. See O2S, Bank 1, Bank 2.

Solenoid:

A device consisting of an e ectrica coi which when energized, produces a magnetic fie d in

a p unger, which is pu ed to a centra position. A so enoid may be used as an actuator in a

va ve or switch.

9620 Professional OBD II Scan Tool 3

Vehicle ServiceInformation

The following is a list of publishers who have manuals containing electronic engine

control diagnostic information. Some manuals may be available at auto part stores

or local public libraries. For others, write for availability and pricing, specifying the

make, model and year of vehicle.

Service Manuals:

Chilton Book Company

Chilton Way

Radnor, A 19089

Haynes Publications

861 Lawrence Drive

Newbury ark, CA 91320

Cordura Publications

Mitchell Manuals, Inc.

ost Office Box 26260

San Diego, CA 92126

Motors Auto Repair Manual

Hearst Company

250 W 55th Street

New York, NY 10019

Manufacturer Service Manuals:

General Motors:

Buick, Cadillac, Chevrolet, GEO,

GMC, Oldsmobile, & Pontiac

Helm Incorporated

ost Office Box 07130

Detroit, MI 48207

Saturn

Adistra Corporation

c/o Saturn ublications

101 Union St.

ost Office Box 1000

lymouth, MI 48170

Ford Motor Company:

Ford, Lincoln, & Mercury

Ford ublication Department

Helm Incorporated

ost Office Box 07150

Detroit, MI 48207

Chrysler Corporation:

Chrysler, Plymouth, & Dod e

Chrysler Motors Service Training

26001 Lawrence Avenue

Center Line, MI 48015

Suitable manuals have titles, such as:

Electronic Engine Controls

Fuel Injection and Feedback Carburetors

Fuel Injection and Electronic Engine Controls

Emissions Control Manual

. . . or similar titles

34 9620 Professional OBD II Scan Tool

ESC:

E ectronic Spark Contro . An ignition system function that warns the PCM when knock is

detected. The PCM wi then retard spark timing to e iminate the knocking condition.

EST:

E ectronic Spark Timing. An ignition system that a ows the PCM to contro spark advance

timing. The PCM determines optimum spark timing from sensor information engine speed,

thrott e position, coo ant temperature, engine oad, vehic e speed, Park/Neutra switch

position, and knock sensor condition.

EVAP:

Evaporative Emissions System.

Freeze Fra e:

A b ock of memory containing the vehic e operating conditions for a specific time.

Ground (GND):

An e ectrica conductor used as a common return for an e ectric circuit(s) and with a re ative

zero potentia (vo tage).

Hall Effect Sensor:

Any of a type of sensor uti izing a permanent magnet and a transistorized Ha Effect switch.

Ha Effect type sensors may be used to measure speed and position of the crankshaft or

camshaft for spark timing and fue injector contro .

HO2S:

Heated Oxygen Sensor. See O2S.

IAC:

Id e Air Contro . A device mounted on the thrott e body which adjusts the amount of air

bypassing a c osed thrott e so that the PCM can contro id e speed.

ICM:

Ignition Contro Modu e.

I/M:

Inspection and Maintenance. An emission contro program.

ISC:

Id e Speed Contro . A sma e ectric motor mounted on the thrott e body and contro ed by

the PCM. The PCM can contro id e speed by commanding the ISC to adjust its position.

ISO:

Internationa Organization of Standardization.

Knock:

Uncontro ed ignition of the air/fue mixture in the cy inder. A so referred to as detonation or

ping. Knock indicates extreme cy inder pressures or hotspots which are causing the air/

fue mixture to detonate premature y.

Knock Sensor (KS):

Used to detect engine detonation or knock. The sensor contains a piezoe ectric e ement

and is threaded into the engine b ock. Specia construction makes the e ement sensitive

on y to engine vibrations associated with detonation.

KOEO:

Key On Engine Off.

KOER:

Key On Engine Running.

LCD:

Liquid Crysta Disp ay.

LT:

Long Term fue trim.

49620 Professional OBD II Scan Tool

Safety Precautions

General Sa ety Guidelines to Follow When Working on Vehicles

To prevent accidents that could result in serious injury and/or damage

to vehicle or test equipment, care ully ollow these sa ety rules and

test procedures at all times when working on vehicles:

Always wear approved eye protection.

Always operate the vehicle in a well-ventilated area. Do not inhale exhaust

gases they are very poisonous!

Always keep yourself, tools and test equipment away from all moving or hot

engine parts.

Always make sure the vehicle is in Park (Automatic transmission) or neutral

(manual transmission) and that the parking brake is irmly set. Block the

drive wheels.

Never lay tools on vehicle battery. You may short the terminals together

causing harm to yourself, the tools or the battery.

Never use scan tool if its internal circuitry has been exposed to any liquids.

Never smoke or have open flames near vehicle. Vapors from gasoline and/or

charging battery are highly flammable and explosive.

Never leave vehicle unattended while running tests.

Always keep a fire extinguisher suitable for gasoline/electrical/chemical fires

handy.

Always use extreme caution when working around the ignition coil, distributor

cap, ignition wires, and spark plugs. These components contain high voltage

when the engine is running.

When performing a road test, never operate the scan tool alone while driving

the vehicle. Always have one person drive the vehicle while an assistant

operates the tester.

Always turn ignition key OFF when connecting or disconnecting electrical

components, unless otherwise instructed.

Always follow vehicle manufacturers warnings, cautions and service proce-

dures.

WARNING!

So e vehicles are equipped with safety air bags. You ust follow

vehicle service anual cautions when working around the air bag

co ponents or wiring. If the cautions are not followed, the air bag ay

open up unexpectedly, resulting in personal injury. Note that the air

bag can still open up several inutes after the ignition key is off (or

even if the vehicle battery is disconnected) because of a special

energy reserve odule.

9620 Professional OBD II Scan Tool 33

Closed Loop (CL):

A feedback system that uses the O2 Sensor(s) to monitor the resu ts of combustion.

Based on the signa (s) from the O2 sensor(s), the PCM modifies the air/fue mixture to

maintain optimum performance with owest emissions. In c osed oop mode, the PCM

can fine tune contro of a system to achieve an exact resu t.

CO:

Carbon Monoxide

Continuous Me ory Codes:

See Pending Codes.

CPS:

Crankshaft Position Sensor. Sends a frequency signa to the PCM. It is used to reference

fue injector operation and synchronize spark p ug firing on distributor ess ignition

systems (DIS).

CTS:

Coo ant Temperature Sensor. A resistance sensor that sends a vo tage signa to the

PCM indicating the temperature of the coo ant. This signa te s the PCM whether the

engine is co d or warm.

Data Link Connector (DLC):

Connector providing access and/or contro of the vehic e information, operating

conditions, and diagnostic information. Vehic es with OBD II use a 16-pin connector

ocated in the passenger compartment.

Data Strea :

The actua data communications sent from the vehic es PCM to the data connector.

DEPS:

Digita Engine Position Sensor.

Detonation:

See Knock.

DTC:

Diagnostic Troub e Code. An a phanumeric identifier for a fau t condition identified by

the On Board Diagnostic System.

DI/DIS:

Direct Ignition/Distributor ess Ignition System. A system that produces the ignition spark

without the use of a distributor.

Duty Cycle:

A term app ied to signa s that switch between on and off. Duty cyc e is the percentage of

time the signa is on. For examp e, if the signa is on on y one fourth of the time, then the

duty cyc e is 25%. The PCM uses duty cyc e type signa s to maintain precise contro of an

actuator.

ECT:

Engine Coo ant Temperature sensor. See CTS.

EFI:

E ectronic Fue Injection. Any system where a computer contro s fue de ivery to the engine

by using fue injectors.

EGR:

Exhaust Gas Recircu ation. The PCM uses the EGR system to recircu ate exhaust gases

back into the intake manifo d to reduce emissions. EGR Recircu ation is used on y during

warm engine cruise conditions. EGR f ow at other times can cause sta ing or no starts.

EPA:

Environmenta Protection Agency.

9620 Professional OBD II Scan Tool 5

Section 1: Vehicle Computer Systems

1.1 Introduction

This section describes the engine computer contro system, types of sensors and how

the computer contro s engine fue de ivery, id e speed and timing. Additiona information

may be found in the technica support books at your oca ibrary or auto parts store. The

more known about the computer system, the easier the prob em can be diagnosed.

Computer contro s were origina y insta ed on vehic es to meet federa government

regu ations for ower emission eve s and improved fue economy. This began in the ear y

1980s when basic mechanica systems were no onger ab e to accurate y contro key

engine parameters. A computer cou d be programmed to contro the engine under various

operating conditions, making the engine more re iab e. Whi e these ear y systems were

very imited in scope of their diagnostics, providing on y 10-14 troub e codes, they did he p

guide the vehic e repair process.

