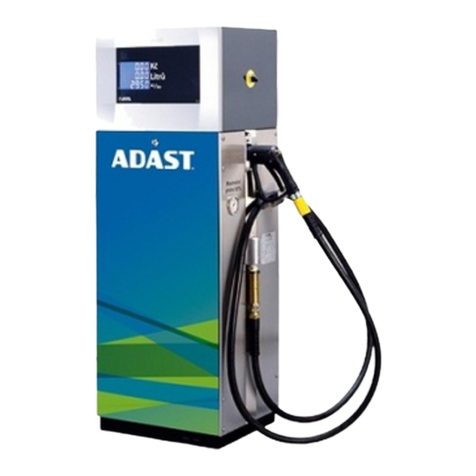

Adast Systems AdBlue V-line 47 Series User manual

Adast Systems, a.s., 679 04 Adamov No. 496, Czech Republic

T +420 516 519 201, F+420 516 519 102, sales@adastsystems.cz

www.adastsystems.cz

MKT 010-004-2007/A

VII/2017

USER´S MANUAL

Instructions for Operation, Maintenance

and Installation

AdBlue® dispenser

MAJOR

V-line AdBlue®47xx.xxx

USER’S MANUAL V-line AdBlue®47xx.xxx

I

OBSAH

1. IMPORTANT NOTICE................................................................................................................................1

2. USE.............................................................................................................................................................2

3. INSTRUCTIONS FOR THE SAFETY OF WORK ......................................................................................2

3.1. Safety of the equipment design ......................................................................................................2

3.2. Operation safety..............................................................................................................................3

3.3. Ecological safety.............................................................................................................................3

3.4. Hygiene...........................................................................................................................................3

4. DESCRIPTION ...........................................................................................................................................4

4.1. Design of the dispenser ..................................................................................................................4

4.2. Skeleton of the dispenser ...............................................................................................................4

4.2.1 Case of the electronic counter ........................................................................................................4

4.2.2 Case of the electronic counter –design 2017 (see fig.)..................................................................4

4.3. Hydraulic system of V-line AdBlue®47xx.xxx dispenser................................................................6

4.3.1 Filter................................................................................................................................................8

4.3.2 Piston flow meter............................................................................................................................8

4.3.3 Electromagnetic(solenoid) valve ....................................................................................................9

4.3.4 Delivery hose AdBlue®.....................................................................................................................9

4.3.5 Delivery nozzle AdBlue®..................................................................................................................9

4.3.6 Connection elements ......................................................................................................................9

4.4. Electronics.......................................................................................................................................9

4.4.1 Communication to the control system .........................................................................................10

4.5. Signalling of dispenser conditions (SO)........................................................................................10

4.6. SOPA design.................................................................................................................................11

4.7. Design with heating of the electronic case ...................................................................................11

4.8. Heating of hydraulic housing.........................................................................................................11

5. TECHNICAL DATA..................................................................................................................................11

6. MARKING.................................................................................................................................................12

7. INSTALLATION........................................................................................................................................12

7.1. Hydraulic part................................................................................................................................12

7.2. Wiring............................................................................................................................................13

8. PUTING INTO OPERATION ....................................................................................................................13

8.1. Puting of the AdBlue® dispenser to operation mode.....................................................................13

8.2. Puting of AdBlue® dispenser to OFF mode...................................................................................14

8.3. New reseting of AdBlue® dispenser into operation after power supply failure..............................14

9. OPERATION.............................................................................................................................................14

10. FUNTION OF MANAGER AND SERVICE KEYBOARD.........................................................................14

10.1 Manual setting of unit prices.........................................................................................................15

USER’S MANUAL V-line AdBlue®47xx.xxx

II

10.2 Setting of unit price values from the control system in AUTO mode............................................ 16

10.3 Display of electronic totalizers...................................................................................................... 16

11. MAINTENANCE OF A DISPENSER AND ITS INDIVIDUAL OPERATING UNITS ............................... 17

11.1. Filter.............................................................................................................................................. 17

11.2. Piston flowmeter........................................................................................................................... 18

11.3. Electromagnetic two-stage valve ................................................................................................. 18

11.4. Sight glass of the dispenser......................................................................................................... 18

11.5. Dispensing hose........................................................................................................................... 18

11.6. Dispensing nozzle ........................................................................................................................ 18

11.7. Dismantling of covers................................................................................................................... 18

11.8. Electronic counter......................................................................................................................... 19

11.9. Maintenance instructions for dispenser body parts...................................................................... 19

12. SUMMARY OF BASIC PRINCIPLES FOR DISPENSER MAINTENANCE ........................................... 20

13. DISASSEMBLY AND DISPOSAL........................................................................................................... 20

14. TRANSPORT........................................................................................................................................... 20

15. PACKING AND STORAGE..................................................................................................................... 21

15.1. Packing......................................................................................................................................... 21

15.2. Storage......................................................................................................................................... 21

16. GUARANTEE AND CLAIMING............................................................................................................... 21

17. SPARE PARTS CATALOGUE................................................................................................................ 22

18. ACCESSORIES....................................................................................................................................... 22

19. DELIVERED DOCUMENTATION ........................................................................................................... 22

20. ENCLOSURES ........................................................................................................................................ 22

USER’S MANUAL V-line AdBlue®47xx.xxx

1

1. IMPORTANT NOTICE

This document is user guide, how to provide installation, operation and maintenance and service of AdBlue®

dispenser.

Stated information in this manual is strictly recomended and producer can not response for damages

caused by non keeping rules described in this guide.

ATTENTION!

AdBlue® dispenser V-line 47xx.xxx AdBlue®designed for filling stations is determined only for

delivery of reduction medium AUS 32 ISO 2224.

It is not allowed to use such AdBlue® dispenser for delivery of flammable fluids !

ATTENTION!

AdBlue®is solution of pure urea and desalted clear water with 32,5 % content of urea.

Solution is used as reducing agent for lowering of nitrogen emissions NOx in diesel powered engines –

in special SCR catalysator (SCR –„selective catalytic reduction“).

AdBlue®is highly corrosive !

AdBlue®begins to crystalize at a temperature –11 oC!

To guarantee proper function of SCR catalysator in motor vehicle is necesarry to provide regullar

check of solution quality AdBlue®as per norm ISO 22241!

Quality, chemical consistence and physical characteristic of solution AdBlue®must be in accordance

with norm ISO 22241-1!

International marking of reducing agent AdBlue®:

AUS 32 ISO 22241

Therefore before puting AdBlue® dispenser into operation must be checked clean surface of storage

tank(s), entering pipeline(s) and purity of dispensed medium - AdBlue®. Further must be provided

revision of power wiring and check of electric connections, to prevent electric shock.

Every AdBlue® dispenser is tested in production plant for funtionality, safety and metrology. Every delivery

contains user´s manual , ES declaration of conformity and service book with units identification of the

AdBlue® dispenser. AdBlue® dispenser is designed and produced carefully to provide long term safety

work.During installation and operation must be kept basic safety rules to prevent device user from

potential injuries.

It is not allowed to provide any hardware changes without written permit of the manufacturer.

Important instructions for installation and operation:

a) Please study carefully the user´s manuall and other documentation efore manipulation with the AdBlue®

dispenser.

b) Please study the delivery content and if you find any discrepancy inform the supplier imediatelly.

c) In time period before installation the AdBlue® dispenser provide storage inside dry protected space.

