Adamczewski AD-MM 500 FE User manual

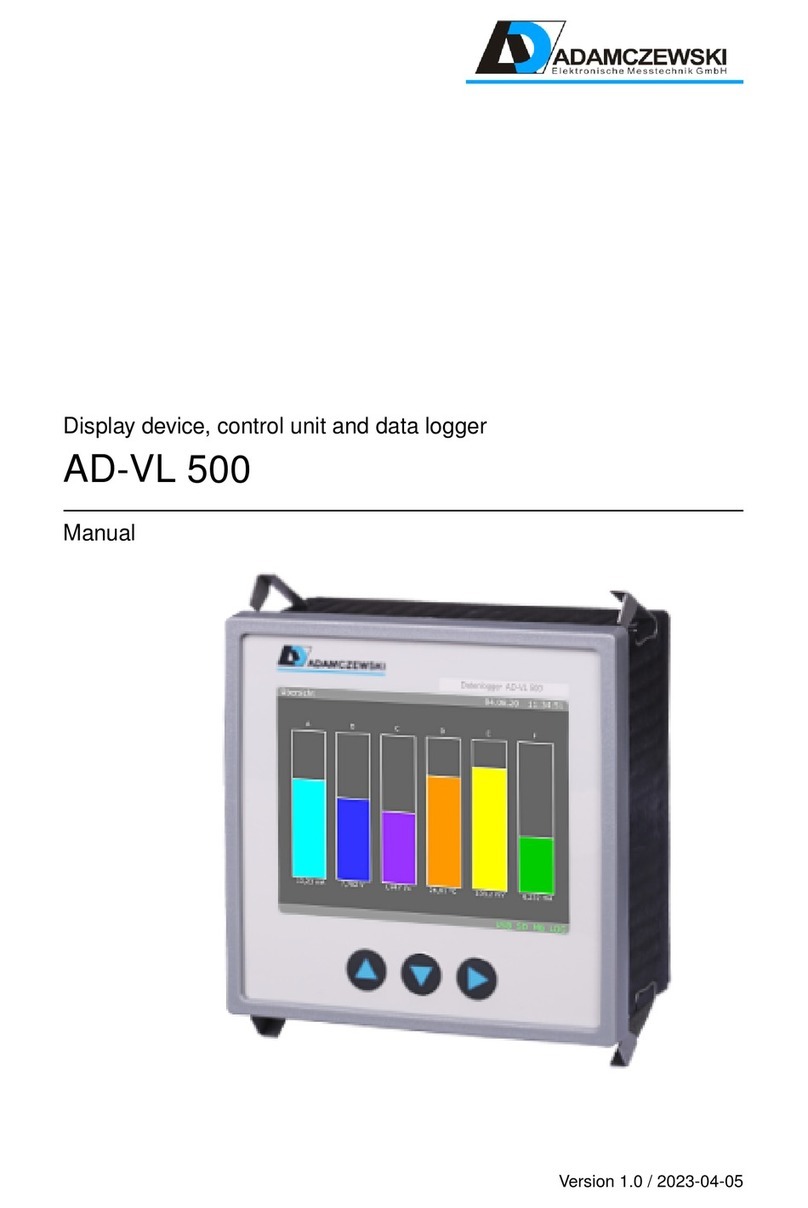

Display device, control unit and data logger

AD-MM 500 FE

Manual

Version 1.0 / 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

Contents

1 About this manual 3

2 Safety 4

3 Product description 6

4 Technical data 8

4.1 Supply......................................... 8

4.2 Housing ........................................ 8

4.3 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.4 EMC .......................................... 8

4.5 Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.6 RS485-Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.7 Configuration interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.8 Network interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.9 USB-Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.10Display......................................... 9

4.11 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Assembly and commissioning 10

6 Operation and menu navigation 11

6.1 Key functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3 Scroll display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.4 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4.1 Select slave and function . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.4.3 Info....................................... 17

6.4.4 Backup to USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Configuration 18

7.1 Logging ........................................ 18

7.2 Displays ........................................ 21

7.3 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4 Channels........................................ 27

8 Modbus 29

9 Wiring diagrams 32

10 Appendix 34

2 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

1 About this manual

This manual is part of the product.

•Read the manual carefully before using the device.

•Keep the manual for the entire service life of the product and have it available for reference.

•Pass the manual on to any subsequent owner or user of the product.

Structure of the warnings

Please consider the documentation. This symbol is intended to warn you of

possible hazards that could arise during assembly, commissioning and use.