In 1994, manufacturers began equipping vehic es with a new c ass of computer techno ogy

which puts more processing power under dash than ever before. It is ca ed On-Board

Diagnostics version II, or OBD II. It is required on a vehic es so d in the US beginning

January 1, 1996 (though most domestic manufacturers introduced it ear ier than required),

and offers increased system monitoring and diagnostic information. This new system stores

a ibrary of more than 650 genera troub e codes and another approximate y 400

manufacturer-specific codes, a of which can be accessed with the scan too . These codes

cover Body Systems (B-Codes), Chassis Systems (C-Codes), Communications Codes

(U-Codes), and Powertrain Systems (P-Codes). Now, basic terms are standardized and

a generic codes wi share a common format and termino ogy that manufacturers and the

Society of Automotive Engineers (SAE) designed.

The OBD II Professiona Scan Too performs OBD II functions on ALL makes of OBD II

comp iant vehic es from 1994 and up.

1.1.1 What The Computer Controls

The main contro areas of the vehic e computer are fue de ivery, id e speed, spark advance,

and emissions contro s. Some on-board computers may a so contro the transmission,

brakes, and suspension systems as we .

1.1.2 What as Not Changed

A computer-contro ed engine is very simi ar to the o der, non-computerized engine. It is sti

an interna combustion engine with pistons, spark p ugs, va ves, and camshaft(s). The ignition,

charging, starting, and exhaust systems are very simi ar as we . Test and repair of these

systems are the same as before. The technica manua s for these components provide

instruction on how to perform the tests. Additiona y, compression gauges, vacuum pumps,

engine ana yzers, and timing ights wi continue to be used.

1.1.3 Computer Control System

The vehic e on-board computer, or Powertrain Contro Modu e (PCM), is the heart of the

system. It is sea ed in a meta box and connected to the rest of the engine by a wiring

harness. The PCM is common y ocated in the passenger compartment, behind the

dashboard (kick pane position), a though some manufacturers ocate the PCM in the

engine compartment. The PCM is programmed by the factory. The program is a comp ex

ist of ookup tab es and instructions te ing the computer how to contro the engine based

on various driving conditions. It does this using sensors to monitor what is happening and

then provide feedback through a network of switches and actuators throughout the vehic e.

32 9620 Professional OBD II Scan Tool

Appendix B:Glossary Definitions

A/C:

Air Conditioning.

A/F:

Air/Fue ratio. The proportion of air and fue de ivered to the cy inder for combustion. For

examp e, an A/F ratio of 14:1 denotes 14 times as much air as fue in the mixture. A

typica idea A/F ratio is 14.7:1.

AC Clutch Relay:

The PCM uses this re ay to energize the A/C c utch, turning the A/C system on or off.

AC Pressure Sensor:

Measures air conditioning refrigerant pressure and sends a vo tage signa to the

PCM.

AC Pressure Switch:

A mechanica switch connected to the A/C refrigerant ine. The switch is activated

(sending a signa to the PCM) when the A/C refrigerant pressure becomes too ow.

Actuator:

Actuators such as re ays, so enoids, and motors a ow the PCM to contro the operation

of vehic e systems.

Air Injection Reaction (AIR) Syste :

An emission contro system operated by the PCM. During co d starts, an air pump

injects outside air into the exhaust manifo d to he p burn hot exhaust gases. This

reduces po ution and speeds warm-up of oxygen sensors and cata ytic converters.

After the engine is warm, the air wi either be dumped back to the atmosphere (or into

the air c eaner assemb y) or sent to the cata ytic converter.

Bank 1:

The standard way of referring to the bank of cy inders containing cy inder #1. In- ine

engines have on y one bank of cy inders. Most common y used to identify the ocation of

oxygen sensors. See O2S, Sensor 1, Sensor 2.

Bank 2:

The standard way of referring to the bank of cy inders opposite cy inder #1. Found on V-

6, V-8, V-10, etc. and horizonta y opposed engines. Most common y used to identify the

ocation of oxygen sensors. See O2S, Sensor 1,Sensor 2.

BARO:

Barometric Pressure Sensor. See MAP Sensor.

Boost Control Solenoid:

A so enoid that is energized by the PCM, in order to contro supercharger boost pressure.

Brake Switch Signal:

An input signa to the PCM indicating that the brake peda is being pressed. This signa

is typica y used to disengage Cruise Contro systems and Torque Converter C utch

(TCC) so enoids. See a so TCC.

CAM:

Camshaft Position Sensor. Sends a frequency signa to the PCM in order to synchronize

fue injector and spark p ug firing.

CARB:

Ca ifornia Air Resources Board. Governing body for emissions contro in Ca ifornia.

CKP REF:

Crankshaft Position Reference.

69620 Professional OBD II Scan Tool

DLC Location

1.2 Data Link ConnectorandLocation

The tester communicates with the vehic e PCM via a data

ink connector (DLC) a so referred to as a J1962

connector. The term J1962 is taken from physica and

e ectrica specification number assigned by SAE (Society of

Automotive Engineers). A standardized DLC means a comp iant

vehic es wi use the same DLC with the generic ink information avai ab e on the same

pins regard ess of vehic e make or mode . In addition to the connector definitions, is a

guide ine on where the connector is to be ocated in the vehic e. This guide ine states

that the DLC shou d be ocated under the dashboard on the driver side of the vehic e.

However, not a OBD II DLCs are ocated under the dash on the driver side. If required,

refer to vehic e service documentation for the DLC ocation.

1.3 OBD II Scan Tool Hookup

The OBD II cab e attached to the scan too fits the OBD II DLC. Because the OBD II J1962

connector contains dedicated pins for power and ground, on y a sing e cab e connection is

required for both scan too power and PCM communication.

Connect the scan too to the DLC. This connection wi provide power for the scan too .

The DLC maintains power even when the ignition is turned off. Therefore, connection to

the battery is not required.

When the scan too powers up, a series of screens are disp ayed. The screens start with

a We come screen and end with a Key Button He p screen.

The screens between the We come screen and the Key Button He p screen are for

too se f-tests and software ID. Refer to this software ID when contacting the Actron

technica support ine with a prob em. To review the key button definitions, push the

(HELP) key; otherwise, press ENTER to continue.

The scan too requires a minimum of 8 vo ts to power up. If a prob em occurs with power-

up, review Section 4: Help and Troubleshooting Tips.

Welcome To

The Global OBDII

SCANTOOL

Press HELP For Key |

Bu on Informa ion

Press ENTER To Con

9620 Professional OBD II Scan Tool 31

REL TPS (0 - 100%)

Relative Throttle Position is re ative thrott e position at norma position.

SECOND AIR (AIR_STAT: UPS, DNS or OFF)

Commanded Secondary Air Status is on newer vehic es and actuators to contro po u-

tion contro .

UPS - UP STREAM modu e is demanding that secondary air be added at exhaust

manifo ds

DNS - DOWN STREAM modu e is demanding secondary air be added at cata ytic

converter

OFF - Modu e is demanding no secondary air to be added.

ST FTRMxy (-100 - 99.22%)

Short-term Fuel Trim Bank ca cu ated va ue represents the short-term re ation of fue

metering on a fue -injected engine.

NOTE: Short-term Fuel Trim calculated value that ha a po itive percentage i a rich fuel

trim and if a negative percentage i pre ent the fuel trim i lean.

ST FLTRMx (-100 - 99.2%)

Short-term Fuel Trim va ue represents the short-term re ation of fue metering on a fue -

injected engine.

NOTE: Short-term Fuel Trim value with a po itive percentage i a rich fuel trim and if a negative

percentage i pre ent the fuel trim i lean.

THR POS (0 - 100%)

Absolute Throttle Position is the position the thrott e is ocated. The more the thrott e is

c osed the ess percent shown.

THROT CMD (0 - 100%)

Commanded Throttle Actuator Control is the position of the thrott e. If thrott e is c osed the

percent wi be 0 and if wide open 100%.

TRIPS SNC CLR (0 - 255)

Number of warm-ups since diagnostic trouble codes cleared. Warm-up is when temperature

of coo ant rises to at east 22°C (40°F) from engine starting and reaching a minimum tempera-

ture of 70°C (160°F). If a diese engine the engine minimum temperature is 60°C (140°F.)

NOTE: If there i more than 255 that the engine warm up the TRIPS SNC CLR will remain

at 255.

TROUB CODE (00 00 - FF FF)

Trouble Code Parameter wi give the diagnostic troub e code that caused a freeze

frame capture. This information is he pfu in diagnosing the cause of a driveabi ity. If no

freeze frame data has been captured this PID wi be zero.

VEH SPEED (0 - 255K/h) or (0 - 158 ph)

Vehicle Speed shows the speed the vehic e is going.

VPWR (0 - 65.535V)

Control Module Voltage is the power input to the contro modu e.

NOTE: 42-volt vehicle may utili e multiple voltage for different y tem on the vehicle.

VPWR may be ignificantly different than battery voltage.

