ACV EVO S User manual

EVO S

Plate Heat Exchanger Kits

40-150 kW Natural Gas

and 40-120 kW Propane

When replacing any part on this

appliance, use only spare parts that you

can be assured conform to the safety

and performance specification that we

require. Do not use reconditioned or

copy parts that have not been clearly

authorised by ACV.

For the very latest copy of literature for

specification and maintenance practices

visit our website www/acv/com/gb

where you can download the relevant

information in PDF format.

I

03/2023

UIN 236072-A01

2Plate Heat Exchanger Kits

IMPORTANT

THESE INSTRUCTIONS MUST BE USED IN CONJUNCTION WITH THE

FRAME & HEADER KIT INSTRUCTIONS SUPPLIED WITH THE EVO S

HEADERS

CONTENTS

1 Introduction.....................................................................3

2 General Description of Cascade Systems ...................3

3 Multiple Boiler System Components............................5

4 Plate Heat Exchanger Kit (Optional Accessory)..........9

5 Installation Drawings for Multiple Boiler Systems....10

Boiler Water Header Size Maximum No. Boilers

in Cascade

Maximum Output

in Cascade (kW)

Evo S 40 DN50 4 160

Evo S 60 DN50 4 240

Evo S 70 DN50 4 280

Evo S 80 DN80 4 320

Evo S 100 DN80 4 400

Evo S 120 DN80 3 360

Evo S 150 DN100 3 450

Evo S - DISCLAIMER

Not all cascades included in this manual are available at initial product launch.

For availability refer to the table below:

Note: This information will be updated in the next revision of this manual.

3

Plate Heat Exchanger Kits

1 INTRODUCTION

This technical data contains information for dimensioning & assembly of a

cascade system kit for the Evo S.

GENERAL DESCRIPTION OF FRAME & HEADER KITS

A requirement to spread the total required heat output over several boilers can

be accommodated by the use of the Evo S multiple boiler frame & header kit

options.

The ue congurations for the range of appliances using these system kits are

C13, C33 & B23 (See appliance manual). Note. In the case of the 150 kW

boiler, this must be ued in accordance to the Clean Air Act.

All headers and pipe work should be insulated in accordance with the Non

Domestic Building Services Compliance Guide. To ensure compliance with the

maximum heat loss criteria, insulation thickness should be calculated according

to BS EN ISO 12241 using standardised assumptions.

2.1 FRAME AND HEADER KIT DESIGN OPTIONS

Note: All boilers need to be sized in accordance to the total required

heat load and the modulation capabilities of the appliances.

2 GENERAL DESCRIPTION OF CASCADE SYSTEMS

continued . . . . .

Max Boilers in Cascade @ stated

Header Size PHEX Options

Boiler Type Boiler Header

Size

No Max Output

(kW)

Evo S 40 DN50 4 160

60 kW, 150 kW, 300 kWEvo S 60 DN50 4 240

Evo S 70 DN50 4 280

Evo S 80 DN80 6 480

150 kW, 300 kW, 450 kW, 600 kWEvo S 100 DN80 6 600

Evo S 120 DN80 5 600

Evo S 150 DN100 6 900 300 kW, 450 kW, 600 kW, 750 kW, 900 kW

Note: The total system output must not exceed the Plate Heat

Exchanger Kit Rating.

One Plate Heat Exchanger Kit required per cascade.

