ADAPCO Guardian 95 G4 User manual

GUARDIAN MODEL

95 G4

©2017

GUARDIAN ULV EQUIPMENT

PRODUCT OF ADAPCO, INC.

2

REMEMBER – YOUR ULV COLD FOG GENERATOR IS ONLY AS SAFE AS

THE OPERATOR!

Hazard control and accident prevention are dependent upon the awareness, concern,

prudence, and proper training of the personnel involved in the operation, transport,

maintenance, and storage of the equipment.

FAILURE TO FOLLOW SAFE OPERATING PRACTICES

MAY RESULT IN INJURY

• Keep all shrouds and guards in place especially the drive belt shroud.

• Before performing any maintenance or service, stop the machine and

disconnect the battery.

• Keep hands, feet and clothing away from power-driven parts.

• Read this manual completely as well as other manuals that come with this

equipment.

• Use ear protection when in close vicinity of equipment when powered up.

• UDo NotU direct air blast from nozzle directly at any part of your body.

• Use appropriate PPE when loading tanks and performing calibrations.

This manual covers the operating instructions and

illustrations for:

Guardian 95 G4 (Std. Fixed Flow ULV Sprayer)

3

TABLE OF CONTENTS

MODEL 95 G4

Contents

SPECIFICATIONS ...................................................................................................................................... 5

GENERAL INFORMATION ......................................................................................................................... 7

INTRODUCTION ................................................................................................................................... 7

SERVICING THE ENGINE ....................................................................................................................... 7

DIRECTION REFERENCE ........................................................................................................................ 8

GENERAL SAFETY INFORMATION ......................................................................................................... 9

SIGNAL WORDS ................................................................................................................................. 10

BEFORE OPERATION CONSIDERATIONS ............................................................................................. 11

OPERATION CONSIDERATIONS .......................................................................................................... 12

MAINTENANCE AND STORAGE .............................................................................................................. 14

FAMILIARIZATION ................................................................................................................................. 15

OPERATOR CONTROLS ....................................................................................................................... 15

AIR PRESSURE GAUGE ....................................................................................................................... 16

PRESSURE SWITCH ............................................................................................................................ 16

FORMULATION FILTER ....................................................................................................................... 16

FORMULATION TANK ........................................................................................................................ 16

INSECTICIDE PUMP ............................................................................................................................ 17

PULSE DAMPENER ............................................................................................................................. 17

FLUSH TANK AND VALVE ................................................................................................................... 17

ATOMIZATION NOZZLE ...................................................................................................................... 17

INSTALLATION ....................................................................................................................................... 18

COLD FOG GENERATOR (ULV SPRAYER) CONTENTS ........................................................................... 18

FACTORY FLUID LEVELS ..................................................................................................................... 19

VEHICLE INSTALLATION ..................................................................................................................... 20

ENGINE STARTING ............................................................................................................................. 22

Key Start ........................................................................................................................................ 23

4

Recoil Start .................................................................................................................................... 24

Remote Pendant Start ................................................................................................................... 24

MAINTENANCE ...................................................................................................................................... 24

CHECKING ENGINE CRANKCASE OIL LEVEL ......................................................................................... 24

CHANGING ENGINE CRANKCASE OIL .................................................................................................. 25

ENGINE AIR CLEANER ........................................................................................................................ 25

BLOWER LUBRICATION ...................................................................................................................... 26

CLEANING THE MACHINE .................................................................................................................. 26

BELT TENSION ................................................................................................................................... 26

CALIBRATION ........................................................................................................................................ 29

FLOW CALIBRATION FMI PUMP ......................................................................................................... 29

DROPLET SPECTRUM CALIBRATION ................................................................................................... 30

FLOW DIAGRAM .................................................................................................................................... 32

TROUBLESHOOTING .............................................................................................................................. 32

NOTES: .................................................................................................................................................. 34

GUARDIAN 95 G4 ULV 1-YEAR LIMITED WARRANTY .............................................................................. 35

Appendix A:........................................................................................................................................... 37

Appendix B: ........................................................................................................................................... 38

5

SPECIFICATIONS

Guardian 95 G4

Engine

Make Kohler

Model Command PRO CH395-3031

Horse Power 9.5

Engine Type Air cooled, 4-stroke, OHV, Single cylinder

Bore & Stroke 78 x 58 mm (3.1 x 2.3 in)

Displacement 277 cc (16.9 cu. In)

Ignition System Solid-state

Direction of Rotation Counterclockwise facing the PTO shaft

Starting System Electric start

Charging System 10 A

Dry Weight 27.8kg (61.5 lbs.)