9620 Professional OBD II Scan Tool 7

1.3.1 Keyboard

The scan too software was designed for easy to operate approach in navigating through

operationa menus. Simp y fo ow instructions that match keyboard symbo s.

Keyboard Functions

The scan too uses 8 keys to navigate through the software-user interface:

ENTER Used to se ect or answer a software request.

HELP Used to request he p when the (|) symbo is disp ayed in the ower right hand

corner of the disp ay.

BACK Used to move one screen back in scan too f ow.

ARROWS

UP/DOWN Used to move the so id cursor (`) in the direction of the arrow or scro

the data ist in the direction you want to move the ist.

LEFT/RIGHT Used to se ect and dese ect items in custom ists. This key is a so

used to answer questions by se ecting yes or no.

ON/OFF Used to turn scan too ON and OFF when not powered by vehic e. Momen-

tari y press and re ease button when turning ON to a ow boot process.

1.3.2 Display

The scan too has a 4 ine x 20 character back it

Liquid Crysta Disp ay (LCD) for easy viewing. The

back ighting is disab ed when the scan too is

powered by its interna batteries. This gives the

user a arge viewing area to disp ay most He p

and Instructiona messages. It puts more

information on the disp ay instead of having to refer to printed materia s. Again the disp ay wi

support a number of he pfu characters that wi prompt the user through test routines. These

characters are shown be ow:

|Question Mark in ower right corner means there is help avai ab e for this screen or

current se ectab e item.

`Pointer (cursor) is used to indicate current se ectab e choice.

[Down Arrow indicates there is additiona information on the next screen.

]Up Arrow indicates there is additiona information on previous screen.

«Diamond to the eft of item indicates it is se ected.

The screen at the right shows how some of these symbo s wi ook on your disp ay.

1.3.3 Lists, Menus, and Questions

The scan too is designed to be as intuitive as possib e. Its functions and contro s are easy to

understand and use. A menu and screen ists operate the same way. Use the UP/DOWN

arrow keys to move the cursor to a se ection. The ENTER key se ects that function or item. The

screen examp es be ow show a few se ections avai ab e on the OBDII Function List.

For examp e: to read vehic es DTCs, move cursor to Read Codes and press ENTER.

To make a different choice, use the DOWN arrow key to move the cursor down to View Data

and press ENTER. This wi se ect the View Data function.

Sometimes, a ist wi be onger than three or four items, and wi not fit on a sing e screen. In

this case, the DOWN arrow symbo ([) is visib e in the ast co umn of the disp ay, indicating

that there are more choices on the next screen, as shown be ow on the eft. Use the DOWN

arrow key to move the cursor down the ist.

OBDII Func ion Lis |

3)Erase Codes ]

4)View Da a [

`5)View Freeze Da a

30 9620 Professional OBD II Scan Tool

IAT TEMP (-40 - 215°C) or (-40 - 419°F)

Intake Air Temperature is a measure of intake air temperature to determine correct air/

fue ratios and spark timing operations.

IGN ADV (-64 - 63.5°)

Ignition Timing Advance for cy inder is a signa of how much spark advance to add to

base engine timing (expressed in crankshaft degrees).

LT FL FTRM (-100 - 99.22%)

Long Term Fuel Trim Bank is the fue mixture adjustment in a range with midpoint being 0.

NOTE: Po itive reading indicate module commanded a long-term rich mixture correction

in re pon e to a lean operating condition. A negative reading indicate module ha

commanded a long-term lean mixture in re pon e to a rich operating condition.

MAF (0 - 655.35 g/s) or (0 - 86.5lb/ in)

Mass Air Flow is the air f ow rate the sensor sends to the computer modu e indicating

mass of air entering engine.

MAP (0 - 255kPa) or (Hg)

Intake Manifold Absolute Pressure disp ays manifo d pressure.

MIL DIST (0 - 65535k ) or (0 - 40,722 iles)

Distance Traveled while Malfunction Indicator Lamp is Active is a counter that disp ays

distance trave ed since Check Engine or Service Engine Soon ight came on.

MIL STAT (ON or OFF)

Monitor Status Data Trouble Code state that modu e is commanding the Ma function Indicator

Lamp (MIL) to be ON if prob em exists.

MIL TIME (0 - 65535 in) or (0 - 1092.25Hrs)

The distance trave ed since the MIL (Check Engine or Service Engine Soon ight) came on.

O2Sxy (0 - 1.275V)

Oxygen Sensor Output Voltage is the vo tage generated from the oxygen sensor to

increase and decrease the amount of exhaust gas.

O2Sxy (-128 - 127.996 A)

Oxygen Sensor Output Current is used for inear or wide ratio oxygen sensors to increase

and decrease the amount of exhaust gas

OBD2 STAT (CA, OBDI, US, NONE, EU and/or JA)

On Board Diagnostic how what vehicle wa made for.

Data Parameter :

CA - Indicate te t vehicle meet California on board diagno tic ARB requirement

OBD I - Indicate te t vehicle doe not meet OBDII requirement .

US - Indicate te t vehicle meet Federal EPA requirement .

NONE - Indicate te t vehicle i not on board diagno tic compliant.

EU - Indicate te t vehicle meet European on board diagno tic requirement.

JA - Indicate te t vehicle meet Japane e on board diagno tic requirment.Outside Air

Temperature give temperature out ide.

NOTE: The Data Parameter can be u ed with each other for example CA/US

OUTSID AIR (-40 - 215°C) or (-40 - 419°F)

Outside Air Temperature gives temperature outside.

PTO STATUS (OFF or ON)

Power Take Off Status a ows modu e to keep track of Power at Take-Off.

REL FRP (0 - 5177.27kPa) or (750.9PSI)

Relative Fuel Rail Pressure (Vacuum) is the fue rai pressure at engine.

89620 Professional OBD II Scan Tool

At the bottom of the ist, there is now on y an UP arrow symbo (]) visib e in the ast

co umn indicating the ast function in the ist has been reached. To return to previous

screens, press the UP arrow key. The UP/DOWN arrow keys work the same way when

scro ing through text such as the He p screen.

The Scan Too may ask a question which requires a response from user. These wi

a ways be YES or NO questions, and are answered with cursor and Arrow keys.

In these screens, brackets <> wi automatica y appear next to defau t response. To

accept defau t choice, simp y press ENTER. Use LEFT/RIGHT arrow key to move brackets

to other response and press ENTER.

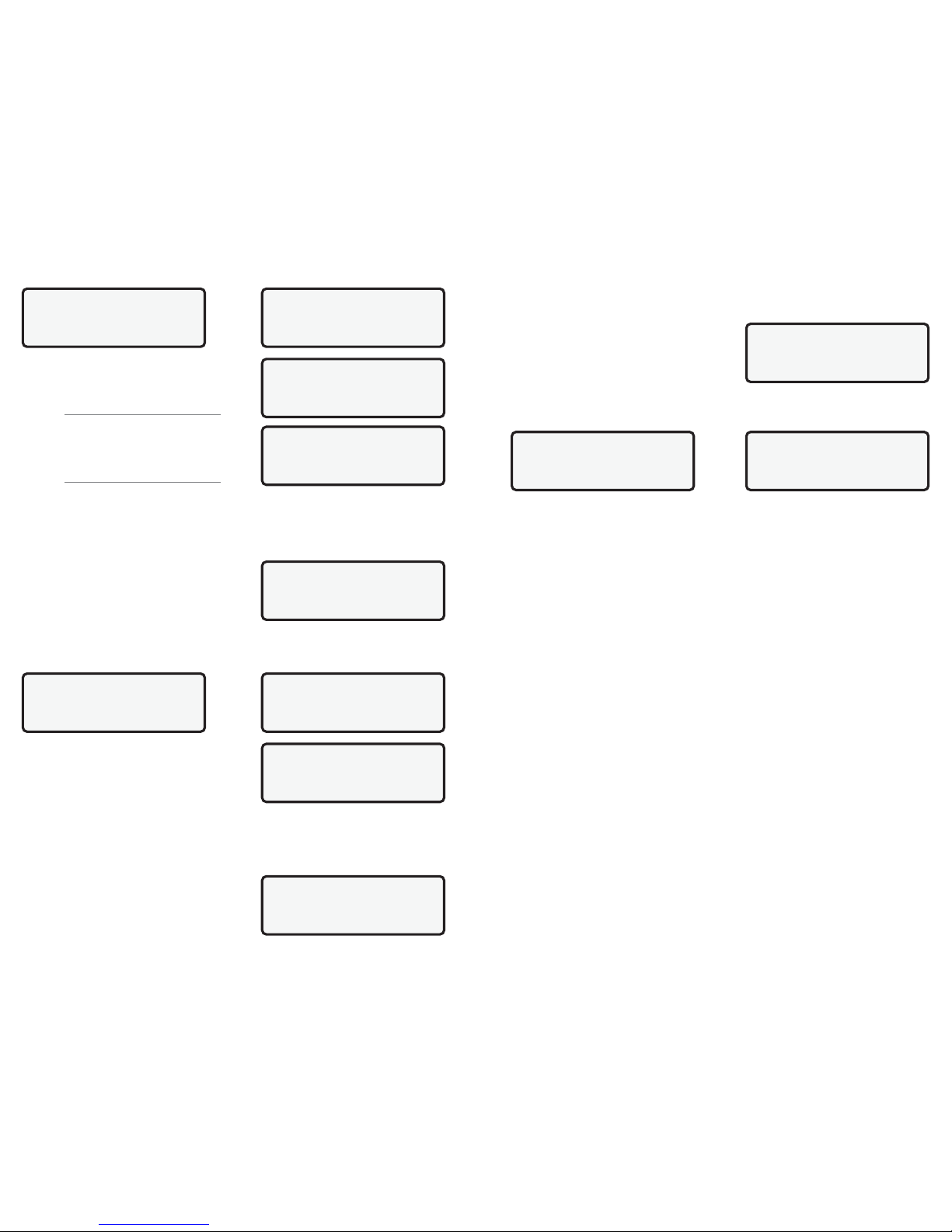

1.4 Tool Setup

On y functions of the Main Menu that pertain to getting started with scan too are discussed