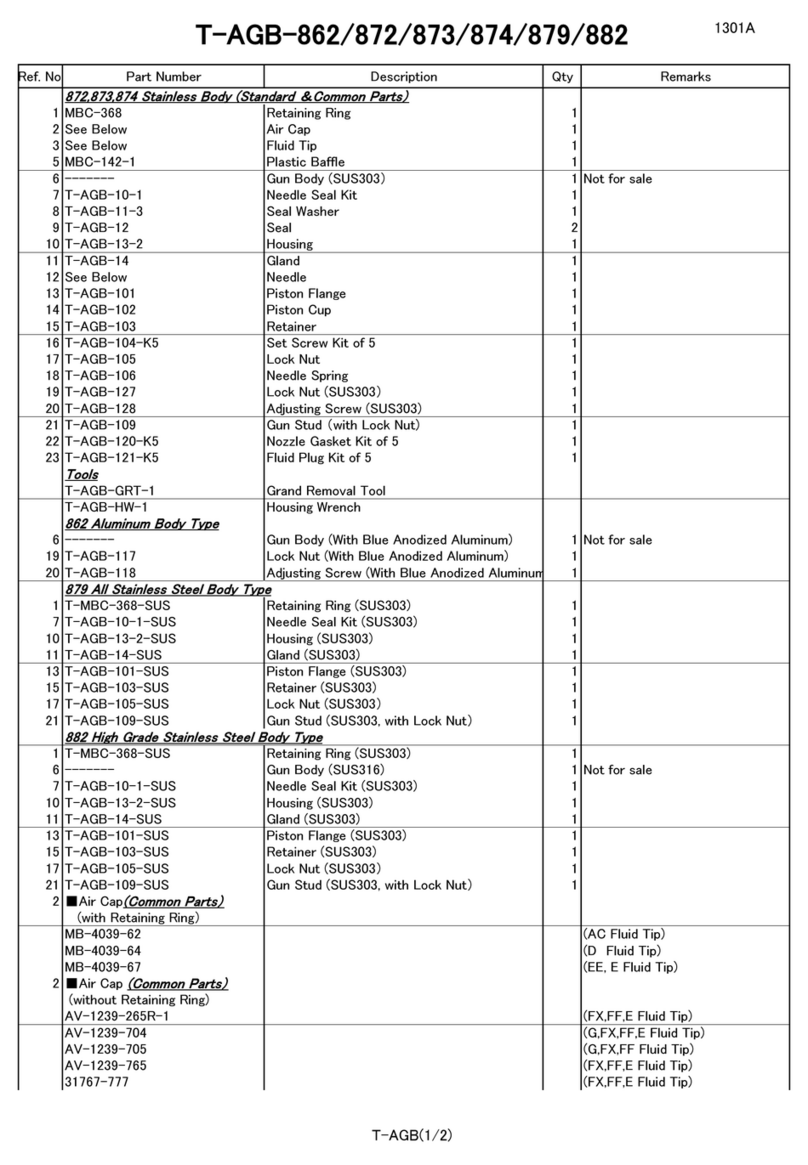

Table 1 - Cascade Options

Table 2 - Available Boilers

kW Product No.

Evo S 40 100008264200

Evo S 60 100008264300

Evo S 70 100008265900

Evo S 80 100008264400

Evo S 100 100008264500

Evo S 120 100008264600

Evo S 150 100008264700

PHE Kits (kW) Outlet Connection Size

60 DN25 FLANGE

150

300

DN50 FLANGE450

600

750 DN80 FLANGE

900

Table 3 - PHEX Kit Outlet Connection Size

4Plate Heat Exchanger Kits

2.2 MULTIPLE BOILER INSTALLATIONS

For installing 1 to 6 boilers, the product range includes water and gas headers capable of assembly using threaded socket,

compression and PN6 ange connections.

2.3 SYSTEM SEPARATION: LOW LOSS HEADER & PLATE HEAT EXCHANGER

A low loss header or plate heat exchanger allows ow separation within a heating system.

This allows two ow circuits to operate with their own ow and pressure drop environments whilst eectively transferring heat to its

adjoined water circuit.

This enables the modern high resistant, high eciency boilers to operate under their optimum conditions, while the main heating circuit

operates to its own controlled optimum requirements. ACV's brazed plate heat exchangers ensure optimum heat transfer eciency and

low resistance within a compact footprint. The heat exchanger allows hydraulic segregation between the boiler primary and secondary

heating circuits. Used in conjunction with ACV's 40-70 kW and 80-150 kW frame and header kits covering duties from 60 kW to 900 kW.

The design is based on standard components and a modular brazed concept. Each unit is manufactured to the highest standard and

part of the AHRI certied program that ensures thermal performance in accordance with the product specications.

Benets

• Compact design

• No gaskets

• Easy install with ACV's Commercial Frame and Header Kits

• Low maintenance/ self-cleaning

• All units are pressure tested

2.4 OUTPUT CONTROL

All pumps are designed to be wired to the appliance to allow a controlled pump over run.

If using an external pump control system the capability of a timed pump over run signal provided by the appliance must be maintained

at all times.

The optional LPB bus accessory control can be installed (1 per boiler) to enable cascade control.

2.5 GAS SUPPLY

All Evo S boilers are compatible with natural gas or propane except the 150 kW model which is natural gas only.

Connection to the gas supply must be in accordance to with all the applicable regulations.

A single frame and DN50 water header kit will require the gas inlet to be made up to the gas tap provided, connecting it to the inlet of

the appliance.

Frame and header kits will be supplied with a 2” or 3" gas header and all the necessary components and pipe work to connect it to the

appliances.

Note: Test points are provided at each end of the 2” or 3" gas header. The test point nearest to the gas inlet is intended to be used as

the appliance inlet pressure point.

2.6 ASSEMBLY

The frames must be located in a suitable place that aords a at and level oor-area of suitable load bearing capacity. Care must be

taken when locating the frames that space is available for the servicing, installation and maintenance of the appliance and all of the

associated connections and equipment. (See appliance manuals)

When using multiple frames they must be bolted together and where necessary secured to the oor.