Fuel Unleaded gasoline

Safety Switch Low oil shutdown

Blower

Make Dresser Roots

Model URAI-33UJ

Dia. Outlet/Inlet 2”- S

Max Performance 3550 RPM

9 PSIG=169 CFM

4 PSIG=186 CFM

Configuration Horizontal mount

Left hand drive facing the PTO shaft

Weight 69 lbs.

Shaft Diameter 0.75 (3/4”)

Paint Black

Drive Couple

Method Belt, banded double V

Typical Size 2/3VX425

Nozzle

Model “VAAT” (Vectored Air Atomization Technology”

Size 2” pipe

Material Aluminum 6061-T6

Chem. Feed Rear center, 3/8” OD tube, 1/4” NPT

No. of Pieces 2, nozzle body, nozzle hood

Mounting 3.25” OD flange, 2.85” 4-hole bolt pattern

Equally spaced, 1/4-20 fasteners

Nozzle Rotation 360º horizontally, 360º vertically

Capacity

Fuel 1.5 Gallon standard

Formulation 15 Gallon (56.7 liters)

6

Lockable formulation tank cap or non-lockable, std option

Flush 1 quart (1.42 liter)

Chemical Pump

Make FMI for fixed or variable flow

Model QB

Type Positive displacement Piston

Piston 3/8” ceramic

Flush valve

Configuration 3-way diverter

Power 12V dc

Consumption 7 watts

Cut-Off Valve

Material Stainless

Rating 5 lbs

Gauges

Pressure 0-15 PSI, glycerin filled, panel mounted

with pressure switch pump lockout

Throttle Control

Throttle Solenoid actuator 12V dc

Choke Control

Choke Solenoid actuator 12V dc

Finish

Type Epoxy Powder Coat chassis

Dimensions

Length 37.8”

Width 29.8”

Height 28” horizontal, 32.9” nozzle pointed vertical

Weight 340 lbs. (dry)

7

GENERAL INFORMATION

INTRODUCTION

Your ULV cold fog generator, known from this point on in this manual as “ULV Sprayer”, was built

to the highest standards in the industry. However, the prolonged life and maximum efficiency of

your sprayer equipment depends on you following the operating, maintenance and adjustment

instructions in this manual.

If additional information or service is needed, contact ADAPCO or if applicable, your authorized

ADAPCO service representative.

We encourage you to contact ADAPCO for repairs. As the designer and manufacturer of this

equipment, ADAPCO professionals are informed and trained on the latest methods to service this

equipment and provide prompt and efficient service in the field or at the service shop and carry

a full line of Guradian ULV service parts and accessories.

THE REPLACEMENT OF ANY PORTION THIS PRODUCT BY OTHER THAN THE

MANUFACTURER’S AUTHORIZED REPLACEMENT PART MAY ADVERSELY AFFECT THE

PERFORMANCE, DURABILITY OR SAFETY OF THIS PRODUCT. USE OF OTHER THAN

ADAPCO/GUARDIAN ULV REPLACEMENT PARTS WILL VOID THE WARRANTY.

For some pictoral clarity, some illustrations and fugures in this manual may show shields, guards,

or shrouds removed. Under no circumstances should your ULV sprayer be operated without

these devices in place.

All information is based upon product information available at the time of approval for printing.

ADAPCO, Inc. reserves the right to make changes at any time without notice and without

incurring any obligation.

SERVICING THE ENGINE

The detailed servicing and repair of the engine is not covered in this manual; only routine

maintenance and general service instructions are provided. For service of the engine during the

limited warranty period, it is important to contact ADAPCO and if applicable, an authorized

ADAPCO service representative or an authorized servicing agent of the engine manufacturer.

UAny unauthorized work done on the engine during the warranty period may void your

warranty.

8

DIRECTION REFERENCE

The “Right” and “Left”, “Front” and “Rear” of the machine are refereced from the operator’s right

and left when standing behind the vehicle and facing in the normal forward direction of the

vehicle. Additionally, the ULV sprayer is designed to be placed in the back of a vehicle with the

engine and blower closest to the rear bumper of the vehicle.

Forward

Rear

Left

Right

9

SAFETY INFORMATION

GENERAL SAFETY INFORMATION

UYour ULV sprayer is only as safe as the operator. Carelessness or operator error may result in

serious bodily injury or death.U Hazard control and accident prevention are dependent upon the

awareness, concern, prudence, and proper training of the personnel involved in the operation,

transport, maintenance, and storage of the equipment. UMake sure every operator is properly

trained and throughly familiar with all of the controls before operating this spray equipment. The

owner/user can prevent and is responsible for accidents or injuries occurring to the themselves,

other people or property.