in the fo owing paragraphs. For a other menu se ections avai ab e, refer to Section 4:

Help and Troubleshooting Tips.

Too Setup is used to change the scan too defau t

unit settings. To change the scan too settings,

se ect Tool Setup from the MAIN MENU and

press the ENTER key.

NOTE: Setting cho en will remain until 9 volt battery i dead.

1.4.1 Changing Measurement Units

After se ecting Too Setup option, too setup menu appears. To choose Eng ish or Metric

measurement units, use UP/DOWN arrows to make se ection and press ENTER. The

disp ay wi ook ike the fo owing screen:

1.4.2 Changing Display Contrast

From the Too Setup menu, se ect Display Contrast and press ENTER. Use the UP/

DOWN arrow keys as indicated on the screen:

View Ins ruc ions

For Crea ing Cus om

Da a Lis ?

Yes <No>

OBDII Func ion Lis |

`1) I/M Readiness

2)Read Codes [

3)Pending Codes

OBDII Func ion Lis |

4)View Da a ]

5)View Freeze Da a [

`6)Record Da a

Se up Tool For

1) English/Me ric

`2)Display Con ras

3)Tool Informa ion

]Increase Con ras

[Decrease Con ras

Press ENTER To Save

Se up Tool For

`1) English/Me ric

2)Display Con ras [

3)Tool Informa ion

Measuremen Uni s

`English(Defaul )

Me ric

9620 Professional OBD II Scan Tool 29

CLR DST (0k -65,535k ) or (0- 40,722 iles)

Distance Since Cleared Diagnostic Codes is distance since diagnostic troub e codes

were erased.

CLR TIM (0 - 65535 in or 1092.25 hours)

Time Since Cleared Diagnostic Code is time since diagnostic troub e codes were erased.

CMD EQ RATxy (0 - 1.99)

Commanded Equivalence Ratio is the ratio of the air/fue mixture.

NOTE: The CMD EQ RAT will read 1.0 while in a clo ed loop of fuel

COOLANT (-40 - 215°C)or(°F)

Engine Coo ant Temperature disp ays engine coo ant temperaturefrom engine coo ant

temperature or cy inder head temperature sensor.

NOTE: The coolant on many die el may u e Engine Oil Temperature in tead.

EGR CMD (0 - 100%)

Commanded Exhaust Gas Recirculation is the percentage of exhaust gas being recir-

cu ated.

EGR ERR (-100 - 99.22%)

Exhaust Gas Recirculation Error wi show the error from changing from one condition to

another.

ENG RUN (0 - 65,535sec.)

Time since Engine Strart is the time the engine is running.

NOTE: ENG RUN top when engine tall or engine i turned off for any rea on.

ENGINE (0 - 16383.75 RPM)

Engine Revolutions Per Minute (RPM) is the speed engine is running.

EQ RATxy

O2 Sensor Equivalence Ratio for Bank x Sensor y.

EVAP REQ (0-100%)

Commanded Evaporative Purge is the position evaporative purge contro va ve is open

in percentage.

EVAP VP (-8192PA - 8191PA) OR (-32.8878 - 32.8838 H2O)

Evaporative Emissions System Vapor Pressure is pressure in the fue tank

FUEL LVL (0 - 100%)

Fuel Level Input is the percentage of fue with 0% equa ing tank is fu and 100% when tank

is empty.

FUEL PRES (0 - 765kPa) or (0 - 110psi)

Fuel Rail Pressure is the fue pressure at the engine in respect to atmospheric pres-

sure.

FUEL SYS (OPEN or CLSD)

Fuel System Status show oop status of fue system banks.

OPEN: Computer modu e is operating in Open Loop contro strategy. The vehic e has

not yet satisfied conditions for the computer modu e to go to c osed oop.

CLSD: Computer modu e current y functioning in C osed oop contro strategy, using

O2 sensor(s) as feedback for fue contro .

OPEN1: Open Loop contro strategy is being used by the PCM due to driving conditions

power enrichment and dece eration enrichment.

OPEN2: Computer modu e is operating in Open Loop contro strategy due to detected

system fau t. Certain actuator or sensor fau ts are usua y the cause.

CLSD1: C osed Loop contro is current storage being used by PCM, but a fau t with at

east one O2 sensor has been detected. The contro system may be using

sing e O2 for fue contro ca cu ations.

9620 Professional OBD II Scan Tool 9

1.4.3 Displaying Tool Information

From Too Setup menu, se ect Tool Infor ation and press ENTER. Use UP/DOWN

arrow keys to view information. Record information in case the need to contact customer

service arises.

1.4.4 Program Mode

Used to update scan too s software. Instructions wi be provided with updates.

1.5 Personal Computer (PC) and PrinterInterface

Scan too is equipped with a standard 9 pin seria interface. Use connection to attach

too to a PC or compatib e printer.

Personal Computer

Use seria adapter to connect to a PC when updating to current avai ab e software.

Software updates may be purchased from Actron by ca ing the to free number

provided or from the Actron website: www.actron.com.

Refer to Section 2.4.13 Print Data for defau t seria port settings and to make

changes to settings.

Printer Connection

Connect a compatib e printer cab e to the scan too and Printer using specifications

be ow:

- If the printer connector is a 25 pin connector or if the gender is not compatib e, an

adapter wi be required.

- Adapters are avai ab e at most oca PC stores or e ectronics out ets.

- A NULL modem adapter is required to be connected in series with scan too and

printer cab e.

1.6 Replacing the Battery

To rep ace the 9V battery, do the fo owing:

Remove screw from back of scan too case.

S ide battery cover back to disengage hooks.

Rep ace 9V battery and p ace in compartment.

S ide battery cover up, making sure hooks engage scan too case.

Insta screw.

1.7 AC Adapter

The AC power adapter powers the too when you review codes and print off-vehic e and when

you update the software via a persona computer. The Scan too is equipped to accept any

110 Vac12 Vdc AC adapter with the fo owing specifications.

300 mA minimum unregu ated wa power adapter.

Dimensions - 5.5 mm Outside Diameter, 2.5 mm Inside Diameter.

Se up Tool For

1) English/Me ric

2)Display Con ras

`3)Tool Informa ion

Tool Informa ion:

`Serial No: 1360447]

SW ID: 86E3H[

HW Ver: 1

POS

NEG

28 9620 Professional OBD II Scan Tool

Appendix A: Global OBD II PID List

Definitions

A parameter identification data (PID) isted was verified on actua vehic es to guarantee

accuracy. Definitions used to describe a PIDs were obtained from re iab e sources and

are accurate at time of printing. It is possib e that some newer vehic es may contain different

data different from that isted. In these cases, refer to an app icab e vehic e service manua .

Data Para eter List For at

The PID ist is organized in a phabetica order the same way the scan too does. For each

PID, the type of reading are provided. Remember to a ways refer to a vehic e service manua

for detai ed diagnostic procedures for troub eshooting incorrect PID readings.

Types of Data Para eters

INPUT: These data parameters are obtained from sensor outputs. Sensor outputs

are inputs to vehic es computer modu e(s). For examp e, if an Oxygen Sen-

sor was generating a 400mV signa , then the scan too disp ays O2S (v) 0.40.

OUTPUT: These data parameters are outputs or commands that come direct y from

computer modu e(s). For examp e; the ignition spark advance is contro ed

by PCM, on most vehic es, monitoring this PID shows spark output from

PCM. The scan too wou d disp ay IGN ADV(°) 10.

CALCULATED: These data parameters are ca cu ated after ana yzing various inputs to the

vehic es computer modu e(s). For examp e, the engine oad. The PCM

ca cu ates this from sensor inputs and disp ays it in a percentage.

