Pneumatic Pressure Test Pump User Manual's

Warnings and cautions

Low pressure gauges can very easily be over pressured if not

careful.

Please take caution when applying pressures.

Do not exceed the safety limit of 1500 psi (100 bar) for 917 or

2000 psi (140 bar) for 918.

Do not switch between pressure and vacuum mode under

pressure. Open the vent valve and isolation valve before

switching between positive to vacuum pressures.

Over tightening connectors may cause damage. Light hand

tightening is sufficient.

Store the pump in a dry non-corrosive environment.

Additel is not responsible for problems or damage resulting from

improper use or operation of the equipment.

All moisture and contaminants should be cleaned out of the liquid

isolator before creating a vacuum. This is accomplished by

venting the pump when at high pressure.

For the least risk in contamination of the reference gauge, the

DUT should be installed to the pressure port which is closest to

the vent valve.

Specification

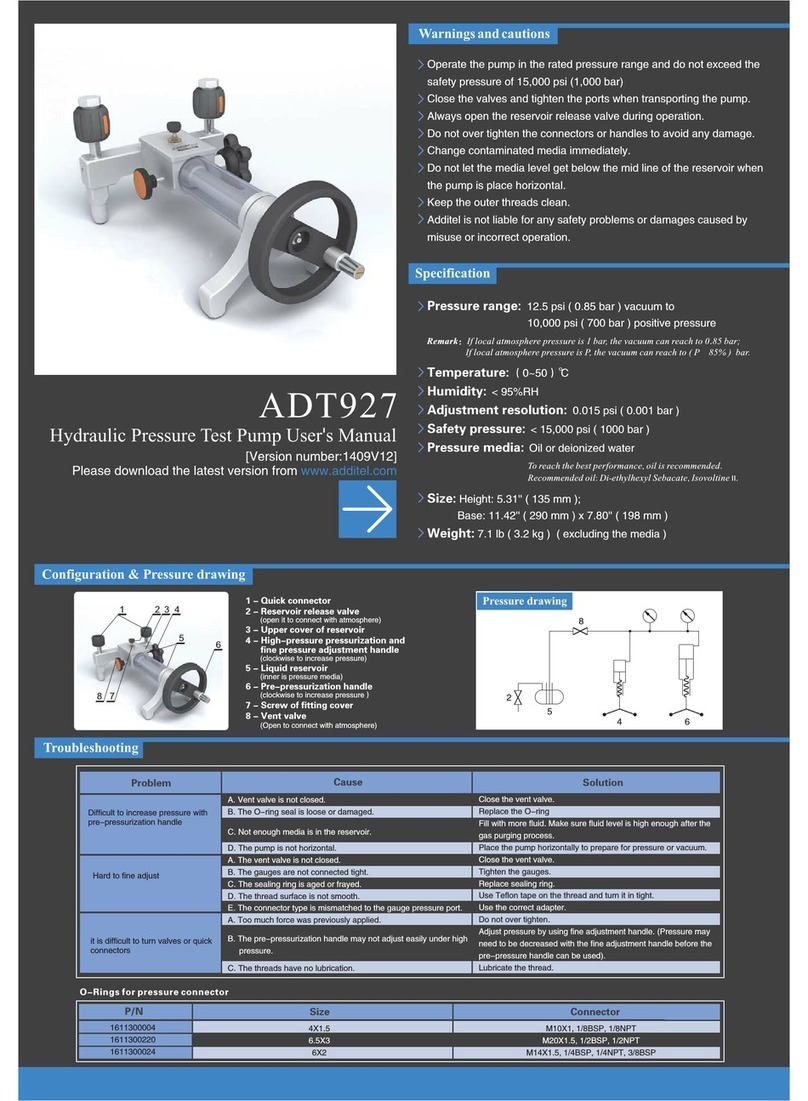

Configuration & Air routine

Troubleshooting

Remark:If local atmosphere pressure is 1 bar, the vacuum can reach to -0.95 bar;

If local atmosphere pressure is P, the vacuum can reach to - 0.95P.

917/918

[Version number:1407V02]

Pressure range:

Temperature:

Humidity:

:

Maximum pressure:

Pressure media:

Size:

Weight:

917: 95% vacuum to 1000 psi ( 70 bar )

8

0~50

< 85%RH

10 Pa ( 0.1 mbar )

917: 1500 100

: 2000 psi ( 140 bar )

Air

Height: 5.5'' ( 140 mm );

Base: 12.4'' ( 315 mm ) x 7.8'' ( 198 mm )

5.7 lb ( 2.6 kg )

91 : 95% vacuum to 1500 psi ( 100 bar )

)℃

psi ( bar )

918

(

Adjustment resolution

3 - Quick connector

7

6

1

8

4

!

31

4

5

8

2

67

Under Vacuu

3

Air routine

1 - Hand pump

2 - Transport handle

7 - Isolation valve (Bypass valve)

(Isolated the calibration volume from the hand pump,

piston, and check valve)

8 - Fine adjust handle

(clockwise to increase pressure)

6 - Pressure/vacuum (P/V) selector

(

DO NOT switch under pressure or vacuum to

avoid damage)

Positive pressure: pull it out; vacuum: push it in

5 - P/V selector lock

4 - Vent valve

(clockwise to close/ counterclockwise to open)

Problem Cause Solution

Hand pump will not generate pressure

It is difficult to increase pressure

Hard to use the fine adjust

It is difficult to turn the quick connector

The isolation valve is not open

B. The O-ring seal is loose or damaged.

A. The isolation valve is not closed

C. The O-ring seal is damaged.

E. The connector type mismatched to the gauge pressure port.

A. Too much force was previously applied.

.

.

A. Vent valve is not closed.

C. P/V selector is in the wrong position

B. The gauges are not tightened.

D. The thread surface is not smooth.

F. Dust or contaminants are blocking the pressure flow

B. The threads have no lubrication

.

.

Open the isolation valve

Replace O-ring seal

Close the isolation valve

Use the correct adapter

Secure the quick connect valves with less force.

.

.

.

Replace the O-ring seal.

.

Close the vent valve.

Pressure: pull the P/V selector out; Vacuum: push the P/V selector in.

Tighten the reference gauge or the gauge under test

Use Teflon tape on the thread and turn it in tight

Pressurize the pump several times and then suddenly vent which will push any

contaminants out.

Apply lubrication to the threads

.

.