A replacement copy of this manual is available from ADAPCO, Inc. or if applicable, an authorized

dealer or reseller of this equipment at:

ADAPCO, Inc.

Attn: Customer Service Department

550 Aero Lane

Sanford, FL 32771

Or call 1-800-367-0659

Additionally, a copy of this manual can be downloaded from the ADAPCO website at

HUwww.MyADAPCO.comUH by using the model number.

READ THIS OPERATOR’S MANUAL

BEFORE ATTEMPTING TO START

OR USE THIS SPRAYER.

10

SIGNAL WORDS

This general symbol means “Attention! Become Alert! Your

Safety is involved!” The symbol is used with the following signal

words to attract your attention to safety messages found on the

decals on the machine and throughout this manual.

The message that follows the symbol contains important information about safety. To avoid

injury and possible death, carefully read the message! Be sure to understand the causes of

possible injury or death.

Signal Word

The Signal word is a distinctive word found on the safety decals on the machine and throughout

this manual that alerts the viewer to the existence and relative degree of the hazard.

The signal word “DANGER” denotes that an extremely

hazardous situation exists on or near the machine that could

result in high probability of death or irreparable injury if proper

precautions are not taken.

The signal word “WARNING” denotes that a hazard exists on or

near the machine that can result in injury or death if proper

precautions are not taken.

The signal word “CAUTION” is a reminder of safety practices on

or near the machine that could result in personal injury if proper

precautions are not taken.

Your safety and the safety of others depend significantly upon your knowledge and

understanding of all correct operating practices and procedures of this machine.

11

BEFORE OPERATION CONSIDERATIONS

1. Become familiar with the safe operation of the ULV sprayer and the operator controls.

2. Never allow children to play on or with the machine. Never allow children to ride in a

vehicle sitting next to or on top of this machine.

3. Always wear appropriate clothing while operating, maintaining, servicing or calibrating

this machine. The wearing of such items as safety glasses, aprons, gloves, and safety

shoes is advisable and may be required by some local ordinances or insurance regulations.

4. Always wear hearing protection. Operating this machine for prolonged periods of time

without hearing protection can cause permanent loss of hearing.

5. Keep the Spray machine and attachments in good operating condition. Keep all shields,

guards, or shrouds in place. If a shield, safety device or decal is defective or damaged,

repair or replace it before operating the machine.

6. Fill the fuel tank with clean, fresh, unleaded gasoline with a minimum octane rating of 87.

To avoid personal injury or property damage, use extreme care in handling gasoline.

Gasoline is extremely flammable and the vapors are explosive.

a. Keep flammable objects (cigarettes, matches, etc.), open flames and sparks away

from the fuel tank and fuel container.

b. Use only an approved gasoline container.

c. DO NOT add fuel to a running or hot engine. Allow the engine to cool for several

minutes before adding fuel.

d. Never fuel the machine indoors or in a small enclosed area without ventilation.

e. Never store the sprayer or fuel container where there is an open flame, spark or

pilot light such as on a water heater or other appliance.

f. Never fill containers inside a vehicle or on a truck or trailer bed with a plastic bed

liner. Always place the container on the ground away from your vehicle before

filling.

12

g. Keep the nozzle in contact with the rim of fuel tank or container opening at all

times until fueling is complete. We recommend not using a nozzle lock-open

device.

h. If fuel is spilled on clothing, change clothing immediately.

i. Replace gas cap and tighten securely.

7. Fill chemical tank to the indicated full level not to exceed 15 U.S. gallons.

a. Keep fill nozzle securely in the opening at all time while chemical is being

transferred. We recommend not using a nozzle lock-open device.

b. Wear appropriate personal protective equipment while filling chemical tank as

required by the specific label of the product being filled.

c. Ensure chemical tank filling is accomplished in a well ventilated area.

d. Affix an approved label to the chemical tank indicating its contents after filling.

e. Thoroughly clean hands after handling chemical filling equipment.

OPERATION CONSIDERATIONS

1. DO NOT permit untrained personnel to operate the machine.

2. Before operating this sprayer, familiarize yourself with all sprayer functions and

engine controls. Knowing the location, function and operation of these controls is

important for safe and efficient operation.

3. DO NOT touch the engine muffler or any part of the exhaust system while running;

wait several minutes for the engine and exhaust to cool and check for heat before

doing so.

4. Blower housing and tubing to the nozzle including swivel elbows and nozzle become

very hot during prolonged operation. DO NOT touch any of these areas while running;

wait several minutes allowing these components to cool before touching.