2.7 SAFE HANDLING

Installation may require 2 or more operatives to move it to its installation site, remove it from its packaging base and during movement into its

installation location. Manoeuvring may include the use of a sack truck and involve lifting, pushing and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques when performing these tasks and the following precautions should be considered:

• Grip the boiler at the base

• Be physically capable

• Use personal protective equipment as appropriate, e.g. gloves, safety footwear

5

Plate Heat Exchanger Kits

During all manoeuvres and handling actions, every attempt should be made to ensure the following unless unavoidable and/or the

weight is light.

• Keep back straight

• Avoid twisting at the waist

• Avoid upper body/top heavy bending

• Always grip with the palm of the hand

• Use designated hand holds

• Keep load as close to the body as possible

• Always use assistance if required

3 MULTIPLE BOILER SYSTEM COMPONENTS

3.1 GENERAL

The multiple boiler systems consist of the following components:

• Frame and Header kit (1 or 2 wide)

• Boiler gas header.

• Boiler ow and return headers supported on mounting skid

• Hardware pack (includes essential connection and valve components)

• Boiler Shunt pump (MUST be used, sold seperately)

3.2 MAIN WATER HEADERS

Each header kit provides water ow and return headers sized either DN50, DN80 or DN100 dependent on total maximum combined

heating output required.

3.3 GAS HEADER

The Gas header consists of custom manufactured manifolds of either 2" or 3" (depending on total heating output). This is located in a

cradle incorporated within the header mounting skid.

3.4 LOW LOSS HEADERS (MIXING HEADER) OPTION

The mixing headers are supplied with an auto air vent and drain point as standard.

3.5 BOILER SHUNT PUMP

Pump kits and External pump controls (sold separately) are designed to provide the optimum ow around the appliance water circuit

ensuring the maximum ow rates are contained within the design constraints of the appliance.

It is not recommended to t additional pumps directly to the appliance circuit unless they have been designed to ensure the maximum

permissible appliance ow rate is not exceeded.

6Plate Heat Exchanger Kits

3.6 BOILER CONNECTION KITS

The connection kit contains the following components:

1. Boiler return leg complete with isolating valve, pump,

non return valve, drain cock and bre seals

2. Boiler ow leg complete with isolating valve, pressure

relief valve and bre seals

3. Header blanking anges, fasteners and gaskets

4. Mixing header fasteners and gasket

3.7 INSTALLATION AREA AND DIMENSIONS

Care must be taken to ensure adequate access for boiler / cascade system installation and servicing.

A minimum of 450 mm clearance must be provided from the front of the installed boilers in cascade to facilitate boiler servicing.

Additional clearance must also be considered in the event of boiler replacement.

Consideration to connecting heating ow and return pipework, gas supply and condensate drainage must be given. Routing of the

condensate drain must be made to allow a minimum fall of 1 in 20 away from the installed boilers in cascade, throughout its length.

Adequate room above the boilers must be provided to install and service the boiler ue system. Further information with respect to ue

and condensate drain connection is provided in the installation and servicing instructions provided within the boilers packaging carton.

REV.BY ECN No. DATE

ALL DIMENSIONS IN MM

DO NOT SCALE, IF IN DOUBT - ASK.

DRAWING VOID IF AMENDED MANUALLY

MATERIAL

DRAWN BY

CHECKED BY

ECN No.

FINISH DATE

SCALE NTS

FIRST

ANGLE

PROJECTION

THIS DOCUMENT IS COPYRIGHT PROTECTED BY IDEAL BOILERS.

IT MUST NOT BE COPIED, REPRODUCED OR COMMUNICATED

TO ANY THIRD PARTY WITHOUT CONSENT OF IDEAL BOILERS.

THIS DRAWING REFERENCES A 3D FILE OF THE SAME

NAME AND UIN. ADDITIONAL DETAIL CAN BE GAINED

FROM THIS 3D FILE

2

2

3

3

4

4

4

REV.BY ECN No. DATE

ALL DIMENSIONS IN MM

DO NOT SCALE, IF IN DOUBT - ASK.

DRAWING VOID IF AMENDED MANUALLY

MATERIAL

DRAWN BY

CHECKED BY

ECN No.

FINISH DATE

SCALE NTS

FIRST

ANGLE

PROJECTION

THIS DOCUMENT IS COPYRIGHT PROTECTED BY IDEAL BOILERS.

IT MUST NOT BE COPIED, REPRODUCED OR COMMUNICATED

TO ANY THIRD PARTY WITHOUT CONSENT OF IDEAL BOILERS.

THIS DRAWING REFERENCES A 3D FILE OF THE SAME

NAME AND UIN. ADDITIONAL DETAIL CAN BE GAINED

FROM THIS 3D FILE

2

2

3

3

4

4

1

2

3

4

5

6

REV.BY ECN No. DATE

ALL DIMENSIONS IN MM

DO NOT SCALE, IF IN DOUBT - ASK.

DRAWING VOID IF AMENDED MANUALLY

MATERIAL

DRAWN BY

CHECKED BY

ECN No.