•Here, actions to avoid the danger are available.

•...

Structure of the hazard warnings

Danger to life or serious injury. Disconnect the system and the unit from the

power supply before starting work..

•Here, actions to avoid the danger are available.

•...

3 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

2 Safety

Intended use

The operating, maintenance and servicing conditions prescribed in this man-

ual must be strictly observed. Maintenance conditions must be strictly ad-

hered to.

The AD-MM 500 FE is intended for connection to an RS-485 interface to which other devices are

connected in bus mode.

The AD-MM 500 FE can be connected to a PC or laptop via the configuration interface.

The AD-MM 500 FE is intended for installation in front panels of control cabinets.

The AD-MM 500 FE has a connection for the supply voltage and can be supplied with AC voltage

up to 250V AC or 24V DC.

Any other use is not in accordance with the intended use!Unauthorised conversions and modi-

fications to the product lead to considerable safety risks and are prohibited for safety reasons!

ADAMCZEWSKI elektronische Messtechnik GmbH is not liable for any damage resulting from

this or for damage or for damage resulting from improper use.

Malfunctions that may impair safety must be eliminated immediately! The installer must make the

manual available to the operator. The installer and the operator must have read and understood

the manual before starting their work.

Foreseeable misuse

In particular, this product must not be used in the following cases:

•In potentially explosive atmospheres. When operating in potentially explosive atmospheres,

sparking may cause deflagration, fire or explosion.

•Use on humans and animals.

Safe handling

This product complies with the state of the art and the recognised safety regulations. Each unit

is tested for function and safety before delivery.

Only operate this product when it is in perfect condition, taking into account the manual, the usual

regulations and guidelines as well as the applicable safety regulations and accident prevention

regulations.

Extreme environmental conditions affect the function of the product.

4 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

•Protect product from shocks

•Use product indoors only

•Protect product from moisture

Qualification of the staff

Installation, commissioning, operation, maintenance, decommissioning and disposal may only be

carried out by technically qualified personnel. Work on electrical parts may only be carried out by

trained in accordance with the applicable regulations and directives.

Changes to the product

Unauthorised modifications to the product can lead to malfunctions and are prohibited for safety

reasons.

Use of spare parts and accessories

The use of unsuitable spare parts and accessories can damage the product. Please use only

original spare parts and accessories from the manufacturer.

Disclaimer

The manufacturer accepts no liability or warranty for damage or consequential damage resulting

from failure to comply with the technical regulations, instructions and recommendations. The

manufacturer is not liable for any costs or damage incurred by the user or third parties as a result

of the use of this appliance, especially in the event of improper use, misuse or malfunctions of

the connection, malfunctions of the appliance or connected devices.

5 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

3 Product description

The AD-MM 500 FE is a display, control unit and data logger for front panel installation.

The display is a 3.5” TFT display with graphics capability.

The AD-MM 500 FE can be connected via its RS-485 interface to one or more units of the ADAM-

CZEWSKI elektronische Messtechnik GmbH or to units of other manufacturers. Any data from

these devices can be displayed and/or logged to an internal SD memory card. The stored data

can be transferred to a USB stick at any time for further analysis.

The AD-MM 500 FE communicates with the connected devices via the Modbus protocol and is

always the Modbus master.

The freely definable displays and display elements can only be created or

changed with the Configuration program AD-Studio . If these are to be created

or changed by the customer, the USB adapter VarioPass available from the

manufacturer is required

.

Features

•Display unit, operating unit and data logger for front panel installation

•Display via graphic-capable TFT display

•RS-485 interface with Modbus-RTU protocol

•Interface for configuration or firmware update

•Creation of own displays with the Configuration program AD-Studio

•Up to 10 configurable displays

•Up to 40 configurable display elements in total

•Up to 12 configurable display elements per display

•Up to 32 configurable Modbus channels.

•Display element types. Numeric, bar, LED, time graph, drag pointer.

•Display element properties such as position, size, labelling, colours freely definable.

•Display element functions such as colour change through hysteresis or window function

definable.

Scope of supply

•AD-MM 500 FE

•All required pluggable terminals.

•This instruction manual

For configuration with the Configuration program AD-Studio you need the optional programming

adapter VarioPass.

6 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

Order code

AD-MM 500 FE RS-485 interface, configuration interface, USB port, Ethernet.

VarioPass (option) USB adapter for configuration and firmware update of the AD-MM 500 FE .