5. DO NOT operate the engine without the blower intake air filter housing being

installed. Debris, cleaning rags or clothing can be sucked into the blower causing

potential damage to the blower or injury to operators.

6. DO NOT direct the air blast from the nozzle at any portion of the body and especially

the face. High volume air can penetrate the skin and cause serious injury even death.

Always point the nozzle in an upward- attitude when sprayer is running and above

13

head level for those on the ground. It is not recommended for anyone to be standing

above the level of the nozzle when running even if the machine is mounted securely

on a vehicle.

7. NEVER walk directly into the air/chemical blast from the nozzle when insecticide or

any other formula is being atomized.

8. DO NOT direct the air/chemical discharge toward bystanders or allow anyone near

the machine while in operation.

9. DO NOT run the engine inside a building or a confined area without proper ventilation.

Exhaust fumes are hazardous and contain carbon monoxide which can cause brain

injury and death.

10. DO NOT operate the machine under the influence of alcohol or drugs.

11. Use care when loading or unloading the machine onto a truck or trailer.

12. Do not change the engine governor settings to over-speed the engine. See the engine

operator’s manual for information on engine settings.

13. NEVER leave the machine running unattended.

14

MAINTENANCE AND STORAGE

1. Allow only trained personnel to service the ULV spray machine.

2. Park the vehicle or place the machine on level ground for fluid level verification.

3. Never make adjustments to the machine with the engine running unless specifically

instructed to do so. If the engine is running, keep hands feet and clothing away from

moving parts.

4. Stop engine and remove or disconnect spark plug wire(s) to prevent accidental

starting of the engine when servicing or adjusting the machine. Wait for all movement

to stop before adjusting, cleaning or repairing.

5. Keep all nuts, bolts and screws tight, to ensure the machine is in safe working

condition.

6. The engine must be shut off before checking the oil or adding oil to the crankcase.

7. Let the engine cool before storing.

8. DO NOT store the machine near an open flame.

9. Shut off fuel while storing or transporting.

10. To shut off engine for prolonged periods of time or seasonal storage, drain the fuel

tank, start the engine and let the engine run out of fuel before storing.

