• Take precautions from allowing powder or any other foreign debris from getting inside the load cell

area. The only way for powder to get inside the load cell area is if the platen is removed and if the

tubes are removed when still full of powder. To prevent this from happening ensure the platen is

always in place when there is powder in the reservoir. Also ensure the powder from the reservoir

and dispense tubes has been completely emptied prior to removing tubes for cleaning. If platen

needs to be removed, to clean spilled powder, ensure both tubes are capped to prevent powder

from falling out of tubes into load cell area.

• Do not press on the platform with your hand. You can damage the load cell.

RECORD KEEPING

• Keep complete records of reloads. Apply a descriptive label to each box showing the date

produced, and the primer, powder and bullet used. Labels for this purpose are packed with SPEER

bullets. Never attempt to guess at the identity of your ammunition.

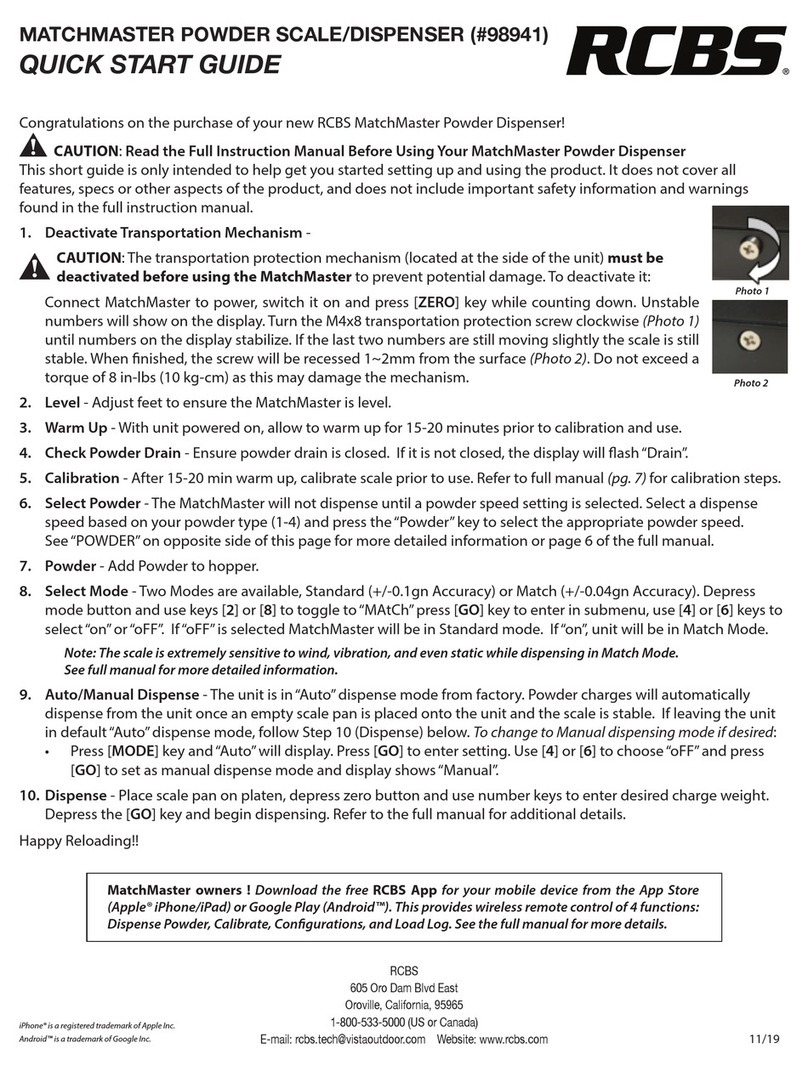

NOTE: The scale was shipped in protective packaging. Save and use for transporting or long-term

storage of the unit. See last page for address and Toll-free Customer Service phone number.

FCC Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment o and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Shielded interface cable must be used with the equipment in order to comply with the limits for a digital device pursuant to Subpart B of Part 15 of FCC Rules. Specications and

designs are subject to change without any notice or obligation on the part of the manufacturer.

Disposal of Electric and Electronic Equipment

(Applicable in the EU and other European countries with separate collection systems)

This equipment contains electric and/or electronic parts and must therefore not be disposed of as normal household waste. Instead, it should be disposed

at the respective collection points for recycling provided by the communities. For you, this is free of charge.

If the equipment contains exchangeable (rechargeable) batteries, these too must be removed before and, if necessary, in turn be disposed of according

to the relevant regulations (see also the respective comments in this unit’s instructions).

Further information about the subject is available at your community administration, your local waste collection company, or in the store where you

purchased this equipment.

3