FINISH DATE

SCALE NTS

FIRST

ANGLE

PROJECTION

THIS DOCUMENT IS COPYRIGHT PROTECTED BY IDEAL BOILERS.

IT MUST NOT BE COPIED, REPRODUCED OR COMMUNICATED

TO ANY THIRD PARTY WITHOUT CONSENT OF IDEAL BOILERS.

THIS DRAWING REFERENCES A 3D FILE OF THE SAME

NAME AND UIN. ADDITIONAL DETAIL CAN BE GAINED

FROM THIS 3D FILE

2

2

3

3

4

4

1

2

3

3

4

5

6

7

REV.BY ECN No. DATE

ALL DIMENSIONS IN MM

DO NOT SCALE, IF IN DOUBT - ASK.

DRAWING VOID IF AMENDED MANUALLY

MATERIAL

DRAWN BY

CHECKED BY

ECN No.

FINISH DATE

SCALE

NTS

FIRST

ANGLE

PROJECTION

THIS DOCUMENT IS COPYRIGHT PROTECTED BY IDEAL BOILERS.

IT MUST NOT BE COPIED, REPRODUCED OR COMMUNICATED

TO ANY THIRD PARTY WITHOUT CONSENT OF IDEAL BOILERS.

THIS DRAWING REFERENCES A 3D FILE OF THE SAME

NAME AND UIN. ADDITIONAL DETAIL CAN BE GAINED

FROM THIS 3D FILE

2

2

3

3

4

4

1

2

3

4

56

7

8

9

3

2

1

5

FLOW RETURN

LEGEND

1. Isolation Valve

2. Boiler Flow Flexible

Connection

3. Pump Union

4. Pump inc Gaskets

5. Non Return Valve

6. 1 ¼” x 1 ¼” x ¾” Tee

7. Drain Cock

LEGEND

1. Isolation Valve

2. 1 ¼” Male/Female Swivel

Elbow

3. Boiler Flow Flexible

Connection

4. 1 ¼” Male Parallel/Taper

Hex Nipple

5. 1 ¼” x 1 ¼” x ¾” Tee

6. ¾” Taper Plug

LEGEND

1. Isolation Valve

2. 1 ¼” Male/Female Mac

Union

3. Boiler Flow Flexible

Connection

4. Pump inc Gaskets

5. Flange Pump Adapter

6. 1 ¼” Male Parallel/Taper

Hex Nipple

7. Non Return valve

8. 1 ¼” x 1 ¼” x ½” Tee

9. Drain Cock

LEGEND

1. Isolation Valve

2. Boiler Flow Flexible

Connection

3. 1 ¼” Male Parallel/Taper

Hex Nipple

4. 1 ¼” x 1 ¼” x ¾” Tee

5. ¾” Taper Plug

FIGURE 1 - DN50 and DN80

FIGURE 2 - DN100

7

Plate Heat Exchanger Kits

3.8 SYSTEM REQUIREMENTS

Notes.

1. Ancillary components can be connected to the system via the G ¾” tapping’s on the header blanking anges. See

diagram below for guidance (diagram for illustration purposes only).

2. The method of lling, relling, topping up or ushing sealed primary circuits from the mains via a temporary hose

connection is only allowed if acceptable to the local water authority.

3. When installing the lling device, it must be connected as shown to fully comply with the water regulations. This

may involve the tting of an approved WRAS approved isolator valve to the mains supply, and appropriate back ow

prevention device.

Pressure relief valve (Supplied with boiler)

1. A spring loaded non-adjustable (40-70 kW) 4 bar and (80-150 kW) 6 bar pressure relief valve complying with the

relevant standards of BS6759 Pt1 is tted close to the boiler with no intervening valve or restriction.

2. A manual testing device.

3. The pressure relief valve outlet should be piped to ensure discharge cannot create a hazard to personal or damage

electrical components or wiring.

Pressure gauge (Not supplied)

A pressure gauge must be tted to the system visible from the lling point.

Expansion vessel (Not supplied)

1. A diaphragm type expansion vessel complying with BS. EN 13831 must be tted without incorporating isolation valves of

any sort.

2. The vessel capacity must be adequate to accept the expansion of system water when heated to 110 °C.

3. The charge pressure must not be less than the static water head above the vessel. The pressure attained in the system

when heated to 110 °C should be at least 0.35 bar less than the lift pressure of the pressure relief valve. For guidance

on vessel sizing refer to the Table 4.

Note: The largest Plate Heat Exchanger (900 kW) with 6 x Evo S 150 kW boilers would require a 18 litre expansion vessel.

System drain cock (Not supplied)

A drain cock should be tted to the lower blanking ange on the lowest header.