The AdBlue® dispenser can not be stored in place with temperature bellow zero(freezing space).

d) Before the installation check completnes of technology as per valid project and check the delivery

pipelines including the connecting fittings.

e) Provide the flushing of technological unit (pipeline systems) by filter unit AdBlue®.Keep flushing

untill filter unit will apear clean.

ATTENTION!

FOR CLEANING OF PIPELINE SYSTÉM MAY NOT BE USED PETROLEUM PRODUCTS OR ANY OTHER

CHEMICALS ABLE TO CONTAMINE DELIVERED MEDIUM AdBlue®!

f) Provide electric connection of AdBlue® dispenser and revision.

g) Strictly follow the manual.

h) By complete of these conditions can be unit set to operation mode.

USER’S MANUAL V-line AdBlue®47xx.xxx

2

i) Service operations and installation can be provided only by trained service persons.

Service operation must be in accordance with operation rules of the filling station.

Producer does not response for damages made by non qualified persons.

j) Provider can start delivery after close of filling station revision and after official metrologic

inspection of AdBlue® dispensers.

k) By delivery of the AdBlue®must be kept basic hygienic rules. Provider must allow to the buer to use

hand protection like as ecoplastic sloves.

l) During operation of AdBlue® dispenser in winter time (ambient temperature lowering (Tamb.) under

freezing point) must be permanent switch on heating function of AdBlue® dispenser and storage

container. This notice is valid even the filling station i sout of order.

PLEASE STORAGE THIS MANUAL FOR NEXT USE!

2. USE

AdBlue® dispensers of type line V-line AdBlue®47xx.xxx is designed for delivery AdBlue®into vehicles with

diesel engine. AdBlue®is reducing agent AUS 32 ISO 22241, used in vehicle catalysators powered by diesel

with catalic selective reduction for lowering of emissions NOx.

They have been designed for the installation at road filling stations and a fleet of vehicles, etc.

By means of a communication line the dispensers are connected to the control system of self-service

operation or serviced operation.

The dispensers are equipment with special requirements concerning safety, metrology and ecology.

ATTENTION!

AdBlue® dispenser V-line AdBlue®47xx.xxx can be operand only with reduction agent

AUS 32 ISO 22241.

Any use for delivery of flammable fluids is not allowed !

3. INSTRUCTIONS FOR THE SAFETY OF WORK

3.1. Safety of the equipment design

AdBlue® dispenser is designed for installation to outside conditions

Enviromental class

C (outside - stationar)

Mechanical class

M 2 - for electronic Beta Control ADPxxx

M 1 –for electronic UNIDATAZ CDC

Electromagnetical class

E 2 - for electronic Beta Control ADPxxx

E 1 –for electronic UNIDATAZ CDC

Enviroment humidity

With condensation

ATTENTION!

AdBlue® dispenser may not be installed to danger explosive zone 0, 1, 2 in meanings of dedicated

zones as per ČSN EN 60079-10-1!

From point of technical requirements settled for measurement units was at the AdBlue®dispenser

performed EU type examination (type certification) according to Annex II, Module B of the Directive

of European Parliament and the Council 2014/32/EU authorised body –Český metrologický institut,

Okružní 31, 638 00 Brno – Notified body No. 1383.

EC - Type Examination Certificate: No. TCM 141/07 –4518

USER’S MANUAL V-line AdBlue®47xx.xxx

3

For the AdBlue®dispenser has been made conformity assesment by type described in EC - Type

Examination Certificate No TCM 141/07 - 4518 and technical requirements according to Annex II,

Module D of the Directive of European Parliament and the Council 2014/32/EU

The producer is competent for “The Declaration of Conformity” with the type based on production

quality assurance of measuring units according to Annex II, Module D of the Directive of European

Parliament and the Council 2014/32/EU

Certificate of the Quality Management System for production, check-out and testing according to

Annex II, Module D of the Directive 2014/32/EU: No. 0119-SJ-C007-07

3.2. Operation safety

The owner is responsible for the filling station operation and is obliged to observe the course of AdBlue®

pumping. In case a customer uses the dispenser incorrectly, the owner shall instruct him about proper use.

Operation regulations of the filling station shall be accessible for the customer, which enables him to get

information on principal obligations.

Operator’s obligation:

–Keep the equipment in safe and proper condition.

–Follow the operation regulations and attendance instructions of the filling station.

–Report immediately any failure to the owner and put the equipment out of operation in case of delay.

–Keep order permanently.

–The dispenser and storage tank operators are not allowed to repair the equipment and to reset any

safety valves.

Performance of service work is a special case. Servicemen are not allowed to break operation safety

during repairs and other activities. When dispenser covers are removed, they shall be very careful to

protect both them and customers against injury.

El. current supply shall be disconnected when handling el. components. Only approved components

shall be used to replace any parts.

All parts subject to approval shall be always in conditions required by the technical documentation

(leakproofness, earthing, electrostatic belts, electrostatically conductive filling hoses, etc.).

3.3. Ecological safety

Dispenser V-line R AdBlue®is in terms of running for ecologically safe environment. The urea solution

was placed by the evaluation of substances hazardous to water class 1 (slightly hazardous for water. The

high solubility of urea in water prevents absorption into the soil.

3.4. Hygiene

ATTENTION!

The dispensers are hygienically harmless for customers and the owner. But protective gloves are advised

to be used during maintenance or filling AdBlue®.

In case skin comes to contact with fuel or impurities, wash the spot with water and soap as soon as

possible. When eyes come to contact, medical treatment is necessary. Do not inhale harmful vapours

when filling AdBlue®.

USER’S MANUAL V-line AdBlue®47xx.xxx

4

4. DESCRIPTION

4.1. Design of the dispenser

The V-line R AdBlue®47xx.xxx dispensers with electronic counter are used to the dispensing of AdBlue® .

These dispensers are one-sided or two-sided simultaneous output of 1 products.

The dispensers are designed as self-holding sectional construction.

The V-line R AdBlue®47xx.xxx dispensers with automatic hose winding are manufactured in two

modifications:

type V-line R AdBlue® 4701.100, 4701.010 –1 product, 1 nozzle

type V-line R AdBlue® 4701.200, 4701.020, 4701.110 –1 product, 2 nozzles

(one sort of product two filling points)

Construction of V-line R AdBlue®47xx.xxx dispensers consist from following basic modules:

- skeleton

- hydraulic system

- electric equipment

4.2. Skeleton of the dispenser

Skeleton –a self-supporting construction consisting of parts with high anticorrosive resistance. The base of

the dispenser is made of steel sheet and heat zinc-coated. Internal parts of the skeleton are made of

stainless sheet. Parts of the body with the exception of the door of the hydraulic module and the

electronic counter case are made of stainless brushed sheet as a standard.

The doors of the hydraulic module and the electronic counter case are finished by high resistence acrylate

painting. The colour shade of the door including the logo can be optional.

Both doors are lockable; being unlocked, swing out and with earth wire disconnected they can be removed

and thus the hydraulic part including electric switch box are accessible. Connect the earth wires when the

door is fitted back.

A case of the electronic counter or ADAMAT electronics is bolted to the hose module column. The counter

case space is closed with lockable covers. The covers are provided with transparent glass. Indicators with

integrated large-area display of dispensed volume, total price of dispensed volume and a price for one unit

of dispensed volume are connected from the case interior to the covers or unresetable electromechanical

total counters (totalizers) and modules of fuel price per unit are integrated to the indicator. The set of

these elements represents all necessary information for the customer.

