ADCA RP45 Series User manual

ADCA

VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI RP45.02 E 07.16

INSTALLATION AND MAINTENANCE INSTRUCTIONS

RP45 - PRESSURE REDUCING VALVES

GENERAL

•These instructions must be carefully read before any work involving products supplied by VALSTEAM ADCA

ENGINEERING S.A. is undertaken.

•The installation procedure is a critical stage in the valve life time and care should be taken to avoid damage to

the valve or equipment.

•Reducing valves are designed to give accurate control of down-stream pressures. They give their maximum

performance only when the equipment associated with them is correctly sized and installed in accordance with

our recommendations.

Warning!

- At start up, the presence of small particles in the fluid (dirt, scale, weld splatters, etc) may cause an imperfect

closure of the seat. If this occurs, proceed to an accurate cleaning.

- Do not touch the equipment without appropriate protection during working operation because it may conduct heat

if the used fluid is at high temperature.

- Before starting maintenance be sure that the equipment is not pressurized or hot.

- The equipments must be used within the working temperature and pressure limits laid down for them, otherwise

they may fail (refer to nameplate and/or IS- Information Sheet).

- Do not remove the nameplate attached to the equipment. Serial number and other useful information stamped on

it.

- This valve is not suitable for oxygen service.

INSTALLATION

- Before to installation remove plastic covers placed on flanges or connection ends. The equipment has an arrow or

Inlet/Outlet designations. Be sure that it will be installed on the appropriate direction.

- Take care with jointing material to ensure that none may be permitted to block or enter the valve.

- Reducing valves are recommended to be fitted with the centre line of the valve in a vertical position to ensure that

the best results are obtained.

- An ADCA pipeline strainer should be installed upstream of the valve to protect from dirt which could damage the

valve or cause mal-functioning.

- The reducing valve pipework should be properly supported and free from strain and it should not be subjected to

undue surges of pressure.

For steam installations we strongly recommend that the reducing valve is positioned where condensation is unable

to collect or that, alternatively, separators and steam traps are fitted so that the pipework drains correctly. The

startup condition should be considered.

- A balance pipe must be connected downstream at least 1 meter from valve. See IS.RP45.01.

- RP45 is designed primarily for steam, compressed air and non-inflammable gases. It has limited use for neutral

liquids since the plug close in the same direction of the fluid flow, which can produce vibrations and water hammer

when used at less than 20% of capacity. To avoid this, valve can be installed with the fluid direction against the plug

under certain conditions. Please consult the factory.

At service conditions where the temperature is more than 100ºC it is necessary to protect the diaphragm against

overheating by using a seal pot.

Never size the valve according to the pipe diameter in which it has to be fitted but according to the required actual

flow .Pipe sizing must also respect the maximum recommended flow velocities according to the medium.

ADCA

VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI RP45.02 E 07.16

- Service conditions less than 100ºC: with gases the valve is ready to work. In case of liquids the actuator must

be filled completely with liquid, so, the vent screw (12) should be open till the water flow without bubbles.

The valve can be installed with the diaphragm pointing upwards or downwards.

- Service conditions more than 100ºC: Fill the seal pot (11) using a funnel (14) until the water emerges from the

actuator vent (12 ) without bubbles .Close the actuator vent screw (12 ) and proceed filling the pot until the water

reaches the top and close it with the plug. The valve is now ready to work.

The valve must be installed with the diaphragm pointing downwards.

Downstream pressure should be adjusted with the key (13). Compressing the spring, spring force increase and

downstream pressure increase. Relaxing the spring, spring force decrease and downstream pressure decrease.

The valve closes when the downstream pressure rises.

Installation area requirements:

•The installation area should have easy access and provide enough space for maintenance and removing

operations.

•The installation area should have the necessary firing system to prevent damage of the equipment due to over

temperature/pressure cause by fire.

START UP

- Current regional safety regulations should be take in to account and followed.

- Protective insulation and warning notice may be required.

- Until the start up of an existing or a new plant, the following must be checked:

- All works are completed.

- The valve is correctly installed.

- All the necessary safety devices have been installed.

- At start up, the presence of small particles in the fluid (dirt, scale, weld splatters, joint particles, remains

of Teflon tape, etc) may cause an imperfect closure of the seat. If this occurs, proceed to an accurate

cleaning.