PCM VALUE: Is information that is stored in the computer modu e(s) memory and deter-

mined to be usefu to service technician. An examp e of this is TROUBLE

CODE va ue, the DTC that caused a freeze frame capture.

NOTE: Several different cau e can have the ame parameter indication. For information on

diagno tic con ult vehicle ervice manual .

DATA PARAMETER LIST

ABS FRP (0 - 655350kPA) or (0 - 95050.5PSI)

Absolute Fuel Rail Pressure is the fue pressure at the engine when reading in refer-

ence to atmospheric pressure.

ABS LOAD (0 - 100%)

Absolute Load Value is the norma va ue of air mass per intake stroke disp ayed as a

percent.

ABSLT TPS (0 - 100%)

Absolute Throttle Position represents norma distance thrott e is opened.

ACC POS D,E or F (0 - 100%)

Accelerator Pedal Position represents norma distance gas peda is pressed.

BARO PRESS (0 - 255kPA) or (0 - 36.9PSI)

Barometric Pressure is norma y received from a dedicated barometer, manifo d abso-

ute pressure sensor and other inputs during certain modes of driving.

NOTE: The Baro Pre may not be the ame a ome weather ervice Barometric

Pre ure due to being read at ea level.

CALC LOAD (0 - 100%)

Calulated LOAD Value indicates oad on engine.

CAT TEMPxy (-40°C - 6513.5°C) or (-40 - 9999.9F)

Catalyst Temperature Bank sha disp ay cata yst substrate temperature for bank cata-

yst, if used by contro modu e strategy for on board diagnostics monitoring, bank,

sensor cata yst or temperature sensor.

10 9620 Professional OBD II Scan Tool

Diagnostic

Connector

Section 2: Diagnosing with theScan Tool

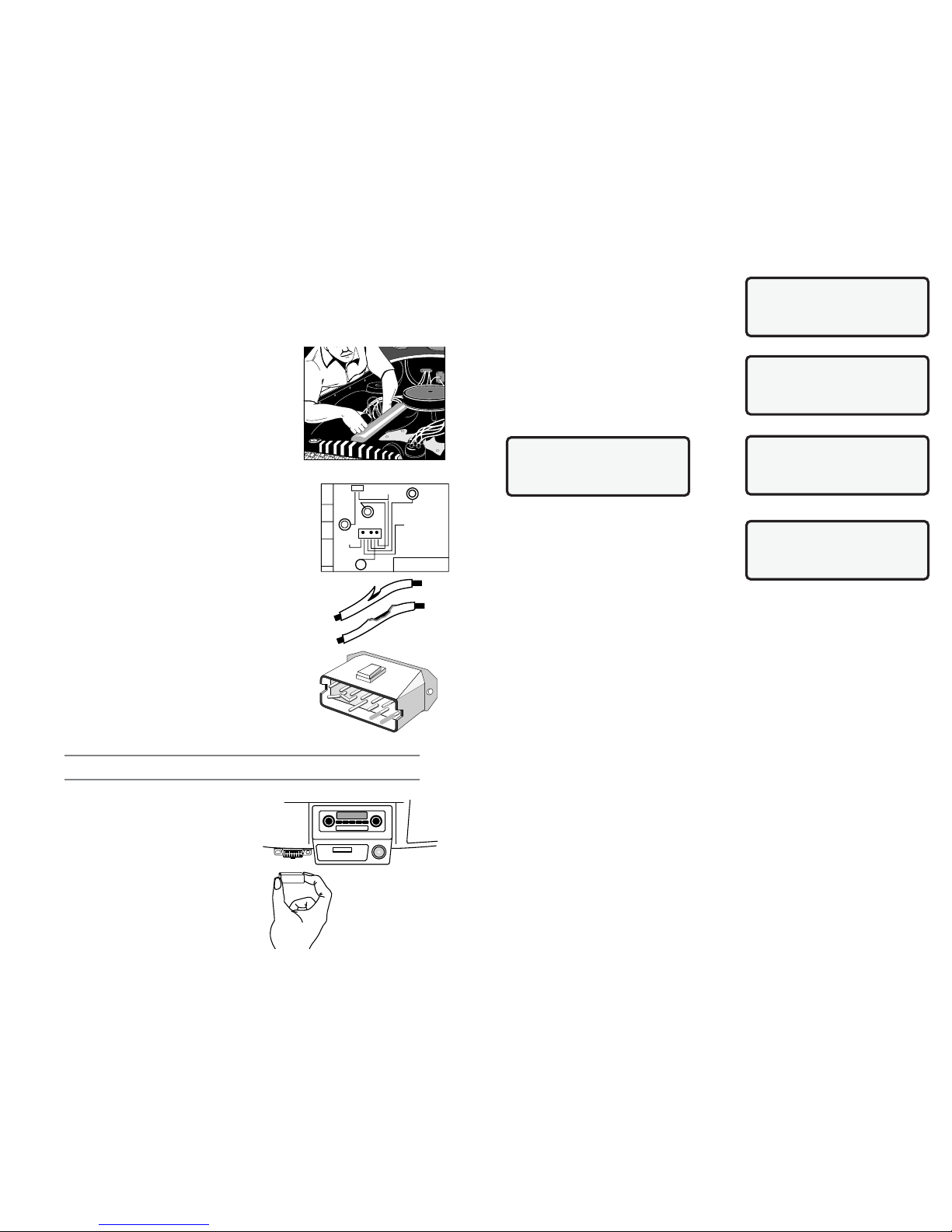

2.1 Preliminary Checks

Before using scan too , perform a comp ete visua inspection. Many driveabi ity prob ems

are found by visua inspection, saving time. Check the fo owing items before proceeding

with scan too testing:

1. Has vehic e been serviced recent y? Sometimes

things get connected in the wrong p ace, or not at a .

2. Dont take shortcuts. Inspect hoses and wiring which

may be difficu t to see because of ocation beneath air

c eaner housings, a ternators and simi ar

components.

3. Inspect air c eaner and ductwork for defects.

4. Check sensors and actuators for damage.

5. Inspect a vacuum hoses for:

Correct routing. Refer to vehic e service manua , or

Vehic e Emission Contro Information (VECI) deca

ocated in engine compartment.

Pinches and kinks.

Sp its, cuts or breaks.

6. Inspect wiring for:

Contact with sharp edges (this happens frequent y).

Contact with hot surfaces, such as exhaust manifo ds.

Pinched, burned or chafed insu ation.

Proper routing and connections.

7. Check e ectrica connectors for:

Corrosion on pins.

Bent or damaged pins.

Contacts not proper y seated in housing.

Bad wire crimps to termina s.

Connector prob ems are common in engine contro

system. Inspect for corrosion, bent, pushed out, or over

expanded pins.

Note: Some connector u e pecial grea e on contact to prevent corro ion. Do not wipe

off! Obtain grea e, from vehicle dealer. It i a pecial type for thi purpo e.

2.2 Connecting the Scan Tool

Remove protective cap from data ink connector,

if present. Connect scan too and fo ow scan

too prompts. Use scan too 9V battery to do se f-

tests, review codes, code ookup or print data

when connection to vehic e is not required.

When scan too powers up, a series of screens

are disp ayed. The screen starts with We come

and ends with a Key Button He p.

FRONT

OF CAR

HVAC

CRUISE

BRAKE BOOSTER

TO TRANS

MOD E

EGR

VAC

REG

FUEL

PRESS

REG

EGR

VAC

REG

9RAC2LAB

T

ER

P

A.

M

9620 Professional OBD II Scan Tool 27

4.3.3 Memory Test

Perform the Me ory Test if the scan too has

troub e disp aying code definitions or performing

functions that use interna memory. Se ect

Me ory Test from the Too Se f-Test menu and

press the ENTER key.

The test begins immediate y and disp ays a

message Memory Test fo owed by periods as

interna memory is tested.

When done, a message disp ays indicating

whether the test passed or fai ed. Press ENTER

to return to the Too Se f-Test menu.

4.3.4 Printer Test

If you cannot print from the scan too , se ect

Printer Test and press the ENTER key. Refer to

section Changing the Printer Settings on

page20.

4.4 Technical Support

1-800-228-7667 (8:00 - 6:00 EST Monday - Friday), or send emai to

Memory Tes Passed!

Press ENTER To Con

Memory Tes Failed

SW ID = F1E8

Press ENTER To Con

Tool Self-Tes |

1) Display Tes

2) Keyboard Tes [

`3) Memory Tes

Memory Tes . . . . .

. . . . . . .

Tool Self-Tes |

2) Keyboard Tes ]

3) Memory Tes

`4) Prin er Tes

9620 Professional OBD II Scan Tool 11

After pressing ENTER from HELP Screen, the

Main Menu disp ays. Se ect Vehicle Diagnosis

and press ENTER.

