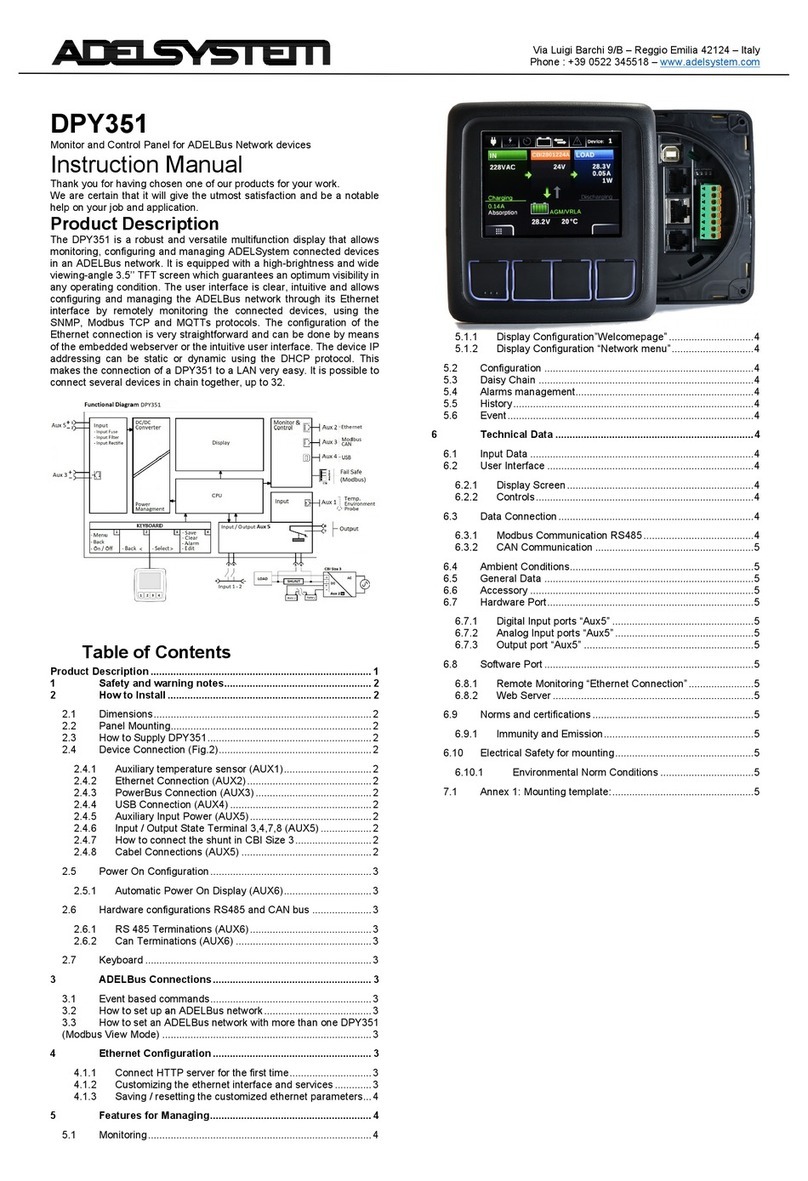

Adel System CBI60 User manual

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual CBI60_4

Page 1

DC Ups CBI60 “All in One”

CBI6012A and CBI6024A

Instruction Manual

Thank you for having chosen one of our products for your work.

We are certain that it will give the utmost satisfaction and be a notable

help on your job and application.

Product Description

New revolutionary product, with Ethernet on Board provided with protocol

connections: HTTPS, SNMPv3, ModBus TCP. The device also features

the ADELBus protocol for connecting other ADELSystem devices.

Thanks to “All In One” CBI series of DC-UPS, it will be possible to

optimize the power management of your system with one single,

extremely compact and cost-effective device, connected directly to the

mains. The available power is automatically distributed between load and

battery giving priority to the load. Battery can supply the load even with

mains so the output power to the load can be twice the nominal power if

required (Power Boost). When mains failure occurs, the load continues

to be supplied by the battery in backup mode. It is also possible to switch

on the device with no mains directly from battery. The “Battery Care”

algorithm performs rapid and automatic charging, continuous battery

charge optimization, flat batteries recovery and real time diagnosis during

installation and operation. Temperature compensation is possible by

connecting the temperature sensor probe. The real time auto-diagnostic

system monitors battery faults such as sulphated battery, shorted cells,

accidental reverse polarity connection or disconnection of the battery.

