TB-9025 Page 2 of 3 © 2015 DESCO INDUSTRIES, INC.

Employee Owned

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

3. Jack Cover

Insert the plastic cover into the yellow wrist strap plug-

in jack that is not being used. The jack on the right ts

standard banana plugs used in North America. The 746

Wrist Strap Tester is now ready for use.

4. Wall Mounting

The enclosed SCS Dual Lock Wall Mounting System

adhesion discs must be screwed onto the wall, using

the attached template, approximately 1.5 m (5 ft.) off

the oor. Drill three holes of 5 mm (0.2 in.) diameter at

marked locations.

5. The enclosed Dual Lock Adhesion Strip must be cut

in two halves and adhered to the rear of the 746 Wrist

Strap Tester, parallel to the bottom edge and below the

battery compartment. Make sure the area on the 746

Wrist Strap Tester where the adhesion strips are to be

placed is free of dust and dirt. Press the back of the case

rmly against the discs to secure the tester to the wall.

6. For removal, lift the 746 Wrist Strap Tester at the two

top corners with both hands.

Testing Procedure

7. Wrist Band/Cord Test

Put the wrist band on with the ground cord attached and

insert the ground cord banana plug into the yellow wrist

strap plug-in jack.

8. Depress the metal contact plate and hold.

9. One of the LED indicators will illuminate. An

illuminated green LED indicates that the wrist strap

assembly performs within the resistance range of 750

kilohms to 10 megohms. If a red LED is illuminated, the

resistance of the wrist strap assembly may be outside

the range of 750 kilohms to 10 megohms. To check the

resistance of the ground cord, leave the banana plug

end attached to the tester. Unsnap the cord from the

wrist band. Place the metal side of the ground cord snap

end against the metal contact plate. Depress the plate

and check to see which LED illuminates. If the red LED

illuminates, the ground cord is outside of the resistance

range. If the green LED illuminates, the ground cord is

“OK” but the wrist band may need to be replaced. NOTE:

In some cases, a high contact resistance between the

person’s skin and the wrist band will cause the tester

to indicate a red LED (greater than 10 megohms). This

higher resistance may be caused by dry skin or hair

on the wearer’s wrist. A loose tting wrist band can

also cause intermittency or high resistance. If these

conditions do not exist, a new wrist band should be

obtained and tested on the person.

Verication Procedure

The 746 Wrist Strap Tester cannot be adjusted by

the user, but the following steps can be used to verify

that the 746 Wrist Strap Tester is operating within its

specication.

Equipment needed

1. Resistance substitution box, 700 kilohms - 11

megohms, accuracy < 2%.

