Table of Contents

Table of Contents........................................................................................................................2

Important Safety Instructions.....................................................................................................3

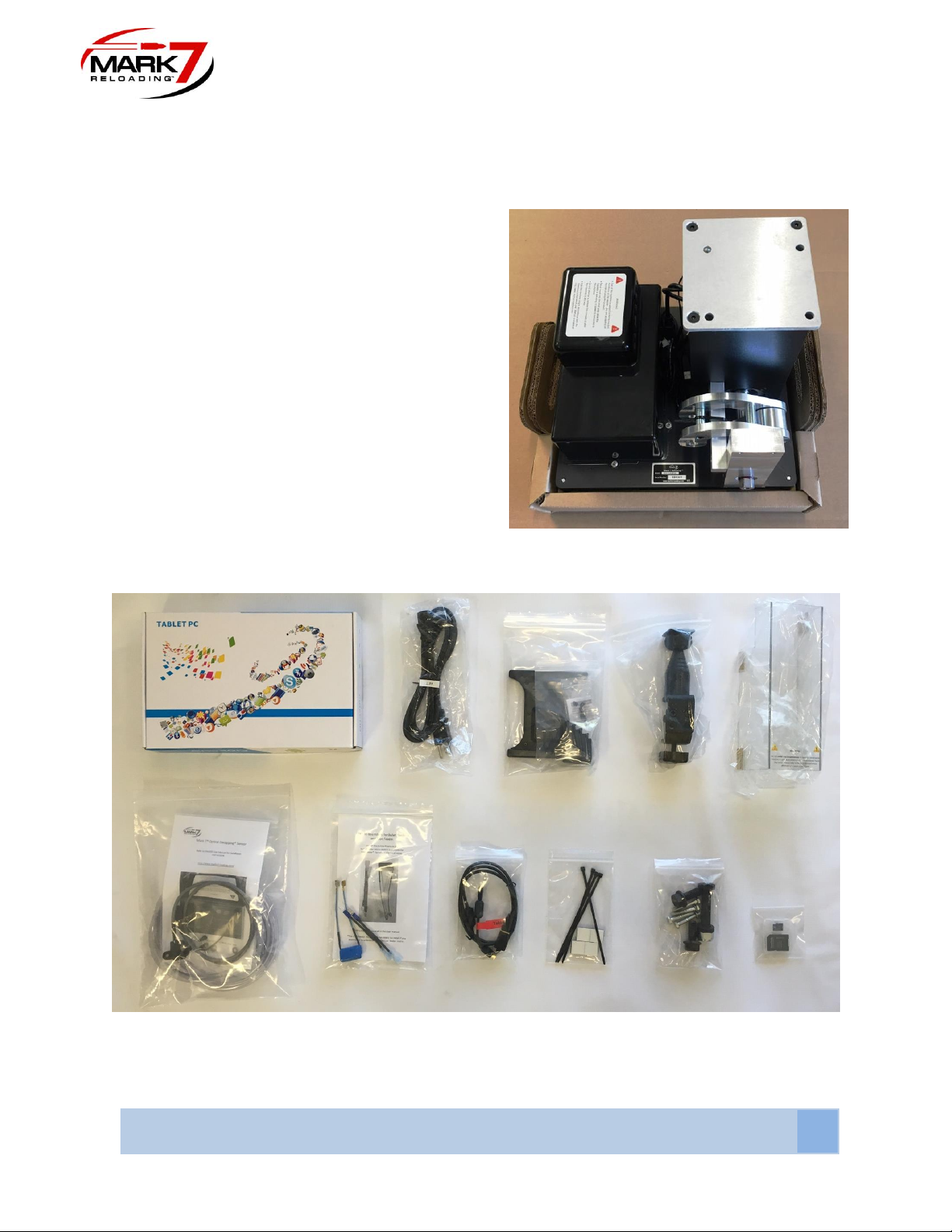

Box Contents...............................................................................................................................6

Set-Up Procedures......................................................................................................................7

