ADMET Gauge Buster 2 User manual

-2-

Gauge Buster 2 Operations Manual ADMET, Inc.

Table of Contents

FOREWARD ....................................................................................................3

1.0 INTRODUCTION........................................................................................4

1.1 Gauge Buster 2 Features ............................................................................................................................4

1.2 Gauge Buster 2 Options..............................................................................................................................5

1.3 Gauge Buster 2 Reporting Capabilities .......................................................................................................5

1.3.1 GageSafeTM Data Exchange Program....................................................................................................5

1.3.2 USB Flash (Thumb) Drive ........................................................................................................................5

1.3.3 HP compatible USB Printer ......................................................................................................................5

2.0 THE KEYS .................................................................................................6

2.1 The <ZERO/0> Key.....................................................................................................................................6

2.2 The <STORE> Key .....................................................................................................................................6

2.3 The <ENTER> Key......................................................................................................................................6

2.4 The <ESC> Key ..........................................................................................................................................6

2.5 The <UP & DOWN ARROW> Keys.............................................................................................................6

2.6 The <NUMBER> Keys ................................................................................................................................6

3.0 THE MENUS and KEYS ............................................................................8

3.0.1 Test Method Specific Menu Selections .....................................................................................................8

3.0.2 Global Menu Selections ...........................................................................................................................9

3.1 The Setup Menu........................................................................................................................................10

3.2 The Report Opt Menu................................................................................................................................10

3.3 The Utils Menu .......................................................................................................................................... 11

3.5 The Print Menu.......................................................................................................................................... 11

3.4 The ID# Menu............................................................................................................................................ 11

3.6 The Disk (-) Menu......................................................................................................................................12

4.0 OPERATION ............................................................................................13

4.1 How to Setup a Test ..................................................................................................................................13

4.2 How to Perform a Test and Save Results..................................................................................................14

4.2.1 Indicator Live Screen During Test ..........................................................................................................14

4.2.2 Indicator Live Screen End of Test/Ready Mode .....................................................................................15

4.3 Printing Test Reports to a HP compatible USB Printer ..............................................................................15

4.4 Download Test Results to a Remote PC ...................................................................................................15

4.5 Download Test Results to a USB Flash (Thumb) Drive .............................................................................15

5.0 CALIBRATION.........................................................................................16

5.1 How to Calibrate Analog Transducers .......................................................................................................16

5.2 What Occurs During Calibration................................................................................................................17

5.3 Saving Calibration Data.............................................................................................................................17

........................................................................................................................................................................17

6.0 TROUBLESHOOTING.............................................................................18

7.0 ELECTRICAL/MECHANICAL DATA .......................................................20

7.1 User Connections......................................................................................................................................20

7.2 USB Port ..................................................................................................................................................21

7.3 Power (AC) Input.......................................................................................................................................21

7.4 Dimensions ...............................................................................................................................................21

7.5 Password ..................................................................................................................................................22

Index..............................................................................................................23

-3-

Gauge Buster 2 Operations Manual ADMET, Inc.

Gauge Buster 2 has been designed and constructed with great care in every phase of assembly. In order to

insure reliability, both the mechanical and electrical components have been built with the best available

materials. Nevertheless, it has been proven that a thorough understanding of the machine, together with

proper attention, will pay big dividends. The sections of this manual provide description and instruction on the

operation and maintenance of the mechanical, electrical and software components.

You as a customer are our most valued asset. We take pride in our systems and are proud that you have

become an owner. We welcome your comments about our products and wish that you express them. It is

the only way that we can continue to build the best available test systems to satisfy your needs. Thank-you

for your support.

HOW TO USE THIS MANUAL

This manual is intended to educate the customer on the capabilities, operation and maintenance of the

Gauge Buster 2. In addition, it is to be used as a supplement for any information supplied by the load frame

manufacturer. Maintenance procedures specified by the load frame manufacturer should be followed unless

specifically noted herein. Read this manual and become familiar with the operation of your test machine prior

to operating the Gauge Buster 2.

TECHNICAL SUPPORT

If a problem should occur with your testing machine:

1 Consult troubleshooting section on-line and in this manual

2 Check that all external inputs are properly connected.

3 Call the supplier/manufacturer of your test machine.

4 Call ADMET's technical support at (781) 769-0850 (9AM to 5PM EST).

FOREWARD

-4-

Gauge Buster 2 Operations Manual ADMET, Inc.

Gauge Buster 2 is a low cost versatile indicator designed for a variety of materials, product, remote on-site

and force calibration testing applications. Features include anAuto-Test-Reset mode for hands free operation,

bar graph load rate display, permanent storage of test data and easy transfer of results into data base pro-

grams. It's accuracy, which exceeds ASTM E4, ease-of-use and ruggedness results in a system of unrivaled

price/performance.

Gauge Buster 2 is ideal for:

• Tension/Compression Testing

• Beam Testing

• Concrete Cylinder Testing

• Cement Cube Testing

• Force Calibration

• Remote On-Site Testing

• Quality Control

• Product Evaluation

• Proof Testing

• Pre-Stressing Jacks

1.0 INTRODUCTION

Display Live Load, Maximum Load, Live Stress and Maximum Stress numerically.

Indicate Load/Stress Rate numerically or with a bar graph. The bar graph rate pointer moves between limits.