Each fault is signaled by a blink code of Diagnosis Led or via Modbus in

order to be easily detected and removed during the installation and after

sales. The continuous monitoring of battery efficiency reduces the risk of

battery damage and allows a safe operation in a permanent connection.

Predefined curves can be selected on the front panel to optimize the

charge of different battery types: Open Lead Acid, AGM and Gel Lead

Acid; Ni-Cd, Li-Ion are rechargeable using the same device. Charging

curves can be customized via Modbus. Output contacts are used to

signal both backup and fault conditions. A rugged casing with bracket for

DIN rail or Wall mounting.

Main Characteristics

•Universal input voltage: single-phase 100–277 Vac

•Load output:24 Vdc 2.5 A; 12 Vdc 5 A

•Battery output:24 Vdc 2.5 A; 12 Vdc 5 A

•“All In One” solution: power supply + battery charger + backup

module in one single device connected directly to the mains

•Suited for different battery types: Open Lead Acid, Sealed

Lead Acid, AGM and Gel Lead Acid; Ni-Cd and Li-ion. 5-stage IUoU

(Recovery, Bulk, Absorption, Float, Refresh Battery) plus Recovery

stage for deeply discharged batteries

•Automatic diagnosis of battery status and battery Life Test

function (Battery Care)

•Switching technology with high efficiency

•Protected against short circuit, overload and inverted polarity

•Solid state output contact for signaling Low Battery or Battery

Replacement and Fault system.

•IP20 protection degree

•Space saving on DIN rail

Safety and warning notes

To safely operate this Device please read and follow all

instructions carefully before attempting to unpack, install,

or operate.

WARNING –Explosion Hazard: do not disconnect

equipment unless power has been switched off or the area

is known to be non-hazardous.

WARNING –Explosion Hazard. Replacement of components may impair

suitability for class I, Division 2.

WARNING –Switch off the system before connecting the module. Never

work on the machine when it is live. The device must be installed

according to EN61010 or EN62368-1. The device must have a suitable

isolating facility outside the power supply unit, via which it can be

switched to idle. Danger of fatal injury!

WARNING –The device is equipped whit an internal fuse. If the internal

fuse blows up (fails opens), it is most probable that there is a fault in the

device. If this failure occurs, the device must be returned to the factory.

How to Install

Mounting

Fig. 1 –Mounting of the CBI60

Din Rail or Panel Mounting

Fig. 1 shows how to install the CBI60. It is possible to mount the device

on DIN rail or on a panel and fix it by 4 screws 2.9x8-16. There is no limit

for the panel thickness.