2. Two lead wires to connect the resistance box to the

746 Wrist Strap Tester.

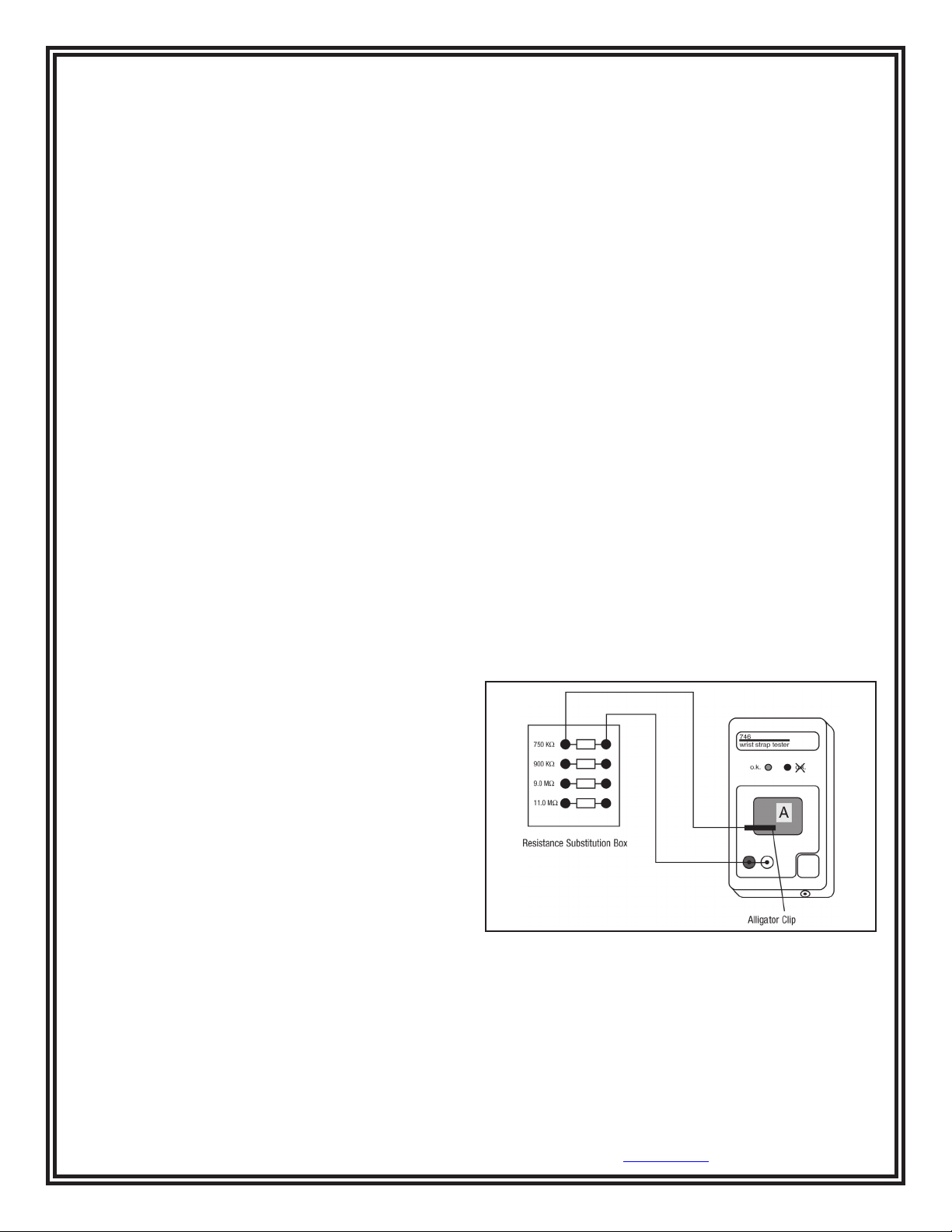

Checking wrist strap test circuit

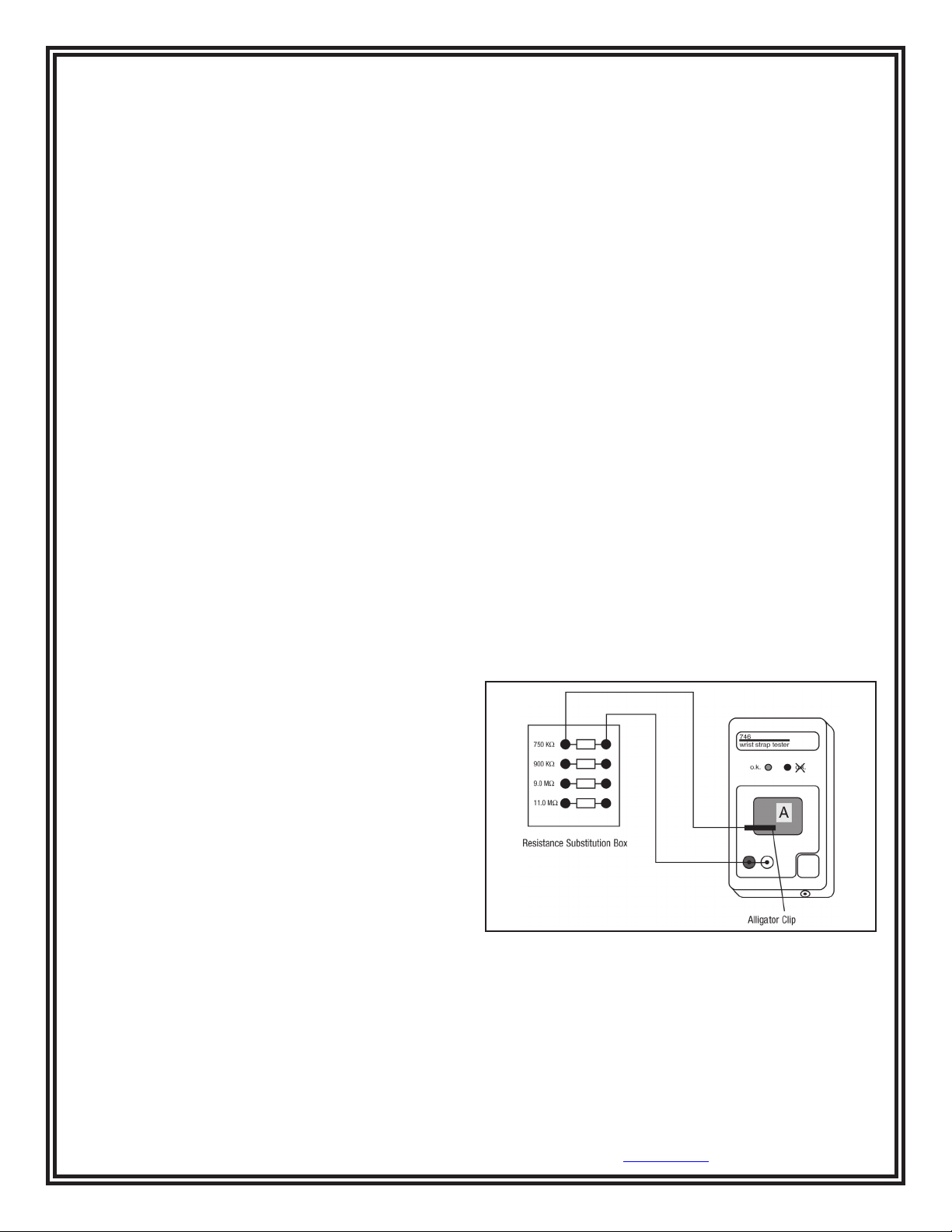

Connect the resistance substitution box to the tester

as shown in Figure 3. Adjust the resistance substitution

box to each value of resistance indicated in the test

table below and press contact plate A. The LEDs will

indicate, as shown below, if the unit is functioning within

specications.

Resistance

Substitution box

settings

Resistance range

of the tester

LED

Indication

750 kilohms 750 kilohms Red

900 kilohms Green

9.0 megohms 10 megohms Green

11.0 megohms Red

The 750 kilohms threshold is approximate for that range

and could vary slightly. Actual threshold resistances are

not listed.

FIgure 3. Checking wrist strap test circuit.