Actron SCANTOOL CP9110 User manual

1

TM

CP9110

UP

DOWN

RIGHT

LEFT

®

by

®

TM

Vehicle Service Information ............. 2

Safety Precautions ............................ 3

Section 1:

Welcome to The Scan Tool ..

4

1-1 Features ........................................ 4

1-2 The scan tool................................. 5

1-3 What You Get................................ 6

1-4 Cartridge and Installation .............. 6

1-5 Cables and Adapters..................... 7

1-6 Operating the scan tool ................. 9

• Powering-up the scan tool .......9

• Keyboard .................................. 9

• Display.................................... 10

• Lists, Menus, & Questions .....10

• Other Functions & Keys ......... 11

1-7 Scan Tool Setup.......................... 12

Section 2:

Computer Vehicle Basics..

13

2-1 Basics of Computer-

Controlled Cars ........................ 13

2-2 About Codes................................ 16

2-3 When to Read Codes.................. 17

Section 3:

Help and Troubleshooting

Tips....................................19

3-1 Tool Problems ............................. 19

3-2 Car Problems .............................. 20

3-3 Scan Tool Self-Tests................... 20

• Display Test ........................... 21

• Keyboard Test........................ 21

• Memory Test .......................... 21

Section 4:

How to Order

Accessories ......................22

4-1 Where to Buy?............................. 22

4-2 Call Actron Direct ........................ 23

4-3 E-Mail & Internet address ........... 23

Section 5:

Appendix ...........................24

Glossary of Terms ............................. 24

Table of Contents

30

15825IndustrialParkway

Cleveland,Ohio44135

U.S.A.

Toll free U.S.: (800)228-7667

©2004ActronManufacturingCo.

AllRightsReserved.

0002-002-2186

FULL ONE (1) YEAR WARRANTY

ActronManufacturingCompany,15825Industrial

Parkway,Cleveland,Ohio44135,warrantstothe

user that this unit will be free from defects in

materialsandworkmanship for aperiodoftwo(2)

years from the date of original purchase.

Anyunitthatfailswithinthisperiodwillberepaired

orreplaced at Actron’s option and withoutcharge

whenreturnedtotheFactory.Actronrequeststhat

a copy of the original, dated sales receipt be

returnedwith the unit to determine if the warranty

period is still in effect.

Thiswarrantydoes not apply to damages caused

byaccident,alterations,orimproperorunreason-

able use.

ACTRON MANUFACTURING COMPANY DIS-

CLAIMS ANY LIABILITY FOR INCIDENTAL OR

CONSEQUENTIALDAMAGESFORBREACHOF

ANYWRITTENWARRANTYONTHEUNIT.

Vehicle Service Information

Thefollowingisalistofpublisherswhohavemanualscontainingelectronicenginecontrol

diagnosticinformation. Somemanualsmaybeavailableat auto partsstoresoryourlocal

public library. For others, you need to write for availability and pricing, specifying the

make, model and year of your vehicle.

Vehicle Service Manuals:

Chilton Book Company

Chilton Way

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA 92126

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

Suitable manuals have titles such as:

“Electronic Engine Controls”

“Fuel Injection and Feedback Carbure-

tors”

“Fuel Injection and Electronic Engine

Controls”

“Emissions Control Manual”

. . . or similar titles

Vehicle Service Manuals from

General Motors Corporation:

Buick, Cadillac, Chevrolet, GEO, GMC,

Oldsmobile, & Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

Saturn

Adistra Corporation

c/o Saturn Publications

101 Union St.

Post Office Box 1000

Plymouth, MI 48170

Vehicle Service Manuals from

Ford Motor Company:

Ford, Lincoln, & Mercury

Ford Publication Department

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Vehicle Service Manuals from

Chrysler Corporation:

Chrysler, Plymouth, & Dodge

Chrysler Motors Service Training

26001 Lawrence Avenue

Center Line, MI 48015

2

Allinformation,illustrationsandspecificationscontainedinthis manualarebasedonthelatest

informationavailable from industrysources at thetime of publication.No warranty (expressed

or implied) can be made for its accuracy or completeness, nor is any responsibility assumed

byActronManufacturingCo. oranyoneconnected withitfor lossordamagessuffered through

reliance on any information contained in this manual or misuse of accompanying product.

Actron Manufacturing Co. reserves the right to make changes at any time to this manual or

accompanyingproductwithoutobligationtonotifyanypersonororganizationofsuchchanges.

3

CAUTION:

Some vehicles are equipped with safety air bags. You

must

follow vehicle

service manual cautions when working around the air bag components or

wiring.If thecautions arenotfollowed, theair bagmayopen upunexpectedly,

resulting in personal injury. Note that the air bag can still open up several

minutes after the ignition key is off (or even if the vehicle battery is discon-

nected) because of a special energy reserve module.

General Safety Guidelines to Follow

When Working on Vehicles

To prevent accidents that could result in serious injury and/or damage

to your vehicle or test equipment, carefully follow these safety rules

and test procedures at all times when working on vehicles:

• Alwayswearapprovedeyeprotection.

• Always operate the vehicle in a

well-ventilated area. Do not inhale

exhaust gases — they are very

poisonous!

• Alwayskeepyourself,toolsandtest

equipmentawayfromall moving or

hot engine parts.

• Always make sure the vehicle is in

Park (Automatic transmission) or

neutral (manualtransmission) and

that the parking brake is firmly

set. Block the drive wheels.

• Never lay tools on vehicle battery.

You may short the terminals to-

gether causing harm to yourself,

the tools or the battery.

• Never use scan tool if its internal

circuitry has been exposed to any

liquids. This includes the scan tool

and Application Cartridges.

• Never smoke or have open flames

near vehicle. Vapors from gasoline

andchargingbatteryarehighlyflam-

mable and explosive.

• Never leave vehicle unattended

while running tests.

• Alwayskeepafireextinguishersuit-

able for gasoline/electrical/chemi-

cal fires handy.

• Always use extreme caution when

workingaroundtheignitioncoil,dis-

tributorcap,ignitionwires,andspark

plugs. These components contain

high voltage when the engine is

running.

• Whenperformingaroadtest,never

operate the scan tool alone while

driving the vehicle. Always have

one person drive the vehicle while

anassistant operates thescan tool.

• Always turn ignition key OFF when

connectingordisconnectingelectri-

cal components, unless otherwise

instructed.

• Alwaysfollowvehiclemanufacturer’s

warnings, cautions and service pro-

cedures.

1989-1995

CHRYSLER

Section 1: Welcome to the Scan Tool – Basics

4

The Actron scan tool has

many features that you

would expect in scan tools

used by the professionals:

• Large 4 line x 20

character LCD display

• High-impact plastic case

• Durable, easy to use

keyboard

• Removable vehicle cable

adapter

• Removable power cable

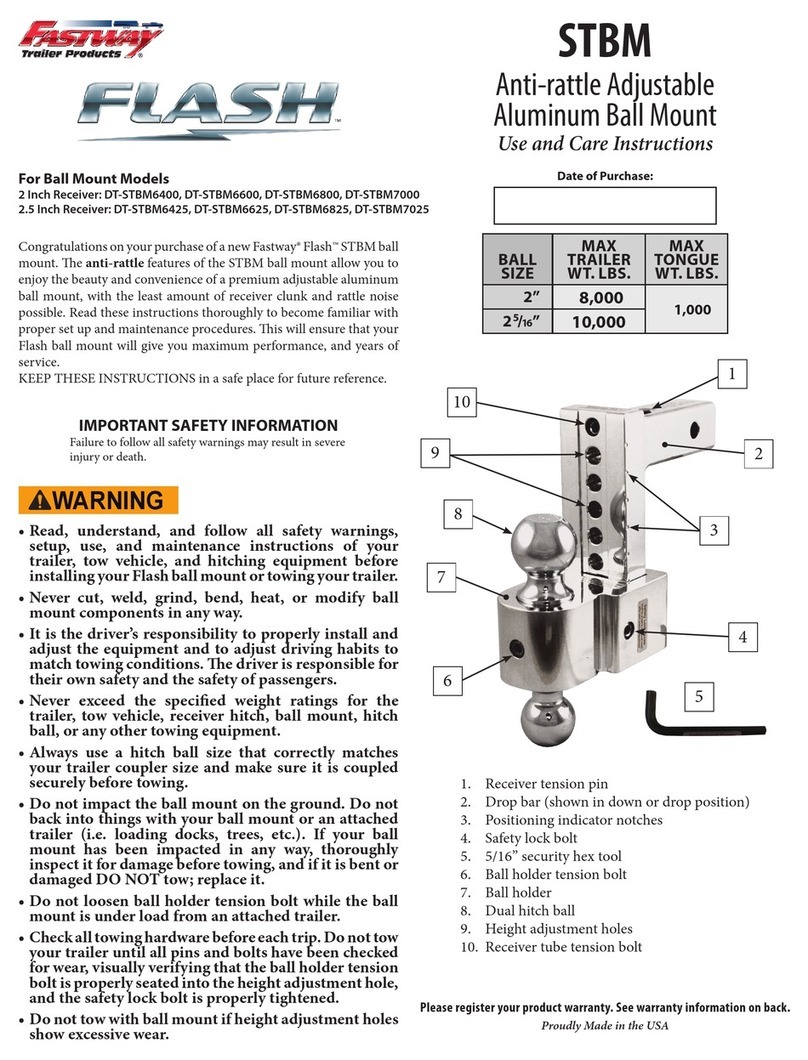

1-1 Actron Scan Tool Features

UP

DOWN

RIGHT

LEFT

®

by

®

TM

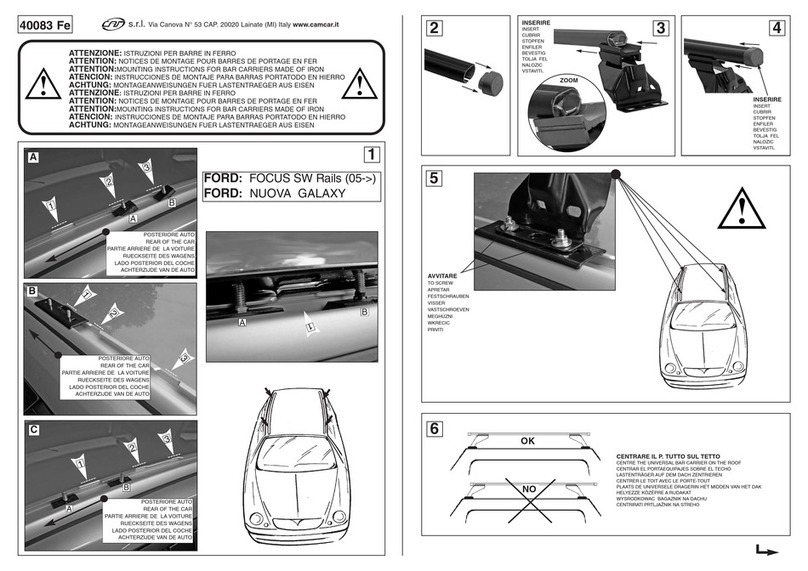

Vehicle Manufacturer Application Cartridges

The manufacturer-specific Application Cartridges offer a universal approach in chang-

ing software as vehicle technology changes. Actron’s separate cartridge and cable

system lets you add vehicle applications to meet your needs.

