SECTION 1 – CAUTION AND SPECIFICATIONS

1) BEFORE OPERATING THE MACHINE, READ THE COMPLETE OPERATOR’S MANUAL.

2) NEVER HAVE THE POWER CORD OF THIS MACHINE PLUGGED INTO AN OUTLET WHEN

ANY OF THE COVERS OF THIS MACHINE HAVE BEEN REMOVED.

3) INSTALL AND OPERATE THIS MACHINE ONLY ON A FLAT, LEVEL, AND DRY SURFACE.

4) USE ONLY THE SPECIFIED ELECTRICAL POWER INPUT WITH THIS MACHINE.

5) ALWAYS TURN THE POWER OFF AND UNPLUG MACHINE PRIOR TO CLEARING ANY

TAPE OR TAPE JAMS FROM THE MACHINE, PARTICULARLY IN THE AREA OF THE

CUTTER.

6) ALWAYS KEEP HANDS, CLOTHING, JEWELRY, AND HAIR AWAY FROM ALL MOVING

PARTS OF THE MACHINE.

7) THIS MACHINE HAS A VERY SHARP CUTTER ASSEMBLY, NEVER PUT HAND OR ANY

OTHER PART OF THE BODY, OR ANY ITEM INTO THE CUTTING OPENING UNLESS THE

MACHINE IS OFF AND THE POWER HAS BEEN UNPLUGGED.

8) NEVER OPERATE THIS MACHINE WITH ANY OF THE SAFETY COVERS OR DEVICES

REMOVED.

9) KEEP THIS MACHINE CLEAN AND DRY AT ALL TIMES.

10) SERVICE ON THIS MACHINE SHOULD ONLY BE PERFORMED BY FACTORY TRAINED

AUTHORIZED SERVICE PERSONNEL.

11) NEVER USE THIS MACHINE FOR OTHER THAN ITS INTENDED APPLICATIONS. USE OF

THE MACHINE ON UNINTENDED APPLICATIONS CAN CAUSE HARM TO THE OPERATOR,

THE MACHINE, AND TO THE PRODUCT. PLEASE CONTACT THE MANUFACTURER IF

THERE ARE ANY QUESTIONS TO WHETHER THIS MACHINE CAN BE USED FOR A

PARTICULAR APPLICATION.

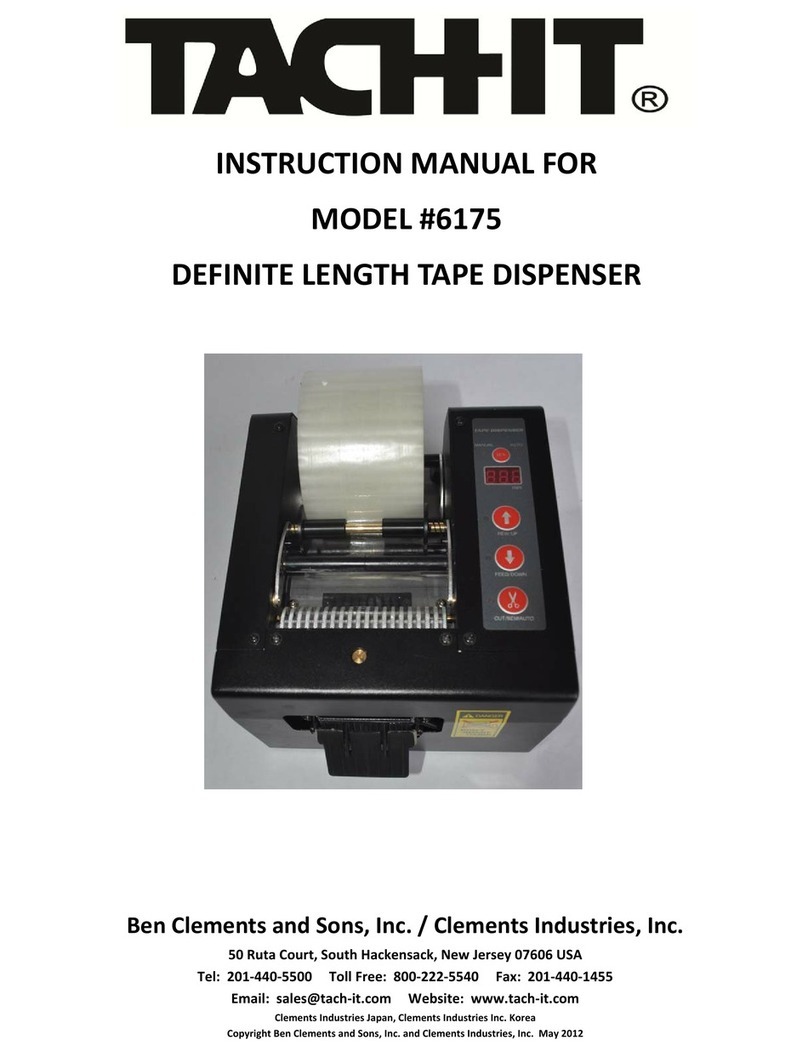

SPECIFICATIONS:

MACHINE LENGTH: 9 1/2” , WIDTH: 5 3/4”, HEIGHT: 5 3/4”, WEIGHT: 7 1/2 LBS

POWER: 110 VOLT (60 mhz)

CORE SIZE: 3”, 1” CORE AVAILABLE (OPTIONAL – AT ADDITIONAL COST)

MAXIMUM WIDTH OF TAPE: 2”

MAXIMUM DIAMETER OF TAPE ROLL: 6”

MAXIMUM LENGTH OF TAPE FED IS: 39” (999 mm)

MINIMUM LENGTH OF TAPE FED IS: 3/4” (18 mm)