Actron OBD II PocketScan Code Reader CP9125 User manual

Safety Precautions ...................... 4

Signal Words and Symbols ............ 4

Important Safety Messages ............... 5

Tool Parts ............................. 6

PocketScan® Code Reader Features ........ 6

Read Codes ........................ 6

MIL Conditions...................... 6

Inspection/Maintenance Monitors (I/M

Monitors ........................... 7

Reading Diagnostic Trouble Codes and Data.. 7

Erasing Diagnostic Trouble Codes and Data .. 9

Diagnostic Trouble Codes................ 10

Code Structure..................... 11

Powertrain Codes................... 11

Body Codes ....................... 11

Network Communication Codes........ 11

Decommissioning ...................... 11

Disposal and Scrapping .............. 11

Electromagnetic compatibility (EMC).... 11

4|User guide | CP9125 |

Safety Precautions

For safety, read, under-

stand and follow all

safety messages and

instruction in manual be-

fore operating the Pock-

etScan® Code Reader.

Always refer to and follow safety

messages and test procedures

provided by manufacturer of vehicle

and PocketScan® Code Reader.

Signal Words and Symbols

DANGER!

Indicates a possible haz-

ardous situation that, if

not avoided, will result in

death or serious injury to

operator or bystanders.

WARNING!

Indicates a possible haz-

ardous situation that, if

not avoided, could result

in death or serious injury

to operator or bystanders.

CAUTION!

Indicates a possible haz-

ardous situation that, if

not avoided, may result in

moderate or minor injury

to operator or bystanders.

IMPORTANT

Indicates a condition that

may result in damage to

test equipment or vehicle

or lost information.

| CP9125 | User guide | 5

Important Safety Messages

Always wear ANSI-ap-

proved goggles for eye

protection.

• Always operate vehicle in a

well-ventilated area.

• Always keep people, tools, and

test equipment away from all

moving or hot engine parts.

• Before testing a vehicle, make

sure the transmission is in PARK

(automatic transmission) or

NEUTRAL (manual transmission)

and the parking brake is set.

• Always block drive wheels and

never leave vehicle unattended

while testing.

• Always keep a fire extinguisher

suitable for gasoline/electrical/

chemical fires redily available.

• Never lay tools on the vehicle

battery.

• Always use caution when work-

ing around ignition coil, distribu-

tor cap, ignition wires, and spark

plugs. Components can produce

a High Voltage while engine is

running.

• Battery acid is caustic. If con-

tacted, rinse with water or neu-

tralize with a mild base (i.e.

baking soda). If in eyes, flush

with water and call a physician

immediately.

• Never smoke or have open

flames near vehicle. Vapors from

gasoline and battery during

charge are explosive.

• Never use the PocketScan® Code

Reader if internal circuitry has

been exposed to moisture.

Internal shorts could cause a fire

and damage.

• Always turn ignition key OFF

when connecting or disconnect-

ing electrical components,

unless otherwise instructed.

Some vehicles are equipped with

safety air bags. Follow vehicle ser-

vice manual cautions when working

around air bag components or

wiring.

WARNING!

A vehicle airbag can open

for several minutes after

the ignition has been

turned off.

• Always follow vehicle manufac-

turer’s warnings, cautions, and

service procedures.