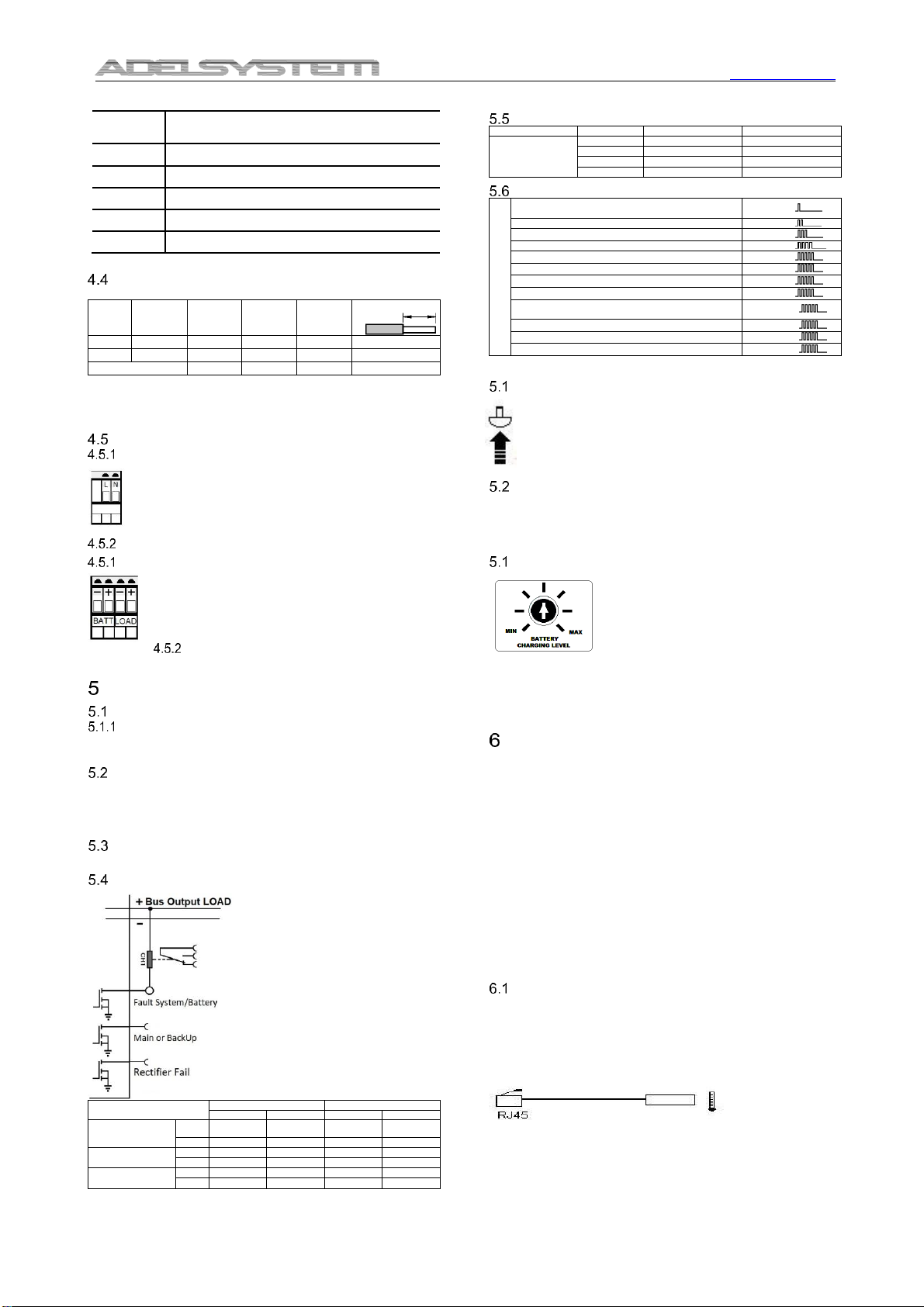

Device Connection (Fig.2)

Fig. 2 –Connection terminal

Reference

Description

1

Battery

2

Load

4

System fault –Rectifier alarm

5

Mains –Backup

6

Mains –Backup LED

7

Battery fault –System fault LED

8

Diagnosis LED

9

Configuration –Start from Battery

10

Input Vac

11

Aux1: RJtemp –DPY353

12

Start from Battery: (close to negative load)

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual CBI60_4

Page 2

19

Battery Config - Life test –Fast Charge –UPS Disabling-

Time Buffering

20

Aux4: Ethernet

21

Network Communication LED

22

ADELBus (CAN)

23

Rectifier Alarm

24

PE for Aux4 “Shield”

Connection terminal and wiring

The following cable cross-sections may be used:

Solid

(mm2)

Stranded

(mm2)

AWG

Torque

(Nm)

Stripping Length

In:

0.2–2.5

0.2–2.5

24 –14

0.5–0.6

7 mm

Out:

0.2–2.5

0.2–2.5

24–14

0.5–0.6

7 mm

Signal:

AMP Modu II

Screw type terminals, 2.5 mm2. Wiring shall be marked to indicate the

proper connection for the power supply. Use copper cables only; for

power connections use wires suitable for at least 75°C

Input and Output Battery connection

Input AC Port L –N:

No.10: Single phase Switching Power Supplies L, N, PE

Battery Connection and Load Connection

Battery Connection Port:

No.1:

-Connect the battery between: terminal 3 (–) and 4 (+)

-One battery (12 Vdc) for CBI12xx;

-Two battery (12 Vdc) connected in Series for CBI24xx;

Output Load:

No.2: Connect this output to the load, terminal 1 (–) and 2 (+).

Drive and Monitoring

Fault - Status conditions

STATUS: Mains or Backup: Input Mains On/Off.

•No.5 Output Open Collector Contact: 1

•No.6: LED

Fault Battery or Fault System

•No.4 Output Open Collector Contact: 2

•No.7: LED

•No.8: Led DIAGNOSIS: Diagnosis of the system through

“blinking code” light signal

Fault Internal Rectifier

•No.23 Output Open Collector Contact: 3

Driver Contact open drain:

Open drain referred to the Load

negative terminal; requires an external

DC power source (max 48Vdc) –drain

current: 20 mA Nom ; 40 mA Max for 3

sec

Mains/Back-Up

Battery or System fault

Port N°5

Led N°6

Port N°4

Led N°7

Mains Input Vac

ON

Closed

■- led off

Closed

■- led off

OFF

Open

■- led On

Closed

■- led off

Battery SOC

less than 30%

YES

Open

■- led On

Open

■- led On

NO

Open

■- led On

Closed

■- led off

Battery or

system Fault?

