|| P a g e

P a g e © Adam Equipment Company 2010© Adam Equipment Company 2010

1.0 CONTENTS1.0 CONTENTS

1.01.0 CONTCONTENTSENTS ................................................................................................................................................................................................................................................ 11

2.02.0 INTRINTRODUCODUCTION.......TION........................................................................................................................................................................................................................... 33

3.03.0 SET SET UPUP.............................................................................................................................................................................................................................................................. 55

3.13.1 UNPACKING UNPACKING AND SETTAND SETTING UP YING UP YOUR ANALYOUR ANALYZERZER........................................................................................................................................................................ 55

3.23.2 ASSEMBLING ASSEMBLING THE THE ANALYZER...ANALYZER..................................................................................................................................................................................................................................... 66

3.33.3 LEVELLING LEVELLING THE THE ANALYZER...................................................................ANALYZER............................................................................................................................................................................. 77

3.43.4

WARM-UP WARM-UP TIMETIME........................................................................................................................................................................................................................................................................................ 77

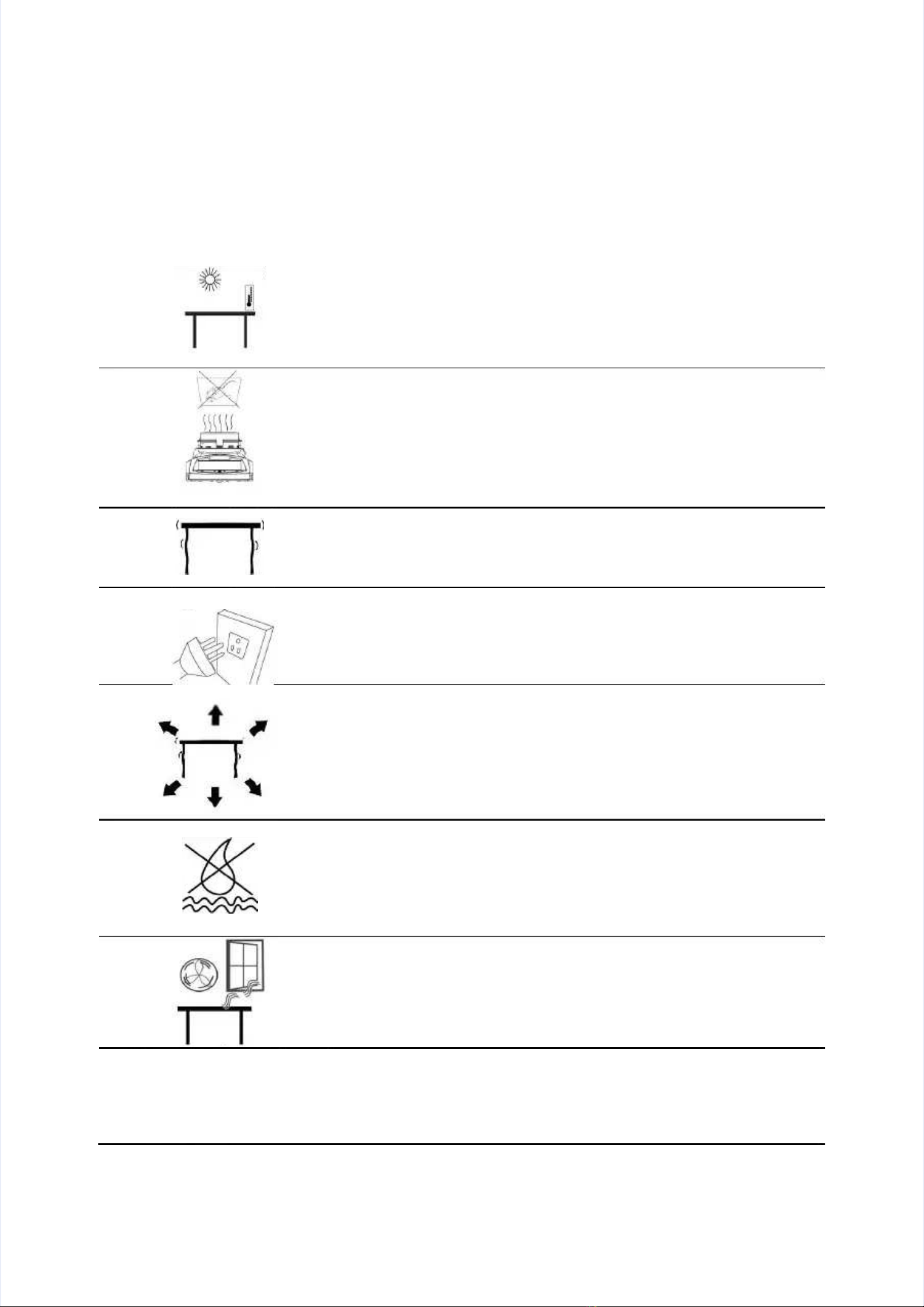

3.53.5 LOCATING ALOCATING AND PROTND PROTECTING ECTING YOUR ANYOUR ANALYZERALYZER.......................................................................................................................................................................... 88

3.63.6 SAFETYSAFETY .................................................................................................................................................................................................................................................................................................................. 99

4.04.0 DISPDISPLALAY Y and and KEYPKEYPAD.....AD................................................................................................................................................................................................... 1212

4.14.1 NUMERIC NUMERIC ENTRY ENTRY METHODMETHOD .............................................................................................................................................................................................................................................. 1414

5.05.0 REAREAR R PAPANEL NEL INTEINTERFARFACES........CES................................................................................................................................................................................ 1515

5.1 5.1 POWERPOWER .............................................................................................................................................................................................................................................................................................................. 1515

5.25.2 DATA DATA INTERFACES............INTERFACES............................................................................................................................................................................................................................................................ 1515

