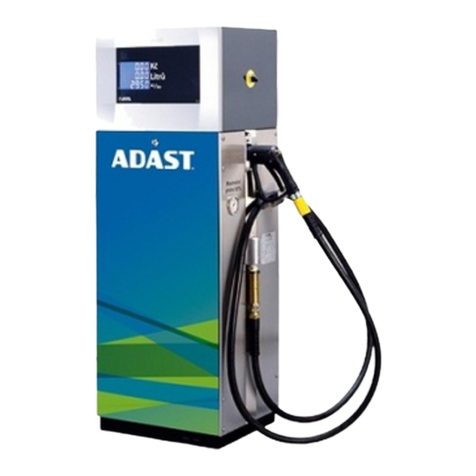

Adast Systems MAJOR V-line 46 Series Operation and maintenance manual

Adast Systems, a.s., 679 04 Adamov No. 496, Czech Republic

T+420 516 519 201, F+420 516 519 102, sales@adastsystems.cz

www.adastsystems.cz

OÚ/003/2005/MSS/A

XI/2018

USER´S MANUAL

Instructions for Operation, Maintenance

and Installation

Multi-product fuel Dispenser operating by Suction or

Pressure Pumping System

MAJOR

V-line 46xx.xxx

V-line 47xx.xxx

USER’S MANUAL V-line 46xx, 47xx

I

CONTENT

1. IMPORTANT NOTICE ..................................................................................................... 1

2. USE.......................................................................................................................... 2

3. INSTRUCTIONS FOR THE SAFETY OF WORK ........................................................................ 2

3.1. Safety of the equipment design................................................................................2

3.2. Operation safety ..................................................................................................3

3.3. Ecological safety ..................................................................................................3

3.4. Hygiene .............................................................................................................4

4. BASIC DESCRIPTION ..................................................................................................... 4

4.1. Design of dispensers..............................................................................................4

4.2. Hydraulic system of the fuel dispenser .......................................................................5

4.3. Electronics .........................................................................................................7

4.4. Vapour recovery system .........................................................................................8

4.5. Signalling of dispenser conditions (SO) ..................................................................... 19

4.6. SOPA design...................................................................................................... 19

4.7. Design with heating of the electronic case ................................................................ 19

5. TECHNICAL DATA .......................................................................................................19

6. IDENTIFICATION .........................................................................................................25

7. PUTTING OF THE FUEL DISPENSER INTO OPERATION...........................................................26

7.1. Putting the dispenser and electronic counter into operation .......................................... 26

7.2. Shutdown of the dispenser and electronic counter....................................................... 26

7.3. Restart of the dispenser and electronic counter after power failure and voltage drop ........... 26

8. ATTENDANCE ............................................................................................................26

9. DISPENSER OPERATION ................................................................................................27

9.1. Dispensing with preselection ................................................................................. 27

9.2. Description of the preselection function .................................................................. 27

10. FUNCTIONS OF KL-MANINF MANAGER AND KL-SERINF SERVICE KEYBOARDS ..............................27

10.1. Manual setting of unit prices ................................................................................. 28

10.2. Setting of unit price values from the control system in AUTO mode .................................. 28

10.3. Display of electronic totalizers............................................................................... 29

10.4. Check of vapour recovery system function................................................................. 29

11. MAINTENANCE OF A DISPENSER AND ITS INDIVIDUAL OPERATING UNITS...................................30

11.1. Pumping monoblock ............................................................................................ 30

11.2. Piston flowmeter ............................................................................................... 31

11.3. Electromagnetic two-stage valve ............................................................................ 31

11.4. Sight glass of the dispenser ................................................................................... 31

11.5. Dispensing hose ................................................................................................. 31

11.6. Dispensing nozzle ............................................................................................... 31

11.7. V-belt of the pump ............................................................................................. 32

11.8. Dismantling of covers .......................................................................................... 32

11.9. Maintenance instructions for dispenser body parts....................................................... 33

USER’S MANUAL V-line 46xx, 47xx

II

11.10. Electronic counter .............................................................................................. 33

12. DISASSEMBLY AND DISPOSAL .........................................................................................33

13. SUMMARY OF BASIC PRINCIPLES FOR DISPENSER MAINTENANCE .............................................34

14. TRANSPORT ..............................................................................................................34

14.1. Transport of V-line 46xx.xxx, 47xx.xxx fuel dispenser and its putting on the base frame ........ 34

15. DISPENSER INSTALLATION ............................................................................................36

15.1. Hydraulic part ................................................................................................... 36

15.2. Wiring ............................................................................................................. 39

16. PACKING AND STORAGE ...............................................................................................40

16.1. Packing ........................................................................................................... 40

16.2. Storage ........................................................................................................... 40

17. GUARANTEE AND CLAIMING ..........................................................................................40

18. SPARE PARTS CATALOGUE............................................................................................41

19. ACCESSORIES ............................................................................................................41

20. DOCUMENTATION DELIVERED ........................................................................................41

21. ENCLOSURES .............................................................................................................42

USER’S MANUAL V-line 46xx, 47xx

1

1. IMPORTANT NOTICE

This document is a guideline for the user how to proceed when installing, attending and maintaining the

dispenser. The information included in the present instructions are mandatory and the manufacturer does

not accept any responsibility for any damage due to their non-observance.

The dispenser is complicated equipment providing many important functions.

Prior to putting into operation tanks and the piping system shall be cleaned and fuel purity shall be

checked. Also el. power distribution and correct wiring shall be inspected to prevent injury by el.

current and to provide explosion proofness –fuels are flammable liquids of the 1st and 2nd danger class!

The manufacturer tests each dispenser considering the function, safety and metrology. Each delivery shall

include the instructions for attendance, maintenance and installation, EC declaration of conformity and a

service book identifying dispenser components. The dispenser, produced with high precision and care,

secures reliable and safe operation. Principal safety regulations protecting the user against injury shall be

kept during operation and maintenance and the dispenser shall be prevented from damage. No

modifications of the dispenser equipment are allowed without producer’s written approval.

The dispenser has been designed for outdoor installation –class according to OIML D11 –C (outdoor -

stationary).

Important instructions for installation and operation:

a) Study the instructions for attendance, maintenance and installation and other manufacturer’s

documents included within dispenser accessories before you start to handle the equipment.

b) Check the dispenser delivery completeness and inform the manufacturer immediately in case of any

discrepancies or damage.

c) The dispenser shall be stored in a dry and protected room before it is installed at the filling station.

d) Prior to dispenser installation check the completeness of the filling station technology according to the

valid design, check the connecting dimensions of the foundation frame including the piping system

outlet.

e) Rinse the process equipment (piping) through the filtration equipment until impurities are removed.

f) The dispenser requires the connection of the vapour return piping of min. DIN 16 –we recommend DN

25.

g) Wiring and inspection of the dispenser shall be carried out.

h) When putting the dispenser into operation, proceed according to the point 7 of the present instructions.

i) A metrology authority specialist shall perform function test and metrology checking.

j) Being these conditions fulfilled, after the approval of a state supervision authority and the verification

of a metrological office representative, usual operation can be started.

k) Only qualified and trained staff of a service company can perform service and installation. Service

procedures shall be performed in compliance with the operation regulations of the filling station. The

manufacturer is not responsible for damages due to the incompetence of the staff.

l) The owner can only start dispensing when the filling station inspection is finished and a metrology

authority carries out metrological verification of the dispensers.

m) When fuels are pumped, basic hygienical precautions shall be adhered. The owner shall enable the

customer to use protective gloves.

