Adey Mini 130 User manual

Installation and servicing

Mini 130/230

Digital Pressurisation Unit

- 2 - - 3 -

CONTENTS Page

Checklist .......................................................................... 4

Important Facts - read before commencing installation ............................... 5

Location ........................................................................... 6

Key Features ....................................................................... 8

Installation ........................................................................ 9

Electrical Installation ............................................................... 13

Commissioning .................................................................... 17

Operation .......................................................................... 21

Maintenance ....................................................................... 22

Environment Protection ............................................................ 23

Technical Specification ............................................................. 24

Trouble Shooting ................................................................... 25

Product Log ....................................................................... 26

Guarantee ......................................................................... 29

PRODUCT DESCRIPTION

Heating and cooling system pressurisation top up unit with integral water storage tank and

electric solenoid piston pump, automated control system consisting of pressure transducer

and water level switch. The tank includes an AB air gap for category 5 fluid isolation (BS EN

1717).

APPLICATION

The ADEY® Pressurisation Unit, (APU) Mini range is designed to provide intermittent water

top up only to compensate for intermittent losses in system pressure in heating and cooling

systems in commercial or industrial applications. These could include slight leaks, air venting,

etc. The units are not designed to deal with sudden losses of system pressure due to

major water losses over extended periods. They are also not to be used for water boosting

applications.

STORAGE

If this product is not to be installed immediately on receipt, ensure that it is stored in a dry,

frost and vibration free location in its original packaging.

WARNINGS:

zThe electrical installation must be carried out in accordance with the current

national electrical regulations.

zThe electrical installation must be installed by a qualified person.

zThe motor is not accessible in normal operating mode. The unit must only be

operated with the front cover in place.

zIn the interests of electrical safety a 30 mA residual current device (R.C.D.

not supplied) should be installed in the supply circuit. This may be part of a

consumer unit or a separate unit.

zThis appliance must be earthed via the supply cord.

zThis appliance must not be used for any other application without the written

consent of ADEY Commercial Limited.

zThis appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

zChildren should be supervised to ensure that they do not play with

the appliance.

zThis product should not be used for the supply of water to more than one

heating/cooling system at a time.

Please read installation details carefully as they are intended to ensure this product

provides long, trouble free service. Failure to install the unit in accordance with the

installation instructions will lead to invalidation of the warranty.

Read this manual carefully before commencing installation.

This manual covers the following products:

Mini 130

CP1-03-04911

Mini 230

CP1-03-04912

As a WEEE producer, ADEY Commercial Limited are obligated to finance the collection,

treatment & recovery of WEEE, and our compliance under these regulations is ensured

via our work with our WEEE Compliance Scheme of choice, B2B Compliance.

