Actron E20CP-III User manual

1

AGTRON

COFFEE ROAST ANALYZER

E20CP-III OPERATIONS MANUAL

Software Version IR128-S5.0 & IR128-S5.5 USB/ADT

2020

Special Application

Spectrophotometer

AGTRON INCORPORATED

9395 Double “R” Boulevard

Reno, NV 89511

PHONE: 1-775-850-4600

FAX: 1-775-850-4611

Made in the USA

2

AGTRON MODEL E20CP-III COFFEE ROAST ANALYZER

OPERATION MANUAL

Version IR128-S5.0 & IR128-S5.5 USB/ADT

July 01/2018

INTRODUCTION

Since the earliest days of roasting, it has been common practice to determine roast development by appearance

alone- specifically the lightness or darkness of the coffee’s color in both whole bean and ground form. Using

color to classify roast introduces an inaccuracy, as the color developed during roasting is somewhat loosely

related to the organic chemistry. Organic chemistry is the source of all volatiles that produce the aromas and

flavors of coffee. Simply stated, it is possible to have two coffee samples roasted to exactly the same color /

appearance that present with quite different roast development in the cup.

AGTRON ROAST ANALYZER THEORY OF OPERATION

The most accurate method for classifying roast development is an analysis of the associated organic chemistry.

However, roasted coffee contains over 860 constituents, making comprehensive chemical analysis not only

expensive but also very difficult to unravel. The most practical alternative is the selective chemical analysis

using abridged spectroscopy.

An accurate correlation with roast development, as it correlates to the organoleptic and olfactory character of the

cup, can be established by identifying specific compounds, such as quinones, which progress during the roasting

process in a linear manner relative to the development of the collective organic chemistry.

The Agtron model E20CP-III evaluates changes to these selected compounds by measuring their photometric

response to specific wavelengths of near-infrared energy. The changes are directly linked to the collective

organic chemistry and thus to volatiles associated with cup aromatics and flavor. Results are posted as a numeric

score from 0.0 to 100.0; the lower the score, the darker the roast.

The span and slope of the Agtron Gourmet Roast Classification Scale is based on two points of reference:

1) A sample with a Gourmet Scale score of 01.2 indicates the thermal reduction of nearly 100% of the organic

chemistry into carbon, which would be devoid of coffee aromatics and flavors.

2) A sample with a Gourmet Scale score of approximately 126.0 would produce a beverage with sufficient

characteristics to be associated with roasted coffee and can be considered a sensory ‘break-point’ where

quintessential coffee aromas and flavors are beginning to be present.

3) The majority of the worlds’ coffees are roasted between Gourmet Scale scores of 30 and 75, with commercial

coffees roasted to scores between 50 and 75, and specialty coffees between 30 and 65.

CONCLUSION

The E20CP-III evaluates the manner in which selected compounds in roasted coffee change relating to beverage

olfactory and organoleptic development. This method of analysis is insensitive to color anomalies and provides

an accurate classification of roast development for quality control and consistency related to sensory assessment.