- Protection varnishes from pipes and flanges, fats, leftover paint, graphite, etc, should also be carefully

clean, because they can be dissolved in the fluids (like steam) blocking the regulation elements after

the first service stop.

- During operation high flow noises can be heard.

ADCA

VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI RP45.02 E 07.16

Procedure:

1. All stop valves should be close.

2. Regulation spring must be relaxed. If not, release tension by turning the adjustment screw counter-clockwise.

3. Open downstream stop valve.

4. Open slowly the upstream stop valve, in order to avoid water hammer damaging, until the input pressure

reaches its limit.

5. Adjust the regulation spring by turning the adjustment screw clockwise, while observing the output pressure

gauge, until the reduced pressure is reached. (There must be some medium consumption on the outlet side

during this process).

6. When the system is stable a readjustment of the regulation spring may be needed.

7. The valve is ready.

Periodical checking:

24 hours after the start up, it is recommended to check pipe connections for leaks and retighten the connections if

necessary.

MAINTENANCE

•We recommend that the pressure reducing valves are serviced as necessary. Pressure reducing valves should

be checked periodically (at least yearly), to verify that they are operating correctly and to clean the internal parts

and screen (if any).

•When reassembling make sure that all gasket faces are clean and always use a new gasket. Tighten cover

bolts uniformly in a diagonal sequence.

•Valves in store for long periods should have their adjusting spring relaxed.

•For further information refer to the relevant RP brochure or consult our Sales Office.

Replacement of actuator diaphragm:

