©AdamEquipmentCompany2019 1

CONTENTS

PN 3.05.6.6.15666, Rev A, November 2019

1.0 INTRODUCTION ....................................................................................................... 3

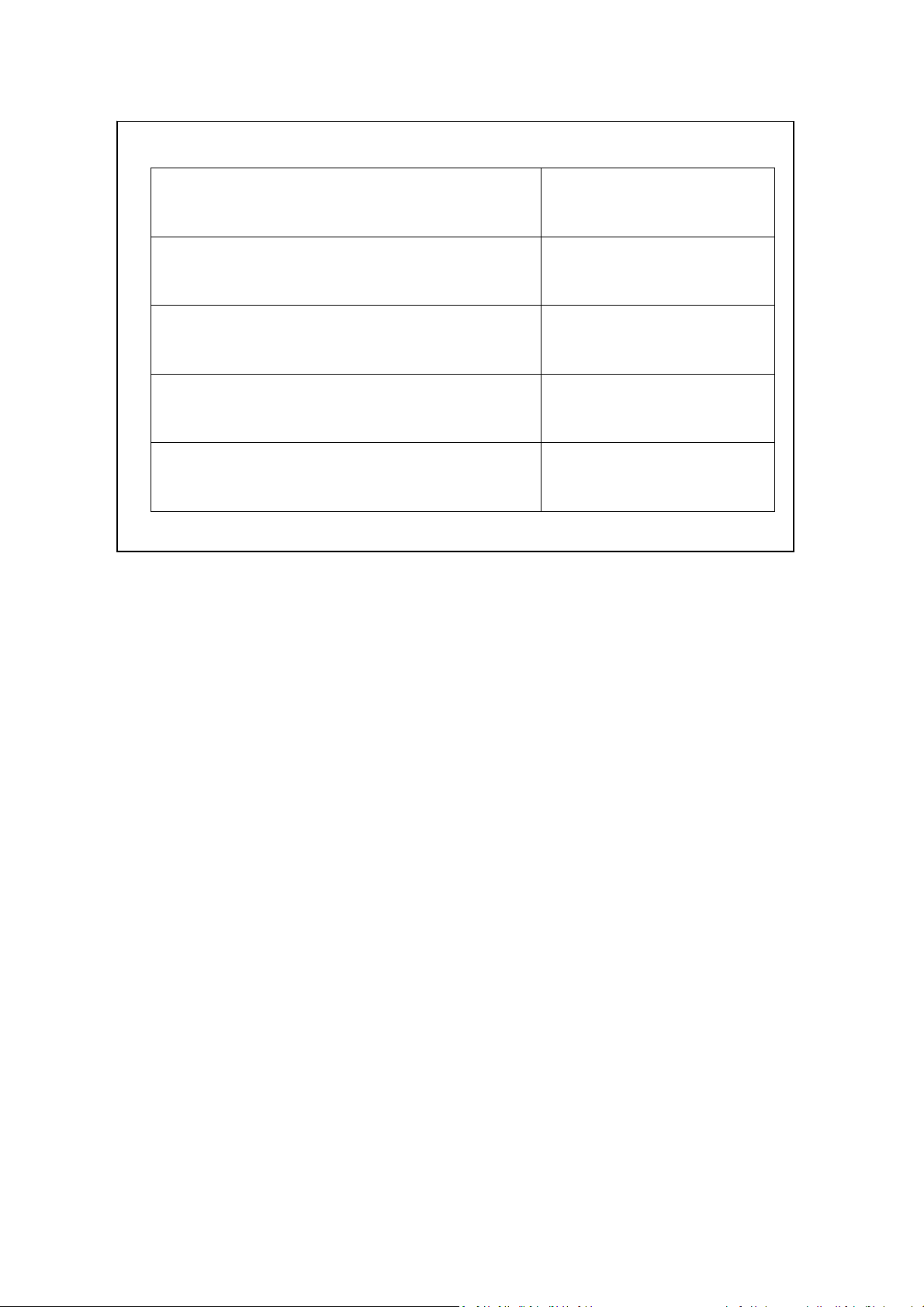

2.0 SPECIFICATIONS ..................................................................................................... 4

3.0 INSTALLATION ......................................................................................................... 5

3.1 UNPACKING .......................................................................................................... 5

3.2 LOCATING ............................................................................................................. 5

4.0 CONNECTION ........................................................................................................... 6

5.0 KEYPAD AND DISPLAY ........................................................................................... 7

5.1 DISPLAY ................................................................................................................ 7

5.2 DISPLAY ................................................................................................................ 9

5.2.1 SYMBOLS AND INDICATORS ............................................................................ 9

6.0 CALIBRATION COUNTER FOR APPROVED INDICATORS ................................. 10

7.0 BATTERY ................................................................................................................ 11

8.0 BACKLIGHT ............................................................................................................ 11

9.0 AUTO POWER OFF ................................................................................................ 11

10.0 OPERATION ........................................................................................................ 12

10.1 ZEROING .......................................................................................................... 12