The covers of the case are hung up on hinges enabling tilting upwards after unlocking and thereby easy

access in the case interior. The user’s local preselection keyboard is located on the case cover as well.

The dispensing nozzles are seated in covers in the „V“ form pressed shape of the column and bearers of the

hose module. When the dispenser is out of operation the dispensing nozzles in covers can be locked.

4.2.1 Case of the electronic counter

The counter case space is closed with lockable covers. The covers are provided with transparent glass.

Indicators with integrated large-area display of dispensed volume, total price, price for one unit and

unresetable electromechanical total counters (totalizers) are connected from the case interior to the covers.

The set of these elements represents all necessary information for the customer.

The covers of the case are hung up on hinges enabling tilting upwards after unlocking and thereby easy

access in the case interior. The user’s local preselection keyboard (if required) is located on the case cover as

well - an independent keyboard for each dispensing point.

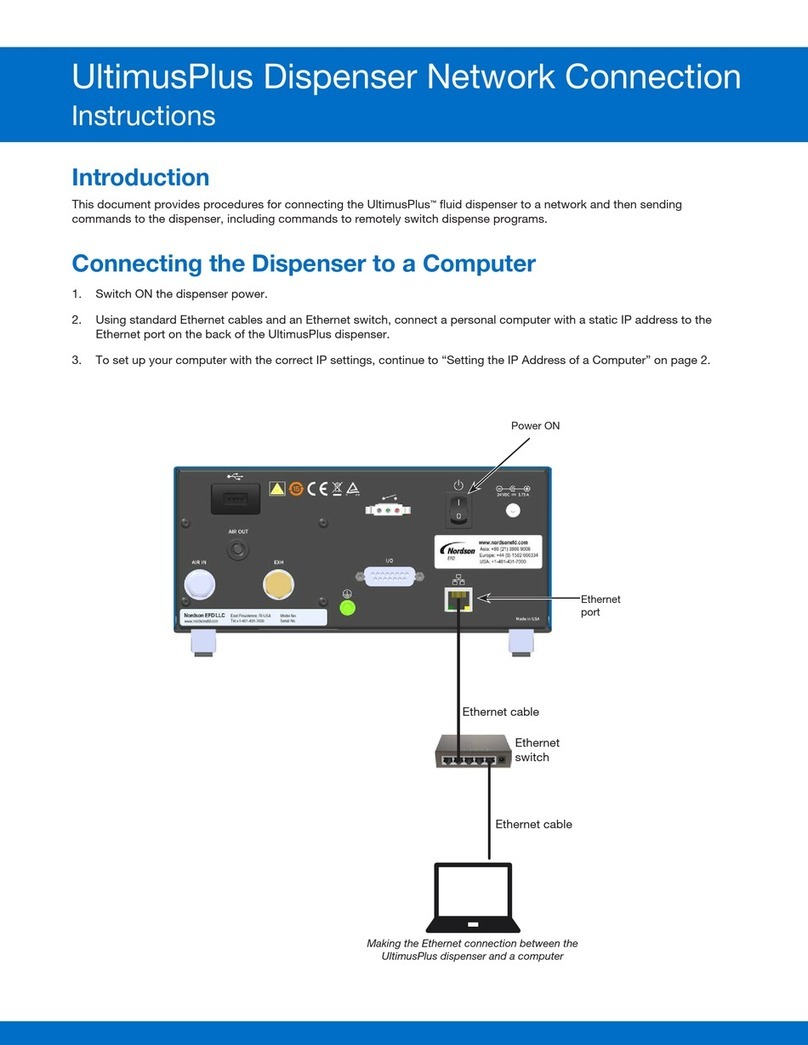

4.2.2 Case of the electronic counter –design 2017 (see fig.)

The counter case (1) space is closed with lockable covers (2). The covers are provided with transparent glass.

On the inside cover of the case is mounted under glass large-area display (3) issued volume and total price,

which displays all necessary information for the customer.

USER’S MANUAL V-line AdBlue®47xx.xxx

5

Above the display is placed IR sensor (5) for

controlling and adjusting the dispenser

calculator manager or servicing keyboard.

On the outer side of the case cover is placed

(optional) keyboard local user preferences

(4) - an independent keyboard for each

dispensing point.

On request they can be built in a case

unresetable electromechanical total

counters –totalizers (6), which are accessed

by opening the cover.

ATTENTION!

Before opening the covers, it is always necessary to disconnect power to the dispenser and

perform a reliable hedge against its re-connection.