YES

■- led off

Open

■- led On

NO

■- led off

Closed

■- led off

Charging Mode Status

Status

Diagnosis (No.8)

Battery fault (No.7)

Charging Type

Float

1 Blink/2 sec

OFF

Absorption

1 Blink/sec

OFF

Bulk

2 Blink/sec

OFF

Recovery

5 Blink/sec

OFF

Faulty Battery / Faulty System

Auto Diagnosis System

Reverse polarity or high battery Voltage

(over 32.5Vdc for CBI 24xxA)

1 Blink/pause

Battery not connected

2 Blink/pause

Battery element in Short Circuit

3 Blink/pause

Overload or short circuit on the load

4 Blink/pause

Bad battery; Internal impedance Bad or Bad battery wire connection

5 Blink/pause

Life test not possible

6 Blink/pause

Rectifier Alarm

7 Blink/pause

Boost condition; battery discharge after 4 min. of overload.

8 Blink/pause

Low battery (under 18.5Vdc for CBI 6024A) Only if started from

battery, no mains input

10 Blink/pause

Mains detector failure

12 Blink/pause

Device over-temperature Alarm

14 Blink/pause

Calibration error

16 Blink/pause

Start from Battery No Input Mains Vac

No. 9: Push-button, max 3 sec., in the front panel to switch ON

the system without the “Mains input Vac” but only the battery

connected. Same function for additional external Button by

connection of pin N°12 (SB). The other side of the external

button must be connected to Negative Load.

Load ON/Off

It is possible to Drive the output Load On/Off by Ethernet connection. This

function allows to switch On/Off the load output for many application as,

Reset PLC, staircase light timer control, emergency light controls, etc…

Charging Current limiter:

In order to protect the battery from excessive

charging currents, the device allows to limit the

maximum charge current by Push Button. Press

button (9) for 2 sec., after that in 20 step it is

possible to select the limit current. Press for

more than 2 sec. to store the selection in

permanent memory.

CBI6024A: from 0 –3A ; 20 step; 1 step 150mA

CBI6012A: from 0 –5A ; 20 step; 1 step 250mA

It is possible set the limiting current also by the internal Web Server,

please refer to the Ethernet section.

Battery Care

The Battery Care philosophy is based on algorithms that implement rapid

and automatic charging, battery charge optimization during time, flat

batteries recovery and real time diagnostic during installation and

operation. Elements in short circuit, accidental reverse polarity

connection, disconnection of the battery, can easily be detected and

removed by help of Blink Code of Diagnosis Led, during the installation

and after sale. Each device is suited for all battery types, it is possible to

set predefined curves for Open Lead Acid, Sealed Lead Acid, Gel, Ni-Cd,

Li-Ion. They guarantee battery reliability over time by continuously testing

the internal impedance status, avoiding any possible risk of damage and

granting a permanent, reliable and safe connection of the battery to the

power supply. The system includes a battery stimulation circuit and

sophisticated algorithms to recognize sulphated batteries or batteries

with a short-circuited element. Battery Test: Automatic. battery

connection check: every 60 seconds. Battery efficiency test: every 220

minutes in float charge. Battery Faults can be monitored by relay and led

blinking.

Battery Charge in Temperature compensated

environment

No. 11 Auxiliary Output “AUX 1”

It is possible to connect the Temperature sensor probe and apply it on

the battery.The function of the probe is for temperature battery

compensation. With this it is possible to meet the requirements of the

EN54- fire certification.

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual CBI60_4

Page 3

Battery Temperature Compensation Charge

Connecting the cable RJTEMP (supplied separately) to Auxiliary Output

AUX1, the CBI will adjust the battery charging voltage in relation to the

Battery temperature:

Fast Charge: Open Lead, AGM, Gel

Float charge: Open Lead, AGM, Gel

+/- 5mV/°C x n. of Cells from -8°C to +60°C

+140 ÷ -200 mV/Cell compared to the value at

20°C

+/- 3mV/°C x n. of Cells from -20°C to +60°C

+120 ÷ -120 mV/Cell compared to the value at 20°C

Fast Charge: Ni-Cd

Float charge: Ni-Cd

+/- 2.5 mV/°C x n. of Cells from -20°C to +60°C

+100 ÷ -100 mV/Cell compared to the value at

20°C

+/- 2.5 mV/°C x n. of Cells from -20°C to +60°C

+100 ÷ -100 mV/Cell compared to the value at 20°C

The device stops charging the battery if the temperature is below -20°C

or above +60°C. The sensor placed on cable RJTEMP must be applied

on the battery.