Cartridge Systems:

GM Cartridge 1984-1995

Ford Cartridge 1984-1995

Chrysler Cartridge 1989-1995

OBDII 1996-up

Professional-Style Adapter Cables:

GM ALDL — 12 Pin

Ford EEC-IV/MCU — 7 Pin

Chrysler SCI — 6 Pin

Scan Tool & Application Cartridge

1984-1995

GM

1984-1995

FORD

Optional Cable Adapters:

Chrysler CCD / LH – 6 Pin

Ford/Mazda MECS – 6 Pin

GM J1962-OBD-II – 16 Pin

Ford J1962-OBD-II – 16 Pin

Chrysler J1962-OBD-II – 16 Pin

5

1-2 The Scan Tool

Actron’s scan tool was developed by ex-

pertsin theautomotive service industry to

help you diagnose today’s vehicles and

assistyouintrouble-shootingprocedures.

Computer-controlled vehicles have a net-

work of sensors that creates a series of

inputs to the engine computer. The com-

puter interprets these inputs and sends

outputs (commands) back to the network

to control air, fuel, vacuum, spark and

other critical functions. When a problem

occurs,the computer willstore a recordof

the event, and take corrective action to

adjustthe circuit atfault.If the circuitdoes

not respond, or the problem cannot be

corrected, a trouble code is stored in the

computer’s memory. In some cases, the

CheckEnginelightmayalsobe activated.

The scan tool will allow you to monitor

these vehicle events for trouble-shooting

and diagnosis, and to read codes from

the computer’s memory to pinpoint prob-

lem areas.

Thescantoolusesstate-of-the-art16 “bit”

microprocessortechnology andhas twice

the computing power of some scan tools

costing thousands of dollars! The scan

tool is programmed to interpret the com-

puter signals and provide you with a “real

time”readoutofvehicledata.Moreimpor-

tantly, the software programs are written

to provide you with detailed, full-screen

readouts of all data. In addition, the Code

Lookup feature allows you to reference

code descriptions without having to page

through an instruction manual.

When the scan tool is connected to the

data connector, a communication link is

established, allowing the scan tool and

the vehicle’s on-board computer to ex-

changeinformation.Thewayinwhich this

information is exchanged is referred to as

a data stream.

As you use the scan tool, you will become

more proficient in trouble-shooting ve-

hicles using the detailed help messages

and code description information. Actron

will also help you become skilled in using

thescantoolfor more than just “scanning”

the vehicle data list. We will show you

many other uses that will expand your

diagnostic limits by using the information

contained in the application manuals that

comewithyour Application Cartridge. No-

start, driveability, and emission problems

will be easier to diagnose than ever be-

fore.

Application Cartridge Installed

1-3 Actron CP9110 – What You Get

When you receive your scan tool, take time

to review all package contents.

The Application Cartridge serial tag is

locatedonthetopcenterofthecartridge. This

serial tag will always be visible when the

cartridge is inserted in the main tool.

Please take time to review all important

documents enclosed. Be sure to review

both boxes for contents.

Review Box Contents

MainTool Box

In addition to the scan tool you should

have received the following items in the

main tool box:

• The Scan Tool

• Carrying Pouch

• Power Cable

• Main Tool Operator's manual

Application Cartridge Box

TheApplicationCartridgeboxthatyoupur-

chasedshouldcontainthefollowingitems:

• The Application Cartridge

• Vehicle Cable Adapter

• Application Manual for that vehicle

SERIAL NO.MODEL NO.

ACTRON MFG.

© COPYRIGHT 1995

PATENT PENDING

Actron Manufacturing warrants the software programs to

be accurate to the level of information released by the

Vehicle manufacturer at the time of release.

(800) 228-7667 1-2325

SERIAL NO.MODEL NO.

ACTRON MFG.

© COPYRIGHT 1995

PATENT PENDING

Actron Manufacturing warrants the software programs to

be accurate to the level of information released by the

Vehicle manufacturer at the time of release.

(800) 228-7667 1-2325

CP9110 123456789

Main Tool Model and Serial Tag

Cartridge Model and Serial Tag

6

UP

DOWN

RIGHT

LEFT

®

by

®

TM

1984-1995

GM

SERIAL NO.MODEL NO.

ACTRON MFG.

© COPYRIGHT 1995

PATENT PENDING

CP9110 12345678

1984-1995 GM

SERIAL NO.MODEL NO.

ACTRONMFG.

©COPYRIGHT 1995

PATENTPENDING

CP9111 123456789

Before You Start

Take time to review the proper procedure

for powering-up your scan tool. The fol-

lowing section, Cartridge and Installation,

should be read before proceeding! This

will help you become familiar with all

operating procedures.

UP

DOWN

RIGHT

LEFT

®

by

®

TM

1984-1995

GM

SERIAL NO.MODEL NO.

ACTRON MFG.

© COPYRIGHT 1995

PATENT PENDING

1-4 Cartridge and Installation

Review the Application Cartridge instal-

lation procedure before you power-up

your scan tool. Hold the cartridge, serial

number tag up, and slowly insert the car-

7

tridgeintothe cartridge opening.Alignthe

cartridge slots with the “keyway” on the

main tool bottom opening. Continue to

gently push the cartridge into the opening

until you feel the main “edge connector”

resistance, then push to engage the car-

tridge to the cartridge stop. The cartridge

is engaged when the alignment of the

serial number tag is even with the top

edge of the Main Tool opening edge and

flush against the cartridge stop. Refer to

the example.

To remove the Application Cartridge simply

grasp the cartridge end and pull away from

the main tool. This action will disengage

the cartridge from the edge connector. Con-

tinue to pull the cartridge out of the open-

ing the rest of the way.

NOTE:You should always havetheAp-

plicationCartridgeinstalledbeforeyou

connect your unit to the power supply.

NEVER UNPLUG THE CARTRIDGE

WHEN POWER IS APPLIED!

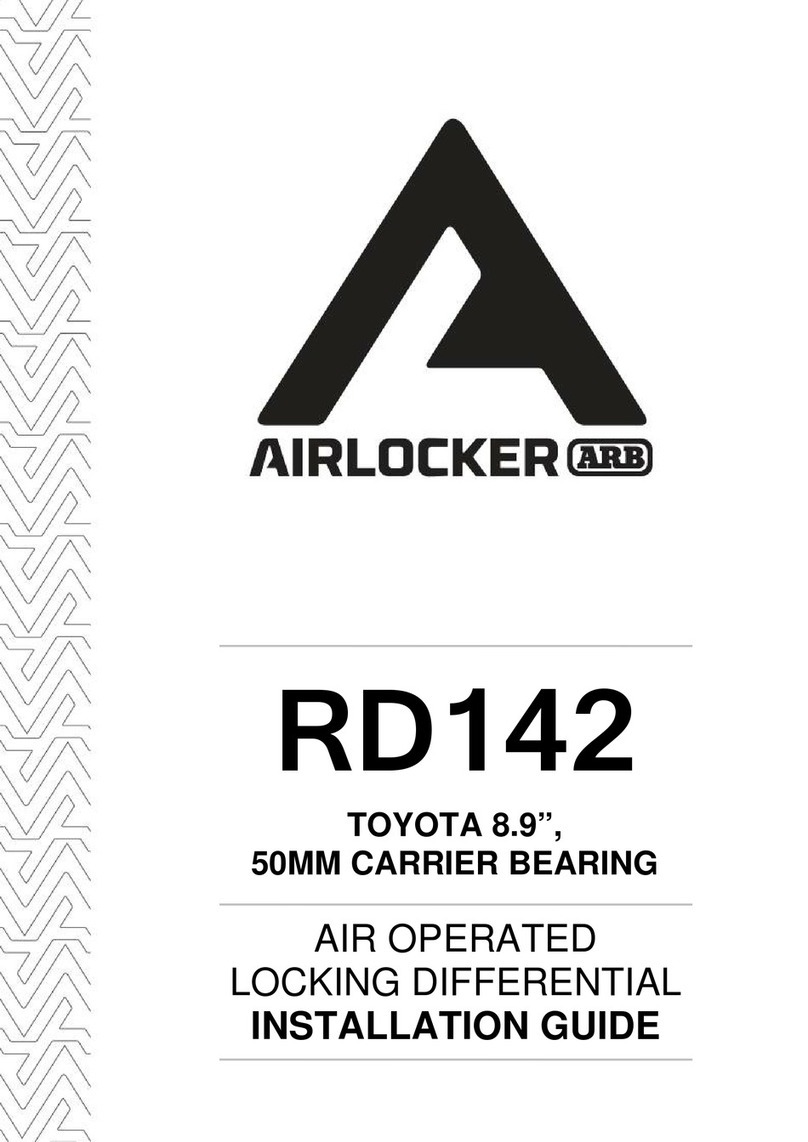

1-5 Power Cables and Vehicle Adapters

Thescantoolcomeswithamainpowercable

designed to plug into the vehicle cigarette

lighter.Theotherendofthecableplugsintothe

scantoolasshownbelow.