USER’S MANUAL V-line AdBlue®47xx.xxx

6

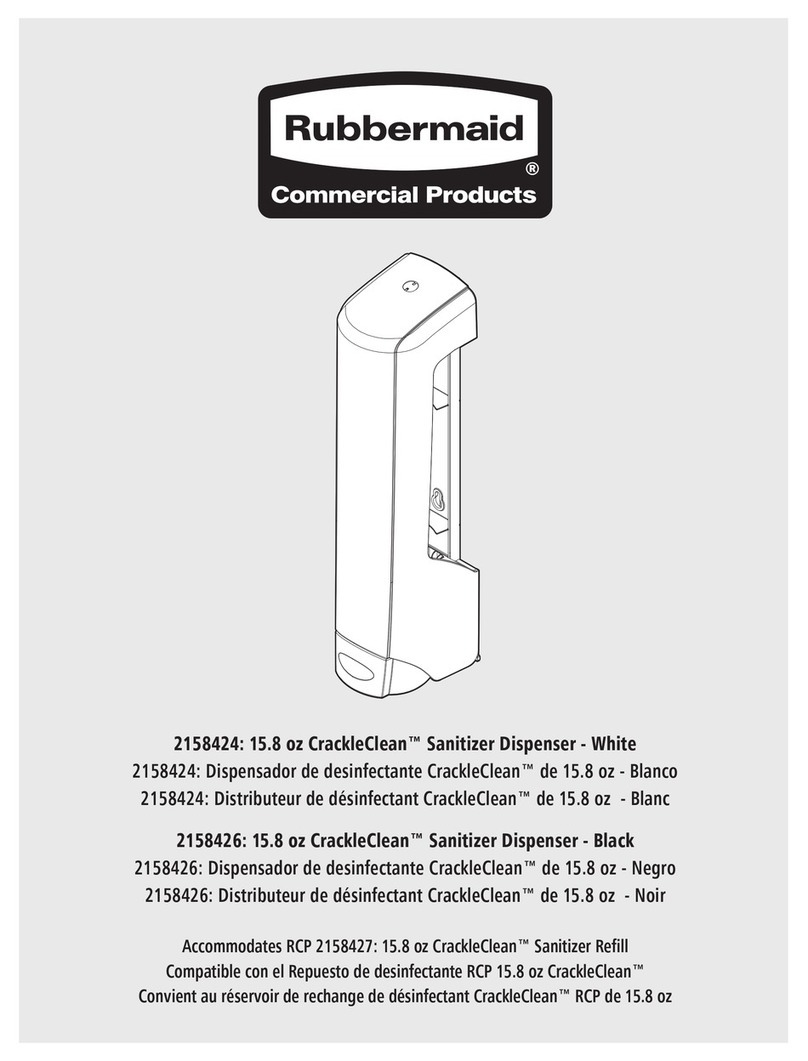

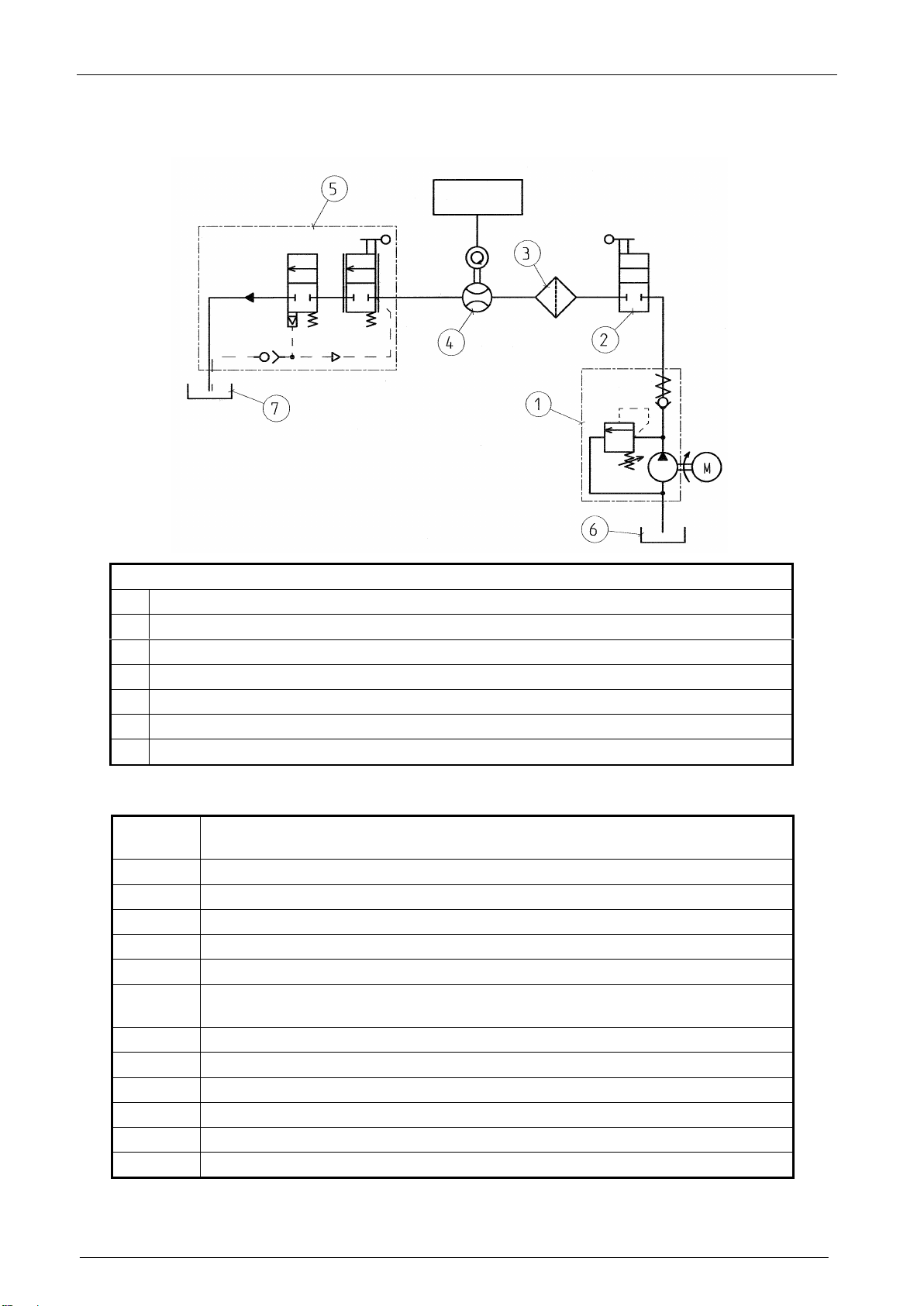

4.3. Hydraulic system of V-line AdBlue®47xx.xxx dispenser

Figure. 1 –Hydraulic scheme of V-line AdBlue®47xx.xxx dispenser

Legend

1

Submersible pump

2

Closing valve

3

Filter

4

Electronic meter ADAST M 403.25 EAP/1 + el. counter ADP1/L, ADP1/T, ADP2/T

5

Delivery nozzle

6

Storage tank of AdBlue®

7

Vehicle tank

Hydraulic system of the V-line R AdBlue®47xx.xxx dispenser consisting of components (Figure 2):

Position

number

Components of AdBlue®hydraulic system of the AdBlue®dispenser

1

Ball valve G 1“

2

Drain ball valve

3

Filter AdBlue®

4

Connecting pipe between the filter and meter

5

Meter flange

6

Four-piston all-aluminium AdBlue® meter with integrated magnetic pulse

transmitter ADAST M 403.25EAP/1

7

Magnetic pulse transmitter METRA MTX 076 or ADAST41

8

Valve flange

9

AdBlue®electromagnetic valve

10

Hose adaptor DN 16

11

Hose DN 16 to the nozzle

12

Heating of hydraulic housing

USER’S MANUAL V-line AdBlue®47xx.xxx

7

Figure. 2

USER’S MANUAL V-line AdBlue®47xx.xxx

8

V-line AdBlue®47xx.xxx series dispensers (pressure design) differ from suction dispensers because they

are not equipped with the pumping monoblock. A safety breaking valve shall be fitted in the connection.

The valve prevents AdBlue®leakage in case of the dispenser damage. This valve is not a part of the

dispenser, as well as the pump, which is located in the underground tank. The pressure dispensers are

equipped with an inlet spherical valve for closing the AdBlue®input in case of repairs.

The pumped AdBlue®is supplied from the central submerged pump located directly in the fuel storage tank

through the safety breaking valve, spherical check valve and the filter with filtering property of 60 µm.

Liquid is discharged from the filter through the meter and the electromagnetic valve to the dispensing hose

with the dispensing nozzle at its end. The dispensing nozzle lever controls the rate of flow.

The pressure system of the distribution should be designed with a submerged pump built-in directly into the

storage tank under the substance level. The tank should be equipped with a detector of the lowest

substance level switching the el. circuit of the pump motor being the min. level attained.

The location of the pump under the lowest fluid level in the storage tank and the min. level control switch

shall prevent the access of air or gas into the pump.

P12 = 0 parameter shall be preselected in the electronic counter for the pressure system of submerged

pumps operation in the storage tank in case of V-line AdBlue®47xx.xxx dispensers operation. At first the

electronic counter starts up the submerged pump in this mode of operation (the fluid in entire hydraulic

system is under pressure) then the counter tests the displays and closes the el. magnetic valve - and the

dispensing is started. Applying these conditions is the requirement 5.1.3 OIML R 117-1 2007 (E).