Device Configurations

Completely automatic, all devices are suitable to charge most batteries

types thank to User Selectable charging curves. They can charge open

lead acid, sealed lead acid, Gel, Ni-Cd and Li-Ion. It is possible to change

or add other charging curves connecting the web server device to a PC.

Configurations

Note: it is also possible to configure the device via Web server

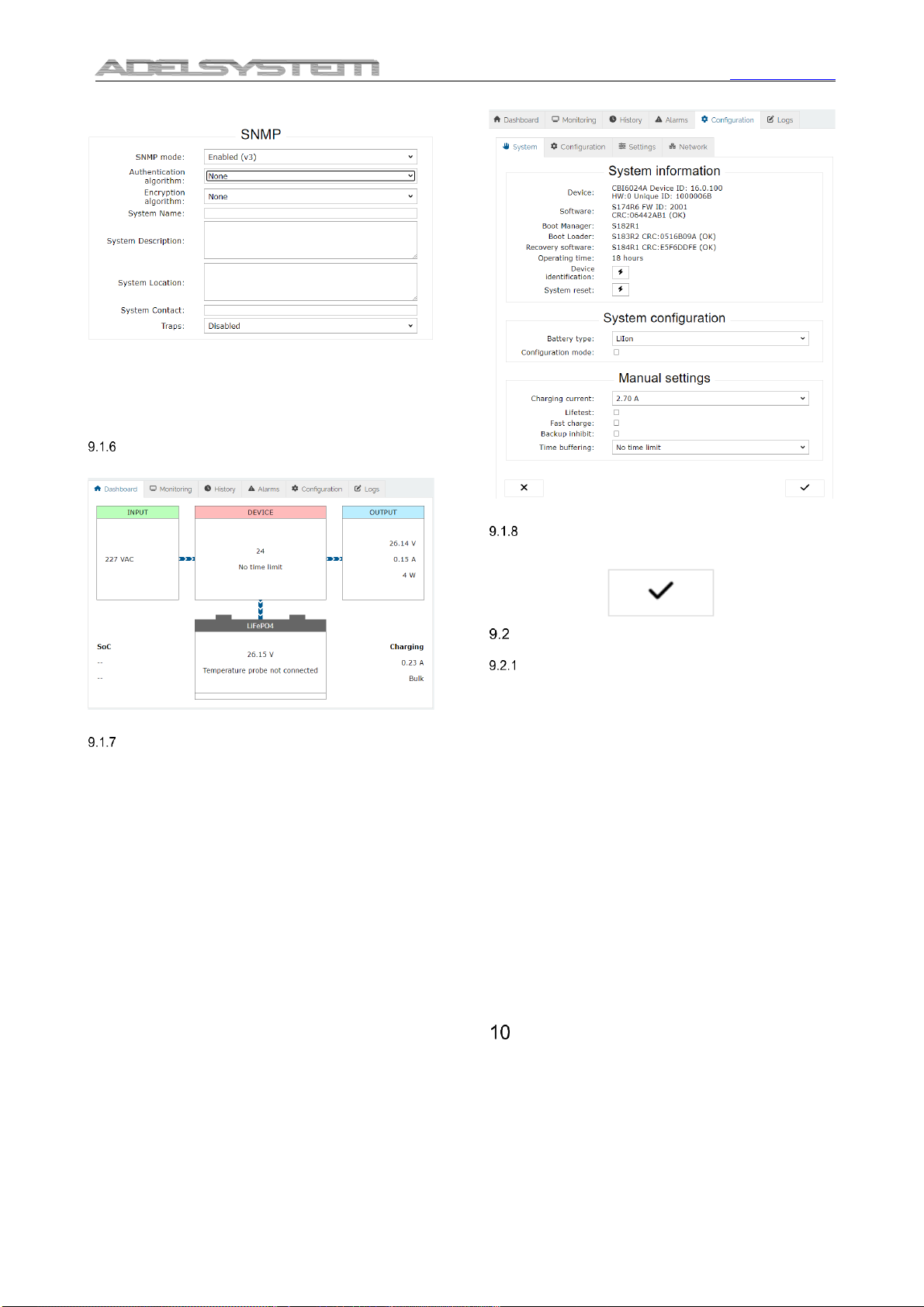

In normal operation the LED bargraph (No.19 in sect.7) gives an

indication of the current (0 to 100% of In) as follows:

•In charge mode with mains:

battery charge current with solid light

•In backup mode without mains: battery discharge current with

blinking light

•In boost mode with mains: battery discharge current with

flickering light

To display the current device configuration on the LED bargraph press

the Config/Start button (No.9 in sect.7) briefly (< 1 sec). The display

returns to normal operation after 10 seconds. Please refer to the pictures

at the end of this section.