3

E20CP-III OPERATION MANUAL INDEX

I. INITIAL ANALYZER SET-UP / Page 4

II. E20CP-III KEYPAD LEGEND & ANALYZER FUNCTIONS / Page 6

III. SETTING THE DATE & TIME / Page 7

IV. ASSIGINING AN ANALYZER UNIT IDENTIFICATION NUMBER / Page 8

V. STANDARD CALIBRATION PROCEDURE / Page 9

VI. TESTING COFFEE SAMPLES / Page 11

VII. SELECTING THE ANALYTICAL SCALE / Page 12

VIII. ACCESSING & EDITING THE CUSTOM SCALE VARIABLES / Page 13

IX. IMPROVING ANALYTICAL ACCURACY AND REPEATABILITY / Page 16

X. NON-STANDARD SCALE CALIBRATION / Page 17

XI. CONNECTING THE E20CP-III TO PC OR DATA ACQUISITION SYSTEM / Page 19

XII. E20CP-III ANALYZER & CALIBRATION DISK RECERTIFICATION / Page 21

XIII. PERIODIC MAINTENANCE / Page 22

XIV. AGTRON GROUND SCORE ROAST DEVELOPMENT CORRELATION / Page 23

XV. WARRANTY INFORMATION / Page 24

XV. CE CERTIFICATE & DECLARATION of CONFORMITY / Page 25

4

I. INITIAL SET-UP

● Carefully remove the analyzer from the shipping box

● Inspect the analyzer for any sign of shipping damage

Contact Agtron immediately if any damage is apparent. A shipping claim for damage needs to be filed as

soon as possible.

IMPORTANT: Keep the box and all packing material. Any unit returned to Agtron for service must be

shipped in the original packaging or Agtron will not accept the unit.

The carton contains the following items:

- E20CP-III Analyzer

- Power Cord

- Large Diameter Yellow Life Disk

- Two Plastic Sample Dishes

- Smaller Diameter Two-Sided Red / Black Calibration Disk & Dish Set

- Rectangular Metal Sample-Dish Tray

- This Operation Manual

● Place the Agtron analyzer on a clean level surface

● Keep the cooling fan vent on the back of the unit free of obstruction

● Avoid placing the unit where it will be in direct sunlight

● Fully-open the sample drawer by pulling it straight out until it hits the bumper stop

● Look into the chassis under the drawer. There are four posts sticking up from a raised platform that is affixed

to the inside bottom of the chassis. Place the large diameter Yellow Life Disk between the four posts so that it

sits flat on the platform.

● Place the rectangular metal sample-dish tray into the cutout on the sample drawer top surface by first placing

the front of the tray with the thinnest edge facing forward against the rubber locating bumpers, then push the

back edge of the tray down into the opening so that the tray recesses fully into the cutout and the side flanges of

the tray sit flat on the drawer top surface.

NOTE: The sample-dish tray should always remain in the analyzer sample drawer. It should only be removed

for periodic cleaning. Always keep the sample drawer in the fully closed position when not in use.

● Fully close the sample drawer

● Connect the AC power cord to its mating socket on the back of the unit. Make certain that the plug is firmly

seated

● Connect the unit to AC mains power

5

WARNING: Use only a 3-prong earth grounded connection. Do not bypass the power cord grounding pin

or serious electrical shock to the operator and damage to the unit may occur.

NOTE: The power switch for the E20CP-III is on the back panel next to the power-cord connector. Always

leave the unit on for best accuracy and stability; it uses very little power, about as much power as a 15-watt light

bulb.

● Turn the power switch to the -ON- position

The display should activate and begin timing a 45-minute warm-up period.

The unit model type, serial number and other information will appear on the display. The startup display

information will repeat until the 45-minute warm-up period is over.

At the end of the warm-up period, the display will show:

<<< COFFEE MODE >>>

Contact Agtron immediately if the Display does not show <<< COFFEE MODE >>> following the initial

warm-up period

Internal shipping damage may have occurred and a claim will need to be filed as soon as possible

6

II. E20CP-III KEYPAD LEGEND & ANALYZER FUNCTION

The front of the analyzer has two panels:

• The lower vertical panel is the sample drawer face. The bottom edge of the drawer has a relief cutout. This is

where you place your fingers to open the drawer. Open the drawer by pulling the panel straight-out from the unit

until the drawer hits the stop bumper. When using the E20CP-III, it is necessary to pull the drawer out fully until

the stop is contacted to initialize auto-calibration.