5.2.15.2.1 FILES FILES ON ON A A USB USB MEMORY MEMORY DEVICEDEVICE ........................................................................................................................................................................................ 1616

5.35.3 SECURITY SECURITY LOCKLOCK ................................................................................................................................................................................................................................................................................ 1717

6.16.1 SETUP SETUP OF OF METHOD....................METHOD.................................................................................................................................................................................................................................................. 1818

6.1.16.1.1 MANUALLY MANUALLY SETTING SETTING TEST TEST PROCEDURPROCEDURESES.................................................................................................................................................................. 2121

6.1.26.1.2 PRINT PRINT CURRENT CURRENT SETTINGS............................................SETTINGS...................................................................................................................................................................... 2626

6.26.2 STORE STORE TEST TEST SETTINGS...SETTINGS................................................................................................................................................................................................................................................... 2727

6.36.3 RECALL RECALL TEST TEST SETTINGSSETTINGS .................................................................................................................................................................................................................................................... 2828

6.46.4 DELETE DELETE TEST TEST SETTINGSSETTINGS .................................................................................................................................................................................................................................................... 2929

6.56.5 REVIEW TEST REVIEW TEST SETTINGS..........SETTINGS........................................................................................................................................................................................................................................ 2929

6.66.6 STORE and RESTORE and RECALLING TEST CALLING TEST SETTINGS FRSETTINGS FROM USB OM USB MEMORYMEMORY...................................................................................................................... 3030

7.07.0 RUNRUNNING NING A A TEST.............TEST........................................................................................................................................................................................................... 3333

8.08.0 PRINPRINT T ANAND D STORE RESULTSSTORE RESULTS................................................................................................................................................................................ 3737

8.18.1 PRINTING PRINTING FINAL FINAL TEST TEST RESULTSRESULTS .......................................................................................................................................................................................................................... 3737

8.28.2 STORING STORING TEST TEST RESULTSRESULTS .................................................................................................................................................................................................................................................. 3737

8.38.3 RECALLING RECALLING TEST TEST RESULTSRESULTS ...................................................................................................................................................................................................................................... 3838