10.2 TARING ............................................................................................................. 12

10.2.1 MANUAL TARE .......................................................................................... 12

10.3 WEIGHING ........................................................................................................ 13

10.4 PARTS COUNTING .......................................................................................... 13

10.5 CHECK-WEIGHING .......................................................................................... 15

10.5.1 SETTING UP WHILE WEIGHING ............................................................... 1 6

10.5.2 SETTING UP WHILE PARTS COUNTING OR % WEIGHING ................... 16

10.6 LIMITS STORING AND RECALLING ............................................................... 17

10.7 PERCENT WEIGHING ...................................................................................... 18

10.8 ANIMAL (DYNAMIC) WEIGHING ..................................................................... 20

10.8.1 ANIMAL WEIGHING PROCEDURE ........................................................... 21

10.9 ACCUMULATED TOTAL .................................................................................. 21

10.9.1 MANUAL ACCUMULATION ....................................................................... 22

10.9.2 AUTOMATIC ACCUMULATION ................................................................. 23

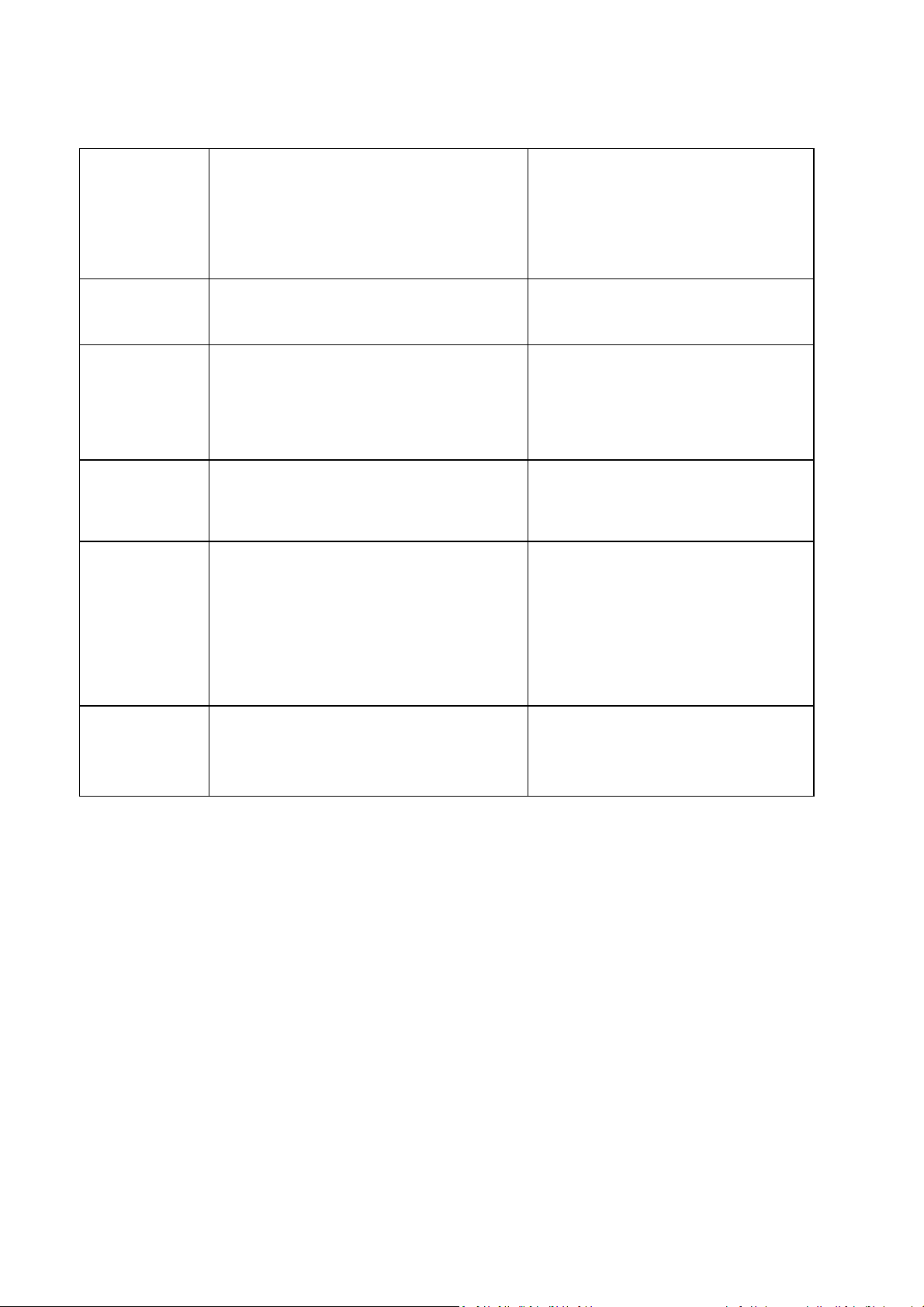

11.0 RS-232 SPECIFICATION ..................................................................................... 24

11.1 INPUT COMMANDS FORMAT ......................................................................... 28

12.0 CALIBRATION ..................................................................................................... 29