Occasionally,you mayfinditnecessaryto

connectdirectlytothe vehicle’s battery. In

these cases you may obtain an optional

battery clip adapter from Actron. Actron

also offers an AC power adapter to power

the scan tool with standard 110V wall

power. Both of these accessories may be

purchased directly from Actron.

Your scan tool has been designed to

operateatthesamevoltagelevelsasyour

vehicle’scomputer.It requires a minimum

of 8 volts to power-up. The scan tool is

circuit protected from voltage variations

and power surges. Should you have a

problem with power-up, review Section

3-1:ToolProblemstoverifythenatureof

yourproblem.NOTE:

Somevehiclesshutoff

powertothecigarettelighterreceptaclewhen

theignitionkeyisintheOFForSTARTposi-

tions.Checkyourvehicletodeterminewhether

thisis the case.

UP

DOWN

RIGHT

LEFT

®

by

®

TM

1984-1995 GM

UP

DOWN

RIGHT

LEFT

®

by

®

TM

Connecting to Vehicle

Cigarette Lighter

AC 110V to 12V

Power Adapter

Optional

Battery

Clip

Connecting to Scan Tool

Vehicle Cable Adapters

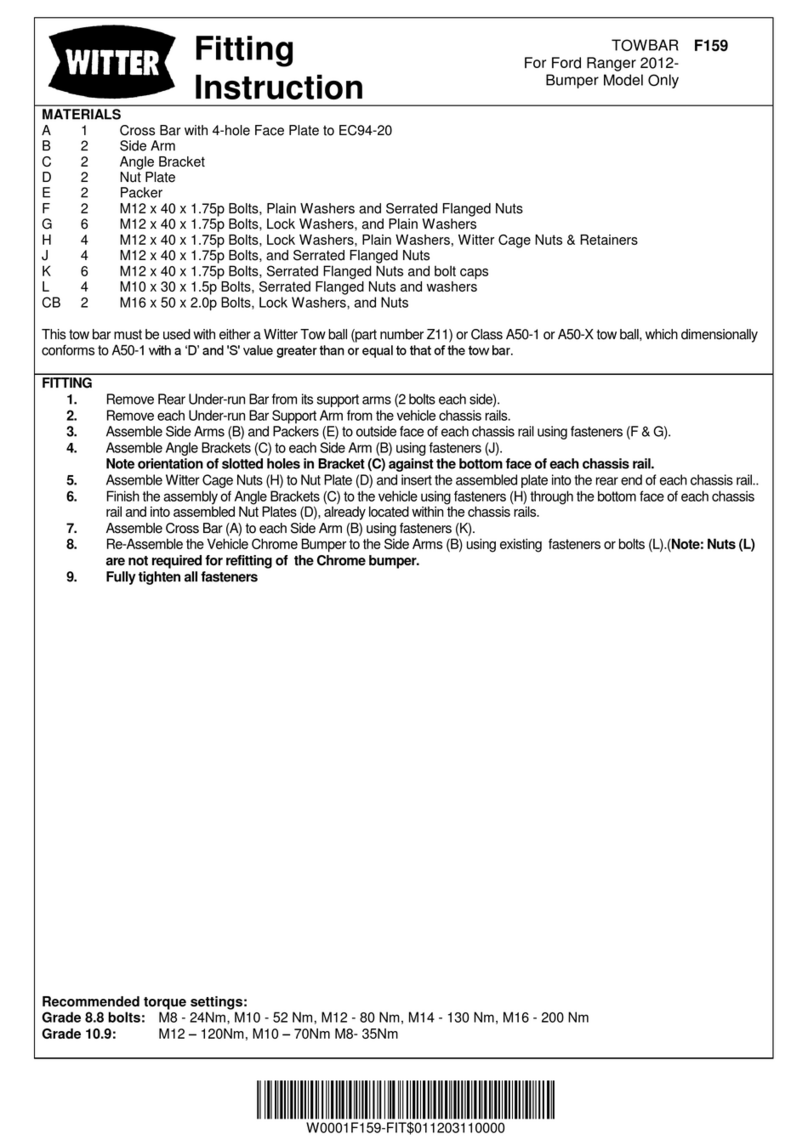

YourscantoolVehicleAp-

plication Cartridge pack

will contain the Applica-

tion Cartridge, application

manual and vehicle cable

adapter for one manufac-

turer (GM, Ford, or

Chrysler). The vehicle

cable adapter will be in-

stalled on the scan tool by

locating the large connec-

tor receptacle on the top

right side of the main tool.

Insertthevehiclecableinto

the scan tool receptacle and use the two

“thumbscrews” to secureit to theconnec-

toras shown in the illustration below. Note

thatyouwillfeela firm seating of thecable

asyousecureittothescantoolconnector.

The vehicle cable adapter should always

be connected to the vehicle before power

isapplied to thescan tool. Thiswill enable

the scan tool to maintain a proper ground

between itself and the vehicle. If you have

connected to the vehicle, powered-up the

tool, and have difficulty establishing a link

between the scan tool and the vehicle,

check the following:

1. Is the ignition on?

2. Verify you have connected the vehicle

data cable to the vehicle’s Data Link

Connector (DLC).

3. Confirm that proper vehicle information

was entered into scan tool.

8

When attaching the data cable to the ve-

hicle, take time to review the specific ap-

plication manual for the cartridge you are

using. This will instruct you on correctly

connecting the cable to the vehicle. Many

ofthevehicleadapters are “keyed” so that

theadapterwillfitonly one way. If youfind

thatyouhaveaspecialvehiclesituationor

the adapter does not fit, call 1-800-

ACTRON-7forassistance.Alwaysdouble

check the application section to be sure

that you are following the proper hook-up

directions.Forfurtherhelpthatisnotavail-

able in the scan tool help screens, see

Section 3: Actron Help for solutions to

your scan tool problems.

As you review the CP9110 Features sec-

tion on page 1-1 and 1-2, you will note

there is a complete view of accessory

vehicle adapter cables. They are for spe-

cial applications that only apply to certain

vehicles. If your vehicle is one of these,

you can order cables direct from Actron

by calling (800) 228-7667.

Connecting the

Vehicle Adapter Cable

9

1-6 Operating the Scan Tool

Powering-upthescantool

The scan tool can be powered-up in three

ways. The most widely used way is with

thesuppliedcigarettelighter adapter. The

scantoolcanalsobepoweredupbyusing

the optional Battery Clip Adapter or 110/12V

AC Power Adapter. If you are powering-

up the scan tool for vehicle testing, then

make sure you connect the appropriate

cable to the data connector before you

supplypowertothescantool.Ifyoudonot

connect the vehicle data cable now, the

scantool

willletyouknowthatyouhavenot

connected the data cable. If you just want

to power-up the

scan tool

to do self-tests,

then you do not need to attach the cable

to the data connector.

Whenthe

scantool

powers-up, a seriesof

screens is displayed. The screens start

with a “Welcome” screen and end with a

“Key Button Help” screen.

Welcome To

The ScanTool

By Actron

Press HELP For Key

Button Information.

Press ENTER To ont

Welcome & Key Button Help Screens

The screens in between the “Welcome”

and the “Key Button Help” screen are for

a tool self-test and the cartridge software

version. Refer to this software version if

you need to contact Actron’s technical

support line with a problem. If you wish to

review the key button definitions, then

push the HELP key; otherwise, press

ENTER to continue forward.