15

FAMILIARIZATION

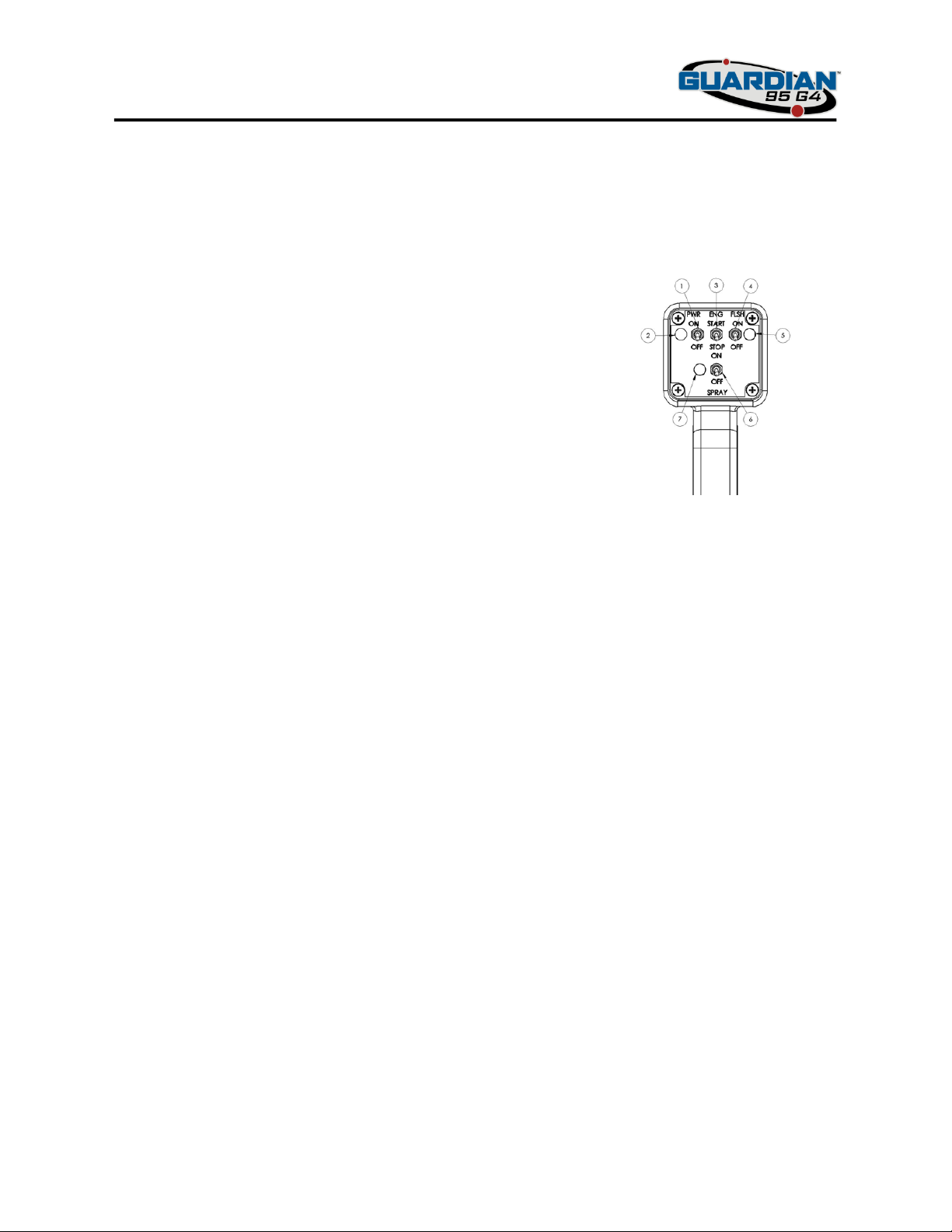

OPERATOR CONTROLS

The below illustration shows the standard operator control pendant and its functions:

1. Power switch when asserted (turned on) applies

power to the control pendant as well as provides

operating voltage to allow fuel flow to the engine.

2. RED LED (Light Emitting Diode) when illuminated

implies the power switch has been turned on and

ready to receive commands.

3. Engine on-off-start switch is a 3 position switch that

controls the status of the sprayer’s engine. When in

the OFF position, a control voltage is sent to the relay

beside the engine. When this relay is energized, the engine’s ignition system is shorted

to Ground. When in the ON position, the engine is ready to run and the ignition is ready.

The START position is a spring loaded momentary switch that engages the engines starter

motor and will continue to engage the starter until the engine is started or the switch is

released.

4. Flush switch when in the ON position sends a control voltage to the 3-way electric

solenoid valve which is connected to both the flush tank and the main formulation tank.

Selecting the flush ON position selects the contents of the flush tank to be pumped

through the insecticide pump when the spray switch is turned on.

5. Yellow LED when illuminated implies the flush tank has been selected.

6. Spray on/off switch turns the insecticide pump on and off when this switch is asserted. If

the sprayer is running (engine on) and the spray switch is asserted, the pump will begin

to run at a calibrated rate. If the engine is not running and the toggle switch on the pump

electronic enclosure is in the down position, the pump will not run when the spray switch

is turned on.

Additionally, the Spray on/off switch when asserted applies a control voltage to the

throttle solenoid (if equipped) increasing engine RPM to a preset (mechanical) position.

When the Spray switch is turned off, the engine reduces to an idle speed. Once ULV

sprayer is warmed up, the throttle should be set to the desired RPM or pressure at which

the applicator wishes to atomize the chemical material.

7. Green LED when illuminated implies the pump switch is in the ON position and if the

sprayer is running, the pump will run and insecticide or flush solution will flow through

the sprayer to be atomized.

