Assembly instructions EN ◼RM 25 I RM 32 ◼13.06.2023 ◼V3.0 3–68

Table of contents

1General....................................................................................................................6

1.1 Contents and purpose of these assembly instructions.................................6

1.2 Explanation of symbols.................................................................................6

1.3 Additional symbols........................................................................................7

1.4 Applicable documents ..................................................................................8

1.5 Warranty.......................................................................................................8

1.6 Liability..........................................................................................................8

2Safety instructions.................................................................................................9

2.1 General.........................................................................................................9

2.2 Intended use.................................................................................................9

2.3 Foreseeable misuse.....................................................................................9

2.4 Obligations of the operator and the personnel...........................................10

2.4.1 Observe the assembly instructions......................................................10

2.4.2 Obligations of the operating company..................................................10

2.4.3 Obligations of the personnel ................................................................10

2.5 Personnel requirements .............................................................................11

2.5.1 Personnel qualification.........................................................................11

2.6 Personal protective equipment (PPE)........................................................11

2.7 Changes & Modifications............................................................................12

2.8 General hazards / residual risks.................................................................12

2.8.1 General hazards at the workplace .......................................................12

2.8.2 Danger due to electricity ......................................................................14

2.8.3 Mechanical hazards .............................................................................14

2.8.4 Danger due to pneumatics...................................................................14

2.8.5 Danger caused by omitting maintenance work....................................14

3Technical data ......................................................................................................15

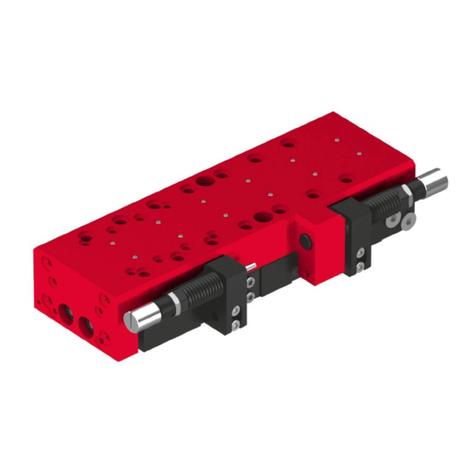

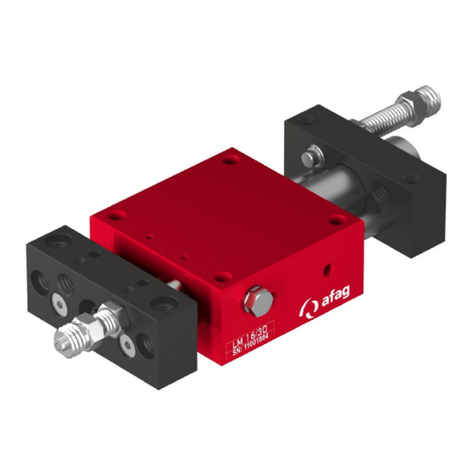

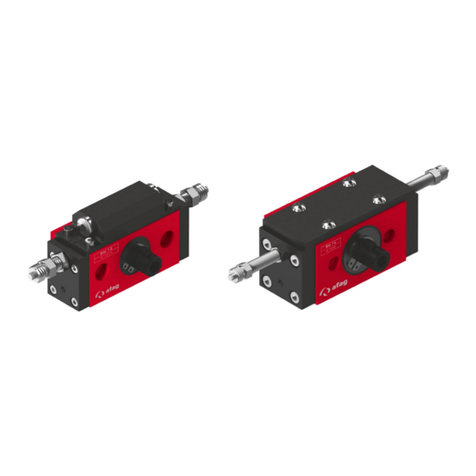

3.1 Rotary module RM 25.................................................................................15

3.1.1 Dimensional drawing RM 25, RMZ 25/1, RMZ 25/2 ............................15

3.1.2 Technical data RM 25, RMZ 25/1, RMZ 25/2 ......................................16

3.1.1 Preferred combinations RM 25, RMZ 25/1, RMZ 25/2.........................17

3.1.2 Module loads RM 25, RMZ 25/1, RMZ 25/2 ........................................18

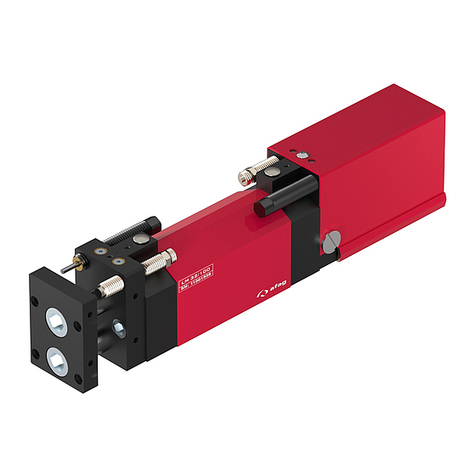

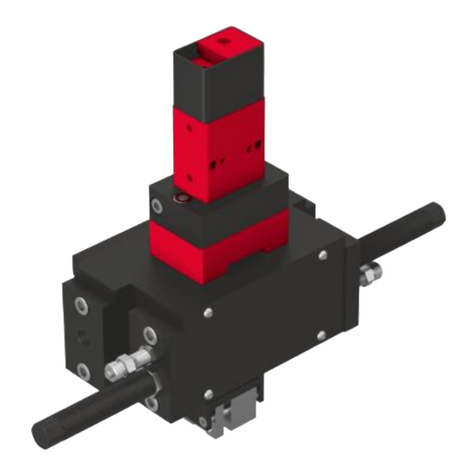

3.2 Rotary module RM 32.................................................................................19

3.2.1 Dimensional drawing RM 32 with flange, RM 32 with shaft.................19

3.2.2 Technical data RM 32 with flange, RM 32 with shaft...........................20

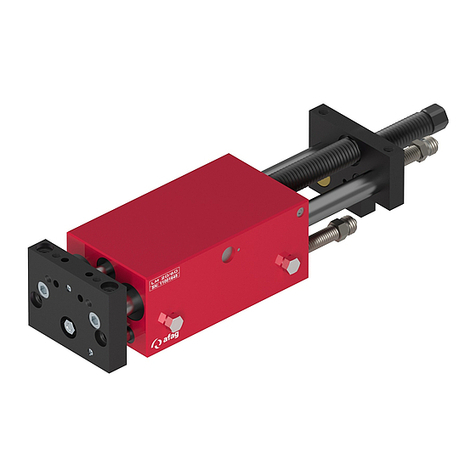

3.2.3 Dimensional drawing RMZ 32/1 with flange, RM 32/1 with shaft.........21

3.2.4 Technical data RMZ 32/1 with flange, RMZ 32/1 with shaft ................22

3.2.5 Dimensional drawing RMZ 32/2 with flange, RM 32/2 with shaft.........23

3.2.6 Technical data RMZ 32/2 with flange, RM 32/2 with shaft...................24

3.2.7 Preferred combinations RM 32 ............................................................25

3.2.8 Module loads RM 32 ............................................................................26