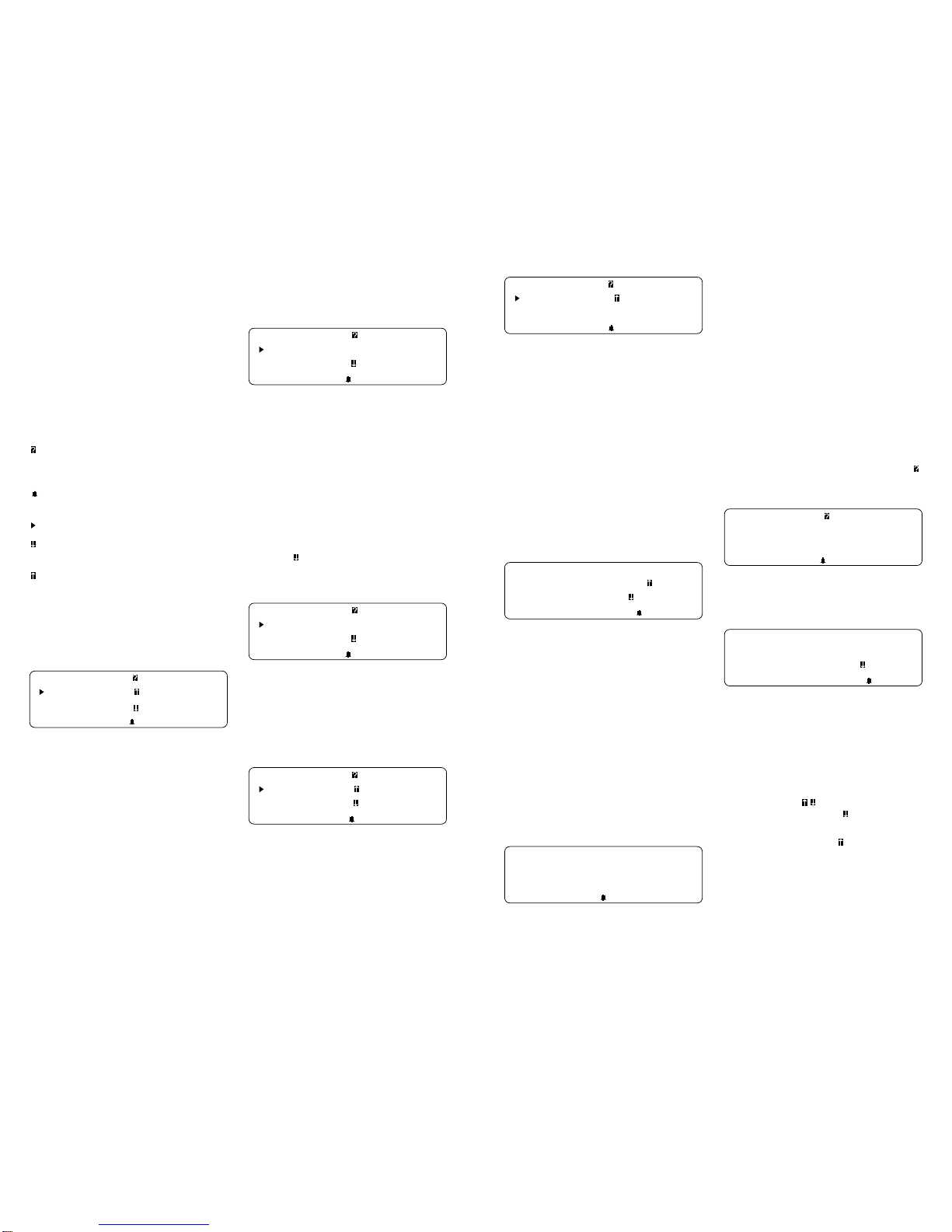

Keyboard

The scan tool software was designed for a

“userfriendly”approachinnavigatingthrough

operationalmenus.Thismakesthescantool

easytooperate.Simplyfollowtheinstructions

thatmatchthekeyboardsymbolsandyouwill

beusingyourscantoollikeanexpertinnotime.

Sincethekeyboardissealed,adampclothcan

be used to gently clean the surface. (

Cau-

tion:

DO NOT USE SOLVENTS LIKE

ALCOHOL! This could remove the

keyboard paint!)

Scan Tool Keyboard and Display

Keyboard Functions

The scan tool uses 8 keys to navigate

through the software-user interface:

ENTER Used to enter or answer a

software request.

HELP Used to request help when

the symbol is in the upper right hand

corner of the display.

FUNCTION Used to return user to

manufacturer’s function list.

BACKUP Used to move one screen

back in scan tool flow.

ARROWS UP or DOWN are always

used to move the solid cursor in the

direction of the arrow or scroll the data

listinthedirectionyouwanttomovethe

list

LEFTorRIGHTarrowsmove

the cursor in the direction of the arrow

and allow you to customize a vehicle

data parameter list.

UP

DOWN

RIGHT

LEFT

Display

The scan tool has a 4 line x 20 character

liquid crystal display (LCD) for easy view-

ing.Thismakesthescantool“userfriendly”

by offering a large viewing area to display

most Help and Instructional messages.

This also puts more information on the

display instead of referring you to printed

materials. Again the display will support a

number of helpful characters that will

prompt you through test routines. These

characters are shown below:

Question Mark in upper right corner

means there is help available for this

screen.

Bell in lower right corner means the

sound alert is on or active.

Cursor used to select menu choice.

Down Arrow indicates there is addi-

tional information on the next screen.

Up Arrow indicates there is additional

information on previous screen(s).

Below is a screen showing how these

symbols will look on your display (NOTE:

This is a GM Function List – Function Lists

forothermanufacturersmaydifferslightly.):

GM Function List

4)Record Data

5)Playback Data

6)Field Service

Lists,Menus, and Questions

Thescan tool is designedtobeasintuitive

as possible. That is, its functions and con-

trols should be easy to understand and

use the first time you try it. All scan tool

menus and screen lists operate the same

way. By using the UP and DOWN arrow

keys, you can move the cursor to a menu

selection of your choice. The ENTER key

selectsthat function. Below isan example

of a Function List with several choices

10

(NOTE: This is a GM Function List –

Function Lists for other manufacturers

may differ slightly.):

GM Function List

1)Read odes

2)Erase odes

3)View Data

Notehowthecursor is pointing at 1)Read

Codes. If you wish to read trouble codes,

press ENTER to select that function. To

make a different choice, such as viewing

data, use the DOWN arrow key to move

the cursor down next to 3) View Data and

press ENTER. This will select the View

Data function.

Sometimes, a list will be longer than three

or four items, and will not fit on a single

screen. In these cases, the down arrow

symbol ( ) is visible in the last column of

the display, indicating that there are more

choices on the next screen:

GM Function List

1)Read odes

2)Erase odes

3)View Data

To go to the next choice, use the DOWN

arrowkeytomovethecursordownthelist.

NOTE: Pressing the DOWN arrow key

moves the function list one line at a time.

After several DOWN arrow key presses,

the screen below appears.

GM Function List

4)Record Data

5)Playback Data

6) Field Service

Now notice that there are arrows pointing

up and pointing down in the last column.

This indicates that you can use the UP

arrow key to move the cursor to the previ-

ous screen or press the DOWN arrow key

several times to move the cursor to the

third screen, shown below:

11

GM Function List

7)Beeper On-Off

8)English-Metric

9) ode Lookup

Notice now that there is only an arrow

pointing up in the last column. This indi-

catesthatyouhavereachedtheendofthis

list, and that all other choices are on

previousscreens. You canreturnto those

screens by pressing the UP arrow key.

(NOTE:ThisisaGMFunctionList–Func-

tion Lists for other manufacturers may

differ slightly.).

These up and down arrow characters on

the screen are used throughout the scan

tool’s software. The UP and Down arrow

keys work exactly the same way, even if

you are just scrolling through text such as

the On-Line Help screen shown below:

3.TEST ONNE TOR:

DAMAGED/LOOSE PINS?

4.TOOL SETUP OK ?

ORRE T VINS,ET ?

Note that there are no choices to make

here, and that there is no cursor to move.

There are, however, up and down arrows

in the last column. These arrows indicate

that there are other screens before and

after this one. Using the UP and DOWN

arrow keys, you can scroll through the

entire message.

Occasionally, you may be asked a ques-

tion by the scan tool which requires a

response. These will always be YES or

NO questions, and are answered in al-

most the same way you make choices on

a Function List. Below is an example of a

YES/NO question:

View Instructions

For reating ustom

Data List?

Yes <No>

In these screens, brackets will automati-

callybenexttothedefaultresponse.Ifyou

wish to accept the default choice, simply

press ENTER. If you wish to change the

answer,usetheLEFTorRIGHTarrowkey

to move the brackets next to the other

response and press ENTER.

Other Functions & Keys

As you have reviewed moving through

lists and functions in earlier sections, you

probably noticed several other symbols

on the screen. In the upper right-hand

cornerofsomescreens,thereisalarge .

ThisquestionmarkindicatesthatOn-Line

Helpis availableforthatparticularscreen:

Operating Error.

heck onnections!

Try Again?

<Yes> No

To enter On-Line Help, press the HELP

key. For the screen above, the help mes-

sage would look like this:

RE HE K FOLLOWING:

1.IGNITION KEY ON?

2.HOOKUP TO VEHI LE

TEST ONNE TOR OK?

All On-Line Help screens have their text

typed in ALL CAPITAL LETTERS. This is

anotherreminder that youareviewingOn-

Line Help screens and not screens asso-

ciated with a function of the Function List.

Some On-Line Help messages are longer

than one screen. If this is the case, the

arrow symbols ( ) will appear in the last

column of the display. A means there is

more On-Line Help information available

on the next screen. A means there is

more On-Line Help information available

on the previous screen. Use the UP and

DOWN arrow keys to page up or down

through a series of On-Line Help screens.

The On-Line Help screen shown above

hasa inthelastcolumn.Toviewthenext

On-Line Help screen, press the DOWN

arrow key. That screen is shown below:

3. TEST ONNE TOR:

DAMAGED/LOOSE PINS?

4.TOOL SETUP OK?

ORRE T VINS, ET ?

Notice now that both arrow symbols ( )

arevisibleinthelastcolumnofthedisplay.

This indicates that you can either page up

to a previous On-Line Help screen, or

page down to the next On-Line Help

screen by using the UP and DOWN arrow

keys. The previous On-Line Help screen

is always the one you just viewed, just as

with Function Lists.

Another symbol on the screen you might

have noticed is the bell ( ) symbol in the

lower right-hand corner as shown below:

Press HELP For Key

Button Information.

Press ENTER To ont

This bell symbol indicates that the sound

alert is on or active. Each time you press

akey,youshouldhearabeep.Ifyoudonot

see this symbol, then the keys should

remain silent when pressed. Information

onchangingthissettingisfoundinsection

1-7: Scan Tool Setup.

12

1-7: ScanTool Setup

Tool Setup is used to change the scan

tool’s default sound and measurement

unit settings. To change the scan tool’s

default settings, select the Tool Setup

optionfrom the FunctionList(NOTE: This

is a GM Function List – Function Lists for

other manufacturers may differ slightly.):

GM Function List

7)Beeper On-Off

8)English-Metric

9) ode Lookup

After selecting the Tool Setup option, you

are given the choice to change either the

ScanTool’smeasurementunitsorwhether

thebeeperwillbeOnor Off. If the bell( )

symbol appears in the lower right hand

corner of the display, then the beeper is

turned On.

Setup Tool For

1) English/Metric

2) Beeper On/Off

Depending on whether you select English/

Metric or Beeper On/Off, the ScanTool will

display one of the following screens:

Measurement Units

English (Default)

Metric

Beeper Sound

On (Default)

O f f

When the beeper sound is turned Off, the

bell ( ) symbol will no longer appear on

the lower right hand corner of the display.