THIS PRODUCT COMPLIES WITH CURRENT EU PRODUCT LEGISLATION

- 4 - - 5 -

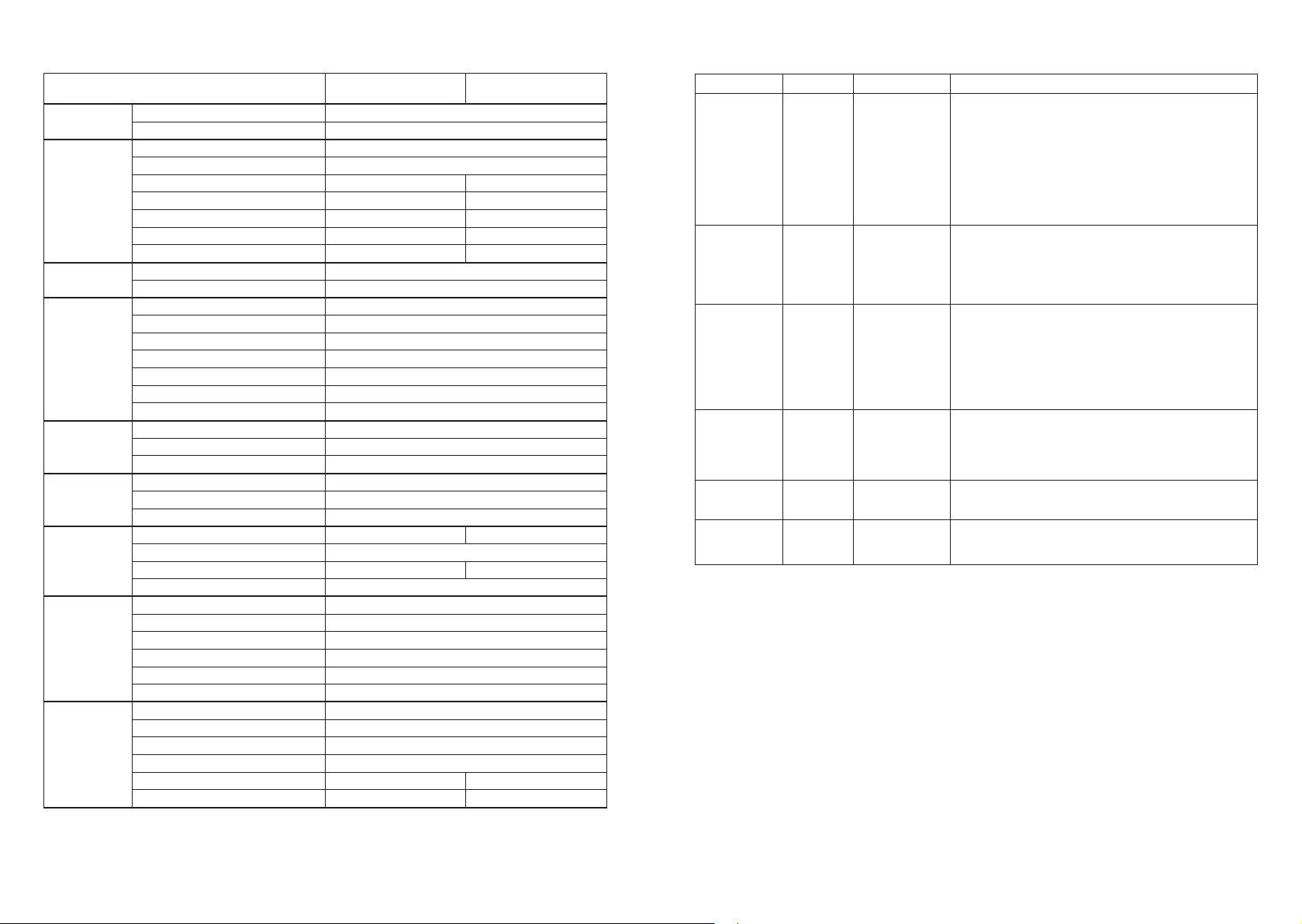

Item Description Qty Item Description Qty

APU 1 Fill valve flow restrictor, blue 1

Front cover 1 Rubber hose sealing washer, to

be used with item C 1

Flexible hose, G ½ 15 mm

compression 1 Cable tie 2

M6 screw 1 Instruction book 1

Wall mounting plate 1

A

E

C

B

D

H

G

F

I

1 IMPORTANT FACTS: READ BEFORE COMMENCING PUMP INSTALLATION

A Water storage capacity.

1.11 The APU Mini has a usable water volume of approximately 2 litres; the length

of time the APU takes to pressurise a system will be dependent on the pressure

differential between the cold fill and set pressures and also the refill rate of the tank.

1.12 Ensure the pumps are primed as described in the priming section before

starting, to avoid causing damage to the pump. See Section 6.20 Hydraulic

commissioning.

B Water temperature

This unit is designed to pump cold water only which should not exceed the following

values:

1.13 The maximum allowable water temperature is 23 oC (see Technical Section).

1.14 The minimum allowable water temperature is 4 oC.

C Pipework - General

1.15 Do not drill holes or put fastenings into the APU Mini tank, this will cause

leakage.

1.16 Secure pipework: Ensure pipework to and from pump is independently

supported & clipped to prevent forces being transferred to inlet and outlet

branches of the unit. Do not secure pipework to the APU Mini, this will cause

damage and possible leakage.

1.17 Flux: Solder joints must be completed and flux residues removed prior to APU

Mini installation (flux damage will void any warranty).

1.18 Pipework design: Care should be taken in the design of pipework runs to

minimize the risk of air locks e.g. use drawn bends rather than 90obends.

1.19 DO NOT introduce solder flux to flexible hose, tank, pump or any

parts manufactured from plastic.

1.20 DO NOT allow contact with oil or cellulose based paints, paint thinners or

strippers, acid based descalents or aggressive cleaning agents.

1.21 DO NOT bend the flexible hose beyond 90o. It must be installed as

detailed, DO NOT kink. See Installation Section 4.14.

D Plumbing installation regulations

1.22 The plumbing installation must comply with the current water and building

regulations.

1.23 The plumbing installation must be installed by a qualified person.

E System filling

1.24 The APU Mini is NOT DESIGNED TO FILL THE SYSTEM FROM EMPTY.

It is only intended to top up the system after occassional water leakage.

Systems should be filled via a dedicated filling loop.

Fig. 1

IMPORTANT: With the appliance removed from its packaging check for any damage prior

to installation. If any damage is found contact ADEYCommercial Ltd within 24 hours of

receipt.

A D

C

Front cover removed for clarity

B

E

Electrical rating

plate & serial

number

G

H

F

CHECKLIST

Note: Your product may vary slightly from the picture above.

- 6 - - 7 -

2 LOCATION - GENERAL

2.11 Location: The APU Mini must be located on a solid wall of sufficient

strength to support the filled weight of the APU Mini, close to the

water source and a suitable overflow position (see Section 10 -

Technical Specification for filled weight). The APU Mini must not be

installed in a loft space. It must also be considered that the noise

and vibration from the APU Mini may be transmitted through the

structure it is sited on. Ensure the minimum clearance requirements

are followed to allow servicing of the unit.

2.12 Access and minimum clearance requirements: For emergencies

and maintenance the APU Mini must be easily accessible and have

the minimum clearance around it as laid out in Fig. 2. Additional

access to the front of the unit will be required to operate the keypad

and view the display.

2.13 Protection: The APU Mini must be located in a dry, frost free area.

2.14 Ventilation: Ensure an adequate air flow to cool the APU Mini.

Separate the APU Mini from other appliances that generate heat.

Do not block the vent holes on the front cover.

2.15 Water retention: Site the APU Mini in a location where in the

unlikely event of a water leak, any spillage is contained or routed

to avoid electrics or areas sensitive to water damage. As part of

the AB airgap (CAT 5 fluid isolation) the APU Mini has a weir type

overflow on the front, water will be discharged from this area in the

event of the failure of the inlet valve or non-return valve.