6|User guide | CP9125 |

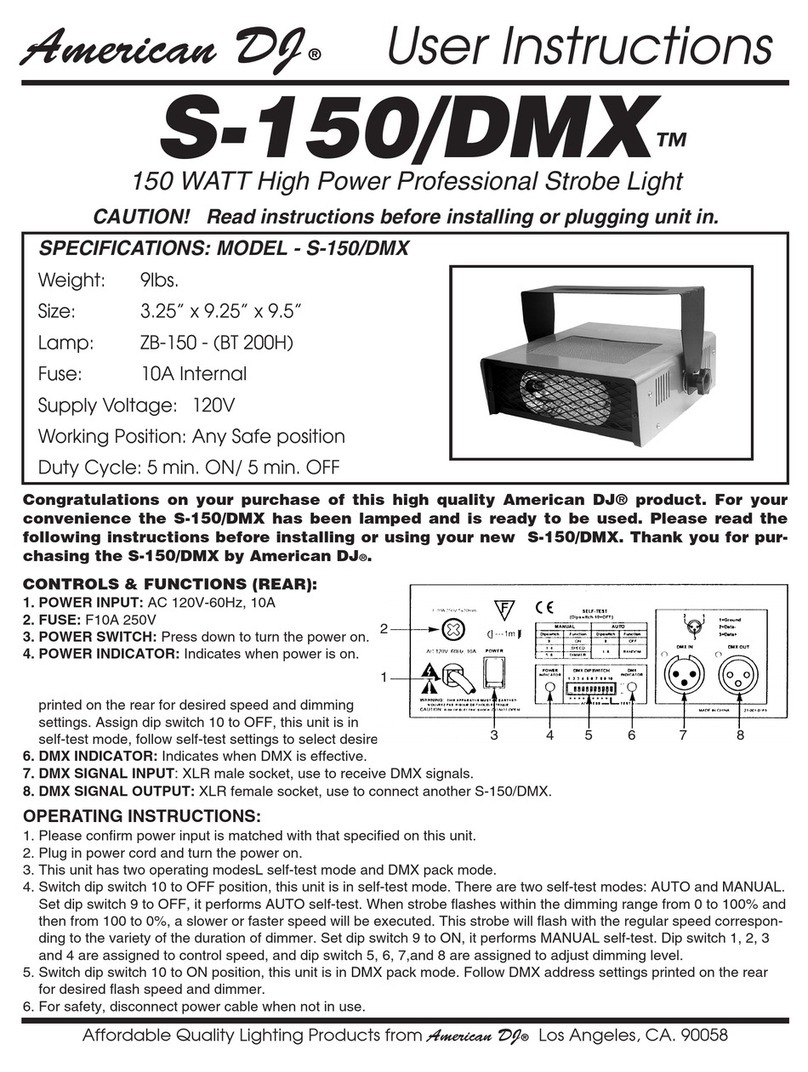

Tool Parts

4

3

2

1

Part Description

1LCD

display Single-line display with 8 char-

acters.

2ERASE

Used to Erase Trouble Codes and

I/M Monitor status from Vehicle’s

Computer Modules and scroll up

through screens. (I/M Monitors

are currently used for state emis-

sions tests.)

3READ Used to view Read Codes, MIL

Status, I/M Readiness Status and

scroll down through screens.

4OBD II

Connector Used to communicate with OBD II

compliant vehicles.

PocketScan® Code Reader

Features

Read Codes

Reading Diagnostic Trouble Codes

allows the PocketScan®

Code Reader to read the codes

from the vehicle’s computer

modules.

• Diagnostic Trouble Codes:

Diagnostic Trouble Codes are

used to help determine the

cause of a problem or problems

with a vehicle. Diagnostic Trou-

ble Codes are set when a fault is

present for a sufficient amount

of time.

• Pending Codes:

Pending Codes are also referred

to as “continuous monitor

codes” and “maturing codes.”

Pending Codes occurs when the

code has not occurred a specific

number of times (depending on

vehicle,) causing the code to

mature.

MIL Conditions

MIL (Malfunction Indicator Lamp)

Status displays the

state of the vehicles computer

module(s).

• MIL ON:

Indicates that the Malfunction

Indicator Lamp on vehicle should

be ON indicating a possible

emissions problem.

9If the MIL Status is ON and the

MIL is not illuminated with the

engine running, then a problem

exists in the MIL circuit.

• MIL OFF:

| CP9125 | User guide | 7

Indicates the Malfunction Indica-

tor Lamp should be off and there

should be no emission problems.

9Some manufacturers will turn

the MIL off if a certain number

of drive cycles occur without the

same fault being detected.

9Diagnostic Trouble Codes

related to a MIL are erased from

the computer’s memory after 40

warm-up cycles if the same fault

is not detected.

Inspection/Maintenance Monitors

(I/M Monitors

The I/M Monitors (Inspection /

Maintenance) function displays a

SNAPSHOT of the operations for the

Emission System.

9After a specific amount of drive

time (each monitor has specific

driving conditions and time

required), the computer’s “moni-

tors” will decide if the vehicles

emission system is working

correctly.