Display and operating elements

The AD-MM 500 FE has a colour graphics-capable TFT display for showing the data and three

buttons for operation and configuration.

TFT-Display

Up SetDown

Figure 3.1: Display and operating elements of the AD-MM 500 FE

key ’Up’ Scroll up; increment digit

key ’Down’ Scroll down; decrement digit

key ’Set’ Confirm input

7 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

4 Technical data

4.1 Supply

Name Value

Supply voltage 20 ... 253 V AC/DC

Max. Power consumption 2.0W / 4.0VA

4.2 Housing

Name Value

Dimensions (WxHxD) 96x96x63 mm

Panel cut-out 92x92 mm

Protection class front cover IP 54

Protection class terminals IP 20

Connection technology removable screw terminals

Construction panel housing

Weight 350 g

4.3 Environmental conditions

Name Value

Ambient temperature 0 ... 50 ◦C

Storage and transport -10 ... 70 ◦C (avoid condensation)

Degree of contamination 2

4.4 EMC

Name Value

Product family standard EN 61326

Emitted interference EN 55011, CISPR11 Class B

4.5 Electrical safety

Name Value

Product family standard EN 61010-1

8 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

4.6 RS485-Interface

Name Value

Connector 3-pin socket 3.81mm pitch

Standard RS-485

Function Modbus Master

Protocol Modbus-RTU

Max. Number of participants 32

Max. Bus length 100 m

Bus termination 120 Ohm (both ends at bus end)

4.7 Configuration interface

Name Value

Connector jack socket 3mm

Standard UART, manufacturer specific

Function Configuration

4.8 Network interface

Name Value

Connector RJ45 socket

Standard Ethernet

Function reserve for later extensions

4.9 USB-Interface

Name Value

Connector socket type A for USB stick

Standard USB 1.0, 2.0

Function data transfer

4.10 Display

Name Value

Type 3.5” TFT

Resolution 320x240 Pixel

4.11 Operation

Name Value

Type 3 short-travel keys

9 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

5 Assembly and commissioning

Electrical connection

The terminals of the auxiliary voltage inputs are dangerous to touch

.

•Disconnect the mains voltage and secure it against reconnection.

•Ensure that the connections are protected against accidental contact.

•Protect all connections against electrostatic discharge.

Commission the appliance

•Switch off the power supply.

•Check that there is no voltage.

•Mount the unit.

•Connect power supply and RS-485.

•Switch on power.

•Configure the unit. See chapter 6 for details.

•Check function.

10 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

6 Operation and menu navigation

6.1 Key functions

The menu is controlled by the three keys ’Up’, ’Down’ and ’Set’, see chapter 3. The following

abbreviations apply to the key functions:

up Press the ’Up’ key briefly.

UP Press the ’Up’ key for longer than approx. 3 sec.

down Press ’Down’ key briefly

DOWN Press the ’Down’ key for longer than approx. 3s

set Press the ’Set’ button briefly.

SET Press the ’Set’ key for longer than approx. 3s

NO key combinations are used in the entire menu (one-finger menu)

.

11 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

6.2 Normal operation

Modbus error

Normal operation

SET

Scroll display

SET

Main menu

set

Modbus error

Figure 6.1: Menu structure of the AD-MM 500 FE

After switching on the unit, you reach the state Scroll display as shown in the picture 6.1.

Press SET to enter the Main menu. From the main menu press SET to return to the display.

In Scroll display the configured displays can be scrolled through and displayed with ’up’ or

’down’ or automatically.

In the Main menu (see chapter 6.4), among other things

•Settings can be made on the AD-MM 500 FE

•the logged data is saved on a USB stick

•Settings of a slave can be made via its slave menu

•The simulation of an input of a slave can be executed

Since the AD-MM 500 FE often accesses the connected slaves to display the data as well as in

the main menu, there is a higher-level error monitoring of the master-slave data traffic. If an error

is detected, the status Modbus error is immediately branched to. The error is displayed and

must be confirmed with ’set’.

Possible errors are e.g.

12 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

•Timeout. The slave does not answer. Reasons can be an incorrect slave address, the slave

is not connected or does not respond for another reason.

•Slave Exception. Reasons can be, for example, an incorrect number of data words or an

incorrect or non-existent register.