16

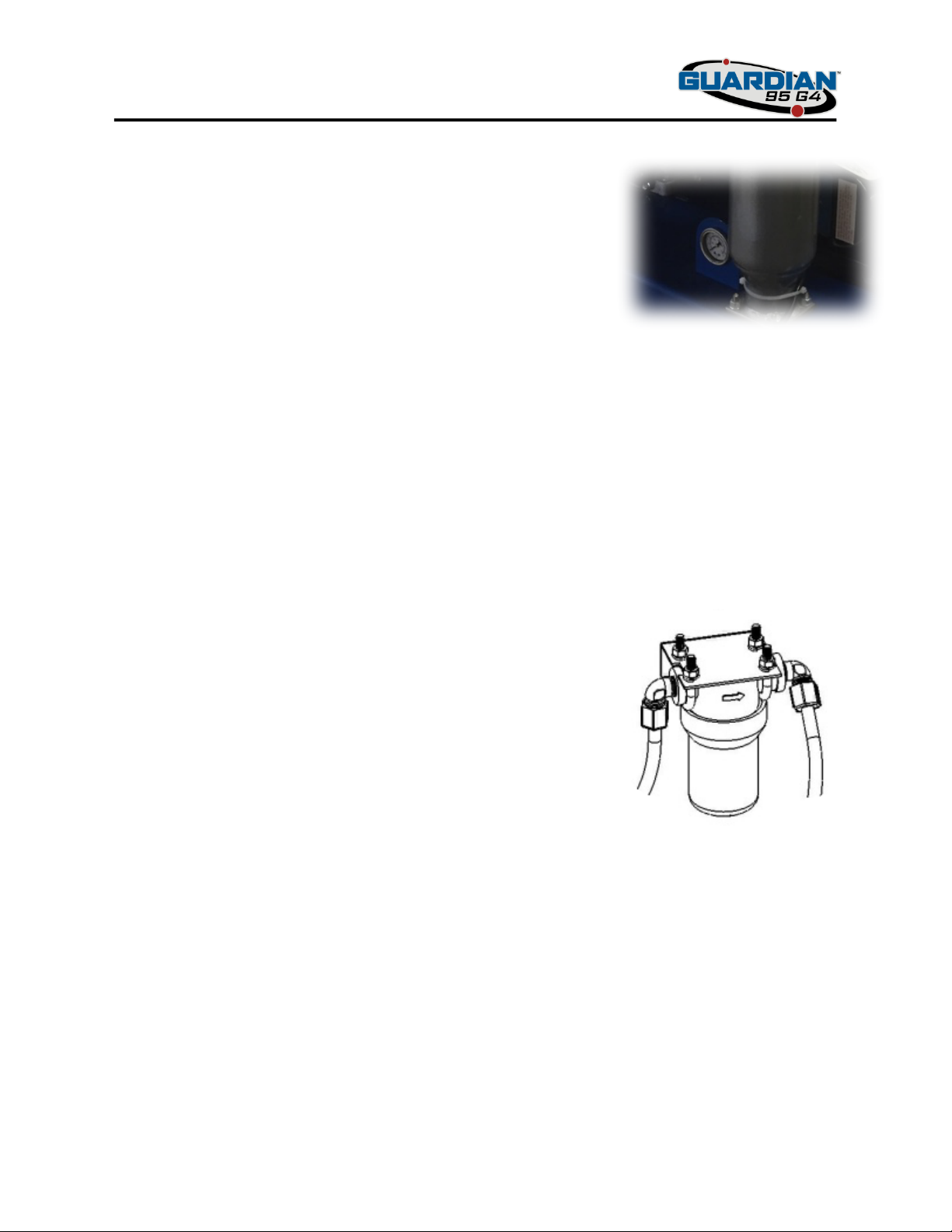

AIR PRESSURE GAUGE

The air pressure gauge is a glycerin filled type with a pressure

range from 0-15 psig. When the engine is running and throttle

adjusted to the desired engine RPM, atomization nozzle back

pressure is most often the overriding factor in assuring correct

atomization of a given flow rate or range of flow rate. Back

pressure is measured from a fitting on the cross over tube

through a short flexible hose to the gauge.

PRESSURE SWITCH

A pressure switch is located on the side wall of the “Wet” section of this ULV sprayer. Attached

to it is a section of flexible hose back to a fitting located on the crossover tube. The purpose of

this pressure switch is to ensure the insecticide pump cannot be inadvertently turned on without

sufficient air pressure. If this was to occur, the pressure switch does not allow the circuit to

“make” thus the insecticide pump will not run. The pressure switch can be overridden by

asserting the toggle switch on the back end of the pump’s electronic enclosure (toggle up)

allowing the pump to run regardless if back pressure is present or not.