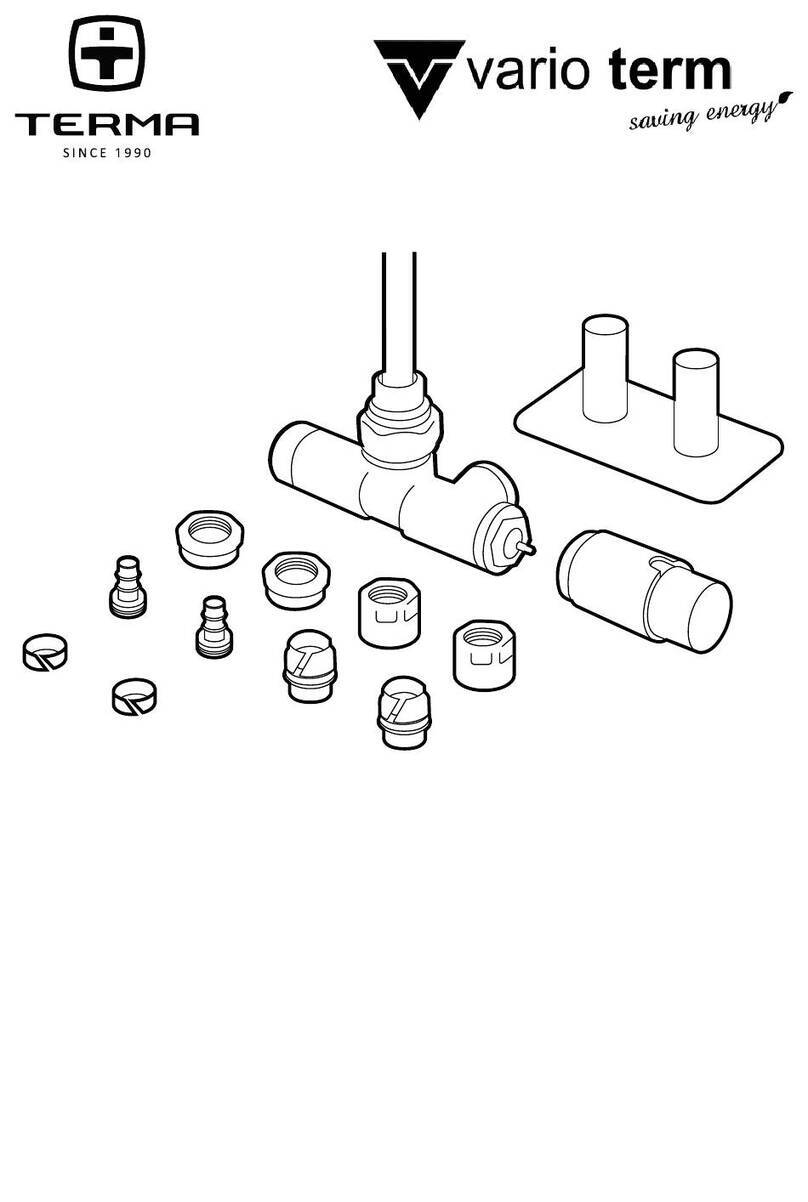

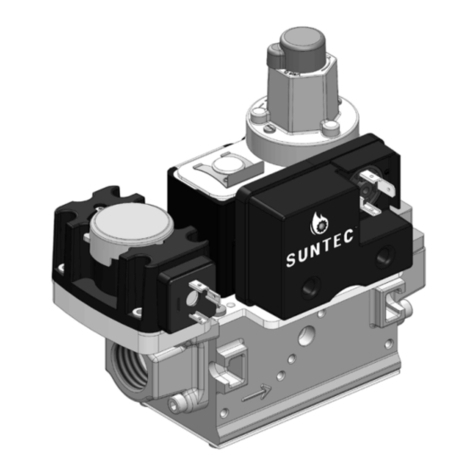

In reference to the fig.1 proceed as follow:

1. Isolate the valve and make sure the system is depressurized.

2. Drain the actuator and condensate vessel through the actuator vent screw (9), if applicable.

3. Relax the valve regulation spring, turning the key anti-clockwise.

4. Remove the actuator from the valve by unscrewing the nut (8) and turning the actuator anti-clockwise.

5. Remove the screws and nuts (7).

6. Remove the bottom cover (1).

7. Untighten the nut (6), remove the washer (5) and replace the diaphragm (4).

8. Refit all the items in reverse order (tighten the actuator bolts evenly).

9. Fill the condensate vessel again as the above instructions, if applicable

Fig. 1 –Actuator

ADCA

VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI RP45.02 E 07.16

Replacement of spring:

In reference to the fig.2 proceed as follow:

1. Relax the spring (9) by unscrewing the bearing support (10). Do so by inserting a small lever and rotating.

2. Remove the actuator on top of the valve, also by unscrewing it (do not use a tool for this, use your hands)

3. Nut (11) will be loose at this point, remove it.

4. Following, continue to unscrewing the bearing support (10) in order to remove it along with the bearing and the

spring support.

5. Replace the spring.

6. Screw the spring support, the bearing and the bearing support (10) back on to their original position.

7. Finally screw the nut (11).

8. Install the actuator on the valve and screw it tightly, against the nut. Tighten well.

Fig. 2 –RP45 valve

PN16 PN40 Category

DN15 to DN50 DN15 to DN32 SEP- art. 3, paragraph3

DN65 to DN150 DN40 to DN100 1 (CEMarked)

/ DN125 to DN150 2 (CEMarked)

CEMARKING ( PED- European Directive )

ADCA

VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI RP45.02 E 07.16

RP45G

RP45S

RP45S

RP45I

RP45GT

RP45ST

RP45ST RP45IT

RP45GN*

RP45SN*

RP45SN *

RP45IN *

Body design conditions PN16 PN40 PN40 PN16 PN40 PN40 PN16 PN40 PN40

Max.upstream pressure 13 bar 25 bar 25 bar 13 bar 25 bar 25 bar 13 bar 25 bar 25 bar

Max.downstream DN15/100 13 bar 18 bar 18 bar 13 bar 18 bar 13 bar 13 bar 18 bar 18 bar

Max.downstream DN125/150 12 bar 16,5 bar 16,5 bar 12 bar 16,5 bar 16,5 bar 12 bar 16,5 bar 16,5 bar

Min.downstream pressure 0,15 bar 0,15 bar 0,15 bar 0,15 bar 0,15 bar 0,15 bar 0,15 bar 0,15 bar 0,15 bar

Max.operating temperature 200ºC 250ºC 250ºC 200 ºC 200 ºC 200 ºC 80 ºC 80 ºC 80 ºC

25:1 25:1 25:1 25:1 25:1 25:1 10:1 10:1 10:1

10:1 10:1 10:1 10:1 10:1 10:1 10:1 10:1 10:1

Max.cold hydraulic test 24 bar 25 bar 25 bar 24 bar 25 bar 25 bar 24 bar 25 bar 25 bar

Max.hyd. factory valve body test 24 bar 60 bar 60 bar 24 bar 60 bar 60 bar 24 bar 60 bar 60 bar

*Suffix N : - a maximum turndown ratio 10:1 should be observed. Other soft materials on request.