• The upper panel has the LCD display and a function keypad

KEYS ANALYZER FUNCTION

[0] –[9] Enters numeric values and access combination key functions

[CAL] Activates calibration routine using stored high & low values; no editing function

[F-CAL] Displays stored high & low calibration values

[SCALE] Toggles: Agtron Scale →Gourmet Scale →Custom Scale

└← ← ← ← ← ← ←←┘

[DATE-TIME] Displays date and time and allows editing

[FNC] Accesses equation for editing custom scale variables

[SEND DATA] Automatically sends display data via serial port once per refreshed display

[EXIT] or [●] Exits most functions without saving changes

[6] + [SEND DATA] Toggles Auto Data-Transmit ON ←→ OFF

[3] + [F-CAL] Enables editing stored high & low calibration values

SYSTEM RESET Depress and release the push-button on the upper right corner of the rear panel

7

III. SETTING THE DATE / TIME

• Momentarily depress the [DATE/TIME] key on the function keypad

Current date and time settings will be displayed as follows:

MM:DD:YY= (Month:Day:Year) / HH:MM:SS = (Hours:Minutes:Seconds)

The bottom of the display will alternate between the following three statements:

[SKIP]KEY EXITS

- and -

[+/ -]SET DATE/TIME

- and -

[SCALE]PGM UNIT ID#

Note: To program an analyzer identification number, refer to page 8

If the date and time displayed are correct:

• Depress the [SKIP] key on the function keypad to save the settings and exit the Date & Time function

If you wish to change the Date & Time displayed:

• Depress the [+/-] key

The display will show: YEAR (YY):

• Using the numeric keypad, enter the last two digits of the year (i.e. 2018 would be 18)

The display will show: MONTH (MM):

• Enter the month in two-digit format (01 = January to 12 = December)

The display will show: DAY (DD):

• Enter the day of the month in two-digit format (01to 31)

The display will show: 24 HOUR (HH):

• Enter the current hour in 24hour format (i.e. 7 am would be 07, 10 am = 10, 12am / Noon = 12,

6 pm = 18, 12 pm / midnight = 24)

The display will show: MINUTE (mm):

• Enter the current time minutes in two-digit format (00 to 59)

Note: Seconds are not editable

The display will now show the new Date & Time settings

• Depress the [SKIP]key to accept the displayed Date & Time and exit the edit function

8

IV. ASSIGNING A UNIT IDENTIFICATION NUMBER TO THE E20CP-III

This function is useful when data is being transmitted from multiple Agtron analyzers. If programmed, a Unit

Number will accompany the data transfer and allow data to be easily tracked to the machine of origin.

• Depress the [DATE/TIME] key followed by the [SCALE] key

The display will show: AGTRON UNIT (NN):

• Use the numeric keypad to enter the two digit number to be assigned to the unit (01 –99)

•If you wish to exit without entering an ID number, key in 00

As soon as a two digit ID number is entered, the display will show:

<<< COFFEE MODE >>>

Note: If a unit number of 00 is entered, no unit identification number will be displayed when transmitting

analyzer data

Note: The unit will automatically save the number assigned to it and exit back to the Mode screen. The Unit

Number may be reprogrammed at any time using the same method.

9

V. STANDARD CALIBRATION PROCEDURE

The standard CALIBRATION procedure should be performed at a minimum, every 4-hours of use, to maintain

instrument accuracy. Calibration can be performed more frequently if desired. Additionally, once the

DATE/TIME is set, the computer keeps track of calibration intervals and will also prompt the user to recalibrate

every 24-hour cycle when the time reaches 00:00:01.

The E20CP-III also automatically calibrates each time the sample drawer is opened. It reads the Yellow Life

Disk under the drawer and adjusts to a reference established during the standard calibration procedure.

The E20CP-III can be configured to read samples in the Commercial Scale (the standard scale for E20CP

models), the Gourmet Scale (the standard scale for Agtron M-BASIC models), or a user defined Custom Scale.