Decreasing the rate moves the pointer left. Increasing the rate moves the pointer right. Adjust the upper and

lower rate limits depending on the testing requirements. Ex: ASTM C39 28-42 psi/sec.

Activate average load rate analysis to calculate and report actual test speeds.

Select between force units of Lb, N, KN, Kg and stress units of psi, MPa, KPa, ksc.

Define specimen geometries as cylinder, cube, beam center point loading, beam-3rd point loading, round and

general area.

Activate/De-Activate Cylinder ASTM C39 correction factor.

Define cylinder break type according to ASTM C39.

Perform beam tests according to ASTM C78 and C293.

Store up to 2,000 test results to permanent memory. Results include Date, Time, Specimen ID#, Maximum

Load, Maximum Stress, Average Load Rate plus a statistical summary of each.

Store up to 6 test methods to permanent memory. Test methods enable the user to define and store cylinder,

beam and cube test procedures to memory. With the press of a key they can be quickly recalled for fast efficient

testing.

Activate Auto-Store to automatically store the results of each test.

Auto-Test-Reset is standard and automatically enables the indicator for the start of the next test without requir-

ing operator interaction.

Define and detect the end of test with the Sample Break Detector.

Digital output activates at sample break or machine overload.

Transmit via the USB communications port results, XY data, test methods and calibration data to a remote

computer running ADMET's GageSafeTM Data Exchange Program. See reverse side for more details.

Store up to 6 load cell calibrations for multiple load cell systems. The load calibration algorithm allows up to 10

calibration points per cell with piecewise linear fit between points. Accuracy exceeds ASTM E4 Standards and

in general is better than 0.5% from 1% of full scale to full scale.

Gauge Buster 2 comes standard with one analog input for measuring force and stress. Optional digital encoder

and analog inputs can be installed to measure displacement or strain. Ideal for measuring modulus or poisson's

ratio according to ASTM C469.

With the servo control option Gauge Buster 2 can be used with ADMET's MegaForce Automatic Loading Sys-

tem to ensure that all tests are performed according toASTM standards. The user specifies the loading rates to

achieve precise closed loop control.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1.1 Gauge Buster 2 Features

-5-

Gauge Buster 2 Operations Manual ADMET, Inc.

•

•

•

•

•

•

•

•

•

•

1.2 Gauge Buster 2 Options

GageSafeTM Data Exchange Software

Connection for USB Flash Drive

Connection HP Compatible USB printer

Bar Code Reader input to scan specimen number into the Gauge Buster.

Concrete Traker Database Program.

Battery Pack for portable applications.

Digital position or analog strain inputs

Servo control output for MegaForce

Shunt Calibration.

Pressure Transducers: 1,000; 2,500; 5,000; 10,000 psi

•

•

•

There are three options for exchanging data with the Gauge Buster 2:

1.3 Gauge Buster 2 Reporting Capabilities

GageSafeTM Data Exchange Software

USB Flash (Thumb) Drive

HP Compatible USB printer

Note that each of these is an option purchased separately from the Gauge Buster 2 digital indicator.

GageSafe is a PC-based program for exchanging data with the Gauge Buster 2. It is a Windows XP/Vista/7

compatible program that is capable of viewing, printing and storing test results uploaded via the USB communi-

cations port or read from a USB flash drive. The Gauge Buster 2 can also upload via the USB communications

port or write to a USB flash drive Test Methods and Calibration Data. GageSafe can read, create, edit and store

Test Methods and Calibration Data. The Test Methods and Calibration Data can then be uploaded back into the

Gauge Buster 2 via the USB Communications Port or USB flash drive. Gauge Buster 2 has six Test Methods

permanently stored in memory. The user can use the six Test Methods to define procedures for testing cylin-

ders, cubes and beams. With the press of a single key, they can quickly switch between methods for fast

efficient testing. GageSafe is sold separately.

1.3.1 GageSafeTM Data Exchange Program

1.3.2 USB Flash (Thumb) Drive

Connect a USB flash (thumb) drive to the Gauge Buster 2 and write Test Results, XY Data, Test Methods and

Calibration Data to its memory. Connect the USB flash drive to the computer running GageSafe and view/ print/

edit the stored data. Plug the USB flash drive back into the Gauge Buster 2 and load the data stored on the flash

drive back into the Gauge Buster 2 (USB flash drive sold separately).

1.3.3 HP compatible USB Printer

Connect an HP compatible USB printer to the Gauge Buster 2 and print a Single Test Report which includes an

XY curve, Test Reports that include tabulated results from multiple tests, test methods and calibration data

(printer sold separately).

-6-

Gauge Buster 2 Operations Manual ADMET, Inc.

2.0 THE KEYS

2.1 The <ZERO/0> Key

The ZERO key performs the following functions.

• Defines a new zero load.

• Places the Indicator Test Status in Ready Mode.

• Clears out the previous test results from the test buffer and initializes the indicator for the

next test. Make sure the previous test was stored prior to pressing ZERO or it will be lost.

• Enters the number zero.

2.2 The <STORE> Key

The STORE key writes the current test result which consists of peak load, date, time and specimen ID# to

permanent memory then increments the specimen ID#. All results stored to memory can be printed or

download to a remote computer.

2.3 The <ENTER> Key

The ENTER key performs the following functions.

• Accepts/assigns the value in a data entry field to that field.