SAVE FOR FUTHER USE!

ATTENTION!

The dispenser shall not be installed in an explosion danger zone 0, 1, 2 in compliance with zones

specified in the EN 60079-10!

USER’S MANUAL V-line 46xx, 47xx

2

2. USE

Multi-product fuel dispensers type series V-line 46xx.xxx and V-line 47xx.xxx with electronic counter

used for the dispensing of liquid petroleum products - automotive petrol, diesel, kerosene, etc., of

alternative liquid fuels (biofuels) - biodiesel (B 10 - B 100) - a mixture of diesel fuel with FAME

(Fatty Acid Methyl Ester) and a mixture of automotive petrol with bioethanol (E10 - E 85) (flammable

liquids I. to IV. hazard class and group explosivity IIA) with dynamic viscosity up to 20 mPa.s and with

flow rate optional 40, 60, 70, 80, 110, 120, 130, 150 dm3. min-1.

Special modification dispensers type series V-line 47xx.xxx/OIL are determined to dispensing liquid

fuels on the base of vegetable oil (rape oil, sunflower oil, soya oil, which are modified for internal

combustion in diesel engines) and mineral oils with maximum dynamic viscosity up to 1000 mPa.s and

with flow rate optional 40, 60, 70, 80 dm3. min-1.

They have been designed for the installation at road filling stations and a fleet of vehicles, etc. By means

of a communication line the dispensers are connected to the control system of self-service operation or

serviced operation.

The dispensers are equipment with special requirements concerning safety, metrology and ecology.

The dispensers are equipped to exhaust vapours; thus ecological operation of filling stations is provided,

i.e. the prevention of harmful petrol vapours leakage into atmosphere.

The instructions for attendance, maintenance and installation serve the user to gain information on the

design, correct attendance, maintenance and safe installation.

3. INSTRUCTIONS FOR THE SAFETY OF WORK

3.1. Safety of the equipment design

The manufacturer guarantees safety of the equipment design.

The dispenser design complies with the EN 13617-1 requirements and it is homologated for the

operation in environment specified by II2G IIAT3 symbols shown on the dispenser plate.

Considering operation safety in environs with explosion danger the dispensers have been EC –type

examination (certification) according to the annex III of the Directive 2014/34/EU –ATEX by an

authorised body FTZÚ, Pikartská 7, 716 07 Ostrava –Radvanice –Notified body no. 1026.

EC - Type Examination Certificate: No. FTZÚ 05 ATEX 0069

Regular inspection of production quality assurance according to Annexes IV and VII of the Directive

2014/34/EU executes FTZÚ, s.p., Ostrava –Radvanice, NO no. 1026.

Notification of quality assurance: No. FTZÚ 02 ATEX Q 020.

Considering legal metrology the dispensers have been EC –type examination (certification) according

to the annex B of the Directive 2014/32/EU –MID by an authorised body Český metrologický institut,

Okružní 31, 638 00 Brno – Notified body no. 1383.

EC - Type Examination Certificate: No. TCM 141/07 - 4505

The producer performed a conformity examination for the fuel dispenser with the type described in

EC –Type Examination Certificate No. TCM 141/07 –4505 and technical requirements according to the

Directive of European Parliament and the Council 2014/32/EU.

The producer is competent for “The Declaration of Conformity” with the type based on production

quality assurance of measuring units according to the Directive Supplement D of European Parliament

and the Council 2014/32/EU.

Certificate of the Quality Management System for production, check-out and testing:

No. 0119-SJ-C007-07.

Regular inspection of production quality assurance, check-out and testing according to the Directive

Supplement D of European Parliament and the Council 2014/32/EU executes authorised body Český

metrologický institut, Okružní 31, 638 00 Brno – Notified body no. 1383.

ATTENTION!

Any handling open flame is prohibited during fuel filling and smoking is prohibited even in vehicles

interior. Also filling vehicle tanks with running motor and any other activities possibly initiating

explosion are prohibited!

USER’S MANUAL V-line 46xx, 47xx

3

3.2. Operation safety

The owner is responsible for the filling station operation and is obliged to follow the course of fuel

pumping. In case a customer uses the dispenser incorrectly, the owner shall instruct him about proper use.

The owner shall also identify the hazard zone of the filling station by warning symbols (smoking prohibited,

open flame prohibited, direction of arrival to dispensers, etc.).

Operation regulations of the filling station shall be accessible for the customer, which enables him to get

information on principal obligations.

Operator’s obligation:

–Keep the equipment in safe and proper condition.

–Follow the operation regulations and attendance instructions of the filling station.

–Report immediately any failure to the owner and put the equipment out of operation in case of delay.

–Keep order permanently.

–The dispenser and storage tank operators are not allowed to repair the equipment and to reset any

safety valves.

Performance of service work is a special case. Servicemen are not allowed to break operation safety

during repairs and other activities. When dispenser covers are removed, they shall be very careful to

protect both them and customers against injury.

El. current supply shall be disconnected when handling el. components. Only approved components

shall be used to replace any parts.

All parts subject to approval shall be always in conditions required by the technical documentation

(leakproofness, earthing, electrostatic belts, electrostatically conductive filling hoses, etc.).

3.3. Ecological safety

In accordance with the „DIRECTIVE 2009/126/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

of 21 October 2009 on Stage II petrol vapour recovery during refuelling of motor vehicles at service

stations“must be filling station for dispensing gasoline equipped according to the national legislative

regulations of the country of destination (installation and operation of fuel dispensers) Decree recovery

system (reverse drain stage II petrol vapor - Equipment recuperate (consultation draft) petrol vapor

displaced from the fuel tank of a motor vehicle during refueling and carrying gasoline vapors to the storage

tank at the service station.

IMPORTANT NOTE!:

Terms of service stations and control petrol vapor recovery system stage II is drived by the

"Directive 2009/126/EC of the European Parliament and Council" and the relevant national legal

regulations in force in the countries of destination (installation and operation of fuel dispensers).

Fuel dispensers ADAST V-line 46xx.xxx, 47xx.xxx for dispensing of petrol are equipped with an

efficient recovery system (reverse exhaust vapor) that meets the requirements of the "Directive

2009/126/EC of the European Parliament and Council”:Volumetric efficiency of vapor recovery

shall be between 95-105% - the rate of the volume of recovered vapor at atmospheric pressure to

total dispensed gasoline into the fuel tank of a motor vehicle is equal to or greater than 0,95 but

less than or equal to 1,05.