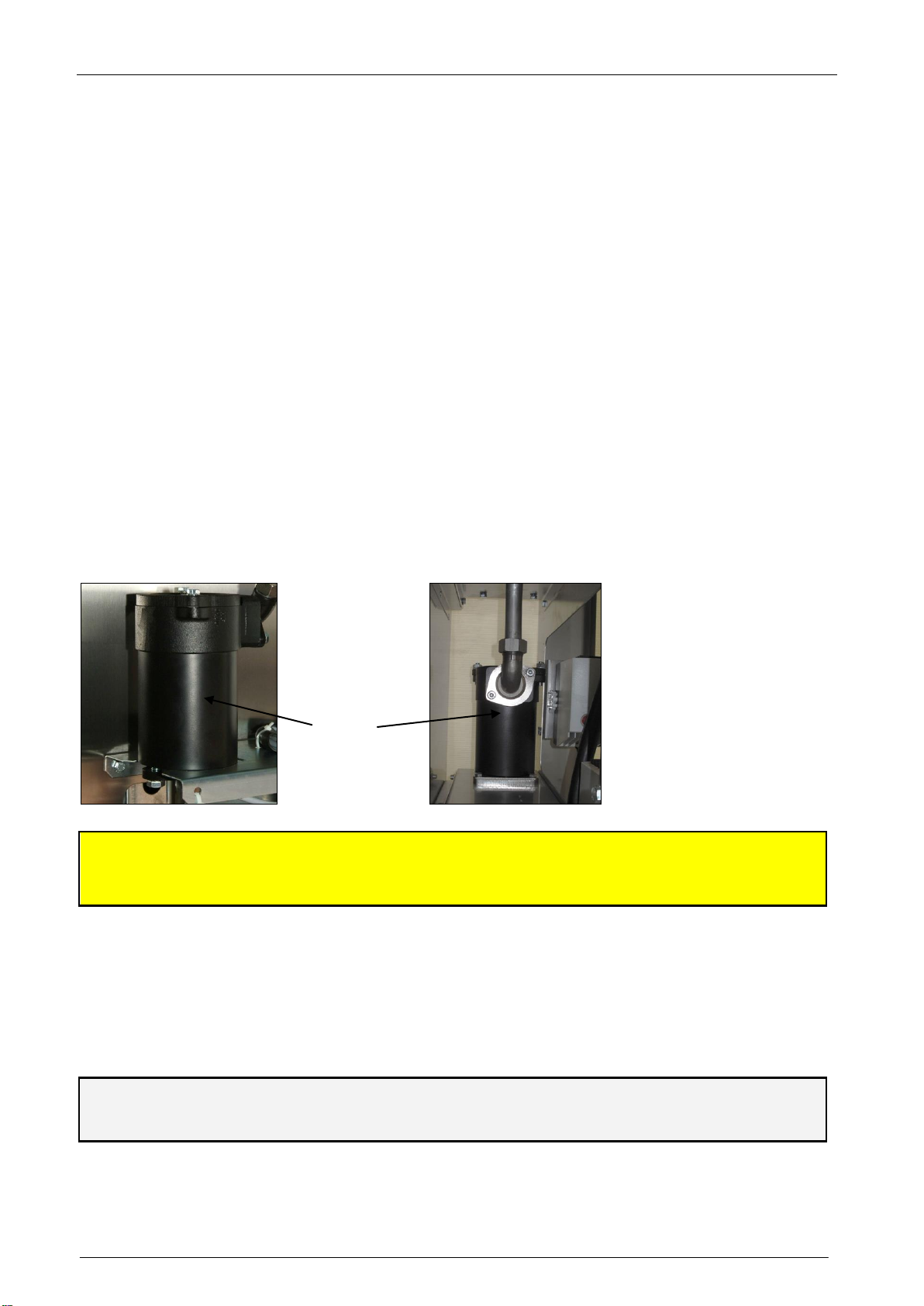

4.3.1 Filter

Whole metalic filter (pos.3) is connected by connection (pos. 4) to inlet of the meter (pos. 4) –to meter

flange (pos. 5) and closing stainless baal valve (pos. 1).

Filter is equipped by stainless filter insert with filtration ability 60 µm.

ATTENTION!

Filter is designed as meter protection from mechanical damage contained imide of dispensed

medium AdBlue®. Purity of dispensed medium AdBlue®must be guaranted by medium subsupplier

and permanent clean policy of storage space inside of storage container.

4.3.2 Piston flow meter

Measuring unit consists from four piston unit and integrated magnetic encoder. Measuring unit is measuring

in flow rate range 4 - 40 dm3.min-1 and operational temperatures of measured medium - 10 až +30 °C and

ambient temperature -40°C to +55 °C for nominal pressure up to 0,32 MPa.

Encoder is reading spins of magnet disc connected to central shaft and transfering the spins to electronic

signal.

Meters are supplied with optional integrated magnetic pulse transmitter METRA MTX 076

or ADAST 41 - M 403.25AP/1, M 403.32EAP/1.

Meters with the designation of EP in electronic calibration, indicating P mechanical calibration.

Filter

USER’S MANUAL V-line AdBlue®47xx.xxx

9

4.3.3 Electromagnetic(solenoid) valve

Electromagnetic valve is placed on meter output. Valve control is provided by electronic counter. Body of

the valve is nicle plated, pistons and bushes are finished from material on teflon basis.

Electromagnetic valve is supplied as option upon costumer request.

4.3.4 Delivery hose AdBlue®

Delivery hose AdBlue®is finished from speciall rubber designed for AdBlue®. Delivery hose is placed on hose

reel and ended by delivery nozzle.

4.3.5 Delivery nozzle AdBlue®

Speciall finishing of components delivery nozzle ELAFLEX AdBlue®made from materials resistent to

medium AdBlue®. The nozzle is equiped by automatic closing valve, function STOP system preventing tank

overfilling and by swivel.

Inside of nozzle spout is build in magnetic valve.The dispensing is possible only if the defined magnetic

zone in filling inlet of vehicle tank will open magnetic svitch in spout of delivery nozzle. By this safety

fiction is eliminated to fill different fuel tank by product AdBlue®. Delivery nozzle is hanged in speciall

vertical cover imide of external module of AdBlue® dispenser. Nozzle space is covered by front doors a in

temperature fall down is heated.

The nozzle with covering doors can be locked if the station is in off mode.

4.3.6 Connection elements

Connections of hydraulic system of container filling station is made by connecting pipes and fittings made

from speciall stainless steels and speciall ruber hose resistent to AdBlue®.

Baal valve G 1“

4.4. Electronics

The dispenser control shall meet the exacting requirements of simplicity and convenience and depends on

the hanging up and lifting of the dispensing nozzle.

ADPMPD/T, ADPMPD/T-PWM, ADP1/T, ADP2/T, ADP1/L electronic counter of an up-to-date design with

central processor board equipped with a high efficient microprocessor. The configuration of the counter

and its modes of operation are adjusted by more than seventy parameters. The counter is provided with a

self-diagnostic system. The counter outlets control the motors, valves, signalling circuits and vapours

exhaustion. The electronic counter processes the impulses coming from the impulse sensor and transmits

them to the display, which displays the dispensed volume, its price and a price per a volume unit. In case

of power failure or voltage drop the data displayed on the LCD remain for 30minutes at least.

Counters ADPMPD/T, ADP1/T, ADP2/T, ADP1/L are standardly equipped for electronic meter calibration

(Electronic Calibration of Meters –EC) and per request by ATC –(Automatic Temperature

Compensation).

Electronic Calibration of Meters (EC) enable to correct measured volume by designed declination in

operation range -5,00 % to +5,00 % of recognised meter non accurancy by step of 0,05 %.

Baal valve G 1“

Filter flange

Connecting pipe

between the

filter and meter

USER’S MANUAL V-line AdBlue®47xx.xxx

10

Providing of calibration is allowed to authorised person, only. The DIP calibration switches must be fixed by

plomb after calibration finish.

Displays: LCD type with BACK LIGHT illumination

LCD displays with BACK LIGHT DISPLAY (BLD) illumination are used especially for their good readability.

The duration of data holding on the display after supply voltage failure is 30 minutes at least. Decimal point

on BLD display devices is represented automatically in accordance with the setting of parameters.