2.16 Supply inlet pressure: The water supply inlet pressure must not exceed 7 bar.

2.17 Ambient temperature: The APU Mini must be sited in a location where the

ambient temperature does not drop below 4 °C or exceed 40 °C.

2.18 Pipework: For optimum performance inlet and outlet pipework must be a

minimum of 15 mm pipe.

2.19 Static outlet pressure: The static outlet head must be 3 metres below pump

maximum cold fill pressure (vertically above the appliance).

2.20 Noise: A flexible hose is supplied as standard which will minimise the

transmission of noise and vibration from the APU Mini pump to the

pipework connected to the appliance outlet. However, care must be taken

when mounting the APU Mini that any noise is not amplified through loose

panels or pipework.

2.21 Flexible hose: Only use the ADEY hose supplied with the APU Mini.

2.22 Isolating valves: Separate system isolating valves (non-restrictive) must be

fitted to allow easy service of the APU Mini. Isolating valves must be mounted

where specified to allow the system isolation and removal of the APU Mini if

needed. See Section 4.14 for installation details.

300

500

300

150 150

Fig. 2

- 8 - - 9 -

3 KEY FEATURES

3.11 The APU Mini comprises of the following main components:-

1. Moulded tank – Main body of the APU, comprising of an integrated water

tank with warning pipe and weir overflow and mounting the solenoid

piston pumps, manifold and controller.

2. Pump assembly – One or two piston pump units mounted into the

moulded tank with vibration isolating rubber mounts.

3. Outlet manifold – Brass manifold with pressure transducer used to monitor

system pressure and connection to the pump(s)

4. Programmable controller – Intuitive, user set controller, allowing system set up

and easy alarm connection.

5. Wall mounting plate – Robust stainless steel wall mounting plate allowing

quick, easy installation and removal if needed.

6. Moulded cover – Moulded acrylic capped ABS cover retained to the

moulded tanks with Dual LockTM fastening system for quick and easy

access.

3.12 Principle of operation: The pressurisation unit consists of a break tank and

one or two piston pumps. The break tank is supplied with mains water from

the left to a float valve and includes an overflow and weir to maintain an AB air

gap in the tank. The unit is connected to the heating/chiller system

via a flexible hose which can exit the unit on either the left or right. The

pumps are connected via a flexible hose to the tank via a rubber connector.

A pressure transducer monitors system pressure and if a reduction in system

pressure is detected, the controller runs the pumps until the system is re-

pressurised to the required pre-set level. If the unit only has a single pump

connected it will run on a 30 minutes on/30 minutes off basis until this level

is reached, if the unit is a twin pump model the pumps run in duty standby

mode (the controller will alternate which pump starts first to even the

wear on the pumps). The manifold is fitted with a non-return valve to ensure

system pressure is maintained once pressurised.

4 INSTALLATION

4.11 Fill valve flow restrictor guidelines: Ensure side entry fill valve is fitted

with the correct filter and flow restrictor combination (dependant on the

mains water pressure) into the G ½ threaded tail as outlined below:

Coloured insert - To be used for water pressure between 1 and 4 bar

White insert - The APU Mini is pre fitted with the white high pressure insert.

Change if the unit is slow to fill or the water pressure is low (below 4 bar).

4.12 Cold mains feed connection: The connection to the cold water mains inlet is

made using a suitable fitting to the G ½ male thread on the left hand side of

the APU Mini. When tightening ensure the fill valve within the tank is not

rotated. If the valve is rotated it may not function correctly with the risk

of flooding. (Do not overtighten).

4.13 Wall plate fixing:

1. When installing the APU Mini on a wall ensure suitable fixings for the wall

structure are used and are suitable to support the unit when fully filled with

water (see technical section for filled weights). The holes in the wall plate are

6 mm in diameter, the maximum permissible screw head height is 3 mm.

2. All holes in the wall mounting plate must have fixings used in them as per

the image below, do not leave out fastenings as this will compromise the

integrity of the wall plate.

3. Ensure you have sufficent room around the area you are mounting the APU

Mini to allow installation, servicing and operation. See section 2.12.

4. Ensure wall plate is fixed to a flat vertical wall and the top of the plate is

horizontal.

1Fig. 3

2

3

4

5

6Fig. 4

Fig. 5

- 10 - - 11 -

5. Retain the APU Mini to the wall mounting plate using the single M6

retaining screw at the top of the wall plate.

6. Fit the plastic cover by pressing as indicated below with the palm of the

hand until the Dual LockTM is heard to ‘click’.

4.14 Pipework connections & guidelines:

1. Before connecting the APU Mini to the system ensure that system flushing

has been performed correctly and all foreign matter, including pipe scale,

has been removed.

Note: Foreign material from the system coming into contact with the

expansion vessel bladder could cause premature failure of the expansion

vessel.

2. Isolating valves MUST be installed on the unit inlet and outlet, before

connection to the flexible hoses to allow the unit to be isolated if required.

The isolation valve on the outlet should be of a lockshield type. See

Fig. 10.

3. A drain valve must be fitted on the outlet of the APU Mini before the

isolation valve. See Fig. 10.

4. The connection to the heating/chilling system is also made with the

supplied flexible hose and a 15 mm compression fitting. The hose is

made water tight with a sealing washer on assembly, nip tight to 4 to

5 Nm for water tight seal. (Do not overtighten).

5. The connection to the heating/chilling system can be made to the left

or right hand side by routing the flexible hose supplied as detailed below.