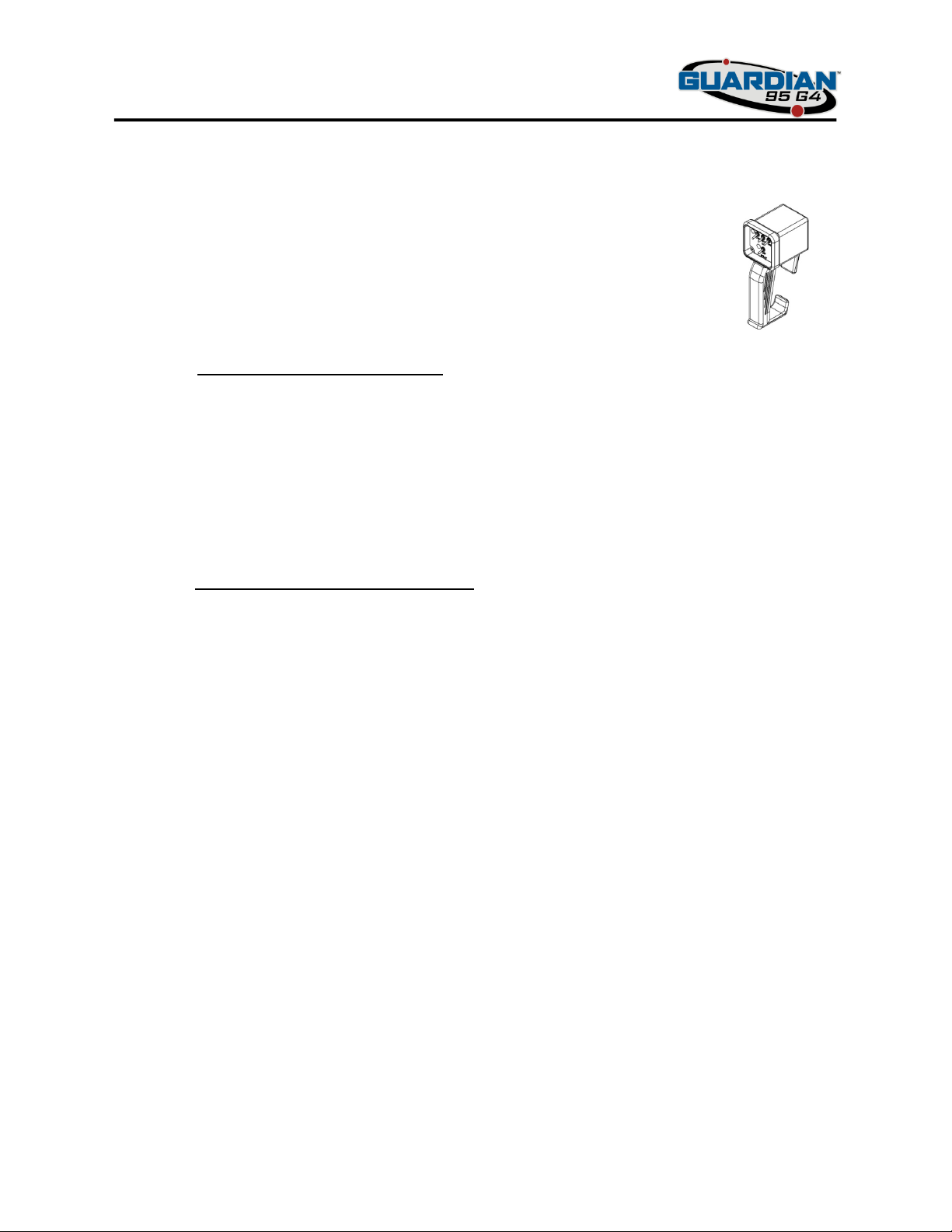

FORMULATION FILTER

Products to be atomized through this ULV sprayer must be

filtered before it is drawn through the insecticide pump to ensure

uniform fluid consistencies and prevent contamination and

potential particulate damage. The glass filled polypropylene

filter assembly consists of 4 pieces; top, bottom, gasket, and

stainless steel 80 mesh screen element. Check this filter often or

no less than once per hundred hours of operation. If you find

that the filter is collecting more and more contaminants, consider

cleaning and flushing the formulation tank more often.

FORMULATION TANK

15 U.S. gallons (56.7 liters) is the capacity of the formulation tank installed on this ULV sprayer.

The black high density polyethylene (HDPE) tank is suitable for all known products used in Vector

control and is engineered for prolonged periods of UV exposure. Additionally, the formulation

tank is supplied standard with a 2 inch threaded cap and a 3-piece Pad locking mechanism for

security concerns (pad lock not included).

17

INSECTICIDE PUMP

The standard pump supplied with the Guardian 95 G4 sprayer is an FMI (Fluid Metering Inc.)

metering pump coupled to a 12-volt DC electric motor. This piston pump is driven by an 8-volt

regulator as recommended by the pump manufacturer. Because of the metering properties of

this insecticide pump, regulating the power to the motor ensures a steady and repeatable flow

each and every time regardless of possible fluctuations in input power. This standard pump

configuration is consider a “Fixed” flow method as the amount of product pumped through the

system and to the atomization nozzle is fixed at a user’s predetermined rate. Variable flow

models of this FMI pump and other types of variable flow pump control systems are available.

PULSE DAMPENER

The FMI insecticide metering pump is a “piston” type pump that has 2 variables associated with

controlling flow. The RPM of the DC motor is a variable that is controlled through the 8V

regulator; the second variable being the angle of the piston itself. Generally speaking, the greater

the piston angle (away from the centerline of the pump), the greater the pulsations that are

generated with each and every pump revolution. For optimal atomization results, a smooth even

linear flow is desired through the nozzle. The pulse dampener traps air inside the bowl which

buffers each pulsation which smoothes out the pumps discharge to a non-turbulent, steady flow.