Pressure Gauge

Expansion Vessel Drain Cock

Return

Flow

Double check valve or

RPZ assembly

(note direction of ow)

Additional

stop valve

Hosepipe

(disconnect

after lling)

Water

Supply

Headers

Temporary Hose

(disconnect

after lling)

Hose unions

Blanking Flanges

Plate Heat

Exchanger Kits

(kW)

Recommended

Expansion Vessel

Capacity (litre)

60 4

150 4

300 8

450 12

600 12

750 18

900 18

Table 4 - Vessel size

8Plate Heat Exchanger Kits

IMPORTANT POINTS

Before commencing installation:

When frame mounting:

• The frames must stand on a at and level oor of suitable load

bearing capacity.

• When using a frame and header kit, the header must be bolted to

the frame before the hoses are connected to the boiler.

MOUNTING FRAME MUST BE SECURED TO

THE FLOOR WITH BOLTS

These Installations refer to perpendicular wall and oor. If walls are

not perpendicular, it is recommended that a frame and header kit be

used. The correct number of frames and headers should be ordered.

Allowances must be made for installation where features are in place

that may aect the nominal installation conditions.

9

Plate Heat Exchanger Kits

4 PLATE HEAT EXCHANGER KIT (OPTIONAL ACCESSORY)

4.1 PLATE HEAT EXCHANGER

Plate Heat Exchanger Blanking Flange

4.2 FITTING PLATE HEAT EXCHANGER AND BLANKING FLANGES

1. Fit the Plate Heat Exchanger and blanking anges in the chosen positions.

Note: Plate Heat Exchanger can be located either LHS or RHS of the headers.

REV.BY ECN No. DATE

ALL DIMENSIONS IN MM

DO NOT SCALE, IF IN DOUBT - ASK.

DRAWING VOID IF AMENDED MANUALLY

MATERIAL

DRAWN BY

CHECKED BY

ECN No.

FINISH DATE

SCALE NTS

234

PROJECTION

THIS DOCUMENT IS COPYRIGHT PROTECTED BY IDEAL BOILERS.

IT MUST NOT BE COPIED, REPRODUCED OR COMMUNICATED

TO ANY THIRD PARTY WITHOUT CONSENT OF IDEAL BOILERS.

THIS DRAWING REFERENCES A 3D FILE OF THE SAME

NAME AND UIN. ADDITIONAL DETAIL CAN BE GAINED

FROM THIS 3D FILE

234

10 Plate Heat Exchanger Kits

5 INSTALLATION DRAWINGS FOR MULTIPLE BOILER SYSTEMS

5.1 GENERAL

Note: The total system output must not exceed the Plate Heat Exchanger Kit Rating - refer to Table 1 for the range of

Plate Heat Exchanger kits available.

11

Plate Heat Exchanger Kits

SYSTEM RETURN

DN25 PN6 FLANGE

SYSTEM FLOW

DN25 PN6 FLANGE

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE

ON EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. FRAME (UIN 232857) ONE SUPPLIED PER BOILER.

3. OPTIONAL 150kW PLATE HEAT EXCHANGER (UIN 232890)

ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 40kW/60kW/70kW

1000

250500

197

591

613

613

450

120

TOP OF BOILER1389

TOP OF FRAME1418

541

120

586

1000

1545

685

396

763

300

5.2.1 INSTALLATION DRAWING OF 1 BOILER ON DN50 FRAME & HEADER KIT WITH

60 kW PLATE HEAT EXCHANGER

1418 TOP OF FRAME

TOP OF BOILER1389

541

613

147

500

SYSTEM FLOW

DN25PN6 FLANGE

SYSTEM RETURN

DN25 PN6 FLANGE

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE

ON EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. FRAME (UIN 232857) ONE SUPPLIED PER BOILER.

3. OPTIONAL 60kW PLATE HEAT EXCHANGER (UIN 232889)

ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 40kW/60kW

541

563

250

500

450

120

934

120

586

685

396

763

300

5.2.2 INSTALLATION DRAWING OF 2 BOILER ON DN50 FRAME & HEADER KIT WITH

150 kW PLATE HEAT EXCHANGER

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT

THE INSTALLATION.

2. OPTIONAL 60 kW PLATE HEAT EXCHANGER (XB150035)

ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 40 kW / 60 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT

THE INSTALLATION.

2. OPTIONAL 150 kW PLATE HEAT EXCHANGER (XB150036)

ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 40 kW / 60 kW / 70 kW

12 Plate Heat Exchanger Kits

5.2.3 INSTALLATION DRAWING OF 3 BOILERS ON DN50 FRAME & HEADER KIT WITH

150 kW PLATE HEAT EXCHANGER

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE

ON EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. FRAME (UIN 232857) ONE SUPPLIED PER BOILER.