Fig. 6

Fig. 7

Fig. 9Fig. 8

Cable tie

- 12 - - 13 -

6. The flexible hose and any wiring can be retained in the desired position

using cable ties and the two metal cable retention points on the top left

and right of the APU tank. See Figs. 8 & 9.

7. The warning pipe should be connected to a suitable drain via a tundish

enabling visual warning of an overflow condition. The overflow fitting is

designed to use 19 to 23 mm diameter plastic waste pipe or connect to

G ¾ threaded pipe. Ensure there is a demountable joint in the pipe to

allow the removal of the APU Mini if needed.

8. Non-return valves, pressure reducing valves and RPZ valves MUST NOT

be installed between the APU Mini and the heating/cooling system. These

devices will prevent the pressure sensor from reading the system pressure

and will lead to incorrect operation of the unit.

9. The APU Mini should be connected to the system return header along with

the expansion vessels as specified in BS 7074. See Fig. 10.

4.15 Typical installation diagram:

4.16 Vessel sizing & location:

1. System expansion vessel sizing should comply with the BS 7074 Expansion

Vessel sizing calculation.

2. The pressurisation unit and expansion vessels should be connected to the

system at the same point, to provide a neutral pressure reading.

3. A lockshield valve and drain valve should be installed at the inlet of each

expansion vessel to allow for servicing.

5 ELECTRICAL INSTALLATION / EARTHING

5.11 Regulations: The electrical installation must be carried out in

accordance with the current national electrical regulations and

installed by a qualified person.

5.12 Safety: In the interests of electrical safety a 30 mA residual current

device (R.C.D. not supplied) should be installed in the supply circuit.

This may be part of a consumer unit or a separate unit.

5.13 Before starting work on the electrical supply ensure power supply is

isolated.

5.14 DO NOT allow the supply cord to contact hot surfaces, including the

motor shell, pump body or pipework. The cord should be safely

routed and secured by cable clips.

5.15 Adjacent pipes: Adjacent suction and delivery pipes should be fitted with

earthing clamps in accordance with current regulations (Fig. 12).

5.16 Earthing: This appliance must be earthed via the supply cord.

5.17 Pipework: Copper or metallic pipework must have supplementary earth

bonding where the continuity has been broken by flexible hoses or plastic

components.

5.18 Additional earthing: Certain installations may require additional earthing

arrangements such as equipotential bonding. Reference should be made to

the relevant regulations concerning this subject to ensure compliance.

5.19 Connections: The APU Mini must be connected to a dedicated fused SPUR via

a lockable isolator to avoid authorized disconnection.

5.20 The electrical connection must be made adjacent to (not behind) the APU

Mini to allow disconnection of the electrical supply should the pump module need to

be removed for service or maintenance.

Fig. 10

Fig. 11

APU Mini

Warning pipe

Drain

valve

Isolation valvesExpansion

vessel

Return

header

Lockshield

valve

Drain valve

Earth continuity

connection

Fig. 12

Flexible

hose

Metallic

pipework

Metallic

pipework

- 14 - - 15 -

5.21 Wiring of connection unit:

WARNING: This appliance must be earthed.

The wires in the mains lead (supply cord) are coloured in accordance with the

following code:

Green and Yellow: Earth

Blue: Neutral

Brown: Live

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identifying the terminals in your

connection unit proceed as follows:

zThe wire which is coloured green and yellow must be connected to the

terminal in the connection unit which is marked with the letter E or by the

earth symbol: or coloured green or green and yellow.

zThe wire which is coloured blue must be connected to the terminal which

is marked with the letter N or coloured black.

zThe wire which is coloured brown must be connected to the terminal

which is marked with the letter L or coloured red.

5.22 Boiler interlock safety function:

The APU Mini is fitted with a single volt free contact specifically assigned for

boiler/chiller shut down in the event that the APU Mini detects system

pressure above the Hi alarm pressure or below the Lo alarm pressure.

The boiler interlock contact will be open circuit below the Lo alarm pressure

and above the Hi alarm pressure.

When the system pressure is in its normal operating pressure range (above Lo

alarm pressure and below Hi alarm pressure settings) the contact is

closed circuit

Always refer to the boiler/chiller manufacturer’s instructions for correct

integration.

5.23 Boiler interlock connections:

The circuit connected to the relay is limited to 5 Amps, 230 V a.c.

maximum. The Installer MUST fit a 5 Amp fuse in the circuit to the alarm

relay to protect the APU Mini from damage.

For connection of output relays follow the steps and images below:

1) Remove the required green connector from the right hand side of the

control board.

2) Strip 6-8 mm insulation from the end of the connection wire

(Max 1.5 mm2CSA).

3) Insert wire into connector and screw down terminal screws to secure

(0.6 Nm max.).

NO

Boiler Interlock

Fig. 13

Fig. 14

Fig. 15

Fig. 16

- 16 - - 17 -

4) Re-insert connector into the correct location on the control board and route

the cable to the back of the APU Mini and secure with a cable tie to the

retainer.

5.25 Supply cord replacement:

The supply cord and internal wiring within the terminal box are routed

and secured to ensure compliance with the electrical standard EN 60335-

1. It is essential that prior to any disturbance of this internal wiring, all

cable routing and securing details are carefully noted to ensure re-

assembly to the same factory pattern is always maintained.

