© Adam Equipment Company 2019

1

1.0CONTENTS

(P.N. 31066 14213, Revision B, October 2019)

1.0 CONTENTS...................................................................................................................1

2.0 INTRODUCTION...........................................................................................................2

3.0 SAFETY.........................................................................................................................2

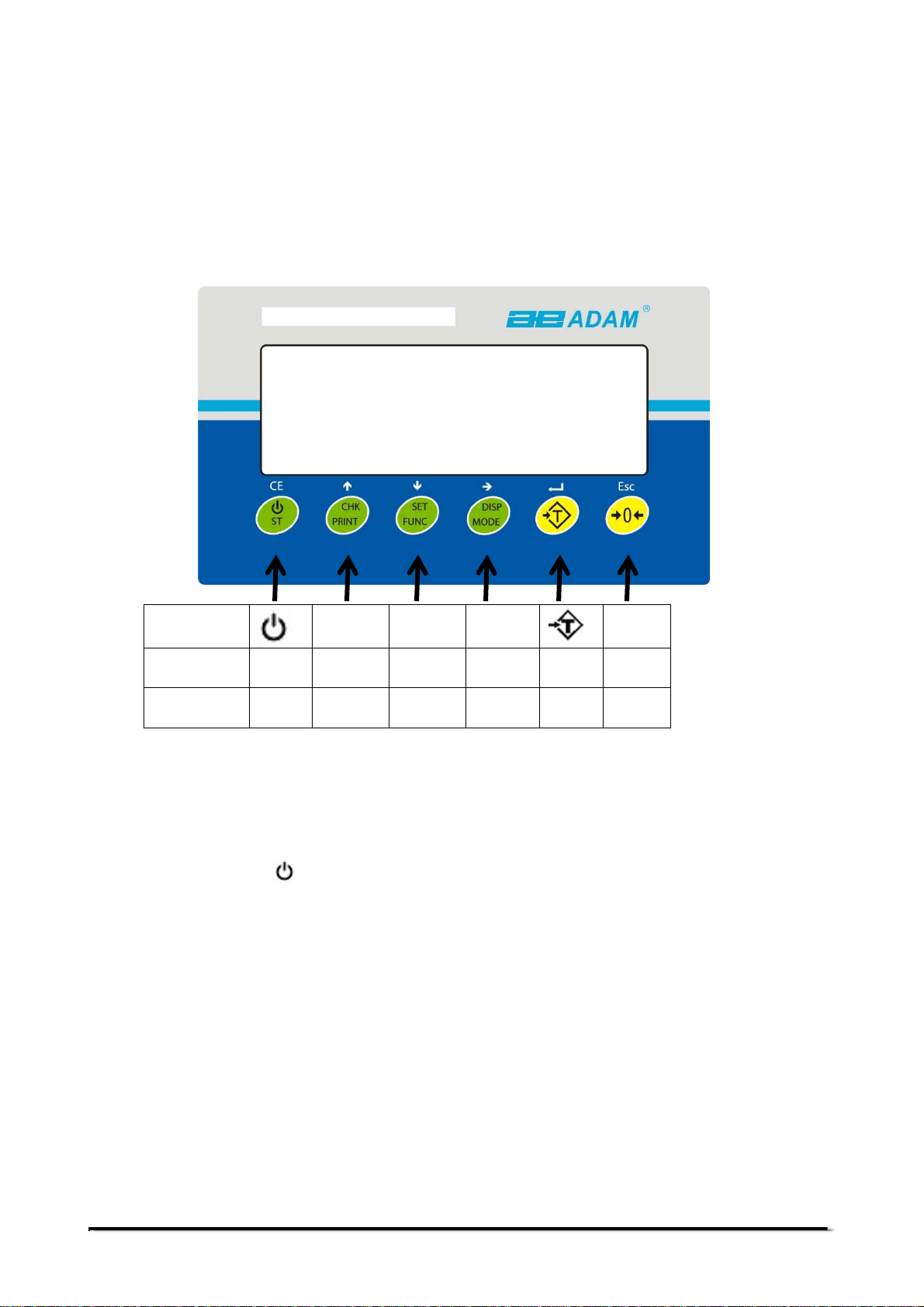

4.0 PANEL INTERFACES...................................................................................................3

4.1 POWER......................................................................................................................3

4.2 DATA INTERFACES..................................................................................................3

4.3 LOAD CELL INTERFACES........................................................................................3

4.4 RELAY INTERFACES................................................................................................3

5.0 INDICATOR MENUS.....................................................................................................4

5.1 SUPERVISOR MENUS..............................................................................................4

5.1.1 “AdCnT”.................................................................................................................5

5.1.2 “dvAL”...................................................................................................................5

5.1.3 “APPro”.................................................................................................................6

5.1.4 “CAPA”...................................................................................................................6

5.1.5 “AVTo-z”...............................................................................................................6

5.1.6 “p-zEro”...............................................................................................................6

5.1.7 “k-zEro”...............................................................................................................7

5.1.8 “FiLtEr”...............................................................................................................7

5.1.9 “G1”......................................................................................................................7

5.1.10 “G2”....................................................................................................................7

5.1.11 “LinEAr”.............................................................................................................8

5.1.12 “m-TaRe”.............................................................................................................8