3.3.1. Check of petrol vapor control system –by the Directive 2009/126/EC

Check of petrol vapor recovery system Stage II at the dispenser shall be in accordance with

Directive 2009/126/ES under the relevant national legislation and regulations applicable in the

countries of destination (installation and operation of fuel dispensers).

Regular checks under Directive 2009/126/EC

1. Checking the operating efficiency of petrol vapor recovery system Stage II must be performed

at least once per year. Checks whether the ratio is the ratio of the volume of paid vapor at

atmospheric pressure to the total volume of gasoline fished into the fuel tank of a motor

vehicle is equal to or greater than 0,95 but less than or equal to 1,05.

2. If the dispensers installed automatic monitoring system, the efficacy of petrol vapor recovery

stage II tested at least once every three years. Any such automatic monitoring system shall

automatically detect faults in the proper function of petrol vapor recovery system Stage II and

in the automatic monitoring system, indicate faults to the service station and automatically

stop the flow of petrol from the faulty dispenser if the fault is not rectified within seven days.

USER’S MANUAL V-line 46xx, 47xx

4

IMPORTANT NOTE!:

All fuel dispensers used for dispensing gasoline must be equipped with clearly labeled, indicating

the need for customers to fully insert the nozzle into the filler neck of the vehicle tank.

Check of petrol vapor recovery system Stage II at fuel dispensers

ADAST MAJOR V-line 46xx.xxx, 47xx.xxx.

To check the operating efficiency of petrol vapor recovery system Stage II are two procedures:

1. Procedure for dispensers where the pump driven by an electric pump without electronic

control system vapor recovery:

The test is performed for pumping petrol into a suitable volumetric container at 50% and 100%

of the nominal flow of petrol. Measuring the effectiveness of this system is carried out solely

for the purpose meter designated as a special meter Bürkert G4-RF1 connected to the suction

nozzle attachment with a universal connector UMAX 2 companies ELAFLEX).

2. Procedure for dispensers with electronically controlled petrol vapor recovery system Stage

II, which allows to perform the test without using gasoline:

The test is carried out so-called "dry way" apparatus approved for this purpose - eg special

meter Bürkert G4-RF1 connected to the suction nozzle attachment with a universal connector

UMAX 2 companies ELAFLEX). Gas meter Bürkert G4-RF1 is via pulse output is connected

through a special cable to enter the electronic counter. Linking meter counter and must be

done at a gas station through the reduction of RP/M/EX, which contains zener barrier for

intrinsic safety.

3.4. Hygiene

The dispensers are hygienically harmless for customers and the owner. But protective gloves are advised to

be used during maintenance or filling fuel.

In case skin comes to contact with fuel or impurities, wash the spot with water and soap as soon as

possible. When eyes come to contact, medical treatment is necessary. Do not inhale harmful vapours when

filling fuel.

4. BASIC DESCRIPTION

4.1. Design of dispensers

Skeleton –a self-supporting structure consisting of parts with high anticorrosive resistance. The base of the

dispenser is made of steel sheet and heat zinc-coated. Internal parts of the skeleton are made of galvanised

sheet. Parts of the body with the exception of the door of the hydraulic module and the electronic counter

case are made of stainless brushed sheet as a standard.

High resistance acrylurethane enamel is applied on the hydraulic module door and the electronic counter

case. The colour shade of the door including the logo can be optional.

The subframe of the dispenser is manufactured and delivered in two modifications depending upon the

design of the lower part of the filling station equipment:

-without drip-pan –the drip-pan is a part of the lower equipment

-with drip-pan –the drip-pan is glued into the dispenser base with bonding and sealing cement

Both doors are lockable; being unlocked, swing out and with earth wire disconnected they can be removed

and thus the hydraulic part including electric switch box are accessible. Connect the earth wires when the

door is fitted back.

4.1.1. Case of the electronic counter

A case of the electronic counter or ADAMAT electronics is bolted to the hose module column. The counter

case space is closed with lockable covers. The covers are provided with transparent glass. Indicators with

integrated large-area display of dispensed volume, total price of dispensed volume and a price for one unit

of dispensed volume are connected from the case interior to the covers or unresetable electromechanical

USER’S MANUAL V-line 46xx, 47xx

5

total counters (totalizers). The set of these elements represents all necessary information for the

customer.

The covers of the case are hung up on hinges enabling tilting upwards after unlocking and thereby easy

access in the case interior. The user’s local preselection keyboard is located on the case cover as well.