NOTE: If you change the Beeper and

MeasurementUnits to asettingotherthan

the default, then all changes will revert

back to the default settings the next time

the scan tool is used.

13

Section 2: Vehicle Computer Basics

2-1 Basics of Computer-Controlled Cars

This section explains the engine com-

putercontrol system, thetypesof sensors

and how the computer controls engine

fuel delivery, idle speed and timing. Addi-

tional information may be found in techni-

cal support books at your local library or

autopartsstore.Themoreyouknowabout

the computer system, the better you can

diagnose vehicle computer problems.

Computer controls were originally in-

stalled on vehicles to meet federal gov-

ernment regulations for lower emissions

levels and improved fuel economy. This

began in the early 1980’s when basic

mechanical systems were no longer able

to accurately control key engine param-

eters. A computer could be programmed

to control the engine under various oper-

ating conditions, making the engine more

reliable. While these early systems were

very limited in the scope of their control,

providing only 10-14 trouble codes, they

did help guide the vehicle repair process.

Today,computercontrolshavemadecars

and trucks faster, cleaner, and more effi-

cient than ever before. In fact, without the

government mandates for fuel efficiency

and emissions control, cars and trucks

today would not be nearly as powerful,

reliable, and comfortable as they are.

What the computer controls:

The main control areas of the vehicle

computer are fuel delivery, idle speed,

spark advance, and emissions controls.

Some on-board computers may also con-

trolthetransmission,brakes,andsuspen-

sion systems as well.

What has not changed?

Acomputer-controlledengineisverysimi-

lar to the older, non-computerized en-

gine. It is still an internal combustion en-

ginewithpistons,sparkplugs,valves,and

camshaft(s). The ignition, charging, start-

ing, and exhaust systems are very similar

aswell. Youtestandrepairthese systems

just as before. The technical manuals for

these components show you how to per-

form the tests. Additionally, compression

gauges, vacuum pumps, dwell/tach

meters, engine analyzers, and timing

lights will continue to be used.

The Engine Computer Control system

The vehicle’s on-board computer, or

Powertrain Control Module (PCM), is the

“heart”ofthesystem.Itissealedinametal

box and connected to the rest of the en-

gine by a main wiring harness. The PCM

islocated,inmostcases,inthepassenger

compartment, behind the dashboard or in

the “kick panel” position, although some

manufacturers locate the computer con-

trol module in the engine compartment

area. Most PCMs can withstand a lot of

vibration and are built to live in a rugged

environment.

The PCM is permanently programmed by

the factory engineers. The program is a

complex list of look-up tables and instruc-

tions telling the computer how to control

the engine based on various driving con-

ditions. To do its job, the computer uses

sensors to know what is happening and

then provide instructions back to a net-

work of switches and actuators through-

out the vehicle.

Sensors, switches, and actuators give

the computer information

Sensors are devices which measure op-

erating conditions and translate them into

signals the computer can understand.

OUTPUT

ACTUATORS

SENSORS

INPUT

BRAINS OF THE

COMPUTER

Some examples of sensors: thermistors

(for temperature readings), potentiom-

eters (like a throttle position sensor), re-

lays(for voltage and signalreadings),and

signal generators (such as an 02 sensor).

The network of sensors has the job of

deliveringinformationthecomputerneeds

to know by converting it into electrical

signalsthecomputercanunderstand.Sig-

nals running from sensors to the PCM are

referred to as “inputs.”

Sensors monitor key things such as:

• Engine Temperature

• Intake Manifold Vacuum

• Throttle position

• RPM

• Incoming Air Temperature

• Volume of Incoming air

• Air Fuel Ratio, in percentage ( % )

Switches and Actuators are electric de-

vices energized by the computer to allow

commands to perform a specific function.

Switches are often called relays (such as

the coolant fan switch). Actuators might

include solenoids (such as fuel injector

valves) and small motors (such as the Idle

Speed Control). Not all of the computer’s

outgoing signals are routed to switches

and actuators. Sometimes information is

sent to other system computers like trans-

mission, brakes, ignition modules, and trip

computers. Signals running from the PCM

to other components are called “outputs.”

How the computer controls fuel deliv-

ery

Engine operation and emissions perfor-

mance depend upon precise fuel delivery

and ignition control. Early computer sys-

tems controlled fuel by electronically ad-

justing the carburetor metering and jet

systems. Soon, however, this was re-

placedby themoreprecisefuel deliveryof

fuel injection.

In an electronically carbureted system,

the computer simply controls fuel flow

basedon howfar the throttleis opened by

the driver. The computer “knows” how

much air can flow through the carburetor

at various throttle openings, and adds the

appropriate amount of fuel to the mixture

at the carburetor.

Fuel injection is somewhat more sophis-

ticated in the way it delivers fuel. The

computerstilladdsanappropriateamount

of fuel to the entering air, but now it uses

fuelinjectors(either in a throttle bodyorat

each intake port). Fuel injectors are far

more precise than carburetor jets, and

create a much finer fuel “mist” for better

combustion and increased efficiency. In

addition,mostfuelinjection systems have

ways of measuring exactly how much air

is entering the engine, and can calculate

the proper air/fuel ratio using lookup

tables. Computers no longer have to “es-

timate” how much air the engine is using.

In many modern systems, the computer

also uses information provided by sen-

sorstogiveitanideaofhowwellitisdoing

itsjob,andhowtodoitbetter.Sensorscan

tell the computer how warm the engine is,

how rich or lean the fuel mixture is, and

whether accessories (like the air condi-

tioner) are running. This feedback infor-

mation allows the computer to “fine tune”

the air/fuel mixture, keeping the engine

operating at its peak.

What the Computer needs to know:

•Engine operating condition. Sensors

used are: coolant temperature, throttle

14 15

position, manifold pressure (vacuum),

air flow and RPM.

•Air intake. Sensors used are: mass air

flow,manifoldabsolutepressure,mani-

fold air temperature and RPM.

•Air/fuel mixture status. Sensors used

are: oxygen sensor(s).

NOTE: Not all engines use every sensor

listed above.

Open and Closed Loop Modes:

Open or closed loop operation refers to

the way the computer is deciding how

much fuel to add to the air entering the

engine. During cold start and other low

demand, low temperature situations, the

computer operates in open loop mode.

This means that it is relying on a set of

internal calculations and data tables to

decidehowmuch fuel to add to the incom-

ingair.Itusessensorssuchasthecoolant

temperature sensor (CTS), the throttle

position sensor (TPS), and the manifold

absolute pressure sensor (MAP) to deter-

mine optimum mixtures. The important

difference here is that it

does not

check to

seeif the mixturesarecorrect, leaving the

computer adjustment loop open.

In closed loop mode, the computer still

decideshowmuchfueltoaddbyusingthe

sensors listed above, and by looking up

the appropriate numbers on a data table.

However,itnowchecksitselftodetermine

whether the fuel mixture is correct. It is

able to check itself by using the informa-

tion provided by the oxygen sensor(s)

(O2S) in the exhaust manifold. The oxy-

gen sensors will tell the computer if the

engine is running rich or lean, and the

computer can take steps to correct the

situation.Inthisway,thecomputercloses

theadjustmentloopbycheckingitselfand

making necessary corrections. It should

be noted that the O2 sensors must be at a

veryhighoperatingtemperature(approxi-

mately 650° F) before they will begin to

feed information back to the computer.

This is why open loop mode is neces-

sary—togive the O2sensors time towarm

up to operating temperature.

As long as the engine and O2 and Coolant

TemperatureSensorsareatoperatingtem-

perature, the computer can operate in the

closed loop mode. Closed loop mode in-

suresthattheair/fuel mixture is at theideal

14.7:1 air/fuel ratio needed for efficient

combustion. But in stop and go cycles, the

O2 sensor may in fact cool down enough

that the computer will need to rely on a set

of internal parameters and go into open

loop mode again. In some cases, this may

also happen during extended periods of

idling. Many newer vehicles now use

heated O2 (HO2S) sensors to prevent this

condition.

In many vehicles, the computer controls

other systems related to open and closed

loop modes, including idle speed, elec-

tronicspark control, exhaustgasrecircula-

tion, and transmission torque converter

clutches.Inopenloopmode,someofthese

systemswillbeadjustedtospeedthewarm-

ingof the engine andget the computer into

closed loop mode as quickly as possible.

OBD II: The Next Horizon

In1994,manymanufacturersbeganequip-

ping cars with a new class of computer

technology which puts more processing

powerunder your dashthan everbefore. It

is called On-Board Diagnostics, Second

Generation, or OBD-II. It is required on all

vehicles sold in the US beginning January

1, 1996 (though most domestic manufac-

turers introduced it earlier than required),

and offers increased system monitoring

and diagnostic information. This new sys-

tem will store a library of 400 general

trouble codes and another 400 manufac-

turer-specific codes. These codes cover

Body Systems (B-Codes), Chassis Sys-

tems(C-Codes),andPowerTrainSystems

(P-Codes).Now,basictermsarestandard-

ized and all generic codes will share a

common format and terminology that the

manufacturers and the Society of Auto-

motive Engineers (SAE) designed. You

will be glad to know that as your car gets

smarter, it will be easier for you to keep

track of what is going on under the hood.

16

Engine computers can

find

problems

Thecomputersystems in today’svehicles

do more than control engine operations—

theycanhelpyoufindproblems,too!Spe-

cial testing abilities are permanently pro-

grammed into the computer by factory

engineers. These tests check the compo-

nents connected to the computer which

are used for (typically): fuel delivery, idle

speedcontrol, spark timing,emissionsys-

tems, and transmission shifting. Mechan-

ics have used these tests for years. Now

you can do the same thing by using your

Actron scan tool!