Lighting

LED diodes are used for the illumination of displays at dispensers.

ON / OFF switching of the illumination is automatically carried out with the activation of electronics.

Totalizer: non-resettable electronic counter of dispensed volume and its price –11 digits –or non-

resettable electromechanical counter of dispensed volume –7 digits.

Electronic counter of ADPMPD/T, ADPMPD/T-PWM, ADP1/T, ADP2/T, ADP1/L series operates with a 2-

channel impulse generator producing 2x 100 impulses per 1 dm3. The HW and SW counters of the

ADPMPD/T, ADP1/T, ADP2/T, ADP1/L series enable high metering accuracy and the application of the

electronic calibration using the 2-channel impulse generator.

IMPORTANT NOTICE:

Connection of the magnetic pulse transmitter ME 01-05, ME 01-05-05, MTX 076 and ADAST 41 to the

electronic counter ADP1/L (connector X1), electronic counter ADP1/T, ADP2/T (connector X2) and

electronic counter ADPMPDx/T, ADPMPDx/T-PWM (connector X3) - see enclosure 8, 9, 10.

The local electronic preselection system in IP67 design is integrated into the counter case. The

preselection enables the Customer’s preselection of the exact volume or the price of the product to be

dispensed. The two-stage or proportional electromagnetic valves ensure the closing of flow and exact

dispensing of the preselected volume / price and smooth initiation of dispensing.

The fuel dispensers can be equipped with ADAMAT filling automatic equipment. This equipment enables

dispensing and payment of the product by means of contactless, magnetic and chip cards including receipt

printing. This equipment undertakes simultaneously all functions of the dispenser electronic counter for

non-public and public dispensing. The electronics of the filling automatic equipment can be complemented

by the ADPMPD/T, ADPMPD/T-PWM, ADP1/T, ADP2/T, ADP1/L electronic counter with public dispensing.

The fuel dispenser is connected through a communication line to the control system, which controls the

operation of the whole filling station (releasing of dispensers, volume preselection, unit price variation,

self-diagnosis, etc.). The dispensers can be operated even at the filling stations without any control system

–i.e. in serviced operation.

Circuit diagrams for the connection of individual dispenser types to the switchboard of the filling station –

see enclosures.

4.4.1 Communication to the control system

The ADP1/T, ADP2/T, ADP1/calculator can operate independently and/or can be controlled by a site

control system.

The calculator is connected to the site control system via the RS-485 line, which is controlled by its own

communication protocol EASY-CALL, and /or according to IFSF standards (communication level LON or

TCP/IP- Ethernet).

Communication to different control systems shall be consulted with the manufacturer of the dispensers

in advance.

The fuel dispensers connected to the control system can be operated in the mode of volume preselection or

the financial sum preselection from the control system (the dispensers have to be equipped with two-

stage or proportional electromagnetic valves).

4.5. Signalling of dispenser conditions (SO)

On Client’s special requirement the fuel dispenser can be equipped with a red signal light, which gives

information to the customer and the operator about the present dispenser condition –the dispenser is

blocked or ready for fuel filling.

USER’S MANUAL V-line AdBlue®47xx.xxx

11

4.6. SOPA design

On Client’s special request the dispenser in service mode can be equipped with magnetic release switch

(SOPA design). The operator of the filling station can release the dispenser for single filling operation in this

mode. After nozzle lifting the displays are reset and fuel filling is started.

After hanging up the nozzle, the dispensed volume and quantity values are permanently displayed until the

dispenser is magnetic released and the dispensing nozzle is lifted off subsequently. The red signal light

informs both the operator and the customer about the condition of the dispenser.

4.7. Design with heating of the electronic case

On the special customer´s requirement the fuel dispenser can be delivered with heating of electronic case

by heater 250 W. For feeding of the heating is used an individual cable.

4.8. Heating of hydraulic housing

In the closet hydraulically dispenser is built powerful fan heater with thermostat - power 950 W. Protects

interior hydraulic hose module and the module against condensation and thermal protection components of

the hydraulic system of the dispenser against crystallization and AdBlue®freezes when temperatures drop

below freezing.

5. TECHNICAL DATA

Electronic counter

ADPMPD/T, ADP1/T, ADP2/T, ADP1/L

Tankautomat (CRID)

ADAMAT/PNN, ADAMAT/PNA, ADAMAT/EMV

Display

Iluminated LCD - BACK LIGHT DISPLAY (BLD)

ADAMAT - Graphic BLD, Touch screen

Connecting piece –pressure system

DN 25 with external screw G 1“

Minimum innner diameter required

DN 16 (stainless pipe or special rubber hose for AdBlue®)

Alternative DN 19 –rubber hose for AdBlue®

Measured fluid

AUS 32 ISO 22241 (AdBlue®)

Accuracy of measurement

± 0,5 %

Max. operating pressure pmax

0,32 MPa

Min. operating pressure pmin

0,12 MPa

Max. flow rate Qmax

40 dm3.min-1

20 dm3.min-1

10 dm3.min-1

Min. flow rate Qmin

4 dm3.min-1

2 dm3.min-1

2 dm3.min-1

Min. measured quantity (MMQ)

2 dm3

2 dm3

2 dm3

Maximum flow rate when dispensing from one

nozzle Qmax

40 ±4 dm3.min-1 (for dispenser 4701.xx0/40)

20 ±2 dm3.min-1 (for dispenser 4701.xx0/20)

10 ±1 dm3.min-1 (for dispenser 4701.xx0/10)

Maximum flow rate when dispensing from both

nozzless simultaneously Qmax

30 ±3/30 ±3 dm3.min-1 (for dispenser 4701.20x/40/40)

30 ±3/5 ±1 dm3.min-1 (for dispenser 4701.11x/40/10)

15 ±2/5 ±1 dm3.min-1 (for dispenser 4701.11x/20/10)

5 ±1/5 ±1 dm3.min-1 (for dispenser 4701.02x/10/10)

Ambient operating temperature

-40 °C to +55 °C

Medium temperature

-10 °C to +50 °C

Filtration ability

Standard 60 µm

Reach of dispensing hose

4,5 m (V-line R)

Max. level of noise

<60 dB

Power supply of electronics

Unap

Pnap

1/N/PE AC 230 V ±15 % 50 Hz

input 85 VA

Power supply of ADAMAT

electronics

Unap

Pnap

1/N/PE AC 230 V ±15 % 50 Hz

input 120 VA

Power supply of electronic case

heating

Unap

Pnap

1/N/PE AC 230 V ± 15 %, 50 Hz

input 250 VA

USER’S MANUAL V-line AdBlue®47xx.xxx

12

Power supply of hydraulic case

heating

Unap

Pnap

1/N/PE AC 230 V ± 15 %, 50 Hz

input 950 VA

Basic sensed unit

0,01 dm3

Number of impulses per 1 dm3

100

Permissible deviation of sensed volume

+/-1 impulse, i.e. 0,01 dm3

Price displayed

6 digits with the setting of digit position

Volume displayed

6 digits with the setting of digit position

Unit price displayed

4 digits with the setting of digit position

Total volume counter

electromechanical - 7 digits

electronically - 11 digits

Communication interface

RS 485; EASY CALL

Pumalan extended

FULL DART

NARA standard

RS 485; IFSF –LON, TCP/IP (Ethernet)

Average operating period of a repair

too = 25 minutes

Average service life

tz= 5 years

6. MARKING

All manufactured and delivered dispensers are provided with a rating plate, which includes the following

data and is located on a visible point of the dispenser body:

1.