To change the device configuration, complete the procedure below (note:

if the procedure is not completed no settings are saved; the procedure is

aborted if no command is given for 60s).

With battery disconnected:

•press the Config/Start button (No.9 in sect.7) for more than 2

seconds, until the first led starts blinking

•press briefly the button to cycle through the battery types as

shown by LEDs 1,2,3 (please refer to the pictures at the end of

this section) then confirm with a long press until the 4th LED starts

blinking

•LED 4: Config Mode: ON/OFF

•Long press to enable a complete configuration via Web Server,

Modbus/SNMP and APY351/ADELViewSystem (Led ON).

•Short press to configure basic parameters from the device front

panel or from the web server System page (Led OFF)

•If Config Mode was selected, the procedure terminates here

•LED 5: Option: not used: continue with a short-press

•LED 6: Life Test; long press to enable the function (Led ON), short

press to disable

•LED 7: Fast Charge; long press to enable the function (Led ON),

short press to disable

•LED 8: UPS Disable; long press to disable the UPS function (Led

ON), short press to keep it enabled

•LED 9: Buffering time: press briefly the button to select the max

backup duration, then confirm with a long press. The current

selection is shown with other LEDs blinking together with LED 9

as follows:

•Led 1: 30 sec; Led 2: 120 sec; Led 3: 300 sec; Led 4: 10 min; Led

5: 15 min; Led 6: 20 min; Led 7: 30 min; Led 8: 45 min; All leds:

Infinite time

•Note: the last selection (infinite time) is confirmed automatically

also with a short press

•More values can be selected by Web Server, Modbus, SNMP and

with DPY351 or ADELVIEWSystem

•End Programming: the device shows the selected configuration

for 10 seconds then resumes normal operation,

With battery connected:

•press the Config/Start button (No.9 in sect.7) for more than 2

seconds, until the 5th led starts blinking

•follow the procedure above from step “LED 5: Option” (Battery

Type and Config Mode can be changed only when the battery is

not connected).

Data and Communication

ADELBus connection

Remote device connection by terminals 22. This device features the

ADELBus communication protocol for the connection of other devices on

CAN bus, for monitoring, configuring, driving and updating them(fig.3).

Battery Type chemistry Selection

LED Config

(Size 5)

Float charge

(Volt/Cell)

Fast charge

(Volt/Cell)

Open Lead

2.23

2.40

(AGM) Low

2.25

2.40

Gel Battery

2.30

2.40

Ni-Cd

1.4V/cell

(12V:10 cells)

(24V:20 cells)

(48V:40 cells)

1.45V/cell

(12V:10 cells)

(24V:20 cells)

(48V:40 cells)

Li-Ion (4)

LiFePo4

3.45V/cell

12Vfield: 13.8V

24Vfield: 27.6V

48Vfield: 55.2V

3.65V/cell

12Vfield: 14.6V

24Vfield: 29.2V

48Vfield: 58.4V

Config Mode (5)

Configure with ADELViewSystem or Web

Server for CBI60

Functional Setting

Battery Life

test ON

Life test enabled

Fast Charge

Enable (3)

Fast Charge enabled.

UPS Disabling

UPS function enabling. Use terminal 12 for

connection to external Contact.

Time Buffering

1 blink => 0.5, 2 blink => 1,

3 blink => 5, 4 blink => 10,

5 blink => 15, 6 blink => 20,

7 blink => 30, 8 blink => 45 min

9 Solid => ∞infinite”

(Time = minute)

“Start from

Battery” (No

Input Mains)

System switch ON from battery without

mains. For connection to external Push

button use terminal 12

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual CBI60_4

Page 4

Fig. 3 –Connection to DC Ups

Fig. 4 –Connection RTConn cable

For the ADELBus connection, please connect the cable RTConn to AUX1

on the device as shown in Fig.4 and connect the other side of the cable

to the CAN terminals L (Brown) and H (White) of the CBI60, with a line

termination (LT) resistor 120 Ohm, present inside the cable kit.

Ethernet Configuration

Configuration of the Ethernet interface by HTTP server via the Web

browser:

Connect HTTP server for the first time

Connect the device to the network with a standard CAT5e or better LAN

cable plugged into the Aux4 connector (RJ45) on the bottom of the unit,

as shown in section 4.3. The CBI60 is factory-configured to operate with

a fixed IP address (192.168.1.100) on the standard HTTP port (number

80).