If the supply cord is to be changed or is damaged, it must be replaced

with a special cord assembly available from ADEY or one of their approved

repairers. On disassembly note the cord retention and routing system.

Re-assemble to the same pattern. For information on cable connection

consult the wiring diagram.

Model Fuse Size (AMPS)

All models 5

5.24 Fuses: The following fuse size should be used:

6 COMMISSIONING

6.11 Pre-commissioning checklist:

Before starting the commissioning process the following conditions must be

met. If these conditions are not adhered to, damage to the equipment,

system and property may result.

zEnsure the unit is sited in a frost free area, away from precipitation and

water sprays/jets.

zAll necessary pipe/electrical connections should have been made to a

satisfactory standard by a qualified person.

zThe temperature and pressure at the point of connection are within the

operating limits of the pressurisation unit.

zThe heating/cooling system is fitted with a safety valve and expansion

vessel sized appropriately.

6.12 In order for the pressurisation unit and heating/cooling system to function

correctly the following conditions must be met. If these conditions have not

been met, the commissioning process should not continue.

zEnsure the system connection has been made into the heating/chiller

system return header.

zEnsure Non-return valves, pressure reducing valves or RPZ valves are NOT

installed between the pressurisation unit and the heating/cooling system.

zThe expansion vessel is pre-charged to the correct pressure (equal to

initial system design pressure).

6.13 Prior to commissioning, fill the heating/cooling system via a filling loop. The

APU Mini is NOT designed to fill the system from empty, it is only intended to

top up the system after occasional water leakage.

zEnsure the heating/cooling system is filled and pressurised to the required

cold fill pressure, with the water at approximately ambient temperature.

zEnsure the system is dosed with a suitable corrosion inhibitor. Note the

APU Mini is not designed for dosing chemicals into the system, this must

be done via other means.

6.14 Expansion vessel setting:

zTo set or check the expansion vessel charge pressure the lock-shield

valve between the APU Mini and the vessel must be closed and the

vessel drained using the drain valve.

zA suitable gauge should be used to check the charge pressure.

zIf the charge pressure is too high it can be reduced by releasing air from

the vessel pre-charge valve or by using a pressure gauge with an integral

air release valve.

zIf the charge pressure is too low a small increase can be provided using a

car foot pump otherwise an oil free compressor or nitrogen bottle is

recommended.

zWhen the correct pressure is set the Schrader valve protective cap must

be replaced.

zCheck the integrity of the pipe-work. Ensure the lock-shield valve

between the system and the expansion vessel is open and the drain

valve is closed.

Fig. 17

Retainer

Cable tie

- 18 - - 19 -

6.15 Controller overview

The pressurisation unit controller is designed to be intuitive to use and allows

functions and alarms to be set by the installer/user.

The functions are set using the 3 buttons (A, B, & C) on the front of the

controller and with the help of on screen prompts via the back lit LCD display.

On the front of the APU a green ‘power on’ light will be displayed whilst the

unit is powered. If an alarm or error is raised the red ‘Error’ light will be

displayed.

A number of pressure set points can be set using the menus, these set points are

detailed below, 1 to 4 and in the description of the function.

Button A Enters menus or selects values.

Button B Scrolls down through menus or reduces set values.

Button C Scrolls up through menus or increases set values.

6.16 Function list & explanation

The functions are contained within an initial display and a settings menu.

6.17 Initial display

On start up, and during normal operation, if the APU has had no button inputs

for 1 minute, the system pressure will be displayed (see Section 7.11).

6.18 Setting of APU Mini see Fig. 19

To access the setting of the APU Mini see the following procedure:

1 Press and hold button A for 5 seconds.

2 P1 will be displayed and the red Error light will slowly flash. See Fig. 20.

3 Using buttons B & C select the P function required.

4 Press button A to enter the function.

5 Using buttons B & C increment the value required up and down.

6 Press button A to confirm setting.

7 Press and hold button A until the red Error light stops flashing and the APU

Mini reverts to normal operation. This operation will save the changed

values.

P1 System pressure (2)

see Fig. 18

Sets the required system pressure. Set in 0.1 bar

increments up to the maximum set value for the APU model.

APU 130 & 230, 3.0 bar max.

P2 Differential pressure (3)

see Fig. 18

Sets the pressure the APU will turn on at as the system

pressure falls. Relative to the set system pressure. Set in

0.05 bar increments below the System pressure (2), cannot

be set above 0.1 bar below the System pressure (2).

P3 Hi Alarm (1)

see Fig. 18

Sets high system pressure alarm. Set in 0.05 bar increments

above the System pressure (2). Cannot be set below System

pressure + 0.5 bar. Alarm auto resets when system pressure

is reduced below alarm level.

If no button inputs are received within 1 minute the APU Mini will revert to

normal operation and the red Error light will stop flashing.

Note – Pumps do not operate when in the setting menu.

The following functions can be set and modified:-

TIME

PRESSURE

HIGH ALARM SET VALUE (1)

LOW ALARM SET VALUE (4)

SYSTEM PRESSURE SET VALUE (2)

DIFFERENTIAL SET VALUE (3)

PUMP 'OFF'

PUMP 'ON'

NORMAL OPERATION

SYSTEM

PRESSURE

Fig. 18

Fig. 19

AB C

Fig. 20

AB C

- 20 - - 21 -

6.19 Pre-set values

The APU will be delivered with the following pre-set values:-

P4 Lo Alarm (4)

see Fig. 18

Sets low system pressure alarm. Set in 0.05 bar increments

below the System pressure (2) - Differential pressure

(3) - 0.05 bar. Alarm auto resets when system pressure is

increased above alarm level

P5 Pump number Sets number of pumps fitted to APU. 1 or 2 pumps. Factory

set to suit model.