Measuring device manufacturer and address

Adast Systems, a.s., CZ –679 04 ADAMOV 496

2.

Name of measuring device

AdBlue®dispenser

3.

The „CE“ marking and supplementary

metrology marking

4.

Type

See enclosure No 16 and 17

5.

Number of EC –type examination certificate

TCM 141/07 –4518

6.

Accuracy class

0,5

7.

Serial number and year of manufacture

According to dispensers manufacturer files

8.

Liquid temperature range –TLiq [°C]

-10 to +50

9.

Ambient temperature range –TAmb [°C]

-40 to +55

10.

Mechanical class

M 2

11.

Electromagnetic class

E 2

12.

Liquid

AdBlue®

13.

Minimum measured quantity (MMQ) [L]

2

14.

Maximum flowrate Qmax [L/min]

40

15.

Minimum flowrate Qmin [L/min]

4

16.

Maximum pressure pmax [bar]

3,2

7. INSTALLATION

7.1. Hydraulic part

ATTENTION!

THE DISPENSER INSTALLATION CAN BE CARRY OUT ONLY BY THE ORGANISATION AUTHORISED BY

MANUFACTURER.

Read carefully the article 1. IMPORTANT NOTICE.

USER’S MANUAL V-line AdBlue®47xx.xxx

13

The AdBlue®dispenser can be joined only to process equipment (tanks, piping) of perfect tightness and

cleanness. The supplier of the process equipment is responsible for its tightness and cleanness.

Prior to the installation the organisation shall perform the inspection of used power and communication

cables.

The dispenser is mounted to the base frame M12 × 70 bolts through special pads (pads are supplied

dispenser).

When the AdBlue®dispenser is installed, they shall check the tightness, function of hydraulic equipment of

the dispenser, supply piping and fittings. They also check power and communication cables including their

lines and fixing.

Prior to official metrological testing the dispenser (every dispensing nozzle) has to operate for min. 5

minutes in max. flow rate

The process and service equipment of filling stations can be operated only when they have been built

up according to the approved design and on the basis of positive result of licence regime.

7.2. Wiring

ATTENTION!

For safety operation must be used electrical connection of AdBlue® dispenser from switchboard with

oveload protection and for parameters 230 V / 50 Hz / Power supply of electronics and heating –see

article 5 - TECHNICAL DATA

Earthing conductor shall be connected to the shaft under every dispenser.

Leads to the AdBlue®dispenser must be sealed to prevent its interior from the penetration of liquids

(AdBlue®) or vapours. Only cable terminals resistant to AdBlue®effect can be used in the shafts under

dispensers. The cable bushings can always be used for one cable only.

ATTENTION!

Emergency switching off: It shall be enabled to switch off the filling equipment from one point, which

is accessible anytime. The electric equipment situated in the explosion hazard area can be switched

off by means of the emergency breaker located outside the explosion hazard area. The switch for

normal operation can be also used as emergency breaker.

Supply conductors are connected to the junction box located in the dispenser.

The communication line cable is connected to the junction box for the communication line.

There are two wiring systems of the filling station: either the communication line is connected to the

dispenser (i.e. self-service operation with the control system) or not (i.e. service operation).

The dispenser in self-service operation with the control system is connected through the communication

line to the control system which controls operation of complete filling station (i.e. dispenser release,

preselection of volume and price, unit price alteration, selfdiagnostics, etc.).

8. PUTING INTO OPERATION

ATTENTION!

Before start must be made revision of wiring. Also is recomended to heat imide container space to

minimum temperature 5 °C (start the heater if needed).

8.1. Puting of the AdBlue® dispenser to operation mode

Hang up the delivery nozzle.

Switch on the power supply in main board of filling station (electronics supply in winter and heating).

By hang out of delivery nozzle will be made display test (test of eights), when the eights will be

zerowed the delivery can be started.

Place the nozzle in.

In case of turn on of DU with hang out nozzle must bet he nozzle hunged in and hanged out again, to

activate DU (reset display).

After this is possible to provide delivery of AdBlue®.

USER’S MANUAL V-line AdBlue®47xx.xxx

14

8.2. Puting of AdBlue® dispenser to OFF mode

Switch off power feed in filling station main terminal.

8.3. New reseting of AdBlue® dispenser into operation after power supply failure

After power supply failure or voltage fluctuation will stay data on display about the price and volume

of last provided transaction since interval of last time of nozzle hang out.

In case if power supply happened during of medium tanking , the nozzle has to be hang in (on the

display will stay value of the volume and price) and cash in the amount shown on the display.

By renewing of power supply is the electronic counter in operation mode and another delivery can be

made by hang out of the delivery nozzle.

ATTENTION!

After puting into operational mode in expected low temperature period (Tamb.) under 0 °C, the

rating must be turned ON permanatly. This is obligation even in „Out of order“ mode.

Termostat of heater to be set on value +5 °C!!

9. OPERATION

By hang out of delivery nozzle the connecting switch controlled by magnet placed in nozzle boot will start

the electronic couter of AdBlue® dispenser, will be made reset of the display after it the connecting of

pump elektromotor and mening of electromagnetical valve placed in hydraulic vave of AdBlue® dispenser (if

installed).

By AdBlue® dispenser for pressurre sytem will be switched in of pump elektromotor placed in container tank

imediatelly after hang out of the nozzle (before providing of test and display reset). Electromagnetic valve

is open after providing of test and display reset.

After placing of delivery nozzle spout to the vehicle tank and push of nozzle lever the tanking is started

(medium delivery). The vehicle tank must be equipped by magnetic adaptor (like ELAFIX 40) to allow the

spout open.

Delivery speed is controlled by nozzle lever (pus hor repase). When the dispensing is finished, the nozzle is

placed out from vehicle tank input and placed to the nozzle boot of DU will be by magnetic switch to

dissconection of power feed to submersible pump.

The records of last dispensing will stay displayed untill next one delivery.

The delivery nozzle is controlled as per instructions shown in enclosure no. 4 of this manual.