LIMITING CONDITIONS

Max.reducing ratio

Rangeability

USEFUL NOTES ON VALVE AND PIPE SIZING - If the flow is unknown it is possible to estimate it based on pipe

size or equipment heat requirement - please consult.

PARTS LIST FOR RP45 PRESSURE REDUCING VALVES:

VALVE SIZE

DN

VR.9451.015 Stainless steel bellows DN15-DN25 6 1

VR.9451.032 Stainless steel bellows DN32-DN40 6 1

VR.9451.050 Stainless steel bellows DN50-DN65 6 1

VR.9451.080 Stainless steel bellows DN80 6 1

VR.9451.100 Stainless steel bellows DN100 6 1

VR.9451.125 Stainless steel bellows DN125 6 1

VR.9451.150 Stainless steel bellows DN150 6 1

VR.9455.060 Regulating spring nr 60 DN15-DN40 9 1

VR.9455.061 Regulating spring nr 61 DN50-DN65 9 1

VR.9455.062 Regulating spring nr 62 DN80 9 1

VR.9455.063 Regulating spring nr 63 DN100 9 1

VR.9455.064 Regulating spring nr 64 DN50-DN65 9 1

VR.9455.065 Regulating spring nr 65 DN80 9 1

VR.9455.066 Regulating spring nr 66 DN15-DN40 9 1

VR.9455.067 Regulating spring nr 67 DN50-DN65 9 1

VR.9455.068 Regulating spring nr 68 DN80 9 1

VR.9455.069 Regulating spring nr 69 DN100 9 1

VR.9455.070 Regulating spring nr 70 DN125-150 9 1

VR.94502.015 Piston body, valve disc, bellows, spindle DN15-DN25 2, 4, 6, 8 1

VR.94502.032 Piston body, valve disc, bellows, spindle DN32-DN40 2, 4, 6, 8 1

VR.94502.050 Piston body, valve disc, bellows, spindle DN50-DN65 2, 4, 6, 8 1

VR.94502.080 Piston body, valve disc, bellows, spindle DN80 2, 4, 6, 8 1

VR.94502.100 Piston body, valve disc, bellows, spindle DN100 2, 4, 6, 8 1

VR.94502.125 Piston body, valve disc, bellows, spindle DN125 2, 4, 6, 8 1

VR.94502.150 Piston body, valve disc, bellows, spindle DN150 2, 4, 6, 8 1

CODE

DESIGNATION

QTY.

POS.NR.

VR.9459.001 Diaphragm A1 / A11 / A10S / A12S / B1 -- 1

VR.9459.002 Diaphragm A2 / A21 / B1 / B21 -- 1

VR.9459.003 Diaphragm A3 / B3 -- 1

VR.9459.004 Diaphragm A4 / B4 -- 1

VR.9459.005 Diaphragm C11S -- 1

CODE

DESIGNATION

QTY.

POS.NR.

ACTUATOR

ADCA

VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI RP45.02 E 07.16

TYPICAL INSTALLATION

ADCA

VALSTEAM

ADCA

We reserve the right to change the design and material of this product without notice.

IMI RP45.02 E 07.16

Remarks:

* By-pass is optional. In case the by-pass is not allowed than stop valve 9B should be placed after pressure gauge

14 allowing the isolation of safety valve.

PN, classes and materials according to the operating pressures.

The balance pipe connection is recommended to enter downstream pipe at a minimum of 1 meter from the valve.

Information sheet are available (IS - RP45) and typical assembling drawing.

Special assembling designs may be produced on request.

PRODUCTS RETURNING

- Information regarding any hazards and precautions to be considered because of contaminating fluids and

residues or mechanical damage that may represent a health, safety or environmental risk, must be provided in

writing by the distributors and costumers when returning products to Valsteam ADCA engineering.

- Health and safety data sheets regarding substances identified as hazardous or potentially hazardous must be

provided with the information mention above.

- LOSS OF WARRANTY: Total or partial disregard of above instructions involves loss of any right to warranty.

Other manuals for RP45 Series

1

This manual suits for next models

9

Table of contents

Other ADCA Control Unit manuals