A different static IP address can be assigned to the CBI60 or a dynamic

IP address can be assigned using the DHCP protocol. The network

configuration can be carried out using the internal webserver. Type the

IP address of the CBI60 into any browser’s address bar (as an example

"192.168.1.100") then the login page appears requesting the username

and the password.

To access the internal webserver, at the login page, the following

credentials must be used:

Username: admin

Password: password

Note: after 20 minutes of inacticity the login credentials must be entered

again.

Customizing the ethernet interface and services

Select “Configuration” and then “Network” to display the following groups

of parameters and other information:

•Account

•Generic configuration

•TCP/IP Configuration

•HTTP(s) Configuration

•SNMP

Account:

The Account group (Fig. 6) allows the customization of the data for the

HTTP server login page. Any changes must be confirmed with the

confirm button at the bottom of the page.

Fig. 6 –Account settings

Generic and TCP/IP Configuration

Fig. 7 shows the TCP/IP Configuration group with parameter default

values. They allow unique identification of the unit in the network.

Fig. 7 –IP settings

If “Dynamic (DHCP)” is selected, the IP address is automatically

assigned by a DHCP server, that must be active on the network; in this

case the System IP, Subnet Mask and Gateway textboxes show the

assigned values and are not editable.

The CBI60 supports access using the Virtual LAN protocol. In the case

“VLAN ID” checkbox is not selected the CBI60 will not operate in the

VLAN. If “VLAN ID” checkbox is selected then a “VLAN ID” textbox will

appear and should be populated with an ID in the range 1 to 4094,

matching the one of the VLAN the unit is operating in.

Any changes must be confirmed with the confirm button at the bottom of

the page.

HTTP(s)

The CBI60 supports HTTP and HTTPs protocols. If the client system

supports multicast DNS (mDNS) the device can be accessed by its name

(as set under Generic Configuration) followed by “.local”.

HTTP Port allows redirecting the HTTP traffic to a port different than the

standard HTTP port 80. In that case, access to the HTTP server from a

browser must be made using the syntax http://ipaddress:portnumber.

As an example, if the IP address is 192.168.1.100 and the selected HTTP

port is 5678 then the following IP string should be entered in the browser

http://192.168.1.100:5678.

Secure HTTP (HTTPS) can also be selected, using an internal certificate

or a certificate provided by the customer.

Fig. 8 –HTTP(s) configuration

SNMP

The CBI60 can act as SNMP server. An ADELsystem MIB table file is

provided which consists of a list of parameters that can be remotely read,

or read-written through the SNMP protocol. Each parameter (OID) is

mapped one-to-one to a Modbus RTU holding register. Refer to the

document “Adelsystem parameter table”for the description of each

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual CBI60_4

Page 5

parameter.

Fig. 9 –SNMP settings

All the fields in the SNMP group of settings allow a maximum of 31

characters, except “System Description” and “System Location”, which

allow 255 characters maximum. The actual content of the page depends

on the SNMP version selected (v1, v2c or v3).

Any changes must be confirmed with the confirm button at the bottom of

the page.