• Turns ON/OFF a menu option.

2.4 The <ESC> Key

The ESC key performs the following functions.

• Returns to the Live Indicating Screen from any menu.

• Clears a data entry mistake by restoring the original number in a data entry field.

2.5 The <UP & DOWN ARROW> Keys

The ARROW keys allow the operator to scroll through menu items.

2.6 The <NUMBER> Keys

The NUMBER keys are used to select a menu option from within a menu or input a numerical value in a data

entry field.

-7-

Gauge Buster 2 Operations Manual ADMET, Inc.

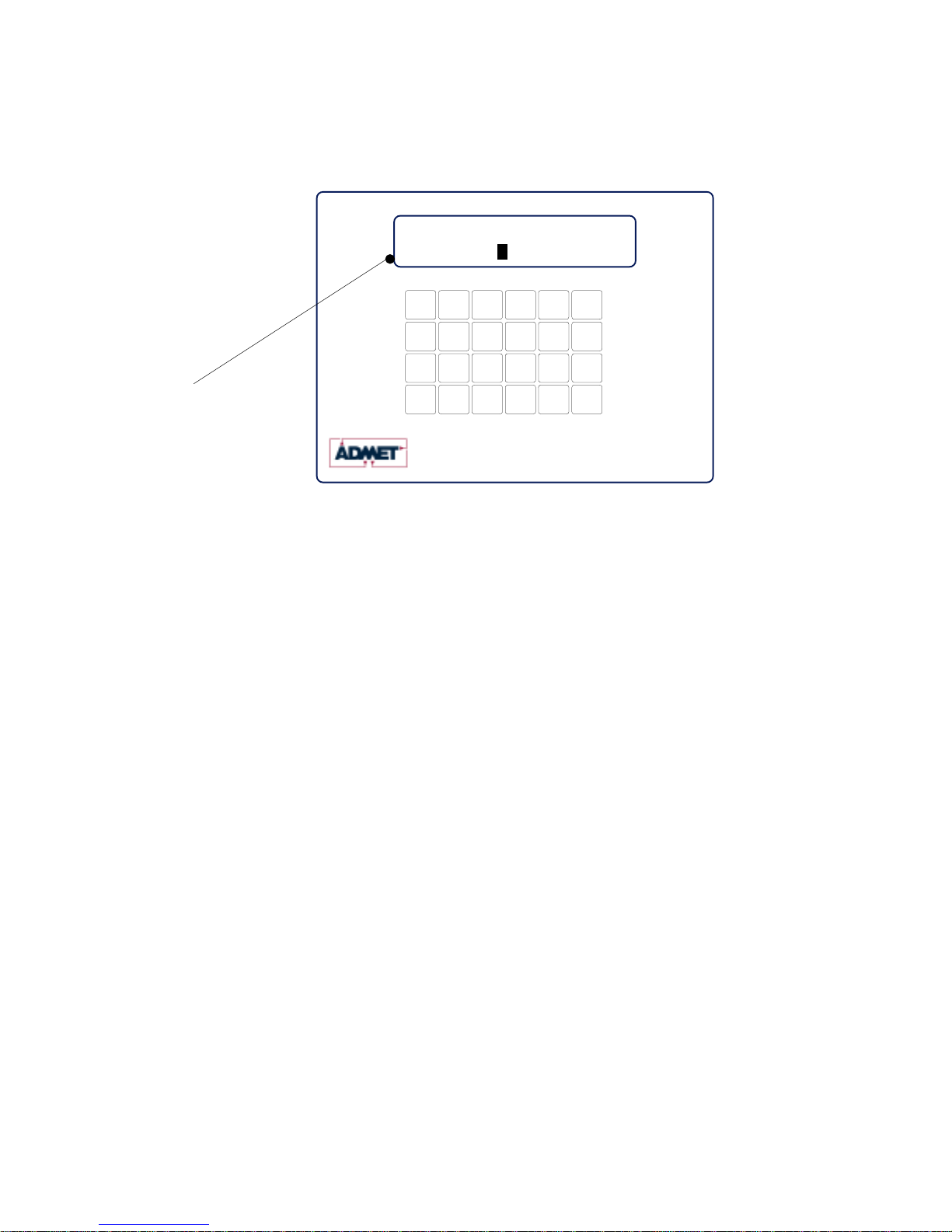

Figure 2.1 - Gauge Buster 2 Keypad and Screen Display.

Control Print 0

Zero (.)

Freeze

1

4

Store

Utils

23

56

ENT

Start

È

Jog Dn

Ç

Jog Up

Method

Test 7

ID# 89

ESC

Stop

Report

Options

Setup

(-)

Disk

Test Rate

136745 LB

M3

Gauge Buster 2 781-769-0850

www.ADMET.com

24 key tactile keypad

Active Test

Method L- - - - - - - - - -- - - - - - -H

2 line x 16 character LCD with 3/8" H characters

Live Load

Display while specimen

under test: Live Load and

Load Rate Pointer shown

between High and Low

Rate Limits.

-8-

Gauge Buster 2 Operations Manual ADMET, Inc.

3.0 THE MENUS and KEYS

3.0.1 Test Method Specific Menu Selections

The Gauge Buster 2 can store up to 6 test methods.

These menu items apply to the current selected test method and need to be set for each test method being

used.