The Commercial Scale offers greater dynamic range (the capacity to measure a wider range of roast

classifications and grinds including soluble coffee powders)

The Gourmet Scale offers higher resolution (shows a greater difference in scores between two roast

classifications)

The Custom Scale allows the user to arithmetically modify the Commercial Scale

The E20CP-III can also be calibrated with REFERENCE COFFEE SAMPLES of known or desired score

(see section VIII. “Non-Standard Scale Calibration”)

1) Remove the two-sided Red-Black Calibration Disk set and dish from its storage box

IMPORTANT: The two-sided calibration Disk & Dish set supplied with the analyzer is your permanent

calibration reference. Disk & Dish sets are matched by serial number to a specific E20CP-III and can

only be used with that unit.

NOTE: There are two adhesive labels affixed to the side of the Calibration Reference Disk dish. One label lists

the red-side and black-side calibration reference scores; these disk values are pre-programmed into your

analyzer at the factory. The other label shows the unit serial number and disk certification date.

NOTE: Avoid touching the surface of the disks. Periodically clean the disk surfaces with a dilute solution of

alcohol and pure water and a soft cotton cloth using very light pressure. Keep the disk set stored in the box

provided, away from direct sunlight or heat

.

● Do not leave the calibration disk set in the analyzer

●Do not use the dish supplied with the calibration disk set for coffee samples

IMPORTANT: Always place the calibration disk into the shallow side of the dish

2) Momentarily depress the [CAL]key on the function keypad

The display will show: - OPEN SAMPLE DRAWER -

< SET REFERENCE MODE >

3) Fully open the sample drawer

The display will show: -- HIGH REFERENCE --

RED-DISK / SAMPLE

10

4) Place the Calibration Disk into the shallow side of the dish with the Red-Side facing up. Place the dish / disk

into the sample tray in the drawer.

Make certain that the dish sits flat and fully into the recess in the sample tray

5) Fully close the sample drawer

The display will first show: -- HIGH REFERENCE --

SETTING TO →XXX.X

The analyzer will set the Life Disk measured value as the factory High Reference disk calibration value

The display will then show: -OPEN SAMPLE DRAWER-

6) Fully open the sample drawer

Momentarily, the display will show: * SETTING REFERENCE *

KEEP DRAWER OPEN

The analyzer will measure the LIFE DISK under the sample drawer and will store a reference value. The

reference value stored is used automatically to recalibrate the analyzer every time the drawer is opened.

The display will change to: -- LOW REFERENCE --

BLACK-DISK OR SAMPLE

7) Turn the Calibration Disk over and place it into the shallow side of the dish with the Black-Side facing up

8) Place the Calibration Disk-set back into the sample tray

9) Fully close the sample drawer

The display will show: -- LOW REFERENCE --

SETTING TO →XX.X

The analyzer will set the Life Disk measured value as the factory Low Reference disk calibration value

The display will quickly flash: CALCULATING SCALE

Followed momentarily by: ** REFRENCES SAVED **

The display finally shows: <<< COFFEE MODE >>>

10) Return the two-sided disk & dish set to its storage box and close the lid

THE E20CP-III IS NOW READY FOR OPERATION

11

V. TESTING COFFEE SAMPLES

Sample Preparation

The E20CP-III is designed to evaluate both whole bean and ground samples. A sample can first be analyzed as

whole bean and then as ground. The difference between the two scores approximates how uniformly or non-

uniformly the sample is roasted. The character of the cup varies with different uniformities.

While both measurements may be included in a QC program, it is the ground score that determines cup

development (true roast classification).

IMPORTANT: It is ultimately the ground roast score that should be the focus for controlling product

consistency.

As with any piece of analytical equipment, good sample preparation is important if meaningful and

repeatable results are to be achieved

1) Whole Bean Sample Preparation

Pour the whole bean sample into the deep side of the sample dish. Put enough coffee into the dish to form a flat

surface that is level with the edge of the dish. Use a straight edge to pat the surface until it is flat.

2) Ground Coffee Sample Preparation

The most accurate and consistent results are achieved by grinding the sample into a container and thoroughly

mixing the grounds to produce homogeneity. It is also important that the particle specification is consistent.