9Some states MAY NOT require all

monitors listed to be “Ready” to

pass the emissions test. Check

with state testing site for exact

requirements. All states will fail

a vehicle that has the “MIL

Light” lit at time of test.

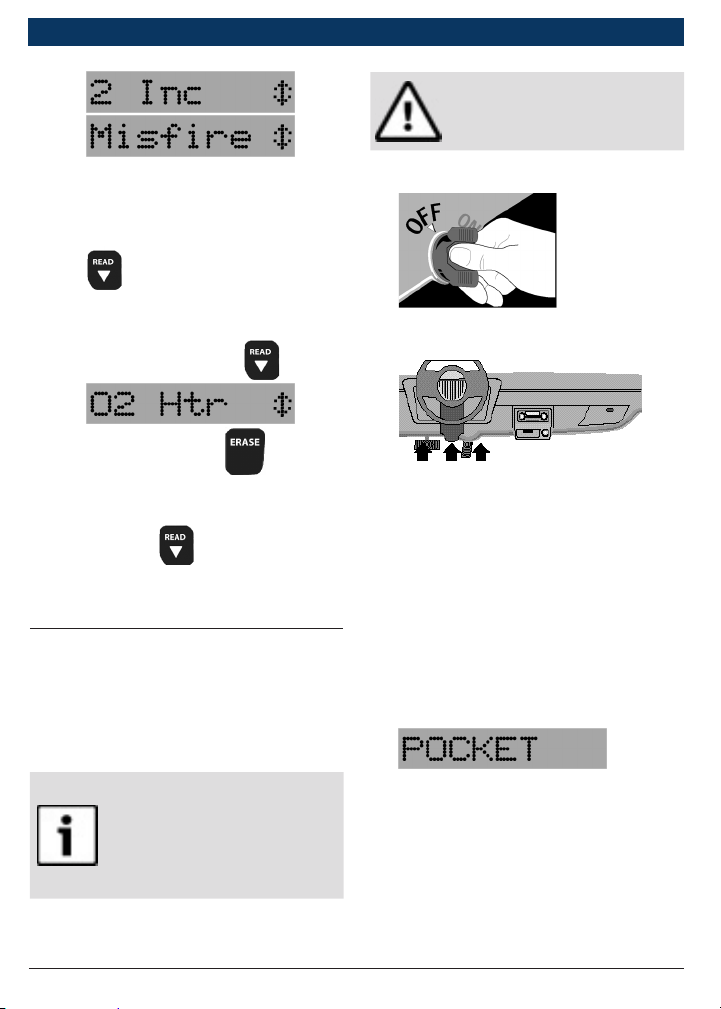

• Monitors Viewed:

Monitor Expanded Name

Misfire Misfire monitor

Fuel Fuel system monitor

Comp Comprehensive components monitor

Catlyst Catalyst monitor

Htd Cat Heated catalyst monitor

Evap Evaporative system monitor

Sec Air Secondary air system monitor

A/C Air conditioning refrigerant monitor

O2 Snsr Oxygen sensor monitor

O2 Htr Oxygen sensor heater monitor

EGR Exhaust gas recirculation

• Monitor Status:

Status Description

Ready Vehicle was driven enough under proper

conditions to complete the monitor.

Inc (Incomplete) Vehicle was not driven

enough under proper conditions to com-

plete the monitor.

• Monitors may be cleared by:

•Using the erase codes function.

• Disconnected or discharged

battery (on some vehicles.)

• Computer module losing

power (on some vehicles.)

Reading Diagnostic Trouble

Codes and Data

WARNING!

Avoid cooling fan. Fan

may turn on during test.

1. Turn ignition key to the OFF

position.

8|User guide | CP9125 |

2. Locate and plug in data link

connector (DLC).

NOTE: The data link connector

should be located under the

dashboard on the driverside of

the vehicle. If the data link con-

nector is not located under the

dashboard as stated, a label

describing the location of the

data link connector should be

there.

3. Observe display toggles between

“Pocket” and “Scan”.

NOTE: For a correct reading for

diagnostic trouble codes and I/M

monitor status, ignition key must

be in the ON position and engine

does not require starting. To get

a correct reading for MIL status,

engine must be started.