The scan too asks to erase data from previous

test. Use LEFT/RIGHT arrow keys to se ect a

response and press ENTER.

A message disp ays Turn Key Off For 10

Seconds, Then Turn Key On and Then Press

ENTER.

2.3 OBD II Functions List

Use UP/DOWN Narrow keys to move cursor(`). Once se ection is made, press ENTER.

Press and re ease BACK key to return to OBD II Function List. Pressing BACK key from

the OBD II Function List returns scan too to Main

Menu. The first time scan too communicates with

vehic e, the communication type is automatica y

detected, and is used unti scan too is turned

OFF or another vehic e is diagnosed.

Not every vehic e wi have every function

isted. If function or part of a function se ected is not supported by a vehic e, a

message screen informing of this wi be shown.

NOTE: If an Operating Error me age i di played, make ure the OBD II J1962 cable i

ecurely attached, and ignition key i ON. Cycle ignition key to OFF for 10 econd ,

then ON. Thi may be required to re et the PCM. If required, elect Ye to te t again.

If problem till exi t , refer to Section 4: Help and Troubleshootin Tips.

2.3.1 I/M Readiness

Purpose of the I/M Readiness test is to disp ay current information on emissions-re ated

systems. These systems are required by OBD II regu ation to be monitored for emissions

testing. OBD II I/M Readiness Monitors are strategies designed to test operations of emission

re ated systems or components. The computer modu e uses these monitors to check for

correct operations of system and components as we as out of range va ues. The computer

modu e may perform a specia test on a system or component to comp ete the monitor. It

may be required to operate vehic e under certain conditions in order to perform an accurate

test. If computer modu e oses power, or codes are erased, monitors may be c eared.

The scan too disp ays the state of vehic e OBD II Monitors.

To enter I/M Readiness viewing mode, se ect I/M Readiness from OBD II Function List

and press ENTER.

A ist of On-Board system readiness tests and

their status wi be disp ayed. Use vehic e service

manua s for more information on emission-

re ated monitors and their status.

Be ow are examp es of comp eted versus not

comp eted I/M Readiness screens:

Use the UP/DOWN arrow keys to view monitor ist. The monitor ist consists of the OBD

MAIN MENU |

`1) Vehicle Diagnosis

2)Tool Se up [

3)Tool Self Tes

OBDII Func ion Lis |

`1) I/M Readiness

2)Read Codes [

3)Pending Codes

Erase Da a From

Previous Vehicle

Tes ?

YES <NO>

Turn Key Off

For 10 Seconds

Then Turn Key On

Then Press ENTER

OBDII Func ion Lis |

`1) I/M Readiness

2)Read Codes [

3)Pending Codes

26 9620 Professional OBD II Scan Tool

MAIN MENU |

1) Vehicle Diagnosis

2)Tool Se up [

`3)Tool Self Tes

@@@@@@@@@@@@@@@@@@@@

@@@@@@@@@@@@@@@@@@@@

@@@@@@@@@@@@@@@@@@@@

@@@@@@@@@@@@@@@@@@@@

Tool Self-Tes |

`1) Display Tes

2) Keyboard Tes [

3) Memory Tes

ENTER To Tes . Look

For Missing Spo s

In Display. Press

BACK When Done

Tool Self-Tes |

1) Display Tes

`2) Keyboard Tes [

3) Memory Tes

Push Bu on To Tes

Key And Display Name

Key:

BAC When Done

4.2.3 One or more modules drops the communication link:

When the OBD II System Tester initia y inks to

the vehic e, it bui ds a ist of a OBD II comp iant

computer modu es. If in the course of scanning the

vehic e, a modu e drops the ink, a message wi

disp ay.

Answering YES wi continue operation without the ost modu e. Answering NO wi try to

restore the communication inks to get a modu es back to an active status.

4.2.4 Keyboard does not function properly:

Perform Keyboard Test by entering Se f-Test and se ect Keyboard Test function.

If the keyboard test shows nothing and you sti experience the prob em, then

contact Actron Technica Support.

4.3 Tool Self-Tests

Too Se f-Tests are used to test the operation of

the disp ay, keyboard, interna memory, and

printer connection (if app icab e).

The Tool Self-Test menu is accessed from the

MAIN MENU. Use the UP/DOWN arrow keys to

se ect the test and then press the ENTER key.

4.3.1 Display Test

Se ect Display Test and press the ENTER key. Press ENTER to begin test.

Display Test wi fi every pixe of disp ay. Look for

pixe s that are not b ack. Press BACK key to exit

to Too Se f-Test menu. Press BACK key again to

disp ay the MAIN MENU.

4.3.2 Keyboard Test

Keyboard Test checks operation of keys. Se ect Keyboard Test from Se f-Test menu and

press ENTER key. Test screen with instructions is disp ayed:

Each time a key is pressed , keys name shou d

appear on disp ay. For examp e, if UP arrow is

pressed, screen wi disp ay Key: UP ARROW. If

name is not disp ayed, key is not working.

Module ($41) Has |

S opped Responding.

Con inue Wi hou I ?

(YES) NO

Push Bu on To Tes

Key And Display Name

Key: UP ARROW

BAC When Done

NOTE: When BACK key i pre ed, OBD II Sy tem Te ter return to Self-Te t Menu, If

not then BACK key i not working.

12 9620 Professional OBD II Scan Tool

Code P0443

EVAP Emission

Con rol Sys em [

Purge Valve C Faul

OBDII Func ion Lis |

1) I/M Readiness

2)Read Codes [

`3)Pending Codes

II monitor name fo owed by monitor state. A monitor that is not supported by test vehic e

wi be fo owed by n/a. A monitor that has been

comp eted is fo owed by ok. If not comp eted,

inc wi be disp ayed. Use the UP/DOWN arrow

keys to scro through the ist.

NOTE: In additon to di playing the tate of the

monitor ince the la t time DTC were

cleared, ome vehicle will di play the

tate of the monitor for thi drive cycle.

U e the LEFT/RIGHT arrow to witch

between the e creen

Press the ENTER key to return to the OBD II Function List.

2.3.2 Read Codes

The Read Codes function retrieves Diagnostic Troub e Codes (DTCs) from vehic es

computer modu es. This function can be

performed with the key on and the engine off or

the key on and engine running.

These codes cause the computer to i uminate

the Ma function Indicator Lamp (MIL) when an

emission-re ated or driveabi ity fau t occurs. The

MIL is a so known as the service engine soon or check engine amp.

Se ect Read Codes and press ENTER. The scan too retrieves the DTCs stored in the

vehic es computer modu e(s).

The scan too disp ays the DTCs or a message

stating SYSTEM PASS: NO CODES FOUND.

Press the DOWN arrow key to view the DTCs or

press the BACK key to return to the OBDII

Function List.

Write down the DTCs for reference, then press BACK to return to the OBDII Function List.

2.3.3 Pending Codes

Pending Codes are a so referred as continuous monitor and maturing codes. An

intermittent fau t causes computer to store a code in memory. If fau t does not occur

again within 40 warm-up cyc es, the code c ears

from memory. If the fau t occurs a specific number

of times, the code matures into a DTC MIL

i uminates or b inks. This function can be per-

formed with the key on and engine running or

not.

SINCE DTCS CLEARED

Misfire Moni or ok |

Fuel Sys em Mon inc

Ca alys Mon n/a

OBDII Func ion Lis |

1) I/M Readiness

`2)Read Codes [

3)Pending Codes

On-Board Readiness

Tes s Are Comple e.

Use [ To View Tes

No All Suppor ed

On-Board Readiness

Tes s Are Comple e.

Use [ To View Tes

DTCs Found: 2

Use [ To View DTCs

Wri e Down Codes

For Reference.

Sys em Pass:

No DTCs Found.

Press BACK For

OBDII Func ion Lis

This Driving Cycle

Misfire Moni or n/a

Fuesl Sys em Mon ok[

Ca alys Mon inc

9620 Professional OBD II Scan Tool 25

Section 4: Help and Troubleshooting Tips

4.1 How to Use Help

The tester contains He p for specific screens,

functions, and error messages. He p is avai ab e

when He p symbo (|) appears in upper right-

hand corner of disp ay.

To enter He p, press HELP key. He p screens

are in CAPITAL LETTERS to remind viewing He p screens, not screens associated with

a function. If He p message is onger than one screen, then use UP and DOWN arrow

keys to page through message. The symbo s ([ and ]) indicate the direction avai ab e.

To exit He p and return to the screen you where He p was entered, press the BACK key.

4.2 Scan Tool Problems

If scan too fai s to power up, ink to vehic e, pass Too Se f-Tests, or function proper y,

then try fo owing Troub eshooting Tips. If these tips fai to reso ve prob em, contact

Actron Technica Support at 1-800-228-7667 (8:00 - 6:00 EST Monday - Friday), or send

4.2.1 Scan Tool does not powerup:

Check OBD II connector for power and ground. If no power, check fuse if app i-

cab e.