Use the <Setup> key to access the Setup Menu. Use

number keys and Up/Down keys to navigate the menu.

1) Specimen Type - Available Geometries: Cylinder,

Round, Flat, Cube, Beam Ctr, Beam 3rd, X-Area

2) Log Threshold - Start logging data threshold

3) Sample Break

a) Percentage of Peak

b) Arm Sample Break Threshold

4) Engineering Units

1) Force - Lbf, N, kN, kg

2) Stress- psi, kPa, MPa, ksc

3) Length- in, mm, cm

4)Age- Hours, Days

5) Rate Display -Available: Pointer, Force/sec, Force/min,

Stress/sec, Stress/min, Extn/min, Extn/sec, Extn.

6) Auto Store - Results, XY Data, Both

7) Load Cell - Select one of up to 6 calibrated cells.

8) Extn (option)

9) AuxCh (option)

Test Method

Select Test Method (1-6)

Setup Menu

Use the <Report Opt> key to access the Report

Options Menu. Use number keys and Up/Down keys

to navigate the menu. Available test report options

are:

Operator ID

Cylinder Cap Type

Specimen Age

Specimen Weight

Cylinder Break Type

Cylinder Correction Factor

Average Rate

Yield by Halt of the Pointer

ASTM C469 Modulus (option)

ASTM C469 Poisson's (option)

Report Options Menu

NOTE: This menu is only active in units enabled for

operating the MegaForce Automatic Pumping System.

Use the <Control> key to access the Control Menu.

Use number keys and Up/Down keys to navigate the

menu.

1) Test Rate

2) Preload

3) Preload Rate

4) Start Control

a) Start Control Load

b) Start Control Speed

5) Hold Load

6) Control Gains (password protected)

a) Proportional Gain

b) Integral Gain

c) Derivative Gain

d) Gain Shift

e) Shift1 (% FS)

f) Shift2 (% FS)

Control Menu (Option)

Use the <ID#> key to access the ID number Menu.

Follow the prompts to input the following information.

Specimen ID

Specimen Dimensions

Operator ID (if active)

Cylinder Cap Type (if active)

Specimen Age (if active)

Specimen Weight (if active)

ID# Menu

-9-

Gauge Buster 2 Operations Manual ADMET, Inc.

3.0.2 Global Menu Selections

These menu items are not test method specific.

UTILS Menu

Use number keys and Up/Down keys to navigate

the menu.

1) Clear Results

2) Set Date/Time

3) Ck Trans & IO

4) Install Def

5) Supervisor (On/Off)

6) Calibrate

-11-

Print Menu

Use number keys and Up/Down keys to navigate

the menu.

USB Print (option to local USB Printer)

1) Current Test

2) Stored Tests

3) Individual Test

4) Print XY Plot

5) Test Method

6) Calibration

Disk Menu (Option)

Host PC

Use number keys and Up/Down keys to navigate

the menu.

1) XY Data -> Host

2) Results -> Host

3) Test Method -> Host

4) Calibration -> Host

5) Thumb Drive -> Test Method (Loads Test Method

from Thumb Drive)

6) Thumb Drive -> Calibration (Loads Calibration from

Thumb Drive)

Disk Menu (Option)

Flash (Thumb) Drive

Use number keys and Up/Down keys to navigate

the menu.

1) XY Data -> Disk

2) Results -> Disk

3) Test Method -> Disk

4) Calibration -> Disk

5) Disk -> Method (Loads Test Method from Thumb

Drive)

6) Disk -> Cal (Loads Calibration from Thumb

Drive)

-10-

Gauge Buster 2 Operations Manual ADMET, Inc.

Press the <Report Opt> key from the Indicating Screen to enter the Report Options/Analysis Menu. Use the

<ARROW> keys to scroll through the menu. Press the <NUMBER> keys to select the menu item. The

following items are found in the Report Opt Menu.

1.)Report Options. Choose which analyses to activate. Use <Arrow> keys to scroll through items and toggle

the 1) key to activate option. Available options include:

Oper ID: Operator ID.

CylCapType: Cylinder Cap Type

SpecAge: Specimen Age

Spec Wt: Specimen Weight

CylBrkType: Cylinder Break Type

CylCorFact: Cylinder Correction Factor

Statistics: Statistics

Avge Rate: Average Rate Calculation

Yld Halt: Yield by Halt of Force

Avge Rate: Average Rate Calculation

C469 Mod: C469 Modulus of Elasticity

C469 Pois: C469 Poisson's Ratio

2.)ReCalc Results. Recalculates all analyses.

3.2 The Report Opt Menu

Press the <Setup> key from the Indicating Screen to enter the Setup Menu. Use the <ARROW> keys to

scroll through the menu items. Use the <NUMBER> keys to select the menu item. The following functions

are provided in the Setup Menu.

1) Specimen Type. Select the specimen type for the sample to be tested. After selecting the type of

specimen, the appropriate dimensions are requested.

2) Data Logging. Specify the Logging Threshold (Log Thresh) and the Data Logging Rate (Log Rate).

Log Threshold is the force value at which data logging begins.