Enginecomputersperformspecialtests

The engine computer runs the special

tests, depending on the manufacturer,

engine, model year, etc. There is no “uni-

versal”testthatisthesameforallvehicles.

Thetests examine INPUTS (electrical sig-

nals going INTO the computer) and OUT-

PUTS (electrical signals coming OUT of

the computer), as well as internal calcula-

tions made by the computer. Input signals

which have “incorrect” values, or output

circuits which do not operate properly are

noted by the test program and the results

are stored in the computer’s memory.

These tests are important. The computer

cannot control the engine properly if it has

incorrect input information or faulty output

circuits.

Code numbers reveal test results

The test results are stored by using code

numbers, usually called “trouble codes”

or“diagnosticcodes.”Forexample,acode

22 might mean “throttle position sensor

signal voltage is too low.” Code meanings

areapartof your scan tool’s software—all

you have to do is look them up! But since

code definitions vary with manufacturer,

model year, and engine, you may also

want to refer to a vehicle service manual

for additional information. These manu-

als are available from the manufacturer,

other publishers, or your local public li-

brary. See page 2formore information on

ordering service manuals.

Read Trouble Codes with the scan tool

You can obtain trouble codes from the

engine computer memory by using the

scantool.Youcanalsomonitortheopera-

tion of systems throughout the vehicle,

helpingtopinpointthesystemwherethere

may be a problem. Once you have read

the trouble codes, you can either:

• Have your vehicle professionally ser-

viced.

Or,

• Repair the vehicle yourself using the

troublecodestolocatethesourceofthe

problem.

2-2 About Codes

Where do Trouble Codes come from and what are they for?

17

Trouble Codes and Diagnostics help

you fix the problem

To find the cause of the problem yourself,

you need to perform special test proce-

dures called “diagnostics.” These proce-

dures are in the vehicle service manual,

andyour scantool makes iteasy to locate

and diagnose malfunctioning systems.

There are many possible causes for any

problem. For example, suppose you

turned on a wall switch in your home and

the ceiling light did not turn on. Is it a bad

bulb or light socket? Are there problems

with the wiring or wall switch? Maybe

there is no power coming into the house!

As you can see, there are many possible

causes. The diagnostics are written for

servicing a particular trouble code take

into account all the possibilities. If you

follow these procedures, you should be

able to find the problem causing the code

and fix it yourself.

Actron makes it easy to fix computer-

controlled vehicles

Using the Actron scan tool to obtain

trouble codes is fast and easy. Trouble

codes give you valuable knowledge -

whetheryougoforprofessionalserviceor

do it yourself. Now that you know what

trouble codes are and where they come

from, you are well on your way to fixing

today’s computer-controlled vehicles!

2-3 When to Read Codes

Many vehicles have a “Malfunction Indicator Lamp” or MIL, which has been referred to

as a “Check Engine” light in the past. With the advent of OBD-II, all engine trouble lights

are now called “Malfunction Indicator Lamps” or MIL.

UsetheMalfunctionIndicatorLamptotellyouwhentroublecodeshavebeen

storedin memory:

• “Check Engine”

• “Service Engine Soon”

• “Service Engine Now”

• marked with a small engine picture or

diagram

The Malfunction Indicator Lamp is nor-

mally OFF when the engine is RUNNING.

NOTE:

The Malfunction Indicator Lamp

will turn on when the ignition key is in ON

position, but the engine is OFF prior to

startingthevehicle.Thisisanormal testof

all the dashboard message lights.

Aboutthe Malfunction Indicator Lamp

MalfunctionIndicatorLamp:

normaloperation

The engine computer turns the Malfunction

IndicatorLamp onandoffasneeded. This

dashboard message is either amber or

red and labeled:

MalfunctionIndicatorLamp:

problemspotted

IftheMalfunctionIndicator Lamp does not

comeon, you may haveanelectricalprob-

lem which needs repair. Refer to the “Di-

agnosticCircuitCheck”stepsinthe“Basic

Diagnostic Procedures” section of your

vehicle service manual.

MalfunctionIndicatorLamp:

intermittent problem

When the light remains ON after the en-

gine is RUNNING:

• Thecomputerseesaproblemthatdoes

not go away (known as a “current” fail-

ure).

• The light will stay on as long as the

problem is present.

• A trouble code is stored in computer

memory(a“history”or“memory”code).

• Use the scan tool at the earliest conve-

nient time to obtain codes.

When the light comes ON, then goes OFF

while the engine is running:

• The computer saw a problem, but the

problem went away (known as an “in-

termittent” failure).

• A trouble code is stored in computer

memory(a“history”or“memory”code).

• Thelightwent out because theproblem

went away, but the code stays in

memory.

• Use the scan tool at the earliest conve-

nient time to obtain codes.

NOTE:

The computer will automatically

erase these codes after several restarts if

the problem does not return.

Poorly running engine, no Malfunction

IndicatorLamp

Most likely, this condition is not due to

computer system failures, but reading

codes can still be useful as part of a basic

trouble-shooting procedure. Check wir-

ing and bulb for “Check Engine” light

failures. Refer to vehicle service manual

for additional diagnostic information.

IMPORTANT:

Some vehicles may not be

equipped with Malfunction Indicator

Lamps.Somemid-80’sFords,forexample,

did not use a Malfunction Indicator Lamp

to warn of problems. On vehicles without

Malfunction Indicator Lamps, it is more

difficult to recognize problems. Some

symptoms of a computer- or sensor-

related problem might be:

• Hard starting

• Poor idle quality

• Poor fuel mileage

• Misfiring or hesitation

• Black or dark gray smoke from tailpipe

• Failure of emissions tests

Invehicles without aMalfunctionIndicator

Lamp, it is important to be alert to any

warningsignsofcomputersystemtrouble.

This is why the scan tool is so valuable.

With it, you can diagnose any vehicle’s

electronicsystems,regardlessofwhether

the vehicle is equipped with a Malfunction

IndicatorLamp.Itis also important to note

that vehicles without Malfunction Indica-

torLampsDO store trouble codesjustlike

any other computer-controlled vehicle.

Readingcodesisstillaveryimportantpart

ofdiagnosingproblemsonthesevehicles.

NOTE:

OnvehiclesequippedwithOBD-II,

the Malfunction Indicator Lamp also sig-

nals an emissions-control related failure.

The vehicle may not run any differently,

but the OBD-II system is designed to note

very small changes in the engine’s opera-

tion which could lead to emissions dam-

age or failure.

18 19

Section 3: Actron Help

3-1 Tool Problems

There may be times when your scan tool

does not seem to be communicating with

thevehicle. It is possiblethatthe vehicle’s

computerwill stopcommunicating, but for

the most part, if you loose the “link,” you

should check the vehicle power adapter

and the cigarette lighter circuit first. Since

the scan tool has built-in diagnostics, it is

easytoisolateaproblemwiththeScanTool

itself. There will be two basic types of

problems that you will deal with: vehicle

problems and tool problems. Both might

affect your test. Remember, the scan tool

always goes through a SELF CHECK

each time you power the unit up, before

testing. Use the trouble-shooting tips be-

low to help diagnose scan tool problems

before calling Actron’s Technical Support

line:

1. The scan tool will not power-up:

A.Check the cartridge – Is it properly

seated?

B.Check the cigarette lighter for power.

Take the cigarette lighter element and

plug it in to verify that it is heating up. If

not, check lighter fuse.

C.

UN-plug and plug back in to verify the

cigarettelighterendisproperlyseatingin

thevehiclecigarettelighterreceptacle.

2. Toolwillnot“Link”tothevehiclecom-

puter:

A.Unplug the vehicle Data Link Connec-

tor (DLC) adapter and plug it back in to

verify that it is properly plugged into the

vehicle DLC.

B.ReviewthevehicleVINinformation and

verify that you have properly entered

the correct vehicle VIN information in

the scan tool setup. Also review the

Actron supported vehicle list (found in

scan tool Application Cartridge

manual).

C.In some GM cars, if there is a Trouble

Code set that refers to the internal

MEMCAL-PROM, you may not get a

vehicle data stream.

3. Your scan tool will not record data:

A.Taketime toreviewthevehicleapplica-

tion manual for the vehicle that you are

working on. Refer to the data recording

section, following the instructions and

try again.

B.Verify that the scan tool memory buffer

is not already full.

C.Use the scan tool self-test and verify

thattheon-boardRAMmemoryisokay.

4. YourKeyboarddoesnotfunctionprop-

erly:

A.Perform the Keyboard Test by entering

the Self-Test and select the Keyboard

Test function. This will test out all but-

tons along with the sound alert.

B.If the keyboard test shows nothing

and you still experience the problem,

thencallActron’stechnicalsupportper-

sonnel at 1-800-ACTRON-7.

3-2 Car Problems

If your scan tool is having difficulty “link-

ing” with the vehicle computer, be sure

that you have double checked all scan

tool interfaces, including the power con-

nectors and the DLC connection. When

you are sure that the scan tool is not

malfunctioning (run scan tool Self-Tests),

thentheproblemmaybewiththevehicle’s

electrical system or with the vehicle com-

puter itself. Check the following:

• If you are using the cigarette lighter

power adapter, verify that the vehicle’s

cigarette lighter and fuse are OK.

• Ifthecigarette lighter adapter is usedto

power-upthescantool, then make sure

the vehicle’s battery has a minimum 8

volt charge. The scan tool requires a

minimum of 8 volts to power-up.

• Verify the ignition key is ON and not in

the accessories (ACC.) position.

• Checkthevehicle’s on-board computer

for a blown PCM fuse. The PCM fuse is

locatedonthefuseblockinthepassen-

ger compartment. If the PCM fuse is

blown,the vehicle’son-boardcomputer

cannot transmit data.

• Checkto be sureyour vehicle’s calibra-

20

tion PROM matches the vehicle setup.

Some GM vehicles have had replace-

ment PROMs installed from newer ve-

hicles to correct driveability problems.