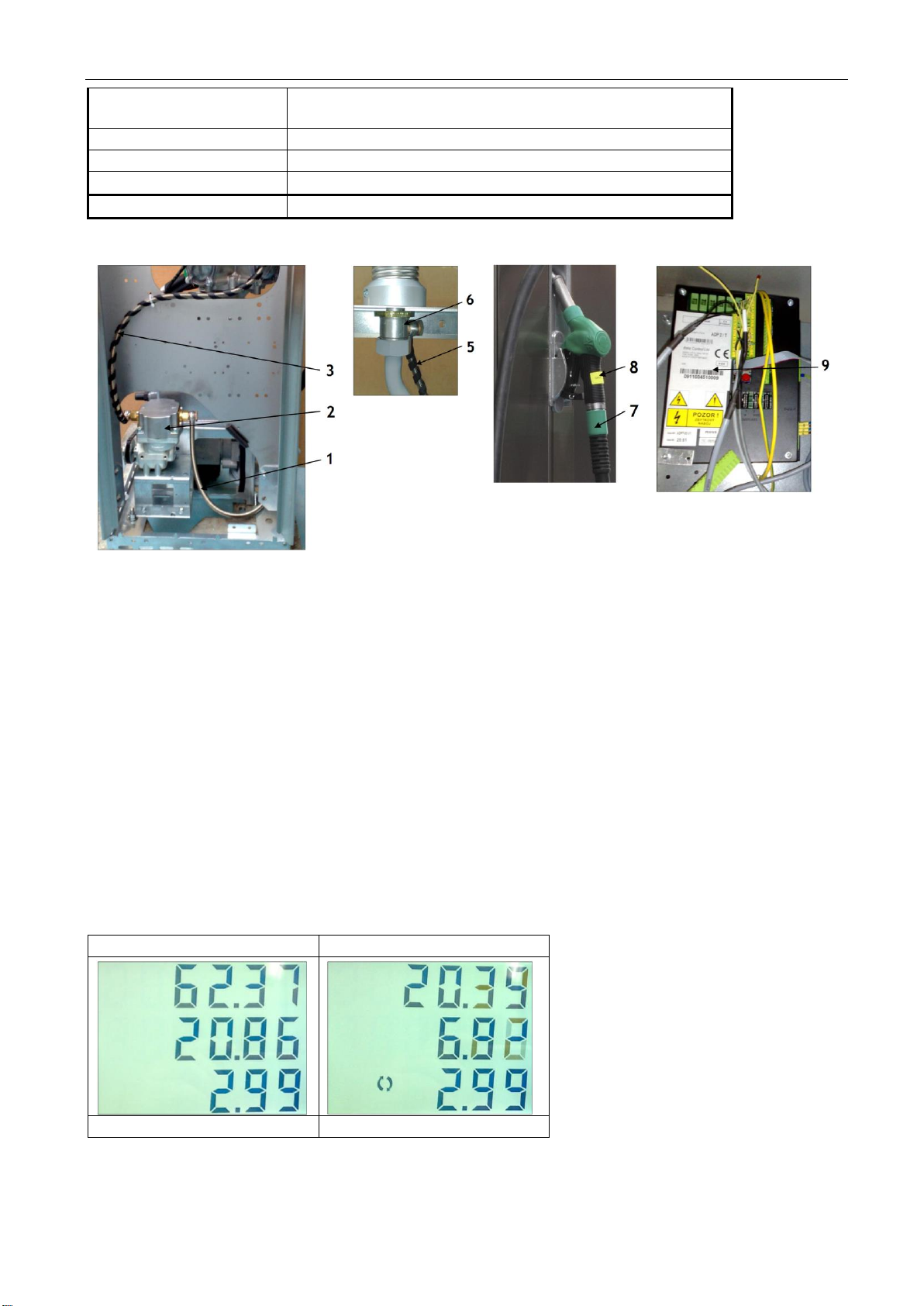

4.1.2. Case of the electronic counter –design 2017 (see fig.)

A case (1) of the electronic counter or ADAMAT

electronics is bolted to the hose module column.

The counter case space is closed with lockable

covers (2). The covers are provided with

transparent glass.

On the inside cover of the case is mounted under

glass large-area display (3) issued volume and total

price, which displays all necessary information for

the customer.

Above the display is placed IR sensor (5) for

controlling and adjusting the dispenser calculator

manager or servicing keyboard.

On the outer side of the case cover is placed

(optional) keyboard local user preferences (4).

On request they can be built in a case unresetable

electromechanical total counters –totalizers (6),

which are accessed by opening the cover.

ATTENTION!

Before opening the covers, it is always necessary to disconnect power to the dispenser and perform

a reliable hedge against its re-connection.

The dispensers of the V-line 46xx.xxx, V-line H, R 47xx.xxx type series are manufactured in two

modifications differing in the design:

-V-line H –high design of the hose module with free hanging dispensing hoses

-V-line R –low design of the hose module with winding gear of hoses

The dispensing nozzles are seated in covers in the „V“ form pressed shape of the column and bearers of the

hose module. When the dispenser is out of operation the dispensing nozzles in covers can be locked.

With respect to the application the dispensers of the V-line H, R 46xx.xxx, V-line H, R 47xx.xxx type series

are supposed to be installed at the following filling stations:

-V-line H, R 46xx.xxx –for filling stations with the suction system of pumping

-V-line H, R 47xx.xxx –for filling stations with central pressure distribution system

4.2. Hydraulic system of the fuel dispenser

The integrated hydraulic unit consists of a pumping monoblock with an integrated large-surface filter, a

meter with integrated impulse sensor connected with the pumping monoblock through a special joining

piece and a driving el. motor of the pump.

Pumping monoblock type series P 64x.xxx/x –is an independent unit for one kind of the pumped fuel. An

integrated compact structure contains an efficient filter, sliding vane pump, control and non-return valves,

safety relief valve with continual control of the operating pressure, cyclone (centrifugal) gas separator and

a venting chamber with a float valve. Progressive design provides 100% separation of gaseous components

and automatic blocking of filling when excessive amount is identified in the product pumped.

The large-surface filter with an integrated non-return valve and standard filtration efficiency 30 µm for

petrol and optional 30 µm or 60 µm for Diesel oil (winter operation in extreme low temperatures).

The pumped liquid passes through the filter and the non-return valve to the pump and the separator where

gases and vapours are separated and pass to the float chamber. Condensed liquid is discharged to the

suction part of the pump and gases are exhausted to the vented part of the dispenser base. The liquid is

discharged from the non-return valve to the meter, then through an electromagnetic valve into the

dispensing hose with a dispensing nozzle at its end. The dispensing nozzle lever controls the rate flow. A

tube sight glass can be installed between the dispensing hose and the nozzle for visual checking.

A three-phase asynchronous motor drives the pump by means of an antistatic V-belt.

USER’S MANUAL V-line 46xx, 47xx

6

Special modification of the pumping monoblok of P 64x.xxx/x/BIO series is intended to pumping of

biofuels - biodiesel (B 10 - B 100) - a mixture of diesel fuel with FAME (Fatty Acid Methyl Ester) and

a mixture of gasoline with bioethanol (E10 - E 85) . It has a special surface protection, which

ensures their high resistance against aggressive biofuels.

Dispensers V-line 47xx.xxx series (pressure design) differ from suction dispensers because they are not

equipped with the pumping monoblock. A safety breaking valve shall be fitted in the connection. The valve

prevents fuel leakage in case of the dispenser damage. This valve is not a part of the dispenser, as well as

the pump, which is located in the underground tank. The pressure dispensers are equipped with an inlet

spherical valve for closing the liquid input in case of repairs.

The pumped liquid is supplied from the central submerged pump located directly in the fuel storage tank

through the safety breaking valve, spherical check valve and the filter with filtering property of 30 µm or

10, 20 µm (optional) for petrol and 30 or 60 µm for Diesel oil. Liquid is discharged from the filter through

the meter and the electromagnetic valve to the dispensing hose with the dispensing nozzle at its end. The

dispensing nozzle lever controls the rate of flow. The tube sight glass can be fitted between the dispensing

hose and the nozzle for visual checking.

Meter type series M 403xxxx/x is composed of a four-piston all-aluminium meter and an integrated

magnetic pulse transmitter. The original meter ensures metering accuracy within a wide range of flow

rates 4 - 150 dm3.min-1 and fuel operating temperatures -20 °C to +50°C (-10 °C to +50°C for biodisel

B 70 to B 100) and ambient temperatures -40 °C to +60°C for nominal pressure up to 0,32 MPa.

The new design made of special materials considerably improves the accuracy and reliability. The universal

design for both mechanical and electronic calibration is an advantage. A two-channel integrating impulse

generator is a part of the meter. The number of impulses is proportional to the swivelling angle of the shaft

and the runoff volume of fuel.

The impulser generates 2 x 100 impulses per 1 dm3. The meter is electronic calibrated by an el. meter

processor with the help of the service keyboard.

Meters are supplied with optional integrated magnetic pulse transmitter Eltomatic ME 01-05 - type

designation M 403.25P, M 403.32P, M 403.25EP, M 403.32EP or with a magnetic pulse transmitter

METRA MTX 075 or ADAST 40 - type designation M 403.25P/1, M 403.32P/1, M 403.25EP/1, M

403.32EP/1.

Special modifications to the type of meters M 403.25хP/B, M 403.25хP/B/1, M 403.32хP/B,

M 403.32хP/B/1 is intended to measure the volume of biofuel - a mixture of gasoline with

bioethanol (E10 - E 85).