3. OPTIONAL 150kW PLATE HEAT EXCHANGER (UIN 232890)

ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 40kW

SYSTEM RETURN

DN25 PN6 FLANGE

SYSTEM FLOW

DN25 PN6 FLANGE

147

541

250500500

563

1500

500 500 500

120

586

613

120

450

685

396

541

TOP OF BOILER1389

TOP OF FRAME1418,0

763

300

5.2.4 INSTALLATION DRAWING OF 3 BOILERS ON DN50 FRAME & HEADER KIT WITH

300 kW PLATE HEAT EXCHANGER

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE

ON EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. FRAME (UIN 232857) ONE SUPPLIED PER BOILER.

3. OPTIONAL 300kW PLATE HEAT EXCHANGER (UIN 232891)

ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 60kW/70kW

SYSTEM FLOW

DN25 PN6 FLANGE

SYSTEM RETURN

DN25 PN6 FLANGE

147

583

250500500

563

500 500 500613

TOP OF BOILER1389

TOP OF FRAME1418

396

541

685

2031

120

639

120

450 763

300

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT

THE INSTALLATION.

2. OPTIONAL 150 kW PLATE HEAT EXCHANGER (XB150036)

ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 40 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT

THE INSTALLATION.

2. OPTIONAL 300 kW PLATE HEAT EXCHANGER (XB150037)

ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 60 kW / 70 kW

13

Plate Heat Exchanger Kits

5.2.5 INSTALLATION DRAWING OF 4 BOILERS ON DN50 FRAME & HEADER KIT WITH

300 kW PLATE HEAT EXCHANGER

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE

ON EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. FRAME (UIN 232857) ONE SUPPLIED PER BOILER.

3. OPTIONAL 300kW PLATE HEAT EXCHANGER (UIN 232891)

ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 40kW/60kW/70kW

147

583

250500500500

563

500500500500

120

639

613

TOP OF BOILER1389

TOP OF FRAME1418,0

450

120

541

396

685

SYSTEM RETURN

DN25 PN6 FLANGE

SYSTEM FLOW

DN25 PN6 FLANGE

2532

2000

300

763

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT

THE INSTALLATION.

2. OPTIONAL 300 kW PLATE HEAT EXCHANGER (XB150037)

ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 40 kW / 60 kW / 70 kW

704

(TOP OF BOILER)1506

(TOP OF FRAME)1535

554

643

680

120

586

1057

120

300

450

894

250

123

SYSTEM FLOW

DN25 PN6 FLANGE

SYSTEM RETURN

DN25 PN6 FLANGE

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 150kW PLATE HEAT EXCHANGER

(UIN 232893) ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80kW, 100kW, 120kW

500

5.2.6 INSTALLATION DRAWING OF 1 BOILERS ON DN80 FRAME & HEADER KIT WITH

150 kW PLATE HEAT EXCHANGER

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 150 kW PLATE HEAT EXCHANGER (XB150038) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80 kW / 100 kW / 120 kW

14 Plate Heat Exchanger Kits

704

250500

123

480

20

480

1000

1622

(TOP OF FRAM)1535

(TOP OF BOILER)1506

894

554

643

680

120

639

SYSTEM RETURN

DN50 PN6 FLANGE

SYSTEM FLOW

DN50 PN6 FLANGE

120

450

300

5.2.7 INSTALLATION DRAWING OF 2 BOILERS ON DN80 FRAME & HEADER KIT WITH

300 kW PLATE HEAT EXCHANGER

5.2.8 INSTALLATION DRAWING OF 3 BOILERS ON DN80 FRAME & HEADER KIT WITH

300 kW PLATE HEAT EXCHANGER

704

500

123

480

2122

(TOP OF FRAM)1535

(TOP OF BOILER)1506

894300

554

643

680

120

639

SYSTEM RETURN

DN50 PN6 FLANGE

SYSTEM FLOW

DN50 PN6 FLANGE

120

450

480 480

20 20

500 250

1500

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 300 kW PLATE HEAT EXCHANGER (XB150039) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80 kW / 100 kW / 120 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 300 kW PLATE HEAT EXCHANGER (XB150039) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80 kW / 100 kW

15

Plate Heat Exchanger Kits

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE ON EITHER

THE LHS OR RHS OF THEASSEMBLY TO SUIT THE INSTALLATION.

2. FRAME (UIN 232858) ONE SUPPLIED PER BOILER.

3. OPTIONAL 450kW PLATE HEAT EXCHANGER

(UIN 232895) ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 120kW

704

894

120

300

450

554

643

680

(TOP OF BOILER)1506

(TOP OF FRAME)1535

120

639

1500

2178

480 480 480

20 20

500 500 250

123

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

5.2.9 INSTALLATION DRAWING OF 3 BOILERS ON DN80 FRAME & HEADER KIT WITH

450 kW PLATE HEAT EXCHANGER

5.2.10 INSTALLATION DRAWING OF 4 BOILERS ON DN80 FRAME & HEADER KIT WITH

450kW PLATE HEAT EXCHANGER

704

894

120

300

450

554

643

680

120

639

2000

2678

480 480 480 480

20 20 20

500 500 500 250

123

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. FRAME (UIN 232858) ONE SUPPLIED PER BOILER.