3) Sample Brk. Select the threshold for arming sample break (Brk Thresh) and sample break percent

age (Sample Break (%)). Sample Break is defined as a percentage of peak load and is used to define

the end of a test. If Break Threshold is 1000lb, Sample Break (%) = 10 percent and Maximum Load

seen during test is 100,000 Lb, then the Gauge Buster 2 will be armed for sample break when load

increases over 1000lbs and test will end (data logging stops, Max Load/Max Stress displayed) when

load drops below 10,000 lbs, which is 10% of the maximum of 100,000lbs.

4) Engineering Units. Used to select between load units of Lb, N, KN, and Kg, Stress units of PSI, Mpa,

Kpa and ksc and rate units on a per second or per minute basis. Length units of in, mm and cm and

Age units of days and hours.

5) Rate Display. a.)Choose type of load rate display with Rate- selection : Select between Load/min,

Load/sec, Stress/min, Stress/sec OR Pointer. Pointer displays the load rate relative to defined lower

and upper limits. The lower limit is marked as an "L" on the rate display line and the upper limit is

marked as an "H" on the rate display line during a test.

b.)Also choose average time period for load rate calculation with AvgTm.

6) Auto Store. If Store is set toAUTO, the results are automatically written to the results buffer and the

specimen ID# is incremented when sample break is detected. If Store is set to MAN, it is necessary to

press the <STORE> at the end of test to save the test results to memory and increment the specimen

ID#.

7) Load Cell-. Use to select load cell. You can select between valid load cell calibrations set up in

the calibration menu.

3.1 The Setup Menu

-11-

Gauge Buster 2 Operations Manual ADMET, Inc.

3.3 The Utils Menu

1)

2)

3)

4)

5)

6)

7)

Press the <Utils> key from the Indicating Screen to enter the Utils Menu. Use the <ARROW> keys to scroll

through the menu. Press the <NUMBER> keys to select the menu item. The following items are found in the

Utils Menu.

Clear Results. Erase all test results stored in the results buffer. Make sure you have printed the data before

erasing memory.

Set Date and Time.

Ck Trans-DOUT and I/0. This function displays Input/Output status as well as the transducer readings in A/D

counts. PossibleA/D values are between -2,200,000,000 and +2,200,000,000.

Install Defaults. Used to put all setup parameters in a known default state. Installing defaults DOES NOT

effect any of the calibration information.

Supervisor. Select Supervisor ON or OFF. This is a password protected field. With Supervisor set to ON,

the user has full access to all menus. With Supervisor set to OFF, the user has access to the ID# field

only.

Stream. Toggle to ON to stream XY data to GageSafe Data Exchange program.

Calibrate. Calibrate a load cell according to ASTM E4 standards. See Section 5.0 for calibration proce-

dures.

Edit Calibration Points. This function allows the calibrator to modify the load value for a given calibration

point.

NOTE: The calibrator can also editA/D counts in the calibration. Select Install Def from the Utility menu. The

screen will read 1)Install; ESC)Exit. Press the "9" key to get into the edit A/D count screens.

Press the <ID#> key from the Indicating Screen to input the Specimen ID number. The Specimen ID number

can be 8 digits long. Input the Specimen ID number and press <ENTER> to accept . Note: The Specimen

ID number will be automatically incremented after the current test result has been printed or stored. You will

then be prompted to enter dimensional information for your selected specimen. Prompts for any items en-

abled in the Report Options menu will follow the specimen dimensions prompt.

3.4 The ID# Menu

3.5 The Print Menu

NOTE: This menu is used to print hard copy printouts to an HP compatible USB printer.

This feature is not included with the standard Gauge Buster 2. The USB printer option and the printer are

purchased separately.

Press the <Print> key from the Indicating Screen to enter the Print Menu. Use the <ARROW> keys to

scroll through the menu. Press the <NUMBER> keys to select the menu item. The following items are

found in the Print Menu:

1) Current Test. Transmits the current test result to the printer.

2) Stored Tests. Transmits stored test results to the printer.

3) Select Test. Transmits one specified test result to the printer.

4) Prn XY Plot. Transmits XY plot to the printer.

5) Test Method. Transmits the current test method to the printer.

6) Calibration. Transmits calibrations to the printer.

-12-

Gauge Buster 2 Operations Manual ADMET, Inc.

3.6 The Disk (-) Menu

The Disk (-) Menu has two sub-menus:

1) Host PC

2.) Thumb Drive

Host PC

The Host PC menu contains options for transmitting data to the GageSafe Data Exchange Program, which is

not included with the Gauge Buster 2 and must be purchased separately.

NOTE: You can upload test methods and calibrations from GageSafe as well. These actions are initiated from

within the GageSafe program and described in the GageSafe manual.

The following items are found in the Host PC menu:

1) XY Data -> Host. Transmit XY data from the current test to GageSafe.

2) Results -> Host. Transmit stored test results to GageSafe.

3) Method -> Host. Transmit Test Methods to GageSafe.

4) Cal -> Host. Transmit calibration to GageSafe.

Thumb Drive

The Thumb Drive menu contains options for exchanging data with a USB Flash (Thumb) Drive.

NOTE: This feature is only enabled if you have the Flash (Thumb) Drive option. It is not included with stan-

dard Gauge Buster 2. The USB flash drive option and the flash drive are purchased separately.

The following items are found in the Thumb Drive menu:

1) XY Data -> Disk. Transmit XY data from the current test to Thumb Drive.

2) Results -> Disk. Transmit stored test results to Thumb Drive.