6.3 Scroll display

Scroll Display

UP || DOWN

Scroll manual Scroll automatic

up /

Display++

down /

Display--

Timer /

Display++

Figure 6.2: Scrolling the displays of the AD-MM 500 FE manually or automatically

The displays can be scrolled up and down either manually with the ’Up’ and ’Down’ keys, as

shown in the image 6.2, or automatically time-controlled. When starting, you can first scroll

through Scroll manual with ’up’ and ’down’. With ’UP’ or ’DOWN’ you branch to Scroll

automatic, where after a corresponding interval you automatically scroll up or down. With ’SET’

you get back to Scroll manual.

The time interval after which it is automatically scrolled up or down can be set

with the Configuration program AD-Studio , the standard time is 5s.

13 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

6.4 Main menu

Main menu

Select slave

Options

Info

Backup to USB

Select Function

Slave menu

Slave simulation

Select Slave

001

Options

User

Language

Brightness

Drag pointer

Datetime

Info

Backup to USB

Slave menu

Slave simulation

Figure 6.3: Main menu of the AD-MM 500 FE

The main menu is used to access a slave on the one hand and to make settings on the AD-MM

500 FE or perform device functions on the other. Settings for the AD-MM 500 FE can be made

under Options.

6.4.1 Select slave and function

In order to work with the slave, you must first set the slave address under Select slave. The

default value is ’1’. Then under Select function you can choose whether you want to make

settings in the slave menu or a simulation.

14 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

Slave menu

Slave menu

Edit parameter

Execute device function

set

[Menu row==Function]

[Menu row==Parameter]

Menu navigation

Figure 6.4: Edit the slave menu with the AD-MM 500 FE

To work with the slave, first select the slave address under Select slave and then under

Select function the slave menu. The AD-MM 500 FE now fetches all the data it needs to

display the menu from the slave. The image 6.4 shows how to navigate in the slave menu, edit

parameters and execute device functions.

The content of the slave menu depends on the device type of the slave. The

way the menu is displayed and operated, however, is always the same, since

these functions are carried out by the AD-MM 500 FE .

15 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

Slave simulation

Slave simulation

Select simulation channel

Input 1 [10,3mA]

Input 2 [5,2mA]

Select display SET /

to main menu

set

UP || DOWN

Manual simulation

Automatic simulation

set / simulation value=measured value

up\

sim.value++

down\

sim.value--

upTimer\

sim.value++ downTimer\

sim.value--

up\

Display++

down\

Display--

Figure 6.5: Run slave simulation with AD-MM 500 FE

The image 6.5 shows how the simulation of an input signal of the slave can be carried out. To run

the slave simulation, first select Select slave in the main menu to determine the slave address.

Then select Slave simulation in the menu Select funktion.

The AD-MM 500 FE now fetches the available simulation channels from the slave and displays

them in the Select simulation channel menu. Only one simulation channel can be selected

and edited at a time. If a slave offers several simulation channels, all other channels will continue

to be recorded as analog inputs.

After selecting the desired channel, you get to Manual simulation. The display is the same

as in normal operation, with the difference that information on the simulation is shown in orange

in the status line. The simulation value can now be incremented and decremented with ’up’ and

’down’. The current measured value of the channel to be simulated is read from the slave as the

start value for the slave simulation.

With ’UP’ or ’DOWN’ you get to Automatic simulation. Here the simulation value is incre-

mented or decremented once per second.

16 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

During manual or automatic simulation, the ’Set’ key has a different meaning:

’set’ takes you to Anzeige ausw¨ahlen and you can select the display as with

Scroll Display.

The simulation can be ended in Manual simulation with SET. If you do not press a button, the

simulation is ended after 3 minutes. In Automatic simulation the simulation continues perma-

nent, the simulation value is ramped up and down. The simulation is not ended automatically!

6.4.2 Options

The following settings can be made in the Optionen menu:

•User. Here you can choose between ’Admin’ and ’Standard’. Depending on the user set-

ting, certain data and functions of the AD-MM 500 FE and also of the slave are not or only

partially accessible.

•Language. The menu language for the AD-MM 500 FE and also the slave menu can be

selected here.

•Brightness. The brightness of the TFT backlight can be set in % here.

•Drag pointers. All drag pointers can be reset here. Note: A drag pointer runs in the back-

ground for each channel, regardless of whether it is displayed or not.

•Date. The date for the display and the log function can be set here.

6.4.3 Info

Various information on the status of the AD-MM 500 FE and the connected slaves are displayed

under Info.

6.4.4 Backup to USB

Under Backup auf USB the content of the internal SD memory card can be transferred to a USB

stick that has been plugged into the back of the device.