Check the scan tool Application Car-

tridge manual for applicable models

and years.

• Make sure the vehicle’s on-board com-

puter has a good ground. If your

vehicle’s on-board computer has a

ground going directly to the computer’s

case, then clean up this connection

and apply a conductive grease to the

mating surfaces.

• On some carbureted engines, the igni-

tion key must be ON and the engine

OFF in order to establish communica-

tion between the scan tool and the

vehicle’s on-board computer. If the en-

gine was running when the Operating

Error occurred, then turn the ignition

key OFF and then ON, but

do not start

the engine

.

• As a last resort, the vehicle’s on-board

computer or calibration PROM may be

defective.Checkvehicleservicemanual

to determine correct computer tests for

your particular vehicle.

3-3 Scan Tool Self-Tests

Scan tool Self-Tests are used to test the

operation of the scan tool’s display, key-

board, and internal memory. The Tool

Self-Tests menu can be accessed when

the scan tool is initially powered-up, and

fromthe FunctionList.Convenienceisthe

reasontheToolSelf-Testsmenuisacces-

sible in two ways. If the scan tool has a

display problem on power-up, you do not

want to enter vehicle set-up information

just to get to the Function List to run the

DisplaySelf-Test.Itisfarmoreconvenient

to have the Tool Self-Tests menu acces-

sible during scan tool power-up. If a key-

board problem happens while you are

Viewing Data, it is easier to run a Key-

board Self-Test from the Function List

than to remove and then re-apply power

to the scan tool.

After the ENTER key is pressed, the dis-

play on power-up looks like this:

Select Function

1)New Vehicle

2)Tool Self-Test

21

The screen below is how the Tool Self-

Tests option appears on the Function List

(NOTE: This is a GM Function List. Func-

tion Lists for other manufacturers may

differ slightly):

GM Function List

7)Tool Setup

8)Tool Self-Test

9) ode Lookup

ToselectToolSelf-Testsoneitherscreen,

use the UP and DOWN arrow keys to

movethecursorsoitispointingtotheTool

Self-Tests option, then push the ENTER

key to select this option.

After selecting the Tool Self-Tests option,

you will be given a menu of scan tool self-

tests to choose from:

Tool Self-Test

1)Display Test

2)Keyboard Test

3)Memory Test

From the above menu, use the UP and

DOWN arrow keys to move the cursor so

itispointing to the Self-Testoptionofyour

choice,thenpushtheENTERkeytoselect

this option.

Display Test

After you have selected Display Test as

your choice, a screen detailing the test is

displayed. The Display Test will fill every

pixel of the ScanTool’s LCD display with

a solid black character. Press ENTER to

display solid black characters.

ENTER To Test. Look

For Missing Spots

In Display. Press

BA KUP When Done

The Display Test Screen is shown below.

Look for pixels that are not black. In other

words, look for missing spots in the solid

black characters. Press the BACKUP key

to return to the Tool Self Test Menu when

done. If you selected Tool Self-Test from

the Function List, then press the FUNC-

TIONkeytoreturntothefunctionlistatany

time.

NOTE:

The beeper is disabled while the

Display Test Screen is visible. Therefore

any key press will not register a beep.

Keyboard Test

The Keyboard Test is used to check the

functionality of the scan tool’s keyboard.

After you select Keyboard Test from the

Tool Self-Test Menu, the Keyboard Test

screen with instructions is displayed.

Push Button To Test

Key And Display

Name Key:

BA KUP When Done.

Eachtimeyoupressakey,checkscantool

display.Thekeyname should appear and

the scan tool should beep. For example,

if you press the UP arrow, the screen will

display “Key: UP ARROW.” If the button

name is not displayed, the key is not

working.TheonlyexceptionistheBACKUP

key. When the BACKUP key is pressed,

the scan tool returns to the Tool Self-Test

Menu. If you are not returned to the Tool

Self-Test Menu, then the BACKUP key is

not working.

NOTE:

The FUNCTION key

will not return you to the Function List

while you are keyboard testing.

Memory Test

The scan tool has already run a Memory

Self-Test during power-up. It is assumed

thatthescantoolpassedtheMemorySelf-

Test on power-up, because you should

not have proceeded any farther if it failed.

Onceyou have reachedthe Function List,

the scan tool may have trouble playing

back recorded data, displaying trouble

code definitions, or doing any other func-

tion that uses the scan tool’s internal

memory. If this happens, it is a good idea

to run the Memory Test again. From the

Tool Self-Test Menu, select the Memory

Test option. A “working please wait” mes-

sage is displayed while the scan tool tests

its internal memory:

Working

** Please Wait **

When the Memory Test is completed,

either a “Memory Test Failed!” or a

“Memory Test Passed!” message is dis-

22

played. Press the ENTER key to return to

the Tool Self-Test Menu.

Memory Test Failed

Press ENTER To ont

Memory Test Passed

Press ENTER To ont

NOTE:

If you selectedToolSelf-Testfrom

theFunctionList,thenpresstheFUNCTION

keytoreturntothefunctionlistatanytime.

Actron

Kits: Model Number

GM OBD II cable kit CP9115

Ford Probe MECS cable kit CP9116

Chrysler L-H engine cable kit CP9120

Chrysler OBD II cable kit CP9117

Battery Clip Adapters CP9118

AC power converter 110/12V CP9119

4-1 Where to Buy

Actron offers a complete line of high qual-

ity automotive diagnostic and repair

equipment. Additional cartridges, cables,

connectors, and adapters for the scan

Section 4: Accessories and How to Order

tool are available from the local retail

store where you originally purchased

your scan tool. The table below lists the

scan tool accessories.

Actron

Replacement Parts: Part Number

Cigarette power cable 38-1908

Carrying Case 400-2080

Main Tool operators manual 2-218601

GM cartridge manual 2-218301

Ford cartridge manual 2-218401

Chrysler cartridge manual 2-218501

23

4-2 Call Actron

In addition to your local dealer, all Actron

equipment and replacement parts are

available directly from the Actron factory.

Productcatalogs,pricing information, and

replacement components can be ordered

by contacting Actron directly.

By US mail:

Actron Manufacturing Company

15825 Industrial Parkway

Cleveland, OH 44135, USA

By phone:

1-800-228-7667

By fax:

(216) 651-2388

ForTechnical Support call:

1-800-ACTRON-7

4-3 E- Mail &

Internet Address

Actron is also available electronically for

comments and ordering information.

Actron’s E-Mail address is:

And while you’re on-line, be sure to check

out Actron’s Website, where you’ll find

equipmentinformation,newproducts,and

technicaltipstohelpyoumakethemostof

your new Actron ScanTool.

On the World Wide Web:

http://www.actron.com

24

Section 5: Glossary of Terms

ClosedLoop(C/L):Thisiswhenacontrolsystem

performs an action (expecting a certain result),

then checks the results and corrects its actions

(ifnecessary)untilthedesiredresultsareachieved.

Example:Fueldelivery.ThePCMoperatesafuel

injector in a way that should deliver an optimum

air/fuel mixture, as long as everything in the fuel

system is operating as expected. In closed loop

operation, the PCM uses the oxygen sensor to

check the results (fuel delivery may be different

than expected because of variations in fuel

pressure or injector operation). If the oxygen

sensor indicates a “rich” condition, the PCM will

compensate by reducing fuel delivery until the

oxygen sensor signals an optimum air/fuel mix-

ture. Likewise, the PCM will compensate for a

“lean” condition by adding fuel until the oxygen

sensor once again signals an optimum air/fuel

mixture.

Thus,closedloop operationmeans the PCMcan

“finetune”controlofasystemtoachieveanexact

result providing the PCM has a means to check

results (like an oxygen sensor).

Data Link Connector (DLC): The Data Link

Connector (DLC) is a universal term for the

interface port between the vehicle’s on-board

computer and the ScanTool. It is sometimes

referred to as the Assembly Line Diagnostic Link

(ALDL), Vehicle Interface Port (VIP), or Serial

CommunicationInterface (SCI). TheDLC is able

to transmit PCM data to the ScanTool as it is

processed. The DLC may be located in the

engine compartment or in the passenger com-

partment, depending on manufacturer. DLC de-

sign also varies from manufacturer to manufac-

turer, ranging from a 6-pin to a 17-pin connector

interface. All vehicles with OBD-II use a 16-pin

connector located in the passenger compart-

ment.The ScanTool requiresmanufacturer-spe-

cificadaptercablestolinkwithnon-OBD-IIDLCs.

DataStream:Thisistheactualdatacommunica-

tions broadcast from the vehicle’s PCM to the

diagnostic connector. The individual manufac-

turers determine the number of “data bytes” a

specific engine will broadcast. The size of the

data stream is usually dependent on the com-

plexity of the engine, transmission, ABS, and

other systems supported by the PCM. All manu-

facturers supply program documents for each

year, engine, and option combination that a

particularPCMsupportsinall themanufacturer’s

Actuator: Devicesthat are powered by thePCM

to control things. Actuator types include relays,

solenoids, and motors. Actuators allow the PCM

to control engine operation.

A/F:Air/Fuelratio.Thisreferstotheproportionof

air and fuel delivered to the cylinder for combus-

tion. For example, if you have 14 times more air

than fuel (by weight) then the A/F ratio is 14:1

(read as “fourteen to one”). The ideal operating

A/F ratio in an automotive application is 14.7:1.

CheckEngineLight(CEL):The“CheckEngine”

light (CEL) will illuminate when the PCM detects

a circuit malfunction in any of the engine feed-

back circuits. When the malfunction occurs, the

CELwillremainlitaslongasthePCMdetectsthe

circuit problem. This will automatically set and

storeatroublecodeinthePCM’smemory.Some

manufacturersalsorefertotheCELasaMalfunc-

tion Indicator Light (MIL), or the Emissions Main-

tenance Lamp (EMR) on some Chrysler trucks.