P6 Pump test

Allows pump 1 or 2 to be forced to run for 15 seconds to

confirm operation.

Using buttons A or B to select pump 1 or 2, then press button

A or B again to run the pump.

P7 Info. Displays software revision. No inputs.

Set Pressure 2 bar

Differential 0.2 bar

Hi Alarm 2.5 bar

Lo Alarm 1.3 bar

6.20 Hydraulic commissioning:

zEnsure both inlet and outlet hydraulic connections are made and

watertight.

zTurn on water supply to APU – Check for leakage and operation of fill

valve.

zAllow the tank to fill and water level to stabilise. Adjust the float of the

fill valve to set the water level if needed.

zClose isolation valve on the outlet of the APU.

zTurn the electrical supply ON to the APU. The system pressure will be

displayed.

zThe APU will run briefly and then turn off after a pre-set run on time.

Due to the small size of the isolated system the APU will signal a Hi

pressure error and the red error light will illuminate on the front of the

APU, this is normal.

zOpen the isolation valve on the outlet of the APU and the APU will

run and start to top the system up.

6.21 For further technical support: Phone the ADEY Customer Service team

on +44 (0) 1242 546717. Our staff are trained to help and advise you over

the phone.

7 OPERATION

7.11 Normal operation:

The ‘Home’ screen will display the status of the system pressure.

A green ‘Power on’ light will be displayed on the front of the APU.

During normal operation the APU will monitor the system pressure and re-

pressurise the system if the system pressure drops below the system pressure

– differential pressure. See Fig. 18.

Example: System pressure 2 bar, differential pressure 0.5 bar, pump will start

to re-pressurise system at 1.5 bar system pressure and stop at a system

pressure of 2 bar.

During the normal operation of a pressurised system, the system pressure

will fluctuate due to temperature changes causing expansion and contraction.

When setting the differential pressure for the Hi \ Lo alarms, please ensure

that the normal system pressure fluctuations are below the Hi pressure alarm

setting and above the differential pressure. If this is not done the APU will try

to compensate for the pressure change causing an over pressure within the

system or alarms being triggered.

7.12 Error and alarm display:

The following errors are shown on the display:

Hi Pressure monitored by the APU Mini is above the Hi alarm set pressure.

Display will flash between Hi and system pressure and red error light

will illuminate. Pumps will not run in this condition.

Lo Pressure monitored by the APU Mini is below the Lo alarm set pressure.

Display will flash between Lo and system pressure and red error light will

illuminate. Pumps will run in this condition.

Er The input signal from the pressure sensor is outside its normal range.

Display will flash Er and red error light will illuminate.

Fig. 21

- 22 - - 23 -

8 MAINTENANCE

8.11 Routine maintenance & service checks:

Every 6 & 12 months (see service log sheets below) the APU should be

inspected for:-

zDamage to the electrical supply cable.

zDamage to the outlet flexible hoses.

zLeakage from the APU or the connecting pipework.

zTest unit operation

zFloat valve check

zWater condition check

zExpansion vessel pre-charge check

8.12 Wiring diagram

There are no user servicable wiring or components inside the controller

assembly. DO NOT remove the retaining screws or the membrane cover over

the display.

8.13 Spares

The APU Mini is designed and built to be a reliable and high quality product, in

the event of spares being required please contact the ADEY Customer Services Team

on +44 (0)1242 546717.

8.14 Long term isolation and restart procedure

If the system is to be shut down for an extended period of time due to

maintainance or system modifications being carried out to the system the

following steps must be taken.

1. Isolate mains inlet water from the APU Mini.

2. Isolate the APU Mini from the system and vent excess pressure to drain.

3. Run the APU to pump excess water from the tank to drain.

4. Isolate the electrical supply from the APU Mini.

5. Ensure the APU cannot freeze. Damage will occur to the pumps if this

is allowed to happen.

6. Cover with plastic sheet or cardboard if work is to be conducted close to

the APU.

8.15 Restart

To ensure the APU Mini is in good working order after a prolonged period of

maintainance the following steps should be taken.

1. Inspect the APU Mini for signs of damage.

2. Check APU Mini tank for debris, remove debris and clean tank if needed.

Debris may cause damage to the pumps if it is allowed to be drawn in.

3. Check pressure vessel pre charge pressures before the system pressure is

increased.

4. Open the mains water isolating valve allowing the APU Mini tank to fill, and

ensure the fill valve is operating correctly and maintaining the correct

water level.

5. Check for signs of leakage.

6. Open the drain valve on the outlet of the APU Mini.

7. Turn on the mains electrical power and ensure both (if fitted) pumps can

run (use test pump option P6 if needed) and are pumping water to drain.

8. Close the drain valve and allow the APU Mini to build pressure; the APU

should turn off as the isolation valve to the system is closed.

9. Open the APU outlet isolation valve and monitor the APU Mini to ensure

there are no leaks as the system pressure increases.

