©2002 Edelbrock Corporation

Brochure # 63-0064 Rev. 11/02

Page 1 of 2

PERFORMER RPM ALUMINUM CYLINDER HEADS

for Big-block Chevrolet V8s

CATALOG #60449* (bare) and #60459* (complete)

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new cylinder heads. If you have any questions or problems, do not hesitate

to contact our Technical Hotline at: (800) 416-8628 from 7:00 am to 5:00 pm, Monday through Friday, Pacific Standard Time or

DESCRIPTION

The Edelbrock Performer RPM Street Cylinder Head is designed for street high performance use, and is interchangeable with any early-

style (1965-75) large oval port big-block Chevrolet cylinder head. This new cylinder head offers "out of the box" bolt-on performance

with no additional porting required. The performance range is 1500-6500 rpm for great throttle response throughout the power band as

well as top-end horsepower. The intake and exhaust ports are CNC machine "matched" and have been designed for maximum flow

velocity when matched with our Performer RPM intake manifold #7161 (for square-bore carbs) or #7164 (for spread-bore carbs),

Performer RPM cam kit #7162, and Performer Series square-bore carburetors or Performer RPM Q-Jet carburetors as seen in our catalog

or website. This Performer RPM Power Package produced 540 horsepower in dyno tests on a 454 c.i.d. Chevy with 9.5:1 compression

on pump gasoline. A totally unique intake port design yields flow numbers traditionally associated with high performance rectangular

port heads, but with the smaller runner size and velocity of an oval port. The 110 cc combustion chamber is a semi-open chamber design

to maximize combustion efficiency with streetable compression ratios. NOTE: This head has no exhaust crossover passage and will not

work on any vehicle requiring EGR. This cylinder head is compatible with both early style Mark IV and late model Mark V blocks.

Complete cylinder heads are assembled with the following components: Stainless steel, one-piece, swirl-polished intake and exhaust

valves with under-cut stems for increased flow; 2-ring positive oil control seals; 7/16" rocker studs and 3/8" guideplates; Edelbrock Sure-

Seat Valve Springs #5745, retainers #9715, valve keepers #9615 and valve spring seats #5770. Complete cylinder heads are assembled

and prepared for installation right out of the box. Bare cylinder heads will have valve guides and seats installed, but will require final

sizing and a valve job to match the valves you will be using.

ACCESSORIES: Although Edelbrock Street Cylinder Heads will

accept OEM components (rocker arms, valve covers, intake

manifold, head bolts, etc.), we highly recommend that premium

quality hardware be used with your new heads.