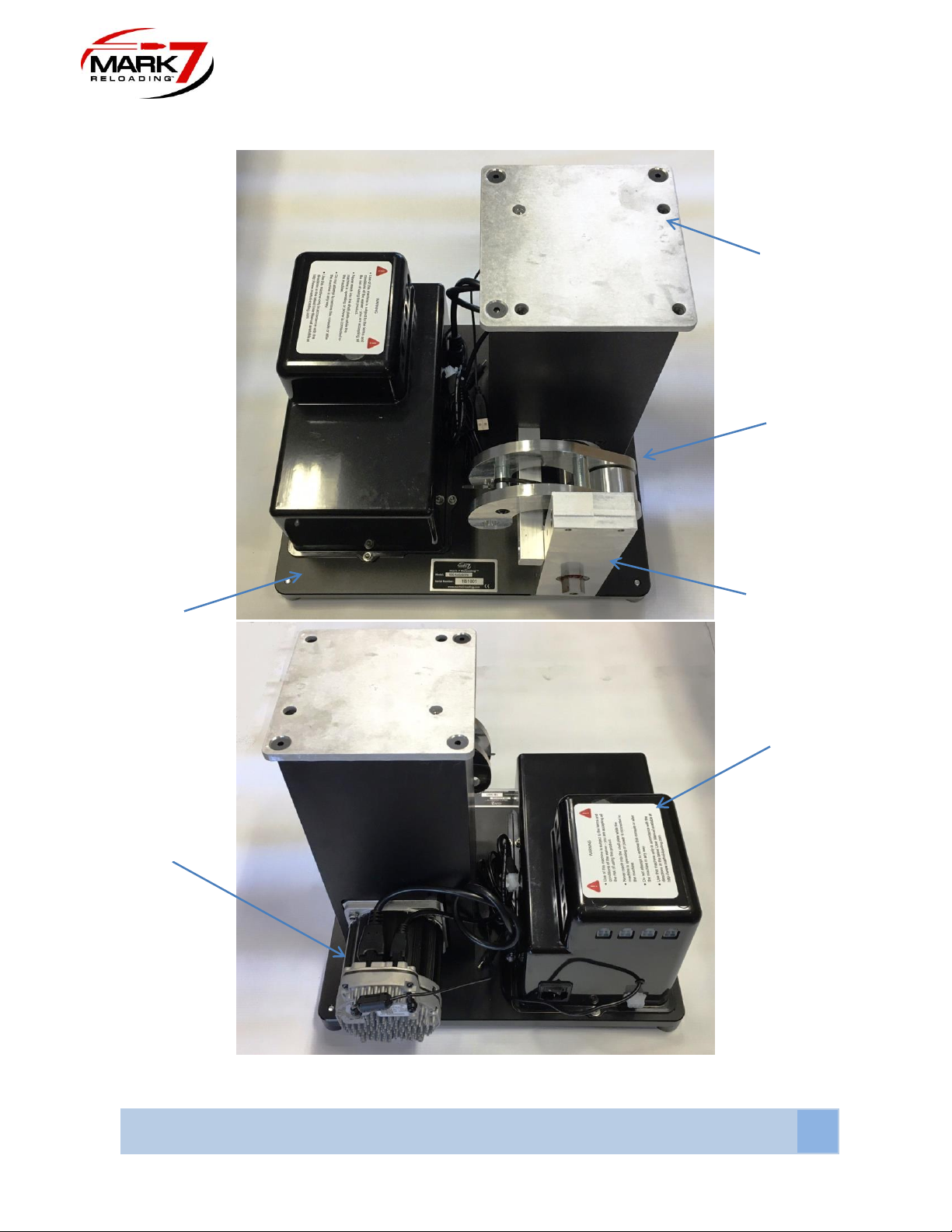

1. Removal Of Equipment From The Packing Carton...............................................................8

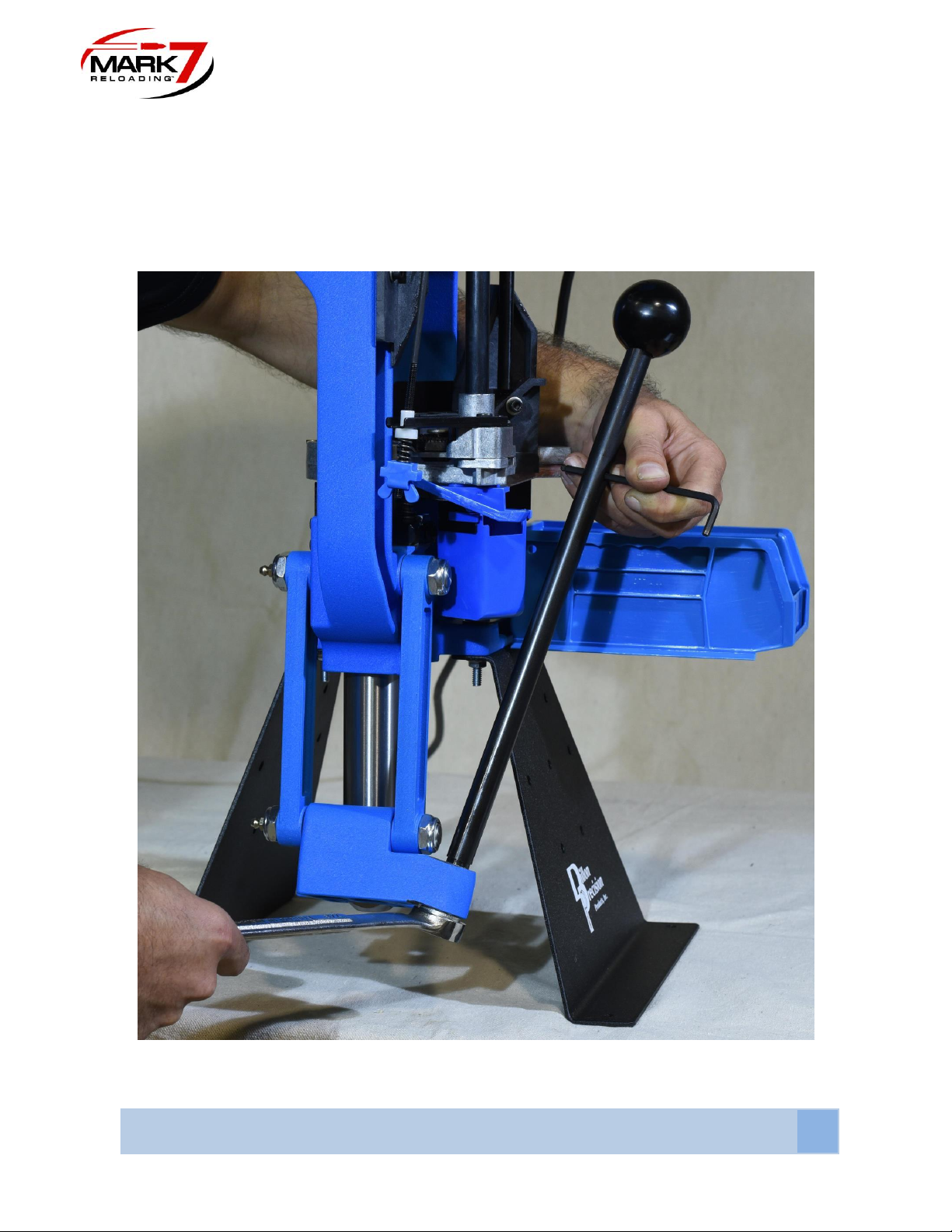

2. Removing 650 Handle...........................................................................................................9

3. Removing 650 Knuckle and Pin ..........................................................................................10

4. Removing 650 Link Arms ....................................................................................................11

5. Removing Link Arm Bottom Pin ..........................................................................................12

6. Reinstalling the 650 Link Arms............................................................................................13

7. Connecting the Mark 7Crank To The 650 Ram...............................................................14

8. Mounting 650.......................................................................................................................15

9. Installing Crank Shield.........................................................................................................18

10. Tablet and Holder Installation............................................................................................19

11. Console Cable Locations and Setup.................................................................................22

12. Manually Driving Press .....................................................................................................25

13. EMI Filter For BulletFeeders .............................................................................................26

14. EMI Filter for Case Feeder ...............................................................................................27

Sensors

Optical Decapping Sensor™ ...................................................................................................29

(Optional)..........................................................................................32

(Optional) ………………..………………………....…………...…….…33

Operating Instructions .............................................................................................................44

Main Screen............................................................................................................................44

Waiver Screen & Software/Firmware version ........................................................................45

Before each session of use of the machine ............................................................................45

Control Screen ........................................................................................................................46

Monitors Screen......................................................................................................................47

Sensors Screen……………………………………………………………………………………….48

Setup Screen...........................................................................................................................49

Software and Firmware Update ..............................................................................................51

General Maintenance and Storage..........................................................................................54