Meters with the designation /В have special surface protection, which ensures their high resistance

against aggressive biofuels.

Meters with the designation of EP in electronic calibration, indicating P mechanical calibration

Electric motors –El. motors 0,55 kW, 0,75 kW, 1,1 kW for pumping and 0,37 kW, or 0,18 kW for vapours

exhaustion are used in the V-line 46xx.xxx suction dispensers.

El. motors 0,37 kW, or 0,18 kW h for vapour exhaustion are used in the V-line 47xx.xxx suction dispensers.

The number of the pumping monoblocks, meters and el. motors is specified according to the dispenser

type.

Dispensing hoses –single and coaxial dispensing hoses meet the requirements of the EN 1360. The

dispensing hose is located in the hose part of the module, which ensures the safekeeping of the hose when

the dispenser is out of operation. In case of fuel filling it enables to pull the hose out in needed length.

Backward safekeeping of the hose into the hose module is enabled by dead weight of the dispensing hose

when the nozzle is suspended or by means of a winding gear.

For pumping biodiesel (B 10 - B 100) - a mixture of diesel fuel with FAME (Fatty Acid Methyl Ester)

must use a special hose for biodiesel - Elaflex Slimline BIO!!

Dispensing nozzles –are supplied according to the Client’s option. The nozzles are automatic, fitted with a

swivelling joint and an effective STOP system used in case of the tank overfilling or in emergency situation.

The nozzles can be fitted with safety disconnecting joints according to the Client’s option. The dispensing

nozzle is hung in the nozzle cover and it is lockable when the dispenser is out of operation.

The dispensers are equipped with electromagnetic (solenoid) valves ON/OFF (double stage), or

electromagnetic proportional valves as a standard.

USER’S MANUAL V-line 46xx, 47xx

7

4.3. Electronics

The dispenser control shall meet the exacting requirements of simplicity and convenience and depends on

the hanging up and lifting of the dispensing nozzle.

ADPMPD/T, ADPMPD/T-PWM, ADP1/T, ADP2/T, ADP1/L electronic counter of an up-to-date design with

central processor board equipped with a high efficient microprocessor. The configuration of the counter

and its modes of operation are adjusted by more than seventy parameters. The counter is provided with a

self-diagnostic system. The counter outlets control the motors, valves, signalling circuits and vapours

exhaustion. The electronic counter processes the impulses coming from the impulse sensor and transmits

them to the display, which displays the dispensed volume, its price and a price per a volume unit. In case

of power failure or voltage drop the data displayed on the LCD remain for 30minutes at least.

Counters ADPMPD/T, ADP1/T, ADP2/T, ADP1/L are standardly equipped for electronic meter calibration

(Electronic Calibration of Meters –EC) and per request by ATC –(Automatic Temperature

Compensation).

Electronic Calibration of Meters (EC) enable to correct measured volume by designed declination in

operation range -5,00 % to +5,00 % of recognised meter non accurancy by step of 0,05 %.

Automatic Temperature Compensation (ATC) is designed to compensate temperature expandity of

dispensed medium based on measured temperature during dispensing. For temperature measuring is used

approved certified temperature sensor –resistance temperature sensor PT 100, in fuel dispensers V-line

46xx.xxx build in entering angle to pumping monoblock and in fuel dispensers V-line 47xx.xxx build in

pipeline after the filter unit.

Calibration tablets for ATC on designed medium (type of fuel) can be integrated into SW of electronic

counter by customer request. Setting of calibration EC or ATC is provided by using of service keyboard KL-

SERINF and setting of proper calibrating switches DIP on body of electronics counter as per instructions

described in manual of electronic counters ADP1/T, ADP2/T or ADPMPD/T.

Providing of calibration is allowed to authorised person, only. The DIP calibration switches must be fixed by

plomb after calibration finish.

Displays: LCD type with BACK LIGHT illumination

LCD displays with BACK LIGHT DISPLAY (BLD) illumination are used especially for their good readability.

The duration of data holding on the display after supply voltage failure is 30 minutes at least. Decimal point

on BLD display devices is represented automatically in accordance with the setting of parameters.

Lighting

LED diodes are used for the illumination of displays at dispensers.

ON / OFF switching of the illumination is automatically carried out with the activation of electronics.

Totalizer: non-resettable electronic counter of dispensed volume and its price –11 digits –or non-

resettable electromechanical counter of dispensed volume –7 digits.

Electronic counter of ADPMPD/T, ADPMPD/T-PWM, ADP1/T, ADP2/T, ADP1/L series operates with a 2-

channel impulse generator producing 2x 100 impulses per 1 dm3. The HW and SW counters of the

ADPMPD/T, ADP1/T, ADP2/T, ADP1/L series enable high metering accuracy and the application of the

electronic calibration using the 2-channel impulse generator.

The local electronic preselection system in IP67 design is integrated into the counter case. The

preselection enables the Customer’s preselection of the exact volume or the price of the product to be

dispensed. The two-stage or proportional electromagnetic valves ensure the closing of flow and exact

dispensing of the preselected volume / price and smooth initiation of dispensing.

The fuel dispensers can be equipped with ADAMAT filling automatic equipment. This equipment enables

dispensing and payment of the product by means of contactless, magnetic and chip cards including receipt

printing. This equipment undertakes simultaneously all functions of the dispenser electronic counter for

non-public and public dispensing. The electronics of the filling automatic equipment can be complemented

by the ADPMPD/T, ADP1/T, ADP2/T, ADP1/L electronic counter with public dispensing.

The fuel dispenser is connected through a communication line to the control system, which controls the

operation of the whole filling station (releasing of dispensers, volume preselection, unit price variation,

self-diagnosis, etc.). The dispensers can be operated even at the filling stations without any control system

–i.e. in serviced operation.

Circuit diagrams for the connection of individual dispenser types to the switchboard of the filling station –

see enclosures.

USER’S MANUAL V-line 46xx, 47xx

8

4.3.1. Communication to the control system

The dispensers are equipped with ADPMPD/T, ADP1/T, ADP2/T, ADP1/L electronic counters, which are able

to communicate to POS Win control systems. A communication serial interface RS 485 or a communication

standard IFSF LON are used for the communication of electronic counters to the superior control system.

Communication to different control systems shall be consulted with the manufacturer of the dispensers in

advance.

The fuel dispensers connected to the control system can be operated in the mode of volume preselection or

the financial sum preselection from the control system (the dispensers have to be equipped with two-

stage or proportional electromagnetic valves).

The POSWIN control system (POS Win EURO) enables the process control and the sale of goods according

to stock cards (999 999 items in 99 groups) including storage facilities. Systems are identical with respect to

the communication to the dispensers; they communicate on the principle of the bus interface RS 485. This

systems combine the basic functions of the filling station, i.e. sale of fuels, sale of dry goods and their

filing. POS system is also able to operate even as a multi-cash one, i.e. its individual parts can be

interconnected in the communication SW network with two backoffices and three tills. If more than five

backoffices or tills are connected, a server has to be included.