Verify vehic es battery is at east 8 vo ts.

Unp ug and p ug back in the Data Link Connector (DLC) to verify connector is

proper y seated to vehic e connector.

If scan too is being powered from an AC/DC 110V to 12V adapter, make sure AC

out et has power.

4.2.2 Scan Tool does not Link withvehicle:

Make sure cab e is correct y connected to DLC. Unp ug the DLC adapter from

vehic e and p ug back to verify connection.

Verify ignition key is ON not in ACCESSORIES position.

Cyc e ignition key OFF for 10 seconds, then ON to reset PCM.

Inspect DLC adapter and computer modu e connectors for cracked, bent,

corroded or recessed pins, and for any substance that cou d prevent a good

e ectrica connection.

In vehic e, verify continuity exists between DLC and computer modu e. In extreme

cases, broken wire(s) may exist.

Check vehic e computer modu e for a b own fuse. Refer to vehic e service manua

for fuse ocation.

Make sure computer modu e is grounded to vehic e. If the computer modu e is

grounded to vehic e, then thorough y c ean connection and app y a conductive grease

to mating surfaces.

The vehic e computer modu e may be defective. Refer to app icab e vehic e service

manua for test procedures and diagnostic f owcharts.

Opera ing Error. |

Check Connec ions!

Try Again?

<Yes> No

SCANTOOL CAN NOT

COMMUNICATE WITH

VEHICLE. CHECK THE [

FOLLOWING:

1.IGNITION KEY ON?

2.HOOKUP TO VEHICLE ]

TEST CONNECTOR OK? [

3.EMISSIONS LABEL

9620 Professional OBD II Scan Tool 13

Se ect Pending Codes and press ENTER key.

The scan too disp ays codes or a message stating SYSTEM PASS NO FAULT

DETECTED. Press DOWN arrow key to view DTCs or press BACK key to return to OBDII

Function List.

The codes disp ay in same format as Read

Codes. The DTC number and computer modu e

that stored it disp ay on first ine. Use UP/Down

arrow keys to view codes.

Press BACK to return to OBDII Function List.

2.3.4 Erase Codes

The Erase Codes function de etes DTCs from vehic es computer memory. Perform this

function on y after systems have been checked comp ete y and DTCs have been

documented. This function shou d be performed with the key on and the engine off.

After servicing vehic e, de ete stored DTCs and verify no codes have been reset. If DTCs

return, the prob em has not been corrected or other fau ts are present.

In addition to c earing DTCs, the Erase Codes function a so erases Freeze Frame, O2

Sensor Data, System Monitors, and On-Board Monitor test resu ts.

Se ect Erase Codes and press the ENTER key. A message appears asking if you are

sure. Press LEFT ARROW to move brackets to desired response and press ENTER.

Se ecting NO disp ays a COMMAND CANCELLED message prompting to press ENTER

to return back to OBDII Function List. Se ecting YES disp ays a screen prompting to turn

ignition key to on and engine off and press ENTER key.

The scan too sends erase command. Press

ENTER to continue and return to OBDII Function

List.

2.3.5 View Data

The View Data function a ows viewing of vehic es Parameter Identification data (PID) in

rea time. As the computer monitors the vehic e, the information is simu taneous y

transmitted to scan too . Apart from Read Codes, View Data is most usefu diagnostic

function for iso ating cause of a vehic e

operation prob em. Viewing data is a so used

for observing sensor data and status of

switches, so enoids, and re ays.

Se ect View Data from OBDII Function List and

press ENTER. The scan too disp ays a menu

with disp ay options.

Use the UP/DOWN arrow keys to se ect an option and press ENTER.

P0389 Mod$1E 1 of 2

Crankshaf Posi ion

Sensor B [

CKT In ermi en

Command Sen

Press ENTER To Con .

OBDII Func ion Lis |

`4)Erase Codes ]

5)View Da a [

6)View Freeze Da a

Erase Diagnos ic

Resul s and Codes?

Are You Sure?

YES <NO>

OBDII Func ion Lis |

4)Erase Codes ]

`5)View Da a [

6)View Freeze Da a

Codes Found: 2

Use [ To View Codes

Wri e Down Codes

For Reference..

Sys em Pass:

No Faul s De ec ed.

Press BACK Key For

Func ion Lis

24 9620 Professional OBD II Scan Tool

3.3 Diagnostic Trouble Code Ranges

Within each genera category, the Diagnostic Troub e Codes are assigned to specific

ranges that cover certain vehic e systems. When disp aying manufacturer-specific (or

non-g oba ), the assigned Diagnostic Troub e Codes disp ays the definition.

Lower Upper Assigned DTC Syste

P0000 P00FF Fue and air metering and auxi iary emission contro s

P0100 P02FF Fue and air metering

P0300 P03FF Ignition system or misfire

P0400 P04FF Auxi iary emission contro s

P0500 P05FF Vehic e speed, id e contro , and auxi iary inputs

P0600 P06FF Computer and auxi iary outputs

P0700 P09FF Transmission

P0A00 P0AFF Hybrid Propu sion

P1000 P10FF Manufacturer contro ed fue , air metering and auxi iary emission

contro s

P1100 P12FF Manufacturer contro ed fue and air metering

P1300 P13FF Manufacturer contro ed ignition system or misfire

P1400 P14FF Manufacturer contro ed auxi iary emission contro s

P1500 P15FF Manufacturer contro ed vehic e speed, id e contro , and auxi iary

inputs

P1600 P16FF Manufacturer contro ed computer and auxi iary outputs

P1700 P19FF Manufacturer contro ed transmission

P2000 P22FF Fue and air metering and auxi iary emission contro s

P2300 P23FF Ignition system or misfire

P2400 P24FF Auxi iary Emissions Contro s

P2500 P25FF Auxi iary Inputs

P2600 P26FF Computer and Auxi iary Outputs

P2700 P27FF Transmission

P2900 P32FF Fue and air metering and auxi iary emission contro s

P3300 P33FF Ignition system or misfire

P3400 P34FF Cy inder deactivation

U0000 U00FF Network e ectrica

U0100 U02FF Network communication

U0300 U03FF Network software

U0400 U04FF Network data

14 9620 Professional OBD II Scan Tool

Selec Cus om Lis

«ABSLT TPS(%) ]

`«CALC LOAD(%) [

COOLANT(oF)

View Ins ruc ions

For Crea ing Cus om

Da a Lis ?

YES <NO>

ABSLT TPS(%) 0.0

CALC LOAD(%) 5.3

ENGINE(RPM)($10) 180[

ENGINE(RPM)($1A) 865

Selec Display Line

2 Lines ]

3 Lines

`4 Lines(Defaul )

Entire Data List

Se ect Entire Data List to disp ay a PIDs supported by vehic e under test.

Custom Data List

To disp ay on y certain PIDs, se ect Custo Data

List. The abi ity to disp ay certain PIDs he ps in

diagnosing a specific driveabi ity symptom or

system.

If choosing to view a Custo Data List, the scan

too asks if he p is needed to view the

instructions. Se ect desired response and press

ENTER.

Use UP/DOWN arrow keys to move

cursor up and down through ist.

Use RIGHT arrow key to se ect or dese ect

PIDs. Se ected PIDs are marked with «

symbo .

Use LEFT arrow key to dese ect a

marked PIDs.

Use the ENTER key to ink to the vehic e and retrieve the marked PIDs.

When finished se ecting PIDs, press ENTER key to begin viewing them.

NOTE: Refer to Appendix A for a complete li t of PID .

View Data Setup

View Data Setup a ows disp ay of PIDs on one,

two, three or four ines. Se ecting fewer ines of

data provides faster update speeds. The scan

too defau t is four- ine disp ay.

When scan too inks to vehic e, PIDs wi disp ay. Navigate through PID ist with fo owing

keys:

Press UP/DOWN arrow keys to scro Up/

Down ine-by- ine through ist.

Press LEFT/RIGHT arrow keys to Page

Up/Page Down.

Press BACK key to return to Se ect Data

To View menu.

The same parameter may appear twice if vehic e is equipped with more than one computer

modu e Powertrain Contro Modu e (PCM), Transmission Contro Modu e (TCM), etc. The

scan too identifies them by identification names (ID) assigned by manufacturer (i.e. $10,

$1A, etc). The computer modu e ID b inks in parentheses. If one or more modu es stops

responding, the scan too disp ays a message that the modu e is not responding and asks to

continue without it. If NO is se ected, scan too attempts to reestab ish communication with

that modu e.