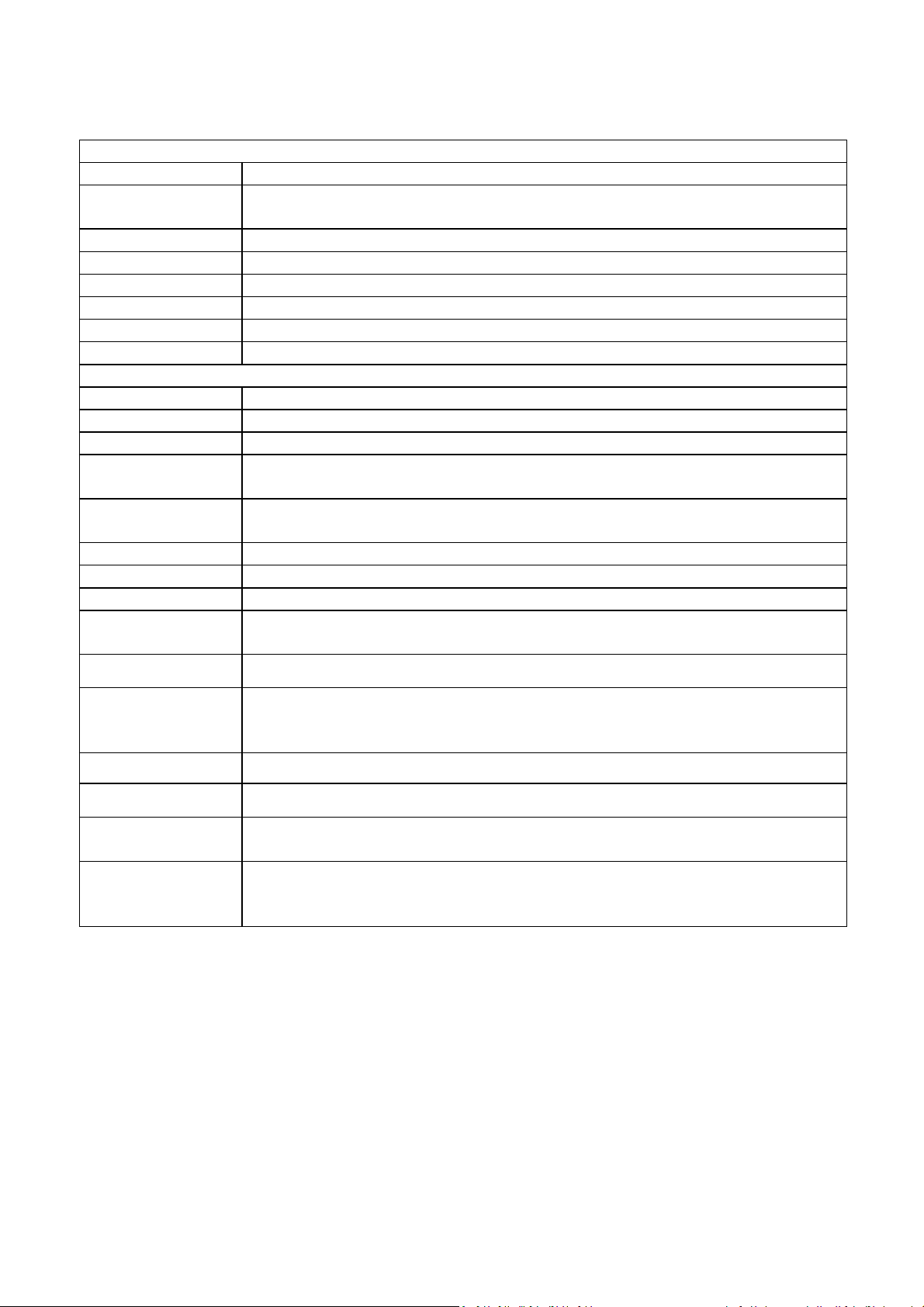

13.0 PARAMETER SETTINGS .................................................................................... 30

13.1 CHECK WEIGHING PARAMETERS ................................................................ 30

13.2 RS-232 PARAMETERS .................................................................................... 32

13.3 INDICATOR PARAMETERS ............................................................................ 34

13.4 PERCENT WEIGHING AND ANIMAL WEIGHING ........................................... 35

14.0 ERROR MESSAGES ........................................................................................... 36

15.0 SERVICE PARAMETERS .................................................................................... 37

15.1 USING “0000” TO ENTER THE CALIBRATION PARAMETER ...................... 37

15.2 USING “2006” TO ENTER THE SERVICE PARAMETERS ............................. 38

15.2.1 F1 -CALIBRATION ...................................................................................... 39

15.2.2 F2–DECIMAL POINT POSITION ................................................................ 40

15.2.3 F3 – CAPACITY .......................................................................................... 40

15.2.4 F4 –INITIAL ZERO RANGE ........................................................................ 41

15.2.5 F5 -RE-ZERO RANGE ................................................................................ 41