10. Check all the pre set values on the APU, to ensure they are still suitable for

the system (after maintainance/modification)

9 ENVIRONMENT PROTECTION

Your appliance contains valuable materials which can be recovered or recycled.

At the end of the product’s useful life, please leave it at an appropriate local civic waste

collection point.

BLACK

WHITE

RED

230 VAC/1PH/50Hz

SUPPLY

N

E

L

GREEN/YELLOW

BLUE

BROWN

BLUE

BROWN

BLUE

BROWN

PUMP 1

BOILER INTERLOCK N/C

L E N

L E N

2

1

PUMP 2

PRESSURE

TRANSDUCER

0 - 6 bar, 0,5 to 4,4 VDC

VOLT FREE ALARM CONTACTS - 5 AMP MAX.

LEVEL SWITCH

OPEN CIRCUIT AT LOW LEVEL

CLOSED CIRCUIT AT HIGH LEVEL

BLACK

RED

COMMON

SIGNAL

+5 VDC

Fig. 22

- 24 - - 25 -

10 TECHNICAL SPECIFICATION

ADEY reserve the right to amend the specification without notice.

10.11 Noise: The equivalent continuous A-weighted sound pressure level at a

distance of 1 metre from the pump does not exceed 70 dB(A).

11 TROUBLE SHOOTING GUIDE

Symptoms Error Code Probable Cause Recommended Action

Pump(s) not

starting

No power to APU Ensure the green light is on the front of the APU, check fuse.

Low water Low water in tank Depress float valve to varify water is filling tank, check water level and

supply.

System pressure =

set pressure

APU functioning correctly. Check the set system pressure.

Sensor error Pressure sensor fault Remove pressure from the APU outlet and verify the displayed pressure

is 0 bar. Er will be displayed if the sensor signal is outside parameters.

(Replace sensor – call ADEY).

Pump(s) will not

stop

System pressure set

too high

System set pressure is set higher than the pump performance capability,

reduce set pressure. Ensure you have purchased the correct APU for the

system pressure required.

Sensor error Pressure sensor fault Remove pressure from the APU outlet and verify the displayed pressure

is 0 bar. Er will be displayed if the sensor signal is outside parameters.

(Replace sensor – call ADEY).

Low pressure alarm

triggered

Low pressure

Leak in system. Check system for leaks. Check for leaking pressure relief valve.

Low pressure alarm

set too high.

Reduce Low press alarm pressure. Check system pressure range during

normal operation.

Sensor error Pressure sensor fault Remove pressure from the APU outlet and verify the displayed pressure

is 0 bar. Er will be displayed if the sensor signal is outside parameters.

(Replace sensor – call ADEY).

High pressure

alarm triggered

High pressure System pressure

too high

Check system operation. Increase High presure alarm set pressure.

Sensor error Pressure sensor fault Remove pressure from the APU outlet and verify the displayed pressure

is 0 bar. Error will be displayed if the sensor signal is outside parameters.

(Replace sensor – call ADEY).

Sensor failure error Sensor error Pressure sensor

outside specifcation

Remove pressure from the APU outlet and varify the displayed pressure

is 0 bar. Er will be displayed if the sensor signal is outside parameters.

(Replace sensor – call ADEY).

Water overflowing

warning pipe or

weir

Water level too high Check function of the fill valve, replace or adjust if needed.

Manifold NRV leaking Isolate APU from system and mains water and replace non-return valve

and manifold.

Mini 130

CP1-03-04911

Mini 230

CP1-03-04912

General Guarantee 2 year

Approvals CE

Features System capacity Up to 6,000 litres

Mounting Wall mount

Pump control system ✓ ✓

Intelligent control interface ✓ ✓

System fill mode - -

Dry run protection ✓ ✓

Noise 60 dB(A) 60 dB(A)

Materials Break tank Polyethylene

Front cover Acrylic capped ABS

Performance Maximum Fill Pressure 3.0 bar (300 kPa)

Maximum flow 1 l/min

Maximum inlet pressure (tank fill valve) 7 bar (700 kPa)

Maximum working pressure 6 bar

Ambient air temperature Min 4 oC / Max 40 oC

Relative humidity 95 % non-condensing

Min./Max. water temperature Min 4 oC / Max 23 oC

Water tank Usable capacity 2 litres

Inlet valve and fill rate Torbeck (side entry) 12 l/min

Fluid category CAT 5 (type AB air gap with weir)

Connections Cold water inlet (flexible hose) G ½ male

Cold water outlet (flexible hose) 15 mm compression x 600 flexible hose

Overflow (compression fitting) G ¾ (19 - 23 mm diameter pipe)

Pump Number of pumps / pump mode 1 / Duty 2 / Duty-standby

Pump type / motor type Solenoid / piston

Duty rating (unit) Int 30 mins on/30 mins off (S3) Continuous (S1)