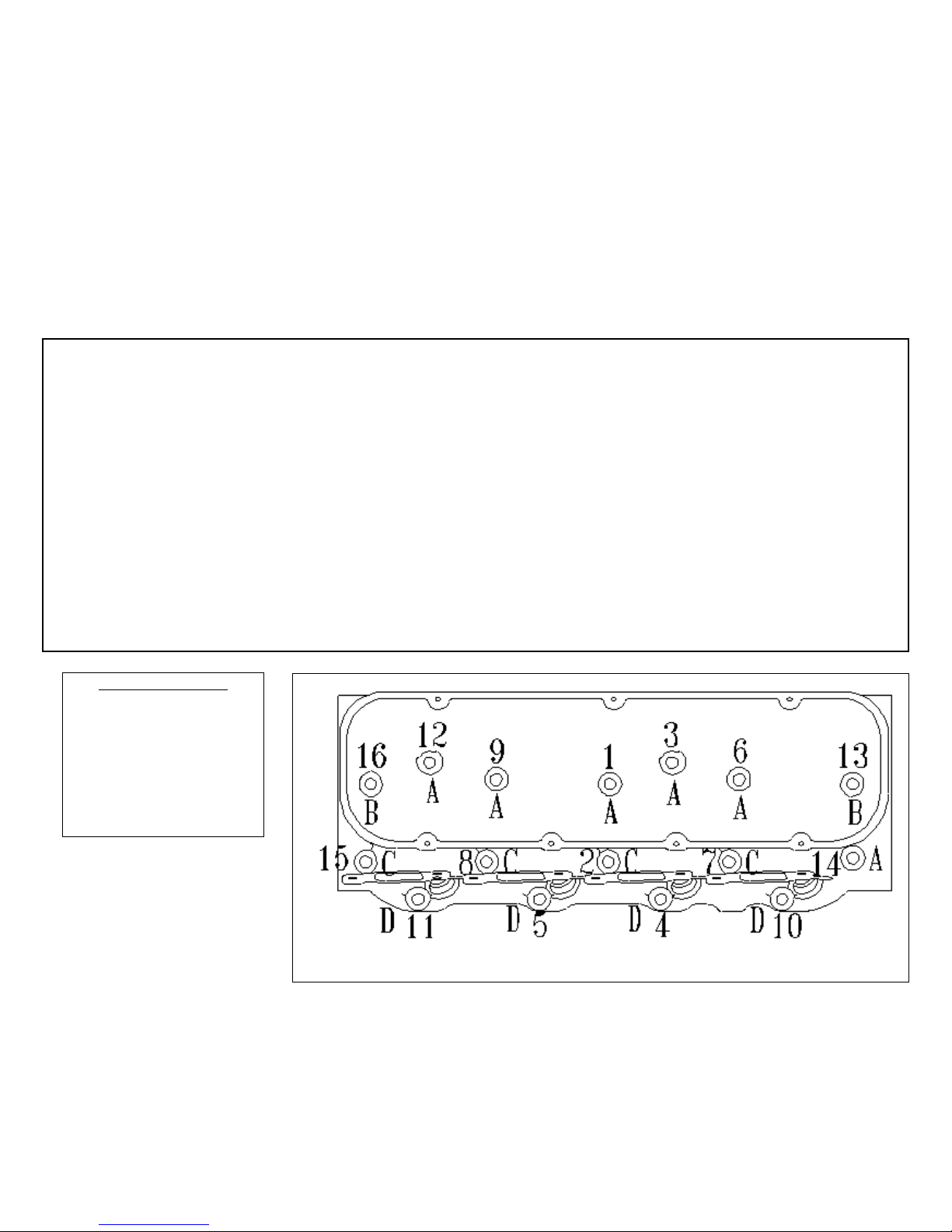

HEAD BOLTS or STUDS: High quality head studs or head bolts

with hardened washers must be used to prevent galling of the

aluminum bolt bosses. Edelbrock Head Bolt Kit #8551 includes

eight longer-than-stock bolts which must be used with these

cylinder heads. If you use any other head bolts, you must use

the eight head bolts and washers supplied with these heads in

positions #15, #8, #2, and #7 in Figure 1. These positions will

not accept stock length head bolts.

NOTE: Head bolts may bottom out in blocks with blind bolt

holes (Bowtie, 502 Mark V, etc.). Check for clearance, and if

necessary shorten bolts or replace with a set specifically

designed for use with blind holes.

ROCKER ARMS: The valve springs supplied will accommodate

valve lifts up to .700". Check the spring pressures required by

your cam manufacturer for your camshaft. This lift is much

higher than stock rocker arms will allow. Roller rocker arms will

be required if your camshaft has more than .500" lift. Stock

rockers may require longer-than-stock pushrods to clear the

valve springs.

NOTE: A visual inspection of rocker arm to valve alignment is

recommended. In some cases, it maybe necessary to loosen the

guide plate and adjust the plate to get proper alignment. Make

sure to re-torque the studs to recommended torque listed below.

VALVE COVERS: Because most roller rockers are physically

larger than stock rockers, taller valve covers are usually required

to clear them. Use Edelbrock Signature Series chrome valve

covers #4680 or Elite Series polished aluminum valve covers

#4280.

INTAKE MANIFOLD: Although stock intake manifolds will fit,

the Edelbrock Street Cylinder Heads are matched in size and

operating range with Edelbrock Performer RPM intake manifolds

#7161 or #7164. If the Performer RPM is too tall to fit under

your hood (Corvettes, etc.), you may use the Edelbrock Torker II

2-O manifold #5061. Additionally, any manifold that matches

Fel-Pro gasket #1212 may be used (Edelbrock Performer, Torker,

Victor Jr., Victor Ram, etc.). Oval port intake manifolds may be

used as-is, or port matched to the same configuration as the

cylinder heads for optimum performance.

*Not legal for sale or use on pollution-controlled motor vehicles.