3. OPTIONAL 450kW PLATE HEAT EXCHANGER

(UIN 232895) ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 80kW/100kW

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

(TOP OF BOILER)1506

(TOP OF FRAME)1535

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE EITHER THE

LHS OR RHS OF THE ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 450 kW PLATE HEAT EXCHANGER (XB150040) ONE PER

CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 120 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE EITHER THE

LHS OR RHS OF THE ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 450 kW PLATE HEAT EXCHANGER (XB150040) ONE PER

CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80 kW / 100 kW

16 Plate Heat Exchanger Kits

5.2.11 INSTALLATION DRAWING OF 4 BOILERS ON DN80 FRAME & HEADER KIT WITH

600 kW PLATE HEAT EXCHANGER

5.2.12 INSTALLATION DRAWING OF 5 BOILERS ON DN80 FRAME & HEADER KIT WITH

450 kW PLATE HEAT EXCHANGER

120

639

(TOP OF BOILER)1506

(TOP OF FRAME)1535

554

643

680

120

300

450

2000

2764

500 500 500 250

123

894

704

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. FRAME (UIN 232858) ONE SUPPLIED PER BOILER.

3. OPTIONAL 600kW PLATE HEAT EXCHANGER

(UIN 232896) ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 120kW

480

20

480

20

480

20

480

704

894

554

643

680

120

300

450

(TOP OF BOILER)1506

(TOP OF FRAME)1535

500 500 500 500 250

123

480

20

480

20

480

20

480

20

480

2500

3178

120

639

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 450kW PLATE HEAT EXCHANGER

(UIN 232895) ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE EITHER THE

LHS OR RHS OF THE ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 600 kW PLATE HEAT EXCHANGER (XB150041) ONE PER

CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 120 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE EITHER THE

LHS OR RHS OF THE ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 450 kW PLATE HEAT EXCHANGER (XB150040) ONE PER

CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80 kW

17

Plate Heat Exchanger Kits

(TOP OF BOILER)1506

(TOP OF FRAME)1535

500 500 500 500 500 250

123

480 480 480 480 480 480

20 20 20 20 20

3000

3764

120

639

554

643

680

120

300

450

704

894

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 600kW PLATE HEAT EXCHANGER

(UIN 232896) ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80kW, 100kW

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

5.2.14 INSTALLATION DRAWING OF 6 BOILERS ON DN80 FRAME & HEADER KIT WITH

600 kW PLATE HEAT EXCHANGER

5.2.13 INSTALLATION DRAWING OF 5 BOILERS ON DN80 FRAME & HEADER KIT WITH

600 kW PLATE HEAT EXCHANGER

554

643

680

704

894

120

300

450

(TOP OF BOILER)1506

(TOP OF FRAME)1535

2500

3246

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. FRAME (UIN 232858) ONE SUPPLIED PER BOILER.

3. OPTIONAL 600kW PLATE HEAT EXCHANGER

(UIN 232896) ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 100kW/120kW

639

120

500 500 500 500 250

123

480

20

480

20

480

20

480

20

480

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN BE EITHER THE

LHS OR RHS OF THE ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 600 kW PLATE HEAT EXCHANGER (XB150041) ONE PER

CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 100 kW / 120 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 600 kW PLATE HEAT EXCHANGER (XB150041) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 80 kW / 100 kW

18 Plate Heat Exchanger Kits

5.2.15 INSTALLATION DRAWING OF 2 BOILERS ON DN100 FRAME & HEADER KIT

WITH 300 kW PLATE HEAT EXCHANGER

5.2.16 INSTALLATION DRAWING OF 3 BOILERS ON DN100 FRAME & HEADER KIT

WITH 450 kW PLATE HEAT EXCHANGER

692

776

790

(TOP OF BOILER)1801

(TOP OF FRAME)1830

120

293

450

704

894

1000

1634

120

639

500 250

123

480 480

20

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 300kW PLATE HEAT EXCHANGER

(UIN 236388) ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 150kW

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

692

790

776

(TOP OF BOILER)1801

(TOP OF FRAME)1830

704

894

1500

2190

120

639

500 500 250

123

480 480 480

20 20

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. OPTIONAL 450kW PLATE HEAT EXCHANGER

(UIN 236389) ONE PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 150kW

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

120

293

450

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 450 kW PLATE HEAT EXCHANGER (XB150043) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 150 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 300 kW PLATE HEAT EXCHANGER (XB150042) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 150 kW

19

Plate Heat Exchanger Kits

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. FRAME (UIN 235596) ONE SUPPLIED PER BOILER.