Pump head and seal PA66/POM NBR

Electrical Power supply / phase / frequency 230/1/50

Power consumption 100 Watts

Current (full load) 0.5 Amps

Fuse rating 5 Amps

Power cable (pre-wired) 1.5 metres

Alarm output Single

Physical IP rating IPX4

Width 293 mm

Depth 145 mm

Height 403 mm

Weight (including fittings) 3.6 Kg 4.2 Kg

Weight (filled) 6.6 Kg 7.2 Kg

- 26 - - 27 -

12 PRODUCT LOG

12.11 Customer details

Customer/company name

Site address

Date

12.12 Equipment details

System volume m3

Expansion vessel(s) fitted & pre-

charge pressure

Boiler(s) fitted

12.13 Commissioning record

Date commissioned

Company

Engineer

System set pressure

Differential pressure

Hi alarm set pressure

Lo alarm set pressure

12.14 Service Log

Service No. 1

Date

Engineer name

Company name

Tel. No

System pressure bar

Differential pressure bar

Check 6 months 12 months

Condition of wiring ü ü

Condition of hoses ü ü

Evidence of leakage ü ü

Test pump operation ü ü

Float valve operation x ü

Level probe operation x ü

Water condition x ü

Exp. vessel pre-charge x ü

Comments

Service No. 2

Date

Engineer name

Company name

Tel. No

System pressure bar

Differential pressure bar

Check 6 months 12 months

Condition of wiring ü ü

Condition of hoses ü ü

Evidence of leakage ü ü

Test pump operation ü ü

Float valve operation x ü

Level probe operation x ü

Water condition x ü

Exp. vessel pre-charge x ü

Comments

Service No. 3

Date

Engineer name

Company name

Tel. No

System pressure bar

Differential pressure bar

Check 6 months 12 months

Condition of wiring ü ü

Condition of hoses ü ü

Evidence of leakage ü ü

Test pump operation ü ü

Float valve operation x ü

Level probe operation x ü

Water condition x ü

Exp. vessel pre-charge x ü

Comments

- 28 - - 29 -

Service No. 4

Date

Engineer name

Company name

Tel. No

System pressure bar

Differential pressure bar

Check 6 months 12 months

Condition of wiring ü ü

Condition of hoses ü ü

Evidence of leakage ü ü

Test pump operation ü ü

Float valve operation x ü

Level probe operation x ü

Water condition x ü

Exp. vessel pre-charge x ü

Comments

Service No. 5

Date

Engineer name

Company name

Tel. No

System pressure bar

Differential pressure bar

Check 6 months 12 months

Condition of wiring ü ü

Condition of hoses ü ü

Evidence of leakage ü ü

Test pump operation ü ü

Float valve operation x ü

Level probe operation x ü

Water condition x ü

Exp. vessel pre-charge x ü

Comments

EC DECLARATION OF CONFORMITY

Product:

Name: ADEY Digital Pressurisation Unit – Mini

Model: Mini 130 - CP1-03-04911, Mini 230 - CP1-03-04912

Manufacturer:

Name: ADEY Commercial Limited

Address: UK Head Office, Gloucester Road, Cheltenham, GL51 8NR, United Kingdom

Object of the declaration:

Pressurisation Unit

The object of the declaration described above is in conformity

with the relevant Union harmonisation legislation:

Machinery Directive 2006/42/EU

Electromagnetic Compatibility Directive 2014/30/EU (EMC)

Low Voltage Directive 2014/35/EU (LVD)

REACH 1907/2006

ROHS 2011/65/EU

and carries the CE mark accordingly.

The product also complies with the requirements of the WEEE Directive

2012/19/EU and carries the WEEE symbol accordingly.

Conformity to the essential requirements of the legislation(s)

have been demonstrated by using the following standards:

EMC:

EN 61000-6-1

EN 61000-6-3

EN 61000-3-2

EN 61000-3-2

Safety:

EN ISO 12100

EN 809

EN 60335-1

EN 60335-2-41

EN 62233

Technical documentation is kept at the following address: ADEY Commercial Limited,

UK Head Office, Gloucester Road, Cheltenham, GL51 8NR, United Kingdom.

This declaration of conformity is issued under the sole responsibility of the manufacturer.

SIGNED FOR AND ON BEHALF OF ADEY Commercial Limited.

Signature:

Neil Watson

Date: 21/10/2019

- 30 - - 31 -

M0995 LF2-01-05000 V1

20939 V1

Telephone: +44 1242 546717 Email: info@adey.com

www.adey.com

Produced from recycled material

A carbon neutral company

All ADEY marks are trademarks of Adey Holdings (2008) Limited. Please visit adey.com/trademarks for a list of ADEY marks

Copyright Adey Holdings (2008) Limited © 2019. All rights reserved.

This manual suits for next models

1

Table of contents

Other Adey Water Pump manuals

Popular Water Pump manuals by other brands

Ribimex

Ribimex Ribiland 100QJD210-0.75 User and maintenance manual

LINC milton roy

LINC milton roy 84T-10 Series instruction manual

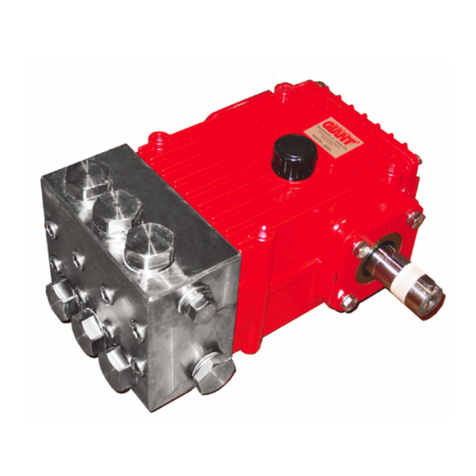

Giant

Giant P450-5100 Operating instructions/ repair and service manual

AquaMark

AquaMark AM-15V Installation, operation & maintenance manual

Grundfos

Grundfos ALPHA Pro Installation and operating instructions

Beckett

Beckett BK17 quick start guide