4.4. Vapour recovery system

Fuel dispensers ADAST POPULAR type line V-line 46xx.xxx, 47xx.xxx are supplied in the following

modifications of petrol vapor recovery systems :

1

System VRC-M

Vapour Recovery Control –Mechanical - control the flow of vapor by

hydromechanical proportional valve integrated into nozzle (Elaflex).

2

System VRC-E

Vapour Recovery Control –Electronic –control the flow of vapor through the

proportional solenoid valve directly controlled by an electronic control unit

dispenser (single-chip microcontroller electronic counter).

3

System VRC-M

+ VRMS

System VRC-M with automatic control system –VRMS (Vapour Recovery

Monitoring System).

VRMS system independently monitors system VRC-M - detect faults in the

proper function recovery system Stage II petrol vapor and VRMS system

itself, indicate faults to the service station and automatically stops the

flow of petrol from the faulty dispenser (dispensing areas), if the fault is

not rectified within seven days.

4

System VRC-E

+ VRMS

System VRC-E with automatic control system –VRMS (Vapour Recovery

Monitoring System).

VRMS system independently monitors system VRC-E - detect faults in the

proper function recovery system Stage II petrol vapor and VRMS system

itself, indicate faults to the service station and automatically stops the

flow of petrol from the faulty dispenser (dispensing areas), if the fault is

not rectified within seven days.

4.4.1. Systém VRC-M

Vapour Recovery Control –Mechanical - control the flow of vapor by hydromechanical proportional valve

integrated into nozzle (Elaflex GRVP).

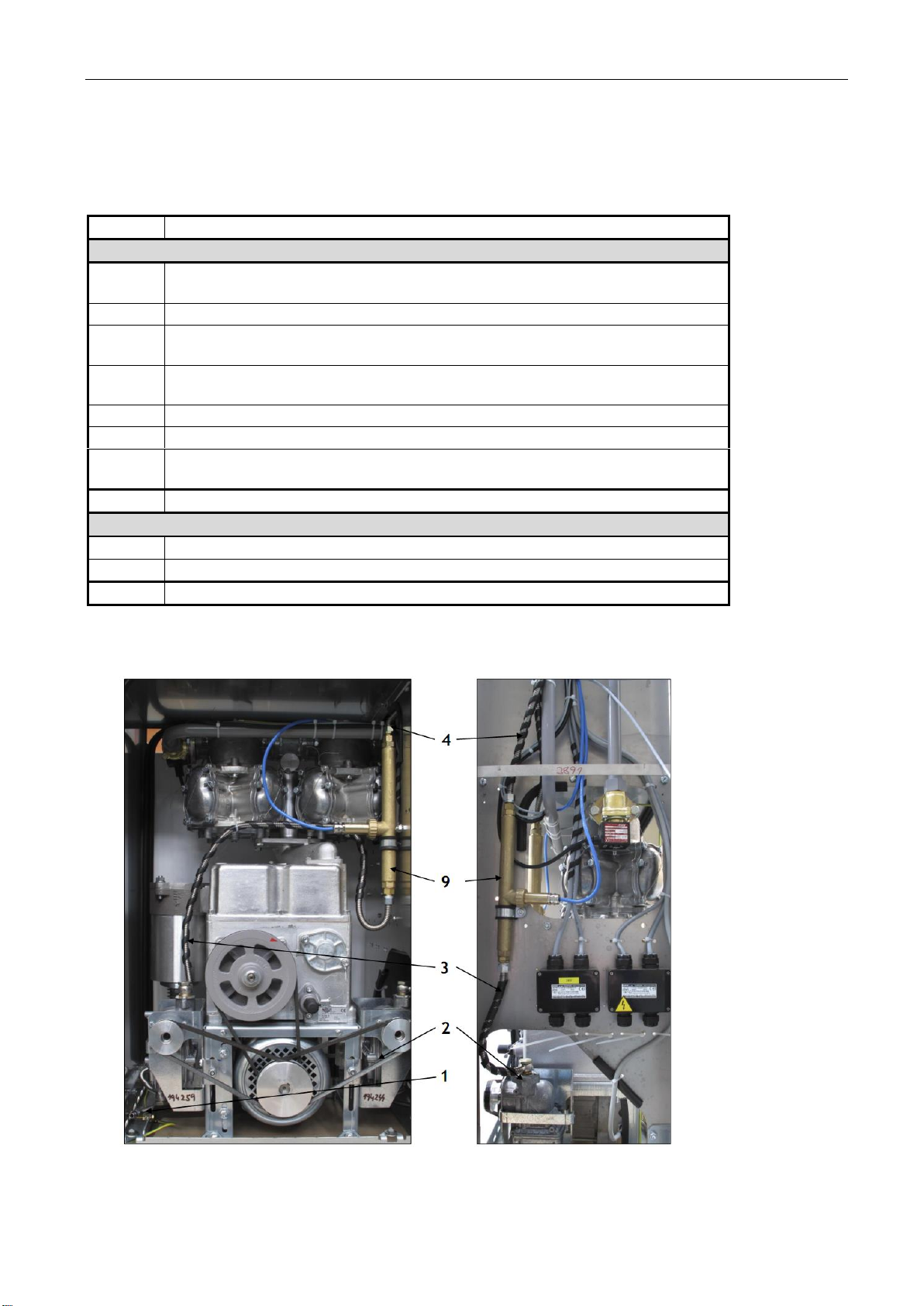

Vapor recovery system VRC-M of the dispensers V-line 46xx.xxx, 47xx.xxx consists of the following

basic components (structural layout and design is evident from Figures 1, 2, 3, 4, 5):

Position

Unit name

1

Flexible pipe with union nut M 16 x 1,5 for connection to outgoing pipe into

storage tank.

2

Piston vacuum pump

3

Flexible connecting pipe between the vacuum pump and coaxial interpiece

4

Coaxial interpiece for connecting of coaxial delivery hose

5

Coaxial delivery hose

6

Delivery nozzle for vapour recovery with integrated hydromechanical

proportional valve (ELAFLEX GRVP)

USER’S MANUAL V-line 46xx, 47xx

9

Pic. 2

Function of system VRC-M

The vacuum in the VRC-M system is created by piston vacuum pump (Item 2), which is powered via a rubber

belt of electric motor of pumping monoblock. For dispensers with pressure system is installed in a compact

unit - electric motor with integrated vacuum pump.

Outgoing gasoline vapors from the tank car when dispensing gasoline are drawn special adapter nozzle

(item 6), through the channel in the body to control flow through the nozzle hydromechanical valve

integrated into nozzle and into the inner coaxial hose DN 8 (Item 5). The coaxial spacer (Item 4) pairs are

fed to a flexible connecting pipe (Item 3), goes on to piston pumps (Item 2). The piston pump (item 2) are

pushed through a flexible pipe to the exhaust pipe vapor (Item 1). connected to the interior of the storage

tank (usually from the lowest octane gasoline.