3. OPTIONAL 750kW PLATE HEAT EXCHANGER

(UIN 232897) ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 150Kw

SYSTEM FLOW

DN80 PN6 FLANGE

SYSTEM RETURN

DN80 PN6 FLANGE

120

717

2500

3322

500 500 500 500 250

123

480 480 480 480 480

692

790

776

120

293

450

894

704

(TOP OF BOILER)1801

(TOP OF FRAME)1830

20 20 20 20

(TOP OF BOILER)1801

(TOP OF FRAME)1830

692

776

790

120

293

450

894

704

2000

2779

120

639

480 480 480 480

20 20 20

500 500 500 250

123

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. FRAME (UIN 235596) ONE SUPPLIED PER BOILER.

3. OPTIONAL 600kW PLATE HEAT EXCHANGER

(UIN 232902) ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 150kW

SYSTEM FLOW

DN50 PN6 FLANGE

SYSTEM RETURN

DN50 PN6 FLANGE

5.2.18 INSTALLATION DRAWING OF 5 BOILERS ON DN100 FRAME & HEADER KIT

WITH 750 kW PLATE HEAT EXCHANGER

5.2.17 INSTALLATION DRAWING OF 4 BOILERS ON DN100 FRAME & HEADER KIT

WITH 600 kW PLATE HEAT EXCHANGER

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 600 kW PLATE HEAT EXCHANGER (XB150044) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 150 kW

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 750 kW PLATE HEAT EXCHANGER (XB150045) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 150 kW

20 Plate Heat Exchanger Kits

5.2.19 INSTALLATION DRAWING OF 6 BOILERS ON DN100 FRAME & HEADER KIT

WITH 900 kW PLATE HEAT EXCHANGER

692

790

776

120

293

450

704

894

(TOP OF BOILER)1801

(TOP OF FRAME)1830

500 500 500 500 500 250

123

480 480 480 480 480 480

20 20 20 20 20

3000

3853

120

717

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS

CAN BE ON EITHER THE LHS OR RHS OF THE

ASSEMBLY TO SUIT THE INSTALLATION.

2. FRAME (UIN 235596) ONE SUPPLIED PER BOILER.

3. OPTIONAL 900kW PLATE HEAT EXCHANGER

(UIN 232904) ONE PER CASCADE.

4. ALL DIMENSIONS IN mm

5. COMPATIBLE BOILERS: 150kW

SYSTEM FLOW

DN80 PN6 FLANGE

SYSTEM RETURN

DN80 PN6 FLANGE

NOTES:

1. PLATE HEAT EXCHANGER AND GAS CONNECTIONS CAN

BE EITHER THE LHS OR RHS OF THE ASSEMBLY TO SUIT THE

INSTALLATION.

2. OPTIONAL 900 kW PLATE HEAT EXCHANGER (XB150046) ONE

PER CASCADE.

3. ALL DIMENSIONS IN mm

4. COMPATIBLE BOILERS: 150 kW

This manual suits for next models

7

Table of contents

Popular Industrial Equipment manuals by other brands

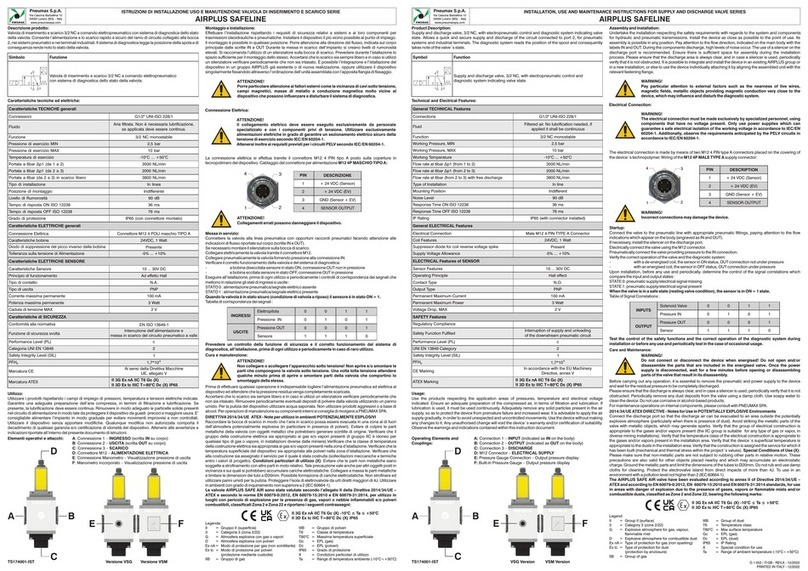

Pneumax

Pneumax AIRPLUS SAFELINE Installation, use and maintenance instructions

Kval

Kval DL-NCD quick start

Marshall Amplification

Marshall Amplification ST3000 Operating/safety instructions

STEIN

STEIN RC-2001 instructions

SCHUNK

SCHUNK SMPL Assembly and operating manual

Siemens

Siemens WZU-485E-MOD operating instructions