3) Method -> Disk. Transmit Test Methods to Thumb Drive.

4) Cal -> Disk. Transmit calibration to Thumb Drive.

5) Disk -> Method. Upload test methods from Thumb Drive to Gauge Buster 2.

6) Disk -> Cal. Upload calibrations from Thumb Drive to Gauge Buster 2.

-13-

Gauge Buster 2 Operations Manual ADMET, Inc.

4.0 OPERATION

4.1 How to Setup a Test

You can store up to 6 test methods in the Gauge Buster 2. Test methods can be transferred to and from the

GageSafe Data Exchange software or a USB Flash (Thumb) drive in units that are equipped with these

options.

Section 4.1 describes how to setup for a test. Section 4.2 describes how to perform a test and store the

results to memory. Section 4.3 describes how to generate test reports. Section 4.4 describes how to down-

load the stored test results to a remote PC.

Step 1: Press <SETUP> from the Indicating Screen. From the SETUP Menu select the following and enter

values for each.

Specimen Type. Specimen type to be tested, Cylinder, Cube, Beam Ctr, Beam 3rd, Round or Area.

Data Logging. Set Logging Threshold. When the logging threshold load value is exceeded, data logging

begins and the test starts.

Set the Data Logging rate appropriate to your test.As data logging rate increases, total test

time buffer decreases. The total test time for each data logging rate is displayed in menu i

tem.

Sample Break. Set the Break Threshold to a load value where you want the Gauge Buster 2 to be armed

for sample break .This value needs to be greater than the data logging threshold.

Set Sample Break % to value to where you want to define the end of test.

For example, ff Break Threshold is 1000lb, Sample Break (%) = 10 percent and Maximum

Load seen during test is 100,000 Lb, then the Gauge Buster 2 will be armed for sample

break when load increases over 1000lbs and test will end (data logging stops, Max Load/

Max Stress displayed) when load drops below 10,000 lbs, which is 10% of the maximum of

100,000lbs.

Rate Display Set Rate Display to force/sec; force/min; stress/sec; stress/min or Pointer.

If pointer then set the low rate and the high rate:

Rate-Lo.Enter the lower rate limit, marked as "L" in the rate display.

Rate-Hi. Enter the upper rate limit, marked as "H" in the rate display.

NOTE: If Specimen Type set to Cylinder, then lo and hi rate values automatically set to appropriate value as

specified by ASTM C39.

Engineering Units. Set load units to Lb, N, KN or Kg. Set stress units to psi, kPa, MPa, or ksc. Set length

units to in, mm or cm, Set Age units to Days or Hours

Auto Store Select if you want to automatically store every test result.

Load Cell. Select the load cell number if necessary.

See Section 3.1 for more information.

Step 2: Press <UTILS> from the Indicating Screen. Clear results from memory. Note: If the stored results

are important, print before clearing. See Section 3.3 for more information.

Step 3: Press the <ID#> from the Indicating Screen. Input the specimen ID#. The specimen ID# will auto-

matically increment after the current test is stored. If any Report Options have been turned ON, additional

prompts will follow.

-14-

Gauge Buster 2 Operations Manual ADMET, Inc.

Control Print 0

Zero (.)

Freeze

1

4

Store

Utils

23

56

ENT

Start

È

Jog Dn

Ç

Jog Up

Method

Test 7

ID# 89

ESC

Stop

Report

Options

Setup

(-)

Disk

4.2 How to Perform a Test and Save Results

If the steps in Section 4.1 were followed, you are now ready to perform a test. The current test settings are

saved in permanent memory and will not change unless they are modified by the operator.

Step 1: Insert the specimen in the machine and move the crosshead to the desired starting position. If using

a hydraulic machine, float the piston by moving off it's stop.

Step 2: Press the <ZERO> key to tare any residual load from the readout.

Step 3: Begin loading the specimen. Once the load exceeds the start test threshold value, the lower display

line will change to the specified rate display (load/stress rate or pointer). Once the load exceeds the break

threshold the Sample Break detector is armed.

Step 4: Once sample break is detected the test is complete and the lower display line will show peak load. If

Auto Store is turned ON, the results will be saved to memory. If Auto Store is turned OFF, press <STORE> to

save the current test results. Note: If you do not press <STORE> before pressing <ZERO> or the start of a

new test, the results will be lost.

To continue running tests, repeat Steps 1, 3, 4.

NOTE: The Gauge Buster 2 is designed to operate in a "hands free" mode. This means that once it has

been setup and properly zeroed, the operator should not have to touch the keypad. If a test result is stored,

the specimen ID# will automatically increment.

4.2.1 Indicator Live Screen During Test

READY and TESTING are the two possible Indicator Modes.

Figure 4.2.1 - The Live Indicating Screen Testing.

L- - - - - - - - - -- - - - - - -H

Display while specimen

under test: LiveLoad and

Load Rate Pointer shown

between High and Low

Rate Limits.

136745 LB

M3

Gauge Buster 2 781-769-0850

www.ADMET.com

24 key tactile keypad

2 line x 16 character LCD with 3/8" H characters

Live Load

Test Rate

Active Test

Method

-15-

Gauge Buster 2 Operations Manual ADMET, Inc.

Control Print 0

Zero (.)