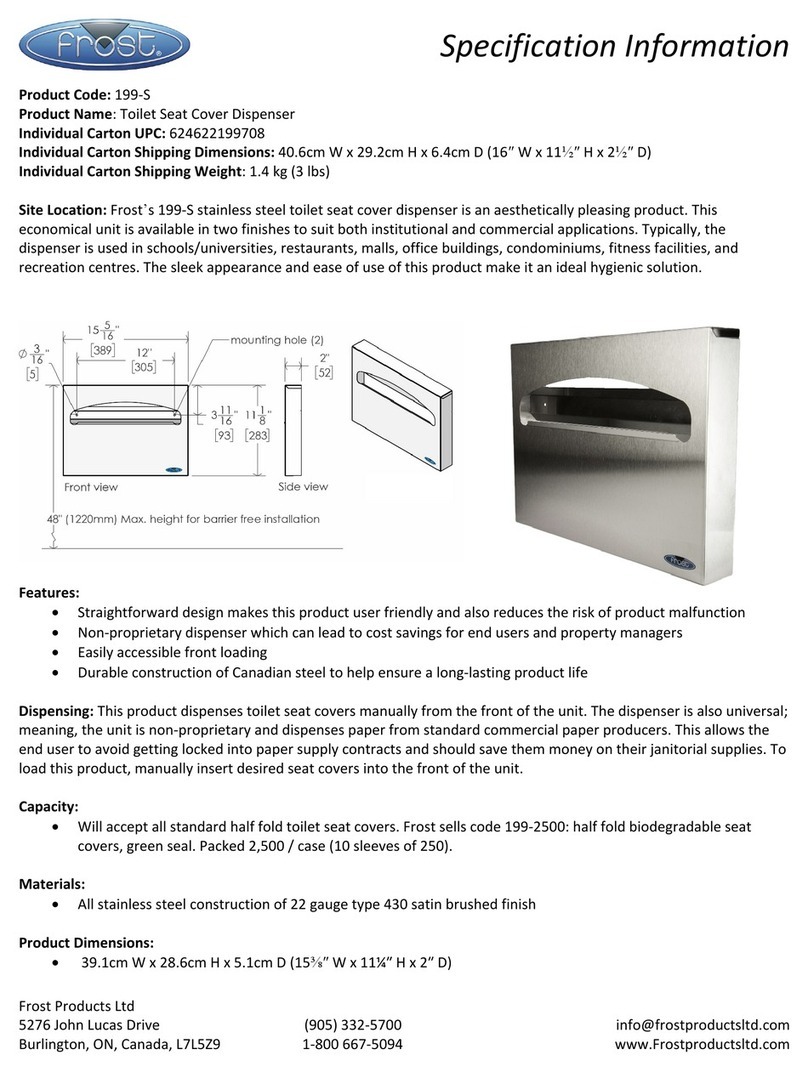

10. FUNTION OF MANAGER AND SERVICE KEYBOARD

The KL-MANINF (as pic. 4)manager keyboard and the KL-SERINF (as pic. 5)service keyboard are delivered

as a design with infrared wireless transmission IR. These device are delivered as option.

IR KL-MANINF manager keyboard

The keyboard enables the setting of unit prices and the situation display of electronic totalizers.

The manager keyboard is equipped with four keys marked „0“, „+“, „–“ and „R“. The „0“ key is used for

the transition to the "setting of unit prices for MAN" and for the termination of any function executed on

the manager keyboard.

The „+“ and „–“ keys are used for proper setting of the unit price values or for the transition to the mode

of "situation display of electronic totalizers".

The „R“ key is used for check of vapour recovery exhaustion.

IR KL-SERINF service keyboard

The keyboard enables the counter setting and the keying of values for electronic calibration of meters and

ATC, the situation display of electronic totalizers, setting of unit prices and setting the vapour exhaust

recovery.

The service keyboard is fitted with four keys, „0“, „+“„–“ as a standard and the "S" key as an extra key.

The "S" key is used for the transition to the mode of "the data setting / calibration".

If the "S" key is not used, the service keyboard can be used for all functions controlled by the manager

keyboard and the keying is identical with that of the manager keyboard.

USER’S MANUAL V-line AdBlue®47xx.xxx

15

Note

If the nozzle has been lifted at least once since the last activation of the counter, the transition to the

setting of unit prices is not executed in the MAN mode. The transition to the setting is also not executed

even in case the nozzle has been either hung up again without fuel dispensing or previous transaction has

not been deactivated by means of RLS entry.

10.1 Manual setting of unit prices

Necessary conditions for the transition to the setting of unit prices

–MAN mode of operation

–the nozzle has not been lifted since the last activation of the counter

–transaction executed shall be acknowledged (deactivation by means of RLS entries).

In the MAN mode the unit prices of fuel product are set by means of the KL-MANINF manager keyboard or

the KL-SERINF service keyboard.

1. The user can enter the setting mode of unit prices by depressing the „0“ key.

2. In the setting mode of unit prices

–the number of side for which the unit price is being set ("1" ... A side, "2" ... B side) is displayed on

the first line of displays (i.e. on the line of total price)

–the number of nozzle for which the unit price is being set is displayed on the second line of displays

(i.e. the line of total volume)

–on the third line of displays the digit, the value of which is being set by the user, is flashing (e.g. on

the line of unit price)

3. The user

–raises the numerical value of the digit actually set (i.e. the flashing one), (digit 9 passes into 0), by

depressing the "+" key we can list through 0-9 values - i.e. the autorepeat function

–shifts the digit setting to higher digit positions by means of the "–" key

shifts the setting from the highest position of the product unit price to the lowest digit position of

the product unit price of the next nozzle by means of the "–" key

4. In this way the user can set successively the price values for all nozzles on the A side, then B side (if it

exists and the products on this side differ in price).

5. Whenever the user can terminate the setting of the unit price values by depressing the „0“ key.

6. Now the unit price values have been written in non-volatile storage in this way and the counter sets the

MAN mode.

USER’S MANUAL V-line AdBlue®47xx.xxx

16

10.2 Setting of unit price values from the control system in AUTO mode

In AUTO mode the unit price values are set from the control system for all transactions independently on

unit price values set for the MAN mode.

The unit price values for the AUTO mode are set for all dispensing points by dynamic statement (command)

"permission to dispense" transmitted from the filling station console or by the "price setting" statement. All

these statements are a part of the specification of the EASYCALL communication protocol.

10.3 Display of electronic totalizers

The ADPMPD/T, ADP 1,2/Tcounter is fitted with non-resettle electronic totalizers of volume and price for

individual dispensing nozzles.

The totalizers can be displayed on the displays of the side by means of the KL-MANINF manager keyboard or

the KL-SERINF service keyboard. The display of the totalizer can be switched by lifting the relevant nozzle.

The sum of the volume (or the sum of the price) is displayed on the displays of the side on the coupled lines

of the total price and total volume.

Both displays of the side display an identical sum.

As the first from the left "U" character is displayed on the total price line for the display of the volume

sum and "A" character for the display of the price sum.

The second character from the left displays the highest digit position of the relevant sum.

The sixth character from the left displays the lowest digit position of the relevant sum.

The sums are counted and displayed with decimal place count according to the data setting of the counter.

The side number and the nozzle number of the totalizer displayed at this moment are displayed on the unit

price line:

e.g..: 1 - 3...A side - nozzle No. 3;

2 - 1...B side - nozzle No. 1.

Display procedure:

1. Both dispensing points shall be free (transitions are not running at any of the both points and

terminated transactions shall be acknowledged).

2. Depress the "+" key to display the volume sum. Depress the "–" key to display the price sum.

3. All segments light up and light out on the displays of the sides after depressing the "+" key (or the "–"

key) (similarly with the transaction starting to checking if all segments display correctly) and total

number of feeding voltage drop-outs is shortly displaced.

4. Then "U" and the volume sum of the relevant nozzle (or "A" and the price sum of the relevant nozzle)

are displayed on the displays of sides.

5. It is possible to carry out the transition to the volume totalizer displays of the next dispensing nozzles

by repeated depressing the "+" key or by lifting the relevant nozzle (as well as the transition to the

price totalizer displays of the next dispensing nozzles by repeated depressing the "–" key or by lifting

the relevant nozzle).

6. Terminate the scanning of electronic totalizers by depressing the "0" key and in case the thermal and

electronic calibration are activated, transition in the display mode of their setting occurs.

7. The setting of thermal calibration for relevant nozzle is activated by the ATC text. The setting of

electronic calibration of the relevant nozzle counter is activated by the EC text.

8. Terminate the scanning by depressing the "0" key and return to the standard mode.

Unit price seting

Shift from most significent

digit, side A , nozzle 1

Shift from most significent

digit, side B , nozzle 1

This manual suits for next models

5

Table of contents

Other Adast Systems Dispenser manuals