4. Start engine.

5. Press and release key.

NOTE: If diagnostice trouble

codes (DTCs) are already being

displayed from a previous read

operation, press and hold

for 3 seconds and release.

6. Observe a moving * on display.

NOTE: If “No Link” message

displays, cycle ignition key to the

OFF position for 10 seconds,

then back ON and repeat “Read-

ing Diagnostic Data” procedure.

7. View codes on display.

NOTE: If

there are no codes present, the

tool will display “0 Codes” and

proceed to display MIL Status

when is pressed.

• To view codes, press and

release .

• If the code is a pending code,

pd will be displayed.

8. View MIL status:

• Press and release .

9. View I/M monitors that are

incomplete.

• Press and release .

| CP9125 | User guide | 9

NOTE: If there are no more

I/M monitors that are incom-

plete, the tool will then

display ready monitors when

is pressed.

10.View I/M monitors that are

ready.

• Press and release .

NOTE: Pressing will

scroll up to review diagnostic

trouble codes and data.

Holding down for 3

seconds will read diagnostic

trouble codes and data again.

Erasing Diagnostic Trouble

Codes and Data

Erasing allows the PocketScan®

code reader to delete the codes and

IM monitor status from the vehicle’s

computer modules.

NOTICE

Only erase diagnostic data

after checking

system completely and

writing down results.

WARNING!

Avoid cooling fan. Fan

may turn on during test.

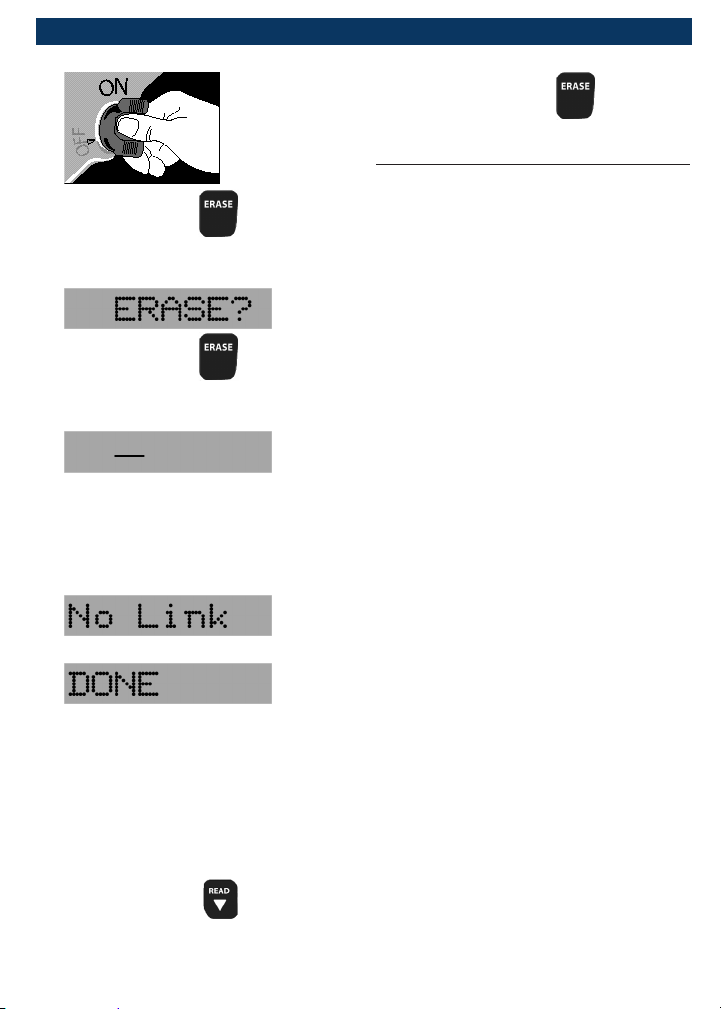

1. Turn ignition key to the OFF

position.

2. Locate and plug in data link

connector (DLC).

NOTE: The data link connector

should be located under the

dashboard on the driverside of

the vehicle. If the data link

connector is not located under

the dashboard as stated, a label

describing the location of the

data link connector should be

there.

3. Observe display toggles between

“Pocket” and “Scan”.

4. Turn ignition key to the ON

position leaving engine off.

NOTE: Make sure that the igni-

tion key is ON and NOT in the

accessory position.