C3 or CCC: Computer Command Control. The

name of the General Motors electronic engine

control system used on most vehicles built since

1982.,

ChryslerSerialCommunicationInterface(SCI):

This is Chrysler’s vehicle adapter (or Data Link

Connector)used to link scan tools with the PCM.

EarlyChryslerOBDsystems(1981-83)broadcast

trouble codes, but gave no operating parameter

data. In 1983, the second phase of Chrysler

OBD, called the Serial Communication Interface

(SCI), was introduced with expanded serial data

andmanytestmodesforthetechniciantoaccess

with a scan tool. SCI provides the following

modes to access vehicle data: Diagnostic Test

Mode,CircuitActuationTestMode(ATM),Switch

Test Mode, Sensor Test Mode, and Engine

Running Test Mode. Each of these modes allow

for different procedures of diagnostic tests and

test routines. These routines are programmed

into the Chrysler Logic Module (LM) which then

passes the information on to the power module

or Single Board Engine Controller (SBEC). The

vehicle diagnostic adapter is located in the en-

ginecompartment on the right-hand side, next to

the SBEC unit with a dust cap marked “Diagnos-

tic.”

25

vehicles. This information is used to design and

build aftermarket diagnostic equipment.

Detonation: Uncontrolled ignition of the air/fuel

mixtureinthecylinder.Alsoreferredtoas“knock,”

detonation indicates extreme cylinder pressures

or “hotspots” which are causing the air/fuel mix-

ture to detonate early. High cylinder pressures

maybe caused byexcessive load(trailer towing,

A/C operation, etc.) or by too much spark ad-

vance. High octane fuel has a higher resistance

to uncontrolled ignition, and may be used to

control detonation when the PCM is unable to

retard timing sufficiently to prevent it from occur-

ring.NOTE: High octane fuel is not a cure for the

problem,only the symptom.If yourvehicle expe-

riences long-term detonation, check for other

causes.

DiagnosticTroubleCodes: Diagnostic Trouble

Codes (DTC) indicate a malfunction flagged by

the PCM. The PCM will display a corresponding

numericalcodenumberbasedona look-up table

in the program of the on-board computer. De-

pending on the manufacturer, the number of

DTCs vary by vehicle and supported systems.

Most systems have the ability to store codes in

memory, which are commonly referred to as

“history codes” or “soft codes.” Malfunctioning

circuits will generate continuous Check Engine

lampillumination, called “current codes” or “hard

codes.” History codes, based on the

manufacturer’sdiagnosticstrategy,willbecleared

from the PCM’s memory after several ignition

circuitstartcyclesifthecircuitdoesnotreflectthe

failure again. This capability does allow the

technician to access some information on which

circuits were malfunctioning at a previous point.

OBD-II systems will transmit many more DTCs

than the past systems, and therefore will allow a

technician the ability to better pin-point failures

andpastevents.They onlywaytoclearcodeson

OBD-II systems will be with a scan tool that has

the proper programming to perform the function.

DIS: Distributorless Ignition System or Direct

Ignition System. A system that produces the

ignition spark without the use of a distributor.

Duty Cycle: A term applied to frequency signals

—thosewhichareconstantly switching between

asmall voltage value (close to zero) and a larger

value (usually 5 volts or more). Duty cycle is the

percentageof time the signal hasa largevoltage

value. For example, if the signal is “high” (large

voltage) half of the time, the duty cycle is 50%.

If the signal is “high” only one fourth of the time,

then the duty cycle is 25%. A duty cycle of 0%

means the signal is always at a “low” value and

not changing. A duty cycle of 100% means the

signal is always at a “high” value and not chang-

ing. The PCM uses duty cycle type signals when

it wants more than just “on-off” control of an

actuator. This is how it works: A 50% duty cycle

signal going to a vacuum switching solenoid

means the solenoid will be “on” (passing full

vacuum) half the time, and “off” (passing no

vacuum) half the time. The average amount of

vacuumpassingthrough the solenoidwillbeone

half the full value because the solenoid is only

“on” for half the time. This signal changes at a

rapidrate,asoftenastentimespersecond.Thus

thePCMcanget a vacuumcontrolledactuatorto

move halfway between “no vacuum” and “full

vacuum.” Other positions can be achieved by

changing the duty cycle of the control signal

which in turn changes the average amount of

control vacuum.

DVM: Digital Volt Meter. An instrument using a

numeric readout to display measured voltage

values as opposed to a moving needle on a

gauge face. Usually the instrument has other

measuring capabilities, such as resistance and

current, and may be called a Digital Multi-Meter

(DMM). Most DVMs have 10 Megaohm input

impedance.Thismeansthe circuitundertestwill

not be electronically disturbed when the DVM is

connected for a measurement.

ECM: Electronic Control Module. The “brains” of

the engine control system. It is a computer

housed in a metal box with a number of sensors

and actuators connected with a wiring harness.

Itsjobistocontrolfueldelivery,idlespeed,spark

advancetiming,andemissionsystems.ThePCM

receives information from sensors, then ener-

gizesvariousactuatorstocontroltheengine.The

ECM is frequently called the PCM (Powertrain

ControlModule)invehicleshavingothercomputers.

These other computers are used for climate

control, entertainment systems, transmissions,

etc.

EFI: Electronic Fuel Injection. A term applied to

anysystemwhereacomputer controlsfueldeliv-

ery to the engine by using fuel injectors.

Engine Parameters: Thisisthetranslated infor-

mation that is displayed on the scan tool screen.

Parameters will include the information inputs

and the output signals from the PCM.

26

ESC:ElectronicSparkControl.This isanignition

system function that works on vehicles having a

knock sensor mounted on the engine block. The

knock sensor is wired to circuitry in a separate

module (early version) or inside the PCM (later

versions).Ifthesensordetectsengineknock,the

ESC function alerts the PCM which will immedi-

ately retard the spark to eliminate the knocking

condition.

EST:ElectronicSparkTiming.Anignitionsystem

where the PCM controls the spark advance

timing.AsignalcalledESTgoesfromthePCMto

theignitionmodule whichfiresthesparkcoil.The

PCMdeterminesoptimumsparktimingfromsen-

sorinformation– enginespeed,throttleposition,

coolanttemperature,engineload,vehiclespeed,

Park/Neutral switch position, and knock sensor

condition.

FBC:FeedbackCarburetor.Thisisusedonearly

versions of computer-controlled engines. It is a

carburetor which can have its fuel delivery modi-

fied by an electronic signal from the PCM. The

signal controls a mixture control solenoid (MCS)

attached to the carburetor body.

Ford Electronic Engine Control IV (EEC-IV):

This is the name of Ford’s Powertrain Control

Module (PCM) used in all Ford cars and trucks

sincethe mid-1980’s. Itis designedto be readby

aftermarket scan tools. Earlier versions of this

PCM were referred to as EEC-I, EEC-II, or EEC-

III, and were only accessible by the dealer via a

specific diagnostic tool. On carbureted vehicles,

Ford used a system called the Microprocessor

ControlledUnit(MCU),whichisaccessiblethrough

an adapter similar to the EEC-IV’s. Other varia-

tions of the EEC-IV vehicle adapter are used on

Ford’shybridvehicles,suchastheProbeandsome

Escort/Tracer models, which use Mazda PCMs

andhavedifferent protocols andcodes.Informa-

tion on these vehicles is widely available, and

mostscantoolssupportthese vehiclesaswellas

the standard Ford EEC-IV systems. Ford’s diag-

nostic strategy offers several avenues to access

codes and test procedures.

Fuel Injector: An electronically controlled flow

valve.Fuelinjectorsareconnectedtoapressurized

fuelsupply(fuelpressureiscreatedbyafuelpump).

Noflowoccurswhentheinjectorisoff(notenergized).

Whentheinjectorisenergized,itopensfully,allowing

fueltoflow.ThePCMcontrolsfueldeliverybyvarying

theamountoftimetheinjectorsolenoidsareturnedon.

Functional Tests: These are tests of PCM-

controlled systems, such as the fuel pump, the

“Check Engine” light, and other switches and

actuators.FunctionalTestsaregenerallydepen-

dentonthevehiclemanufacturer’sOBD strategy

and the PCM diagnostic architecture. Functional

tests require that the scan tool have the ability to

perform bi-directional communications with the

vehicle’s PCM. This means that the scan tool

must “talk” to the vehicle’s PCM, instead of just

“listening” to the incoming vehicle data stream.

Examples of functional tests are: Chrysler’s ac-

tuator/switch tests that allow you to review the

operation of a switch as you turn it on or off from

the driver’s seat, and turning the fuel pump on

and off. On a GM vehicle, a functional test is

placing the vehicle in Ground Mode to check the

PCM’s self-test diagnostics and the “Check En-

gine” lamp operation.

Ground: The return path for current to flow back

to its source (Usually the negative battery termi-

nal). It is also the reference point from which

voltage measurements are made (the connec-

tion place for the negative (-) test lead from a

voltmeter).

Inputs: Electrical signals running into the PCM.

These signals come from sensors, switches or

other electronic modules. They give the PCM

information about vehicle operation.

KOEO: Key On, Engine Off. A test mode where

the PCM is active and feeding data parameters,

but the engine is not running. Because the

engine is not running, some data parameters

maynotbeaccurateoravailableinthismode.On

Ford vehicles, KOEO testing is the only way to

read memory codes stored in the PCM.

KOER: Key On, Engine Running. A test mode

wherethePCMisactiveandfeedingdataparam-

eters, and the engine is running. Since the

engine is running, most data parameters should

be available and accurate.

Knock: See “Detonation.”

Knock Sensor: This sensor is used to detect

engine detonation (or “knock”). When spark

knock occurs, the sensor emits a pulsing signal.

Dependingonthe vehicle,this signal eithergoes

to the PCM or a separate ESC (Electronic Spark

Control) module. Then the spark advance is

retarded until detonation stops. The sensor