Selec Da a To View

En ire Da a Lis

`Cus om Da a Lis

View Da a Se up

9620 Professional OBD II Scan Tool 23

En er Code: P0100 |

Use Arrow Key ^

To Change Or Press

ENTER To Accep

P0A08

DC/DC Conver er ]

S a us Circui [

OBDII Func ion Lis |

13)Review Da a ]

14)Prin Da a

`15)Code Lookup

En er Code: P0A08 |

Use Arrow Key ^

To Change Or Press

ENTER To Accep

P1100

Manufac ure Con rl ]

[

Fuel Air Me ering

3.2 Code Lookup

Code Lookup is used to ook up definitions of Diagnostic Troub e Codes (DTCs) stored

in the scan too . The scan too does not require power from the vehic e to perform this

function. Interna battery power can be used.

To ook up DTC definitions, se ect Code Lookup

from the OBDII Function List and press ENTER.

NOTE: When entering code , only one character can be changed at a time.

To enter a code:

Use the LEFT/RIGHT arrow keys to move

the ^symbo under the character that

needs to be changed. The cursor moves

to the right and wraps around to the

beginning when the end is reached.

Use the UP/DOWN arrow keys to change

the se ected character.

Press the ENTER key to disp ay the

definition.

After entering the code and pressing ENTER,

the code and definition disp ay.

If the DTC is manufacturer specific or does not

exist for the vehic e, some information can be

determined based on the range of the DTC (see

page 24)

In the definition screen, pressing the ([) or (]) arrow key increments/decrements the

code and its definition. Undefined codes are skipped.

Press the BACK key to return to the Enter Code screen. Press the BACK key again to

return to the OBDII Function List.

NOTE: Refer to an appropriate vehicle ervice manual for manufacturer pecific code .

9620 Professional OBD II Scan Tool 15

2.3.6 View Freeze Data

When an emission-re ated fau t occurs, certain vehic e conditions are recorded by the

on-board computer. This information is referred to as a Freeze Frame data. The information

is a snapshot of operating conditions at time of a fau t. This data can be overwritten by

fau ts with a higher priority.

NOTE: If code were era ed, then freeze frame data may not be tored in vehicle memory.

Se ect View Freeze Data from the OBDII Function

List and press ENTER.

The scan too inks to the vehic e and disp ays

Freeze Frame data. Use UP/DOWN arrow keys

to scro through data.

NOTE: If more than one computer module re pon

with freeze fram data, then the frame num-

ber and module di play on the fir t line.

Pre the LEFT/Right key to change mod-

ule .

When done, press BACK key to return to OBDII Function List.

2.3.7 O2 Monitor Test

NOTE: The O2 Monitor Test is NOT AN ON-DEMAND TEST. O2 en or are NOT te ted

when elected via the menu. The O2 en or are te ted when engine operating

condition are within pecified limit .

OBD II regu ations require that app icab e vehic es monitor and test the oxygen (O2)

sensors to determine prob ems re ated to fue and emissions. The O2 Monitor Test

a ows retrieva of comp eted O2 sensors monitor test resu ts.

O2 sensors are ocated before (upstream) and after (downstream) cata yst(s). The

sensors are named (xy) for their position re ative to both cy inder banks and cata ysts.

The O2 sensor for cy inder bank 1 has the prefix 1y whi e the O2 sensor for

cy inder bank 2 has the prefix 2y.

The O2 sensor upstream of the cata yst (c osest to the engine) has the suffix x1

whi e the O2 sensor downstream of the cata yst has suffix x2. If vehic e contains

more cata ysts, the O2 sensor downstream of the second cata yst has the suffix

x3 and the O2 sensor downstream of the next cata yst has the suffix x4.

For examp e, O2S 21 is the upstream O2 sensor for cy inder bank 2.

The fo owing O2 sensor tests are avai ab e:

Rich to Lean sensor thresho d vo tage

Lean to Rich sensor thresho d vo tage

Low sensor vo tage for switch time

High sensor vo tage for switch time

FREEZE FRAME DATA

TROUB CODE P0443

CALC LOAD(%) 85.6[

ENGINE(RPM)($10) 1120

OBDII Func ion Lis |

4)Erase Codes ]

5)View Da a [

`6)View Freeze Da a

FRAME 1 Mod $1A

TROUB CODE P0443

CALC LOAD(%) 85.6[

ENGINE(RPM)($10) 1120

22 9620 Professional OBD II Scan Tool

Example:

P0101 - Mass or Vo ume Air F ow

Circuit Range/Performance Prob em

P0 1 0 1

Powertrain Codes

P0xxx - Generic (SAE)

P1xxx - Manufacturer Specific

P2xxx - Generic (SAE)

P30xx-P33xx - Manufacturer Specific

P34xx-P39xx - Generic (SAE)

Chassis Codes

C0xxx - Generic (SAE)

C1xxx - Manufacturer Specific

C2xxx - Manufacturer Specific

C3xxx - Generic (SAE)

Body Codes

B0xxx - Generic (SAE)

B1xxx - Manufacturer Specific

B2xxx - Manufacturer Specific

B3xxx - Generic (SAE)

Network Communication Codes

U0xxx - Generic (SAE)

U1xxx - Manufacturer Specific

U2xxx - Manufacturer Specific

U3xxx - Generic (SAE)

Bx - Body

Cx - Chassis

Px - Powertrain

Ux - Network Comm.

x = 0, 1, 2 or 3

Vehic e Specific System Specific Fau t Designation

Section 3: Diagnostic Trouble Codes (DTC)

3.1 DTC Format

Diagnostic Troub e Codes (DTCs) consist of a five-digit a phanumeric code. The DTC

format and types are shown be ow. When the on-board computer recognizes and identifies

a prob em, a DTC for that fau t is stored in memory. These codes are intended to he p you

determine the root cause of a prob em.

J2012 and ISO 15031-6 are standards for a DTCs, estab ished by SAE, Internationa

Organization for Standardization (ISO) and other governing bodies. Codes and definitions

assigned by this specification are known as Generic OBD II codes. OBD II requires

comp iance with standards, and has made it standard for a cars, ight trucks, APVs,

MPVs, and SUVs so d in U.S. Codes not reserved by SAE are reserved for manufacturer

and referred to as Manufacturer Specific.

Periodica y, new DTCs are defined and approved by SAE, ISO and other governing

bodies. The scan too software wi be periodica y updated to ref ect these changes. For

more information regarding DTC updates, p ease ca our Technica Support ine at

1-800-228-7667 (8:00 6:00 EST Monday Friday), or send an emai to

16 9620 Professional OBD II Scan Tool

Rich to Lean sensor switch time

Lean to Rich sensor switch time

Minimum sensor vo tage test cyc e

Maximum sensor vo tage test cyc e

Time between sensor transitions

Se ect O2 Monitor Test from OBDII Function List and press ENTER.

Se ect desired test from menu and press ENTER. Grouping O2 sensor tests together

makes data easier to compare.

The O2 sensors ocated upstream (before

cata yst) may perform different y than the ones

ocated downstream (after the cata yst).

Oxygen sensor tests not supported by the vehic e disp ay three dashes as the va ue.

Press the BACK key to return to the O2 Sensor Tests menu or press ENTER to return to

the OBDII Function List.

2.3.8 Non-Continuous Tests

The Non-Contin (Non-Continuous) Tests obtains test resu ts for emission-re ated

powertrain components and systems that are not continuous y monitored. The Non-

Contin Test function is usefu after servicing or after erasing the vehic es memory. Test

resu ts do not necessari y indicate a fau ty

component or system.

The scan too asks the vehic e for any avai ab e

noncontinuous test IDs, and then disp ays them

in a ist. The vehic e manufacturer is responsib e

for assigning the test and component IDs.

Se ect Non-Contin Tests from the OBDII Function List and press ENTER. A ist of tests

app icab e to the vehic e are disp ayed. Se ect a test and press ENTER.

The scan too disp ays the test ID, system or component (ID), test measurement (MEAS),

specification va ue (SPEC) and status (STS).

Refer to the appropriate vehic e service manua for test IDs and definitions.

Test resu ts requested by the scan too may a so inc ude test imits. On y one test imit is

inc uded in the response message and disp ayed on the screen. The test imit cou d be

either a minimum or a maximum test imit.

Low Vol s for Swi ch

O2S 1-1(V) 1.15

O2S 1-2(V) ---[

O2S 2-1(V) 1.28

TEST $01

ID MEAS SPEC STS

74 8861 C000min Low

74 8861 C000min Low

OBDII Func ion Lis |

`7)O2 Moni or Tes ]

8)Non-Con in Tes [

9)On-Board Sys ems

O2 Sensor Tes s

`1) RICH-LN Thresh

2)LN-RICH Thresh [

3)Lo V For Swi ch

OBDII Func ion Lis |

7)O2 Moni or Tes ]

`8)Non-Con in Tes [

9)On-Board Sys ems

Non-Con Tes s Avail

`$0 1

$03 [

$05

9620 Professional OBD II Scan Tool 21

Next, se ect the parity and press ENTER.

Fina y, se ect the printer speed, FAST or SLOW,

and press ENTER.

Now that the printer settings are changed, it is

time to verify the settings. Press the ENTER key

to print the ASCII character set.