10 |User guide | CP9125 |

5. Press and hold for 3 sec-

onds and release.

6. Observe “ERASE?” displays.

7. Press and hold for 3 sec-

onds and release.

8. Observe a moving — on display.

NOTE: If a “NO LINK” message

displays, cycle ignition key to the

OFF position for 10 seconds,

then back ON, and repeat “Eras-

ing Diagnostic Data” procedure.

9. Observe “DONE” displays.

NOTE: If the problem causing

diagnostic trouble code(s) still

exists, the code will return. The

diagnostic trouble code may

return immediately or may

return after vehicle has been

driven.

NOTE: Pressing will read

diagnostic trouble codes and

data and holding will erase

results again.

Diagnostic Trouble Codes

This section contains the J2012

Diagnostic Trouble Codes (DTCs) as

defined by the Society of Automotive

Engineers (SAE).

DTCs are recommendations not a

requirement. Manufacturers may not

follow these, but most do.

Check vehicle’s service manual for

DTC meaning if the code(s) you are

getting does not make sense.

DTC definitions have been assigned

or reserved by the Society of Automo-

tive Engineers (SAE) to direct to

proper service area(s).

Codes not assigned or reserved by

the SAE are reserved for the manu-

facturer and referred to as Manufac-

turer Specific DTCs.

Remember:

•Visual inspections are important!

•Problems with wiring and connec-

tors are common, especially for

intermittent faults.

•Mechanical problems (vacuum

leaks, binding or sticking linkages,

etc.) can make a good sensor look

bad to the computer.

• Incorrect information from a

sensor may cause the computer

to control the engine in the

wrong way. Faulty engine opera-

tion might even make the com-

| CP9125 | User guide | 11

puter show a known good sen-

sor as being bad!

Code Structure

1. Bx = Body

Cx = Chassis

Px = Powertrain

Ux = Network comm.

x - 0, 1, 2, or 3

2. Vehicle specific system

3. Specific fault designation

Example:

P0101 - Mass or volume air flow

circuit range/performance problem

Powertrain Codes

Code Type

P0xxx Generic (SAE)

P1xxx Manufacturer specific

P2xxx Generic (SAE)

P30xx–P33xx Manufacturer specific

P34xx–P39xx Generic (SAE)

Chassis Codes

Code Type

C0xxx Generic (SAE)

C1xxx Manufacturer specific

C2xxx Manufacturer specific

C3xxx Generic (SAE)

Body Codes

Code Type

B0xxx Generic (SAE)

B1xxx Manufacturer specific

B2xxx Manufacturer specific

B3xxx Generic (SAE)

Network Communication Codes

Code Type

U0xxx Generic (SAE)

U1xxx Manufacturer specific

U2xxx Manufacturer specific

U3xxx Generic (SAE)

Decommissioning

Disposal and Scrapping

This CP9125 is subject to Euro-

pean guidelines 2012/19/EU

(WEEE).

Old electrical and electronic

devices, including cables and acces-

sories or batteries must be dis-

posed of separate to household

waste.

• Please use the return and collec-

tion systems in place for dis-

posal in your area.

Electromagnetic compatibility

(EMC)

The CP9125 is a class B product as

per EN61326-1:2013.

Shop for other automotive tools on our website.

Other manuals for OBD II PocketScan Code Reader CP9125

3

Table of contents

Other Actron Test Equipment manuals

Actron

Actron OMEGA Series User manual

Actron

Actron Digital Multitester CP7672 User manual

Actron

Actron AutoTroubleShooter User manual

Actron

Actron CP7818 User manual

Actron

Actron CP7838 User manual

Actron

Actron CP9680 AutoScanner Plus User manual

Actron

Actron Battery/Alternator Tester CP7611 User manual

Actron

Actron CP7817 Installation guide

Popular Test Equipment manuals by other brands

B&K

B&K 606 instruction manual

Tenma

Tenma 72-2650 operating manual

BI COMMUNICATIONS

BI COMMUNICATIONS TX RANGER operating instructions

Coherent Solutions

Coherent Solutions MTPmini user manual

Parker Research Corp

Parker Research Corp B200 operating instructions

SIGLENT

SIGLENT SDS2000X Plus Series user manual