Overfill the shallow side of the sample dish with the homogenized sample of ground coffee. Use a straightedge

(a wood ruler with a metal edge insert works very well) to level the surface. Hold the straight edge perpendicular

to the top surface. Rest the straightedge on the rim of the dish and make a sweeping motion to the opposite side.

Repeat this motion starting at the opposite side. Avoid compressing or overworking the sample surface. The

surface of the coffee should be flat and uniform with no voids or irregularities. Make certain that the sample

covers the entire area of the dish out to the edges.

3) Fully open the sample drawer, the display will show:

CALIBRATING ANALYZER

<- KEEP DRAWER OPEN - >

Followed by: < READY FOR SAMPLE >

Carefully place the sample dish into the rectangular tray, making certain that the sample dish sits flat and fully

into the tray recess.

4) Gently close the sample drawer, making sure it is completely closed

The display will show: --> PLEASE WAIT <--

TESTING ROAST SCORE

(And in example, if the analyzer was configured for the Commercial Scale)

Followed by: ROAST SCORE : XXX.X

COMMERCIAL SCALE

Note: The display will show the scale which is currently in operation

12

VI. SELECTING THE ANALYTICAL SCALE

The analyzer can be configured to read coffee samples in the Commercial Scale, Gourmet Scale, or a user

defined Custom Scale. (See the chart on page 16 for Commercial Scale / Gourmet Scale Correlation)

The Commercial Scale offers greater dynamic range (the capacity to measure a wider range of roast

classifications, including soluble coffee)

The Gourmet Scale offers higher resolution (shows a greater difference in scores between two roast

classifications)

Custom Scale allows the user to modify the E20CP-III Commercial Scale scores with the following

equation: QMS = A x (S x S) + (B x S) +/- C

(See Section VII. for programming instructions)

To Switch / Select Scales:

1) Depress [SCALE]

Each time the [SCALE] button is depressed, selections will toggle in a loop between:

Agtron Scale →Gourmet Scale →Custom Scale

└ ←← ← ← ← ← ← ←←┘

2) Depress [SCALE] until the scale desired is displayed. For example, if the scale desired is the Gourmet

Scale, stop when the display shows:GOURMET SCALE

<READY FOR SAMPLE >

3) Fully open the sample drawer, the analyzer will accept the scale selection and the display will show:

CALIBRATING ANALYZER

<- KEEP DRAWER OPEN ->

Followed by: < READY FOR SAMPLE >

Wait for 30-seconds until the display shows:

<<< COFFEE MODE >>>

4) Fully close the sample drawer

Note: Once the unit is placed in Commercial Scale, Gourmet Scale, or Custom Scale, it will continue to read

product on that scale until switched to a different scale

13

VII. ACCESSING & EDITING THE CUSTOM SCALE VARIABLES

The Custom Scale will only be active if it is selected in Section VI.

Custom Scale Score represents the E20CP-III Commercial Scale score as modified by the equation:

(Custom Scale Score) QMS = A x (S x S) + (B x S) +/- (C)

Where:

S: Represents the E20CP-III Commercial Scale root score

A: Represents a multiplication factor applied to the squared Commercial Scale score

B: Represents a Commercial Scale score multiplier

C: Represents an add or subtract Commercial Scale score offset constant

VARIABLE DEFAULT VALUES & LIMITS

Variable A: Default (0.0000) / Limits (0.00000 to 0.59998)

Variable B: Default (1.000) / Limits (0.000 to 9.876)

Variable C: Default (00.00) / Limits (+/- 00.00 to 98.76)

Depress [FNC] to access / edit the Custom Scale variables

The display first shows: << CUSTOM –SCALE >>

QMS = A x (S x S) + (B x S) + C

Followed by the top line of the display showing:

QMS = A x (S x S) + (B x S) + C

alternating with

[ENTER] To CHANGE

alternating with

PRESS [FNC] FOR NEXT

The bottom line of the display shows: A x (S x S) A = .00000

To move to the Bvariable without editing the Avariable displayed, depress the [FNC] key