Optimal flow of vapor is dynamically regulated by proportional hydromechanical valve depending on the

actual flow of liquid gasoline nozzle.

Proper function of vapor recovery is indicated by shining symbol of two arrows (Fig. 9) on the display of

electronic counter on the appropriate side of the dispenser.

Pic. 3

Pic. 4

System VRC non functional

System VRC is functional

4.4.2. System VRC-E

Vapour Recovery Control - Electronic - control the flow of vapor through the proportional solenoid

valve controlled electronic counter dispenser.

Vapour recovery system VRC-E of fuel dispensers V-line 46xx.xxx, 47xx.xxx consists of the following

basic components (structural layout and design is evident from Figure 1, 2:

Position

Unit name

1

Flexible pipe with union nut M 16 x 1,5 for connection to

outgoing pipe into storage tank.

2

Piston vacuum pump

3

Flexible connecting pipe between the vacuum pump and

electromagnetic proportional valve

4

Electromagnetic proportional valve

USER’S MANUAL V-line 46xx, 47xx

10

5

Flexible connecting pipe between the electromagnetic

proportional valve and coaxial interpiece

6

Coaxial interpiece for connecting of coaxial delivery hose

7

Coaxial delivery hose

8

Delivery nozzle for vapour recovery

9

Electronic counter ADP1/T, ADP2/T

Pic. 5

Function of system VRC-E

The vacuum in the VRC-M system is created by piston vacuum pump (Item 2), which is powered via a rubber

belt of electric motor of pumping monoblock. For dispensers with pressure system is installed in a compact

unit - electric motor with integrated vacuum pump.

Outgoing gasoline vapors from the tank car when dispensing gasoline are drawn special nozzle adapter

nozzle (pos. 8) through the channel in the body of the nozzle flow through the inner coaxial hose DN 8 (pos.

7). Inside of coaxial interpiece (pos. 6) pairs are guided to a flexible connecting pipe (pos. 4), then proceed

to the proportional solenoid valve (pos. 4). From the proportional valve through conecting flexible pipe

(pos. 3) guided to piston vakuum pump (pos. 2). From the piston pump (pos. 2) are drawn through flexible

pipe to outgoing pipe of petrol vapours (pos. 1) connected to imide space of storage tank (usually the

lowest octane gasoline tank).

Optimal flow of vapor is dynamically regulated by proportional solenoid valve directly controlled electronic

counter, depending on the flow rate of liquid gasoline respective meter. Electronic counter controls the

flow of vapor based on information about the volume flow meter calculator from magnetic pulse

transmitter.

Proper function of vapor recovery is indicated by shining symbol of two arrows (Fig. 9) on the display of

electronic counter on the appropriate side of the dispenser.

Pic. 3

Pic. 4

System VRC non functional

System VRC is functional

USER’S MANUAL V-line 46xx, 47xx

11

4.4.3. System VRC-M with VRMS

Vapour Recovery Control - Mechanical - flow control vapor through hydromechanical proportional valve

integrated into nozzle (ELAFLEX) controlled system VRMS (Vapor Recovery Monitoring System).

Systems VRC-M and VRMS working separately (independently).

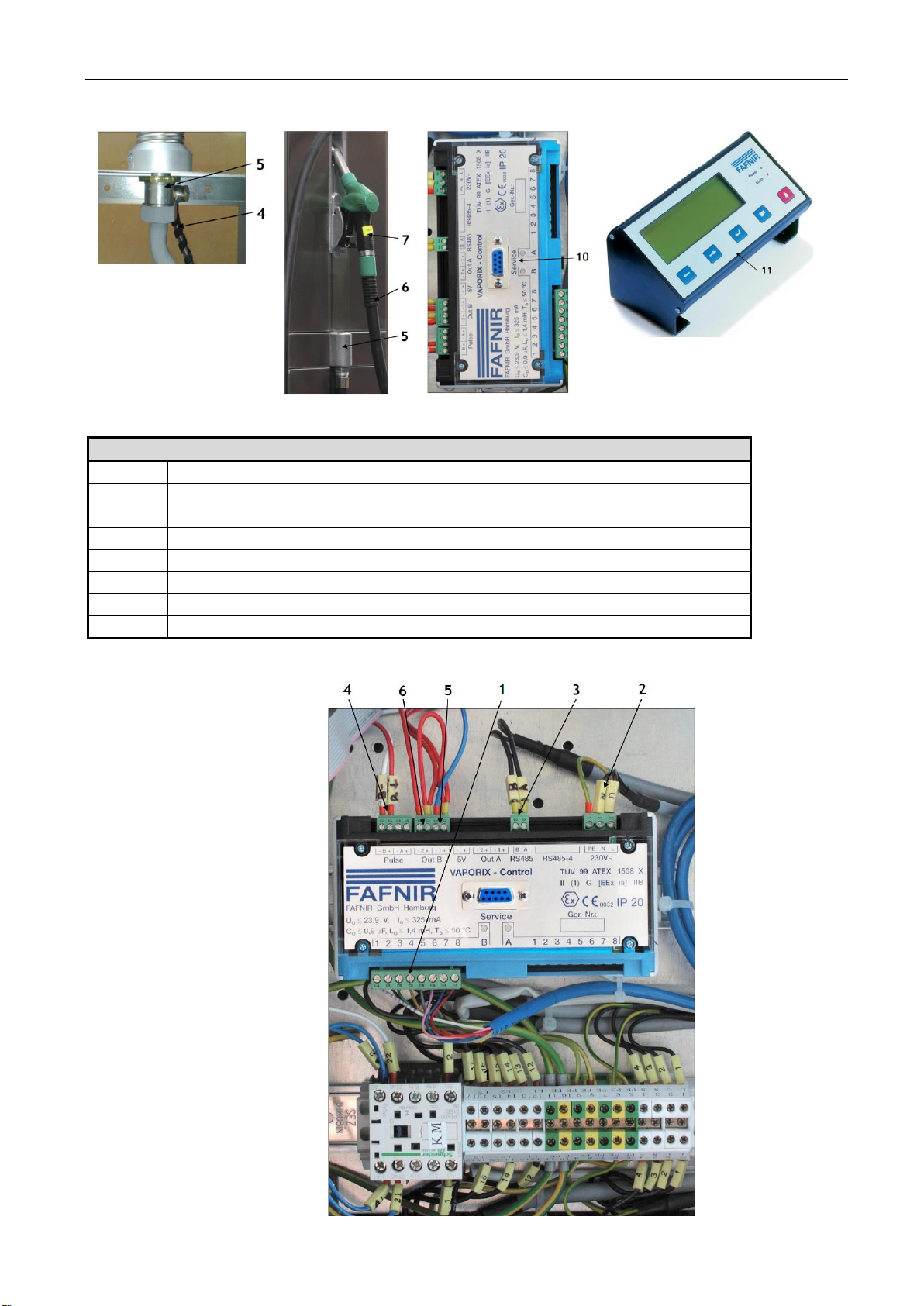

Complete system VRC-M + VRMS contains following components(as on pic. 3, 4, 6, 7, 8, 9):

Position

Unit name

Components of system VRC-M

1

Flexible pipe with union nut M 16 x 1,5 for connection to outgoing pipe into

storage tank.