FLUSH TANK AND VALVE

Some formulations are best not left inside the pump and valves for prolonged period of non-use

due to corrosion and formulation thickening. To clean the insecticide pump and valve, a flushing

solution is pumped through both the 3-way valve and pump and atomized through the nozzle to

clear away residuals remaining inside. A 1.5 Quart flush solution tank is located next to the

insecticide pump; ensure it is filled with a flushing solution before use if flushing is desired. Not

all formulations require flushing but as a general rule, flushing is recommended after each use.

To flush out the spray system after use, with the engine running, assert the toggle switch (lower

right) on the operator’s control pendant to the FLUSH position illuminating the yellow LED next

to it. Turn the spray switch to the ON position. Flushing solution will begin atomization through

the sprayer. Turn the spray switch to the OFF position after the operator is satisfied that

sufficient time has elapsed to clean out the fluid system. Turn the Flush switch back to NORMAL.

ATOMIZATION NOZZLE

The atomization nozzle is designed to efficiently and effectively atomize various oil and water

based formulations to micron diameter droplet sizes as outlined on the specific formulation label.

18

Keep the nozzle clean and free from dings and dents to maintain perfect concentric alignment of

the main body and the nozzle cone. Formulation is fed through the rear of the nozzle by way of

a stainless steel tube exiting from the closest 90° elbow to the nozzle. The nozzle

swivels 360° horizontally and 360° vertically to position the nozzle at the desired attitude. The

most common nozzle position is pointed directly toward the back with an upward 45° degree

attitude.

INSTALLATION

COLD FOG GENERATOR (ULV SPRAYER) CONTENTS

The ULV sprayer is packaged in a corrugated box that protects the machine from damage in

shipping and storage and is strapped to a wooden pallet for easy lifting by a pallet jack or fork-

19

lift. The shipping pallet is not meant nor recommended to be used for permanent or semi-

permanent installation on a vehicle or trailer. The shipping box and pallet may be retained for

storage if desired. Enclosed in this shipping box are the following:

The Guardian 95 G4 ULV sprayer consists of two major sections, the drive train

section and the flow control or “wet” section. To control this sprayer remotely,

an operator’s pendant with cable is supplied (standard) or an optional variable

flow control operators interface is also available.

UThe Drive Train section includes:

a. Engine

b. Positive displacement blower and intake filter

c. Blower discharge piping, atomizing nozzle with chemical injection plumbing,

pressure gauge and tubing

d. Drive belt, pulley’s and guards

e. Battery box, cables, and/or battery tie down strap (Battery not included)

UFlow Control “Wet” section includes:

a. Chemical tank, draw tube, locking cap, and associated chemical tubing and

fittings

b. Fluid filter, pulsation dampener, flush tank,3-way valve and pressure switch

c. Fluid pump with control interface

FACTORY FLUID LEVELS

When you receive your Guardian ULV sprayer, the fluid levels will be as follows:

Engine oil full

Blower oil full

Control Pendant

20

Fuel tank empty

Formulation tank empty

Each machine is fully tested functionally and appropriate fluid levels are serviced beforehand.

Additionally, each machine’s atomization nozzle is fully tested, the results documented and

maintained by the manufacturer.

VEHICLE INSTALLATION

1. Remove the packaging box by cutting and disposing of the strapping material. With a fork

lift or hoist, lift the machine and remove the pallet and wooden runners from the sprayer.

Table of contents

Popular Farm Equipment manuals by other brands

AKO-Agrartechnik

AKO-Agrartechnik BA-1200 instruction manual

Swisher

Swisher L122-315001 owner's manual

Valmar

Valmar 2055 Operator's manual

Hermann Schmidt

Hermann Schmidt TRANSP Instructions for operating

Yetter

Yetter 5000 SERIES Owner's Manual, Part Identification

LEMKEN

LEMKEN Rubin 9 KUA operating manual

Finn

Finn HydroSeeder T75S Operator Instructions And Parts Manual

Metal-Fach

Metal-Fach T711 operating instructions

Checchi & Magli

Checchi & Magli PLASTIC-STOP PLUS Use and maintenance manual

agromaster

agromaster BM Series OPERATOR'S MANUAL AND SPARE PARTS

Flow

Flow Hive Hybrid 3 Assembly guide

IBEX

IBEX TS100 quick start guide