8.48.4 DELETING DELETING TEST TEST RESULTS...............................................RESULTS............................................................................................................................................................................................. 3838

9.09.0 STORSTORING RESULTING RESULTS S IN USB MEMORYIN USB MEMORY .................................................................................................................................................... 4040

10.010.0 ANANALALYZER YZER MENUMENUSS.................................................................................................................................................................................................................. 4242

10.110.1 SUPERVISOR SUPERVISOR MENUS...........................MENUS..................................................................................................................................................................................................................................... 4242

10.1.110.1.1 SERIAL SERIAL INTERFACE INTERFACE PARAMETEPARAMETERSRS .......................................................................................................................................................................................... 4444

10.1.210.1.2 SETUP SETUP PARAMETPARAMETERSERS ...................................................................................................................................................................................................................................... 4545

10.1.310.1.3 CALIBRATION......................................CALIBRATION............................................................................................................................................................................................................................ 4747

10.1.3.1 10.1.3.1 MASS MASS CALIBRATION........................................................CALIBRATION.................................................................................................................................................................................. 4747

10.1.3.210.1.3.2 TEMPERATTEMPERATURE URE CALIBRATION..........CALIBRATION................................................................................................................................................................................................ 4848

10.1.3.310.1.3.3 CALIBRATION CALIBRATION REPORTREPORT.................................................................................................................................................................................................................................. 5151

10.1.410.1.4 PASSCODESPASSCODES .................................................................................................................................................................................................................................................................... 5252

10.1.4.110.1.4.1 FORGOTTEN FORGOTTEN PASSCODESPASSCODES...................................................................................................................................................................................................................... 5252

10.210.2 STORE AND RECASTORE AND RECALL PMB SETTING FROM ULL PMB SETTING FROM USB MEMORY.................................................................SB MEMORY..................................................................... 5353

11.011.0 SERISERIAL AL INTEINTERFARFACE.........................CE..................................................................................................................................................................................... 5656

11.111.1 RS-232 RS-232 HARDWAREHARDWARE...................................................................................................................................................................................................................................................................... 5656

11.211.2 USB USB SERIAL SERIAL HARDWAREHARDWARE .................................................................................................................................................................................................................................................... 5656

11.311.3 INPUT INPUT COMMANCOMMANDSDS ........................................................................................................................................................................................................................................................................ 5757

11.411.4 PRINTING PRINTING RESULTS......................................................................RESULTS................................................................................................................................................................................................ 5757

11.511.5 ANALYZER ANALYZER CONFIGURATCONFIGURATION THRION THROUGH THOUGH THE SERIAL E SERIAL INTERFACEINTERFACE .......................................................................................................... 6060

11.5.111.5.1 TEST TEST PARAMETEPARAMETERSRS ............................................................................................................................................................................................................................................ 6060

11.5.211.5.2 PMB PMB SETUP SETUP PARAMETPARAMETERS........................................................ERS.............................................................................................................................................................. 6161

11.5.311.5.3 ANALYZER ANALYZER RECALL RECALL PARAMETPARAMETERSERS .......................................................................................................................................................................................... 6262

11.5.411.5.4 REQUEST REQUEST VALUES VALUES OF OF PARAMETPARAMETERSERS................................................................................................................................................................................ 6262

11.611.6 CONTINUOUCONTINUOUS S OUTPUT.....................................................................................OUTPUT....................................................................................................................................................................... 6363

12.0 12.0 SPECSPECIFICAIFICATIONS TIONS & & FEAFEATURTURES...........................ES............................................................................................................................................... 6464

13.013.0 MENU MENU STRSTRUCTUCTURE.......URE........................................................................................................................................................................................................... 6767

14.014.0 SASAMPLE MPLE PREPPREPARARATATION................ION.................................................................................................................................................................................. 7373

15.015.0 GUIDAGUIDANCE NCE NOTENOTES...............................S..................................................................................................................................................................................... 7575

16.016.0 WARWARRARANTY NTY STASTATEMETEMENTNT............................................................................................................................................................................................ 7979