5.1.13 “doT”...................................................................................................................8

5.1.14 “C-Con”...............................................................................................................9

5.1.15 “ReseT”...............................................................................................................9

5.2 DEALER MENUS.......................................................................................................9

5.2.1 “L-CaL”...............................................................................................................10

5.2.2 “AdC”...................................................................................................................11

5.2.3 “ GRaviT”...........................................................................................................11

5.3 USER MENUS .........................................................................................................11

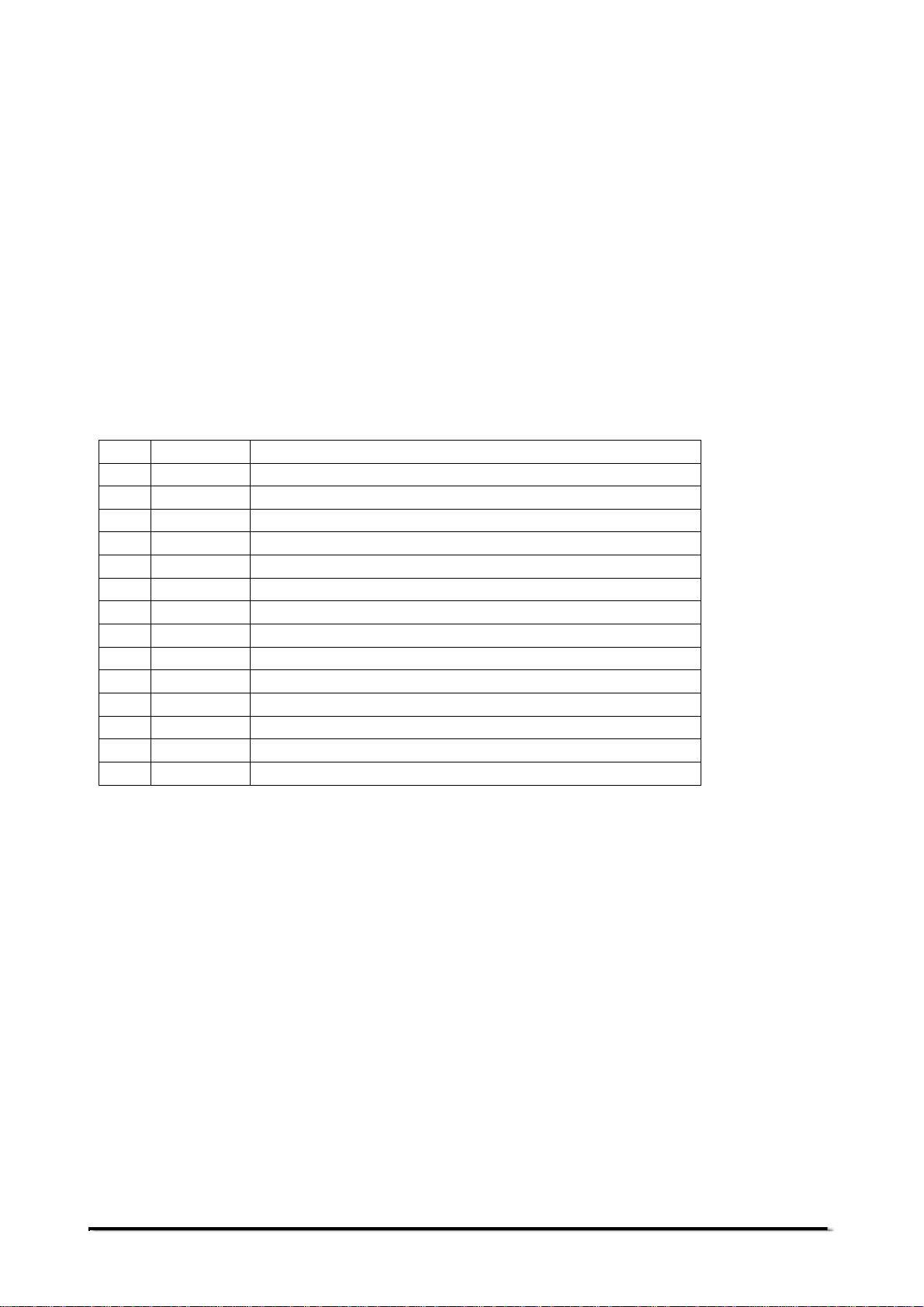

6.0 INDICATOR PARAMETERS .......................................................................................12

7.0 RS-232 PARAMETERS RS232...................................................................................15

7.1 Print settings ............................................................................................................15

7.2 PC settings...............................................................................................................16

7.3 RS-232 INTERFACE................................................................................................16

8.0 CONNECTION OF LOAD CELL..................................................................................17

8.1 Connector Assembly................................................................................................17

8.2 Load cell wire solder with PCB.................................................................................18

9.0 U-BRACKET ASSEMBLY............................................................................................22

10.0 CHANGING LOAD CELL AND RS232 CABLE..........................................................22

11.0 CHANGING BATTERY or BATTERY CABLE............................................................25

12.0 CHANGING TRANSFORMER...................................................................................26

13.0 CHANGING OVERLAY..............................................................................................28

14.0 ACCESSORIES & SPARE PARTS ...........................................................................28