Freeze

1

4

Store

Utils

23

56

ENT

Start

È

Jog Dn

Ç

Jog Up

Method

Test 7

ID# 89

ESC

Stop

Report

Options

Setup

(-)

Disk

Control Print 0

Zero (.)

Freeze

1

4

Store

Utils

23

56

ENT

Start

È

Jog Dn

Ç

Jog Up

Method

Test 7

ID# 89

ESC

Stop

Report

Options

Setup

(-)

Disk

Gauge Buster 2

Figure 4.2.2 - The Live Indicating Screen End of Test/Ready Mode.

20 LB

781-769-0850

www.ADMET.com

24 key tactile keypad

Display after specimen

break detected: Live Load

is displayed on the first line

and Peak Load and Peak

Stress toggle automatically

on the second line.

M3

Active Test

Method PEAK 156829 LB

2 line x 16 character LCD with 3/8" H characters

Live Load

Peak Load/

Stress

A data transfer cable and GageSafe Data Exchange Software manufactured by ADMET is required to

download data to a remote PC. Refer to the GageSafe Data Exchange program manual for downloading

data to a computer.

4.3 Printing Test Reports to a HP compatible USB Printer

4.4 Download Test Results to a Remote PC

If the steps in Section 4.2 were followed, a test report containing all of the results stored to memory can be

obtained.

NOTE: This feature is not included with the standard Gauge Buster 2. The USB printer option and the printer

are purchased separately.

Step 1: Press <PRINT> from the Indicating Screen to see available print options.

Print current test, stored tests, one specified stored test, or XY plot to printer

More information in section 3.5

4.5 Download Test Results to a USB Flash (Thumb) Drive

NOTE: This feature is not included with the standard Gauge Buster 2. The USB Flash Drive option AND the

Flash Drive are purchased separately.

Step 1: Press <Disk (-)> from the Indicating Screen to see available Thumb Drive options.

More information in sectiion 3.6.

4.2.2 Indicator Live Screen End of Test/Ready Mode

-16-

Gauge Buster 2 Operations Manual ADMET, Inc.

You can calibrate up to 6 load cells to the Gauge Buster 2. There can be up to 10 points in each calibration.

Step 1: Turn on the system and allow it to run for 10 minutes before calibrating.

Step 2: Select the Engineering Units for calibration from the SETUP Menu. See Section 3.1 for more

information.

Step 3: Select <7> Calibrate from the Utils Menu.

Step 4: Enter the password. Contact ADMET technical support if you have lost the password.

Step 5: Enter the load cell number. Use zero if your system has only one load cell.

Step 6: Input the full scale range or the capacity of the machine. The range should be input in the currently

active engineering units.

Step 7: Input the resolution or minimum load increment.

Step 8: Press <1> Set Cal Points to enter the measure mode or <ESC> to exit.

NOTE: If you decide to exit the Calibration Menu at this time the values entered for Full Scale and Resolution

will be saved.

Required Information Before Continuing Calibration

The program will enter the measurement mode if <1> is pressed in Step 8. During this mode, the technician

can take up to ten calibration point readings (a minimum of 2 points is required).

NOTE: The first calibration point must be at zero load.

It may be beneficial to take a few more calibration readings in areas of greatest inaccuracy. The number

next to "Set PT No" on the display will indicate how many calibration readings have been taken. As the

calibration points are entered, write down the corresponding load value. After all ten calibration points have

been taken, or the <STORE> key is pressed when using less than ten points, the Gauge Buster 2 automati-

cally switches to engineering input mode. Input the load value corresponding to each calibration point reading

stored. The calibration points are stored sequentially. The first point is zero followed by the second, third and

so forth. Once an engineering unit value has been entered for each calibration point stored, the unit will

automatically save the calibration.

NOTE: Display will prompt for Set PT No 0 when setting the first point. The first point in the calibration MUST

be zero load. After all of calibration points have been stored, the first Engineering unit value entered will be 0.

The prompt for this will be PT(1).

Step 9: Unload the machine or place the transducer at its zero point. If calibrating a hydraulic machine, float

the piston before taking any readings. Press <ENTER> to take the zero reading. The left side of the display

will indicate PT1 has been read.

Step 10: Load the machine to a desired load and press <ENTER> to set a calibration point (voltage measure-

ment). The voltage value is NOT displayed but it has been saved to nonvolatile memory. Write down the

corresponding engineering unit value for each calibration point. Repeat this step until all readings are taken.

5.0 CALIBRATION

5.1 How to Calibrate Analog Transducers

Refer to Section 7.1 for details on transducer connections.

-17-

Gauge Buster 2 Operations Manual ADMET, Inc.

Step 13: To verify the calibration, exit out to the Indicating Screen and apply specific loads to the machine

and compare the reading on the indicator with the standard.

Step 14: If you choose to adjust one or some of the calibration points, use the Edit Calibration function from

the Utils menu. This function will allow you to edit load values for one, some or all calibration points without

forcing you to repeat Steps 2-12.

5.2 What Occurs During Calibration

The calibration procedure allows up to ten calibration points to be entered. Each successive pair of points is

connected by a straight line and the slope of each line is the calibration scale factor used for that region. This

results in a piecewise linear function which maximizes accuracy.

Step 11: Press <STORE> to exit the measurement mode if fewer than ten calibration points are used. The

program will automatically proceed from Step 10 to Step 12 after the tenth reading.