To edit the Avariable, depress the [ENTER] key

The display shows: [ENTER] TO SAVE AND EXIT

A x (S x S) A = .00000

14

Key-in the desired Avalue and depress the [ENTER] key to save and move to the Bvariable

The display first shows: << CUSTOM –SCALE >>

QMS = A x (S x S) + B x (S) + C

Followed by the top line of the display showing:

QMS = A x (S x S) + (B x S) + C

alternating with

[ENTER] To CHANGE

alternating with

PRESS [FNC] FOR NEXT

The bottom line of the display shows: (B x S) B = .00000

To move to the Cvariable without editing the Bvariable displayed, depress the [FNC] key

To edit the Bvariable, depress the [ENTER] key

The display will show: [ENTER] TO SAVE & EXIT

(B x S) B = 00.000

Key-in the desired B value and depress the [ENTER] key to save and move to the Cvariable

The display first shows: << CUSTOM –SCALE >>

QMS = A x (S x S) + (B x S) + C

Followed by the top line of the display showing:

QMS = A x (S x S) + (B x S) + C

alternating with

[ENTER] To CHANGE

alternating with

PRESS [FNC] FOR NEXT

The bottom line of the display shows: (S) +/- C C = +00.00

To move back to the Avariable without editing the Cvariable displayed, depress the [FNC] key

To edit the Cvariable, depress the [ENTER] key

15

The display will show: [ENTER] TO SAVE & EXIT

(S) +/- C C = +00.00

Key-in the desired Cvalue, to change the sign depress the [+/-] key

Depress the [ENTER] key to save the Cvalue, exit the custom scale variable editing subroutine, and return to

normal analyzer function

The display will show: <<< COFFEE MODE >>>

NOTE: When all of the Custom Scale variables are set to the default values, the analyzer will display the root

AGTRON E20CP-III Commercial Scale score when the Custom Scale is selected

16

VIII. IMPROVING ANALYTICAL ACCURACY AND REPEATABILITY

Sample Temperature

Samples should always be analyzed at or very close to room temperature. Never evaluate a hot or warm product,

as this will affect the score.

Grind Specification

The grind coarseness / fineness will affect the amount of surface area that the analyzer sees. It is important to

have a grind similar to the CBC standard for auto-drip:

WEIGHT OF COFFEE RETAINED ON SCREEN #10 & #14 (1168 - 1651 Microns): 03.5%

(00.0% - 03.5%)

WEIGHT OF COFFEE RETAINED ON SCREEN #20 & #28 (589 - 833 Microns): 71.5%

(65.0% - 75.0%)

WEIGHT OF COFFEE PASSING THROUGH SCREEN #28 (Smaller than 589 Microns): 25.0%

(25.0% - 35.0%)

If you do not have access to screens, you can adjust the grind by observing the surface of the coffee during

sample preparation. When the particles plow (form waves) during a second-pass of troweling, the grind is too

coarse. If the surface compacts, compresses and cakes, the grind is too fine. Remember, what looks like an

identical surface to the eye may appear quite different to the analyzer.

Time from Roasting / Cooling / Grinding to Analysis

Once coffee is roasted it begins to decompose. Since the E20CP-III is a system based on chemistry analysis, it

will see the change of decomposition much in the same way you taste it in the cup. A sample’s score can change

(lower) as much as 4 points in 24 hours.

To eliminate this variable, it is important to analyze samples as soon as possible after roasting /cooling. Within

15 minutes is preferable.

NOTE: The drawer must be closed within 30 seconds to read the sample or the calibration will time-out and the

analyzer will not take a reading. If this occurs you must fully close and then fully open the sample drawer to

allow the unit to recalibrate.