2

Piston vacuum pump

3

Flexible connecting pipe between the vacuum pump and measuring probe

VAPORIX-Flow

4

Flexible connecting pipe between measuring probe VAPORIX-Flow and coaxial

interpiece

5

Coaxial interpiece for connecting of coaxial delivery hose

6

Coaxial delivery hose

7

Delivery nozzle for vapour recovery with integrated hydromechanical

proportional valve (ELAFLEX GRVP)

8

Electronic counter ADP1/L, ADP1/T, ADP2/T

Components of system VRMS –Fafnir VAPORIX

9

Measuring probe of vapour flow Fafnir VAPORIX-Flow

10

Electronic unit VAPORIX-Control

11

Electronic control unit VAPORIX-Master

Pic. 6

USER’S MANUAL V-line 46xx, 47xx

12

Pic. 7

Electronic connection of unit VAPORIX-Control

1

Terminal block for connection of measuring probe VAPORIX-Flow

2

Terminal block for connection of input power

3

Output –communication line for connecting of unit VAPORIX Master

4

Pulse inlet from the module VAP of electronic counter

5

Out A(B) 1 –NC contact „STOP“ – red diode

6

Out A(B) 2 - NO contact „ALARM“ – orange diode

7

Indicating LED-diode for side „A“

8

Indicating LED-diode for side „B“

Pic. 8

USER’S MANUAL V-line 46xx, 47xx

13

Pic. 9

4.4.4. System VRC-E with VRMS

Vapour Recovery Control - Mechanical - flow control vapor through hydromechanical proportional valve

integrated into nozzle (ELAFLEX) controlled system VRMS (Vapor Recovery Monitoring System).

VRC-M Systems and VRMS working separately (independently).

Complete system VRC-E + VRMS contains following components (as pic. 3, 4, 15, 16)

Position

Unit name

Components of system VRC-E

1

Flexible pipe with union nut M 16 x 1,5 for connection to outgoing pipe into storage tank.

2

Piston vacuum pump

3

Flexible connecting pipe between the vacuum pump and electromagnetic proportional valve

4

Regulation electromagnetic proportional valve

5

Flexible connecting pipe between the vacuum pump and measuring probe VAPORIX-Flow

6

Flexible connecting pipe between the measuring probe VAPORIX-Flow and coaxial interpiece

7

Coaxial interpiece for conection of coaxial delivery hose

8

Coaxial delivery hose

9

Delivery nozzle for vapour recovery

10

Electronic counter ADP1/T, ADP2/T

Components of system VRMS –Fafnir VAPORIX

11

Measuring probe of vapour flow Fafnir VAPORIX-Flow

12

Electronic unit VAPORIX-Control

13

Electronic control unit VAPORIX-Master

USER’S MANUAL V-line 46xx, 47xx

14

Pic. 15

Pic. 16

USER’S MANUAL V-line 46xx, 47xx

15

Pic. 10 Scheme of inputs and outlets of the unit VAPORIX-Control

USER’S MANUAL V-line 46xx, 47xx

16

Function of system VRC-M with VRMS

Function of system VRC-M

The vacuum in the VRC-M system is created plunger vacuum pump (Item 2), which is powered via a rubber

belt electric pumping monoblock. For dispensers with pressure system is installed in a compact unit with

integrated electric pump.

Outgoing gasoline vapors from the tank car when dispensing gasoline are drawn special adapter nozzle

(item 7), through the channel in the body to control flow through the gun hydromechanical valve integrated

into nozzle and into the inner coaxial hose DN 8 (Item 6). The coaxial spacer (Item 5) pairs are fed to a

flexible connecting pipe (Item 4), then proceed to the measurement sensor VAPORIX-Flow (poz.9) and then

connecting flexible pipe (Item 3) to the piston pump (pos. 2). The piston pump (item 2) are pushed through

a flexible pipe (Item 1) into the duct connected to the vapor inside the storage tank (usually from the

lowest octane gasoline).

Optimal flow of vapor is dynamically regulated proportional hydromechanical valve depending on the actual

flow of liquid gasoline nozzle.

Proper function of vapor recovery is indicated by shining symbol of two arrows (Fig. 9) on the display of

electronic counter on the appropriate side of the dispenser.

Pic. 3

Pic. 4

System VRC non functional

System VRC is functional

Function of system VRMS:

Automatic Monitoring System (VRMS) VAPORIX dynamically controls the system to function properly VRC.

Measuring sensor VAPORIX-Flow (Item 9) indicates the instantaneous flow and vapor flow rates found online

transmitted to the evaluation unit VAPORIX-Control (Item 10), which compares these values with the values

given volume of liquid gasoline from the transmitted pulse output electronic counter (Item 8) into the

VAPORIX-Control - Connection Figure 6 (Item 4).

The operational statue of the system can notify the operator VRMS at the kiosk station via electronic

unit VAPORIX-Master, which is usually located near the pumping station control system - POS. VAPORIX-

Control Units and VAPORIX-Master are communicatively connected via RS 485 interface using a

communication cable.

Function of system VRC-E with VRMS

Function of system VRC-E

The vacuum in the system VRC-E is generated plunger vacuum pump (Item 2), which is powered via a

rubber belt electric pumping monoblock. For dispensers with pressure system is installed in a compact unit

with integrated electric vacuum pump.

Outgoing gasoline vapors from the tank car when dispensing gasoline are drawn special adapter nozzle

(Item 9), through the channel in the gun body flowing into the inner coaxial hose DN 8 (Item 8), attached to

the coaxial spacer (item 7). The coaxial spacer (item 7) are fed to the steam flexible connecting pipe (Item

6), then proceed to the measurement sensor VAPORIX-Flow (poz.11) and then connecting flexible pipe

(item 5) to control the proportional solenoid valve. The valve is kept flexible pipe (Item 3) to the piston

pump (Item 2). The piston pump (item 2) are pushed through a flexible pipe (Item 1) into the duct

connected to the vapor inside the storage tank (usually from the lowest octane gasoline).

Optimal flow of vapor is dynamically regulated by the proportional hydromechanical valve depending on the

actual flow of liquid gasoline trought delivery nozzle.

Proper function of vapor recovery is indicated by shining symbol of two arrows (Fig. 9) on the display of

electronic counter on the appropriate side of the dispenser.

This manual suits for next models

1

Table of contents

Other Adast Systems Dispenser manuals

Popular Dispenser manuals by other brands

Silver King

Silver King Majestic SK10MAJ Technical manual and replacement parts list

NCR

NCR Retrofit OPTIC 5 Touch installation guide

Ecolab

Ecolab SCLS IV Installation and operation manual

Franke

Franke STRATOS STRX635B Installation and operating instructions

Sartorius

Sartorius Microsart e.motion 16713 BO operating instructions

lancer

lancer 9000 series Operation manual