The menu item Backup auf USB only appears in the menu if a USB stick has

been inserted and recognized by the AD-MM 500 FE .

17 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

7 Configuration

The information in this chapter refers to the configuration of the AD-MM 500 FE with the Config-

uration program AD-Studio . All the designations used can be found there. The configuration of

the parameters via the menu of the AD-MM 500 FE is not possible due to the large number of

parameters.

7.1 Logging

Whether to log is determined once per second, see picture 7.1. Logging can be done permanently

without a condition or conditionally. Conditional logging can be controlled by a limit value, a trend

or by a time condition. It also checks the availability of the hardware.

Grenzwert-Trigger,

Trend-Trigger

Zeit-Trigger

Hardwarestatus

RTC

EEPROM

SD-Karte

Hysterese

Fenster

Trend steigend

Trend fa end

Trend g eich

Interva einma ig

Interva täg ich

Startzeit dauernd

Zeitstempe

Log-ModusTriggerkana

Kana [1]

Kana [32]

&

Log-Freigabe

Triggerung

Hardware OK

Loggen

1/s

Dauernd

Figure 7.1: Determining the log enabling of the AD-MM 500 FE

The following parameters are provided to control logging:

Parametername Default value Range Unit

Log enable No No,

Yes

18 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

Parametername Default value Range Unit

Log mode Continuous Continuous,

Hysteresis,

Window,

Trend Rising,

Trend falling,

Trend equal,

Interval once,

Interval daily,

Start time continuous

Trigger channel 1 1 ... 32

Limits 0.0...1.0 float range trigger chan-

nel

Trend delta 1,0 1E-6...1E6 trigger chan-

nel

Trend time 10 1...3600 s

Start time one-time 11.11.2018 11:11:11

End time once 11.11.2018 11:11:12

Start time daily 11.11.2018 11:11:11

End time daily 11.11.2018 11:11:12

Start time continuous 11.11.2018 11:11:12

To start and stop the logging process quickly, use the parameter Log

Release.

Continuous logging

If logging is to be continuous and without condition, the following parameters must be set.

1. Log mode = ’Continuous’

2. Log enable = ’Yes’

The trigger conditions for limit, trend and time are not considered. The log operation starts

immediately and does not end until Log enable = ’No’ is set or another log mode is selected.

Hysteresis-triggered logging

If the trigger condition is to be done by a hysteresis function, the following parameters must be

set.

1. Log mode = ’Hysteresis’

2. Trigger channel = ’1...32’. Channel number for determining the value

3. Limits = ’Your values for lower and upper limit’

4. Log enable = ’Yes’

19 / 36 1.0 2021-05-19

Adamczewski GmbH Manual AD-MM 500 FE

The hysteresis function is enabled when the trigger channel value exceeds the upper limit. It is

deactivated when the value falls below the lower limit.

Window-triggered logging

If the trigger condition is to be done by a window function, the following parameters must be set.

1. Log mode = ’Window’

2. Trigger channel = ’1...32’. Channel number for determining the value

3. Limits = ’Your values for lower and upper limit determining the window’.

4. Log enable = ’Yes’

The window function is enabled when the trigger channel value is within the limits. It is disabled

when it is outside the limits.

Trend-triggered logging

If the trigger condition is to be done by a trend function, the following parameters must be set.

1. log-mode = ’Trend increasing, Trend decreasing or Trend equal’

2. trigger channel = ’1...32’. Channel number for determining the value

3. trend delta = ’Signal difference to be supervised’. Signal difference from which a

trend is detected.

4. Trend Time = ’Time Interval’. Time interval between measurements.

5. Log enable = ’Yes’

Time-triggered logging

Time-triggered logging can be done once,daily, or from a certain time on.

If once is to be logged at a certain time interval, the following parameters must be set.

1. Log mode = ’Interval once’

2. Start-time unique = ’DD.MM.YYY hh.mm.ss’. Start date and time

3. End time unique = ’DD.MM.YYYY hh.mm.ss’. End date and time

4. Log enable = ’Yes’

Logging will occur if the current time is between Start-time unique and End-time unique.

If daily is to be logged at a certain time interval, the following parameters must be set.

1. Log mode = ’interval daily’

2. Start time daily = ’DD.MM.YYY hh.mm.ss’. Start time of the log operation.

3. End time daily = ’DD.MM.YYYY hh.mm.ss’. End time of the log operation.

20 / 36 1.0 2021-05-19

Table of contents

Other Adamczewski Data Logger manuals