Analyzer & Calibration Disk Recertification

The calibration disk set must be periodically re-certified to maintain analyzer accuracy

See Page 21: E20CP-III ANALYZER & CALIBRATION DISK RECERTIFICATION

17

IX. NON-STANDARD SCALE CALIBRATION

CALIBRATING THE ANALYZER TO READ COFFEE SAMPLES TO USER ASSIGNED SCORES

This procedure may be used to calibrate the E20CP-III to user defined product standards

a) Prepare a ground light sample of known score, Agtron 55 score or higher

b) Prepare a ground dark sample of known score, Agtron 25 score or lower

c) If you are matching readings from another AGTRON coffee roast analyzer, calibrate that analyzer with

the standard procedure and read the prepared light and dark samples to establish the desired coffee

scores

1) Write down the desired scores for both the light and dark samples

2) Depress and hold the [3] key then depress the [F-CAL]key

The display will show: -OPEN SAMPLE DRAWER-

<SET REFERENCE MODE>

3) Fully open the sample drawer

The display will show: -- HIGH REFERENCE --

RED-DISK OR SAMPLE

4) Place the light sample into position in the drawer sample tray

NOTE: Make certain the dish sits flat and fully into the recess in the sample tray.

5) Fully close the sample drawer

The display will first show: -- HIGH REFERERENCE --

ENTER VALUE : XXX.X

The High Reference value from the previous calibration will be displayed

6) Enter the desired value for the light sample using the numeric keypad

7) Depress the [ENTER] key on the numeric keypad to accept the new value

The display will show: -OPEN SAMPLE DRAWER-

8) Fully open the sample drawer

The display will first show: * SETTING REFERENCE *

-KEEP DRAWER OPEN -

The display will change to: -- LOW REFERENCE --

BLACK-DISK OR SAMPLE

18

9) Place the dark sample into position in the drawer sample tray

10) Fully close the sample drawer

The display will show: -- LOW REFERENCE --

ENTER VALUE : XX.X

The Low Reference value from the previous calibration will be displayed

11) Enter the desired value for the dark sample using the numeric keypad

12) Depress the [ENTER] key on the numeric keypad to accept the new value

The display will first show: -- LOW REFERENCE --

*** MEASURING ***

Followed momentarily by: CALCULATING SCALE

Followed momentarily by: REFERENCES SAVED

The display will show: <<< COFFEE MODE >>>

Following a calibration using coffee samples of desired score, re-establish values for the two-sided

calibration disk & dish set for future calibration to that scale

a) With the analyzer in the <<< COFFEE MODE >>> fully open the sample drawer and allow the analyzer

to calibrate

b) Place the Calibration Reference disk set into the shallow side of the dish Red-Side facing up and place

it in the drawer sample tray

c) Fully close the sample drawer and allow the analyzer to read the red-side of the calibration disk

Record the new Red-Disk value: ________________

d) Fully open the sample drawer and allow the analyzer to calibrate. Turn the calibration disk over in the

sample dish so that the Black-Side is facing up.

e) Fully close the sample drawer and allow the analyzer to read the black side of the calibration disk:

Record the new Black-Disk value: ________________

● The analyzer will store these new calibration disk values in memory for all future calibrations until

they are user edited

THE E20CP-III IS NOW READY FOR OPERATION

19

X. DATA-TRANSMIT / CONNECTING THE E20CP-III TO A COMPUTER

The Data-Transmit function sends sample analysis results from the Serial or USB connectors on the analyzer’s

back panel to a PC or data acquisition system. Data can be downloaded to spreadsheet programs (like Excel®)

for statistical analysis or QC archiving. Both Serial & USB ports transmit data simultaneously.

If no identification number is programmed for the analyzer, the data will be displayed as:

Analyzer Scale, Product Score, Day/Date, Time

If an identification number is programmed for the analyzer, the data will be displayed as:

Agtron and Unit ID Number (For the Commercial Scale), Product Score, Day/Date, Time

Gourmet and Unit ID Number (For the Gourmet Scale), Product Score, Day/Date, Time

1) Windows based PC RS232 Connection for E20CP-III Data Output

• Open the HYPER TERMINAL and select an available serial port (COM1, COM2, etc.)