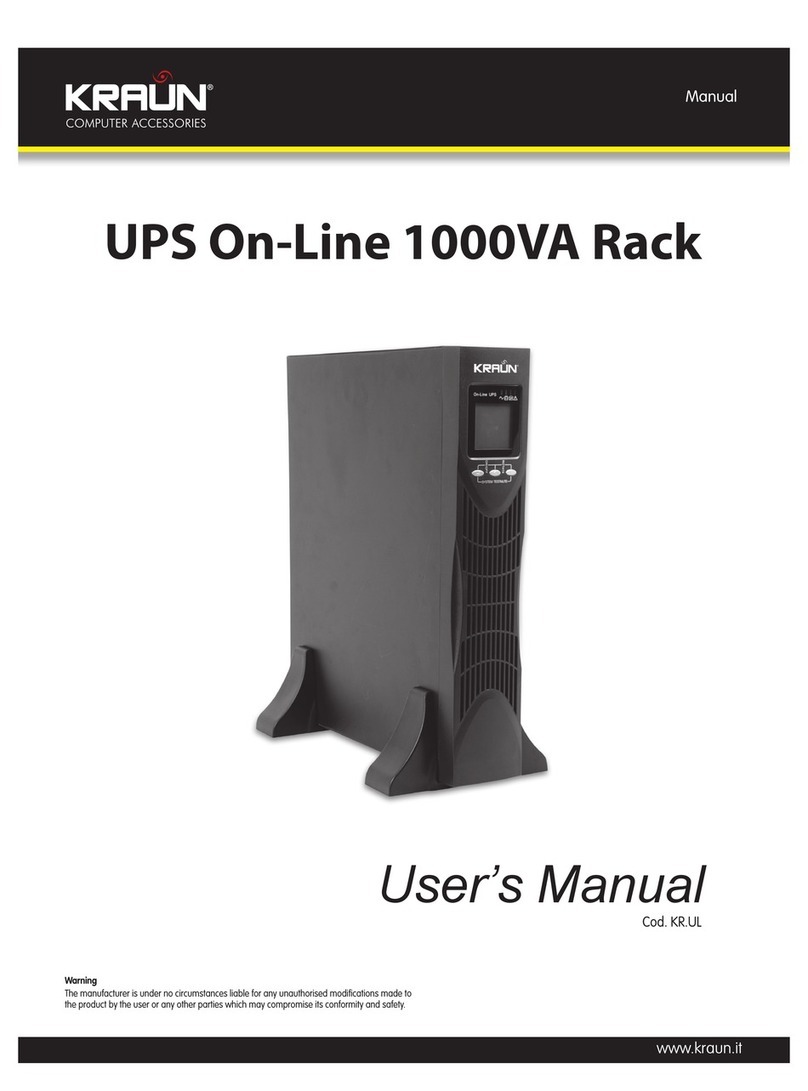

Device status

The Dashboard pageshows the main operating parameters of the

device.

Fig. 10 –Device status

System settings

The System page under Configuration shows detailed information on the

device and installed software, to be communicated to the service

technician if requested. Fig. 11 shows example information: the actual

values will be different.

The “device identification” button allows to locate the CBI60 by emitting

a beep and turning on all leds in sequence.

The “System reset” button allows to reboot the device remotely, only if no

battery connected. Current settings will be maintained. Any changes not

saved with the confirm button will be lost.

“System configuration”and “Manual settings”replicate the settings also

accessible on the CBI60 front panel by pressing the CONFIG button

(refer to the relevant section of this manual). Any changes must be

confirmed with the confirm button at the bottom of the page.

“Battery type” selects the battery chemistry from a drop-down list.

If “Configuration mode” is selected Led 4 ON, the following parameters

(Lifetest, Fast charge, UPS enable and Buffering time) cannot be

changed as they are controlled remotely via Modbus or SNMP.

If “Configuration mode” is not selected Led 4 OFF, the following settings

are available: “Lifetest”, “Fast charge”, “UPS disable” and “Time buffering

time”.

The “Charging current” sets the battery charge current limit.

Fig. 11 –Device settings

Saving the customized parameters

To save the changes into the CBI60 non volatile memory press the

confirm button at the bottom of the page.

How to restore default values in the device

(Customer service)

Resetting the customized parameters to their

default values

In case the login user name or password was forgotten, or the TCP/IP

configuration was set incorrectly and the device is no longer reachable,

please follow this procedure to restore the default settings:

•Turn OFF the device

•Press the CONFIG button on the front panel and keep it pressed

•Turn ON the device and continue to keep the button pressed (all

the 9 configuration LEDs will stay ON during this time)

•After 5 seconds the 4 top configuration LEDs (n. 6 to 9) will blink

alternatively in pairs and the LED 1 will blink slowly showing

“Option 1”

•Release the button

•Now click briefly on the button to select one of 4 options, as shown

by the config LEDs 1 to 4. The options are:

-1: forces Dynamic (DHCP) IP Addressing Mode

(DHCP) until reboot; the TCP/IP configuration must

be changed on the HTTP server in order to make this

setting permanent.

-2: system recovery application, only to be used if

instructed by customer service

-3: restore login credentials, TCP/IP and SNMP

settings to factory default

-4: restore the complete device to factory settings –

WARNING: all user’s settings and logs will be lost,

including the battery type selection.

-Confirm the choice by keeping the CONFIG button pressed

for 5 seconds until LEDs 6 to 9 stop blinking.

Technical Data

Please Refer to Data Sheet product

This manual suits for next models

2

Table of contents

Other Adel System UPS manuals

Popular UPS manuals by other brands

CyberPower

CyberPower OR1500LCDRTXL2U user manual

INFOSEC UPS SYSTEM

INFOSEC UPS SYSTEM Zenergy Station 2000 user guide

Kraun

Kraun 1KVAS user manual

inform

inform DSP FLEXIPOWER SERIES user manual

Huawei

Huawei UPS5000-E-****-FM series user manual

Alpha Technologies

Alpha Technologies Sentra 1000 Operator's manual