• Set HYPER TERMINAL: 9600 baud, 7 or 8 bits, 1 stop bit, No-Parity, No-Handshaking

a) Connecting the Analyzer to a PC or Data Terminal

WARNING: The E20CP-III does not have serial port isolation. Connecting the analyzer to a non-isolated

serial port can permanently damage the internal micro-processor.

•Connect the analyzer serial data port to the PC with an RS232 cable.

Connector legend: Pin 1 (NC) / Pin 2 (transmit) / Pin 3 (receive) / Pin 5 (ground) / Pin 4 (NC)

b) Sending Data / Downloading Data to a Spreadsheet

•Use the HYPER TERMINAL capture feature to downloaded data as a TEXT file

•Open a Windows Spread Sheet to accept a TEXT DELIMITED file

•Open SCORE DATA

•Depending on the analyzer mode selected, data will be formatted as 4 to 7 columns

on the spreadsheet

2) USB Connection for E20CP-III Data Output

IMPORTANT: Software compatible with a FT232R USB component must be downloaded before connecting

to the E30FP-III USB port to avoid complications

Before connecting the analyzer to a PC/Mac computer:

• Open the computer’s browser and navigate to www.ftdichip.com

• Download the D2XX software compatible with the computer’s operating system. There

are detailed installation guides on the D2XX page which can be found under the Driver

Menu side bar.

• Once the software has been downloaded and activated, connect the E20CP-III USB to the computer

20

3) Using the Data Transmit Feature / RS232 & USB

There are two options for transmitting data from the E30FP-III while the USB cable is connected :

1) Manual-Transmit

After a product reading is taken, depress the [SEND DATA] key and the product score, with time and

date, will be transmitted. Only one data transmission will occur for each reading even if the [SEND

DATA] key is pressed again.

2) Auto-Transmit

a) Depress the [6] + [SEND DATA] keys at the same time to activate the auto data transmit feature.

A time and date will be transmitted with the notation that the auto data transmit feature is ON. With

auto-transmit ON, each time a reading is taken the product score with time and date will be

transmitted.

b) Depress the [6] + [SEND DATA] keys at the same time again to deactivate the auto data transmit

feature. A time and date will be transmitted with the notation that the auto data transmit feature is

OFF. No data will be transmitted unless the [SEND DATA] key is depressed.

Note:

• There is no handshaking capability between the E20CP-III and a connected PC or data acquisition

system. All standard analyzer functions operate independently and according to this Owner’s Manual

irrespective of the status and/or connectivity of the data transmit function

Table of contents

Other Actron Measuring Instrument manuals

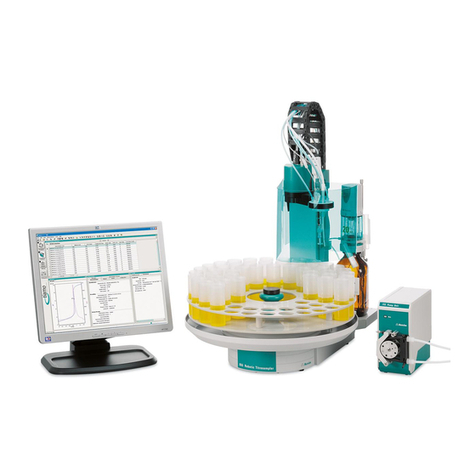

Popular Measuring Instrument manuals by other brands

Martin Lishman

Martin Lishman Grainmaster i2-S instruction manual

DigiVac

DigiVac Bullseye Precision Gauge Piezo user manual

Hanna Instruments

Hanna Instruments HI 93723 instruction manual

Trotec

Trotec BM31 quick start guide

Geometrics

Geometrics Memory-Mag G-856AX Operation manual

Keba

Keba KeMes A100 operating instructions