Step 12: Input the corresponding engineering unit value for each measurement point. After all values have

been entered, the program will automatically generate the corresponding scale factors and store them to

permanent memory.

DONE! READY TO VERIFY CALIBRATION

5.3 Saving Calibration Data

All calibration data can be transferred to and from the GageSafe Data Exchange software or a USB Flash

(Thumb) drive in units that are equipped with these options.

Calibration data can also be printed to HP compatible USB printer in units that are equipped with this option.

-18-

Gauge Buster 2 Operations Manual ADMET, Inc.

6.0 TROUBLESHOOTING

Gauge Buster 2 Troubleshooting

ProblemDescription Possible Causes Action

Not holding peak load

OR

Not tracking load while

machine actually loading and

breaking sample.

OR

Rate Bar not being

displayed.

Sample break threshold

and sample break %

settings

NOTE: The Gauge Buster 2 digital goes into TESTING

MODE when the actual load exceeds the programmed load

threshold value. When the Gauge Buster 2 Digital is in the

TESTING MODE, tehe live load is displayed on the upper

right and the load rate bar or load rate is displayed in the

bottom of the display. If you do not see the load rate bar or

the numeric load rate in the bottom display then you are NOT

in the testing mode and you need to look at your data logging

threshold value.

Ensure that the Break Threshold (Sample Brk menu item in

the Setup menu) is set to a value that is appropriate for the

test. Break Threshold is the point where the Gauge Buster 2

digital is armed for sample break. If the break threshold is too

low then a load drop in the early part of the test could trigger

the Gauge Buster 2 to detect premature specimen break (end

of test) and stop logging data. For example, if the Break

Threshold is set to 10lbs (much too low) and the sample break

percentage is set to 50% and the load climbed to 20lbs and

then dropped to 10lbs the Gauge Buster 2 would detect

sample break, stop logging data and report a peak load of

20lbs.

Ensure that Sample Break (SETUP, End of Test menu) is set

appropriately. Sample Break is defined as a percentage of

peak load and is used to define the end of a test. If Sample

Break = 10 percent and Peak Load = 100,000 Lb, then the

test will terminate when the load drops below 10,000 Lb.

Setting sample break percentage to 0 disables it so the Gauge

Buster 2 will continue logging data until the test buffer is full. If

the sample break percentage is set too high then end of test

can be triggered early.

Applying Load too quickly

after taring Gauge Buster

PLUS

NOTE: The Gauge Buster 2 is designed for hands-free

operation. You should only need to zero the digital once. It is

not necessary and NOT recommended to zero the digital prior

to each test. Doing so can prevent the digital from going into

Testing Mode and not recording the peak load. If you do not

see the rate bar or load rate display on bottom line of the

display it then the digital is not going into testing mode.

Ensure that you are that you are waiting at least 3 seconds

after zeroing digital before running a test (applying load to your

break machine).

-19-

Gauge Buster 2 Operations Manual ADMET, Inc.

Gauge Buster 2 Troubleshooting (cont'd)

ProblemDescription Possible Causes Action

Load reading wrong

Calibration

Ensure that correct load calibration is selected. The Active

Calibration # is displayed in the upper left of the live screen.

The Gauge Buster 2 can store up to six load cell calibrations.

Analog/Digital Electronics Contact ADMET technical support.

Excitation Voltage bad. Contact ADMET technical support.

Load Transducer Cable Replace/fix transducer cable

NOTE: refer to See Electrical/Mechanical Data section of

this manual for cable wiring information.

Load Transducer Replace load transducer

Stress reading wrong Specimen Information

Stress is a calculated value. It is equal to the load divided by

the programmed specimen cross-sectional area.

Ensure that Specimen Type and specimen dimension

information is correct in the SETUP menu.

Load reading unstable

Calibration

Ensure that there is valid calibration in selected load channel.

A valid calibration has at least two points, the first point

MUST be zero, appropriate full scale and resolution settings,

and a good A/D count span between the points in the

calibration.

Analog/Digital Electronics Contact ADMET technical support.

Excitation Voltage bad. Contact ADMET technical support.

Load Transducer Cable

Ensure that cable gain strap is properly wired for transducer

being used.

Replace/fix transducer cable

NOTE: refer to See Electrical/Mechanical Data section of

this manual for cable wiring information.

-20-

Gauge Buster 2 Operations Manual ADMET, Inc.

7.0 ELECTRICAL/MECHANICAL

DATA

Analog Channel Connections

Analog-Load Input

Analog Excitation:

pins 9 & 10 (+Exc & AGND)

5 Vdc

Analog Inputs: pins 1 & 2 (+/- IN)

Analog Input Range:

up to 2.5 mv/v Tie pin 3 to pin 12

up to 4.5 mv/v Tie pin 4 to pin 12

+/- 5 V No Connection

User definable Tie <25 ppm/C resistor

between pin 11 & pin 12.

Gain = 1 + 50000/Rg.

Connect all shields to chassis.

Transducer Identification (Contact Factory)

9

10

11

12

1

2

3

4

5

AGND

IN+/SHUNT

GS1

GS2

6

7

8

13

14

15

IN-

TR TYPE

ENC 5V

DGND

+Exc

AGND

GS3

GS0

SHUNT

ENC A

ENC B

DB15 Female

Figure 7.1.2 - Analog Transducer Pin Designation.

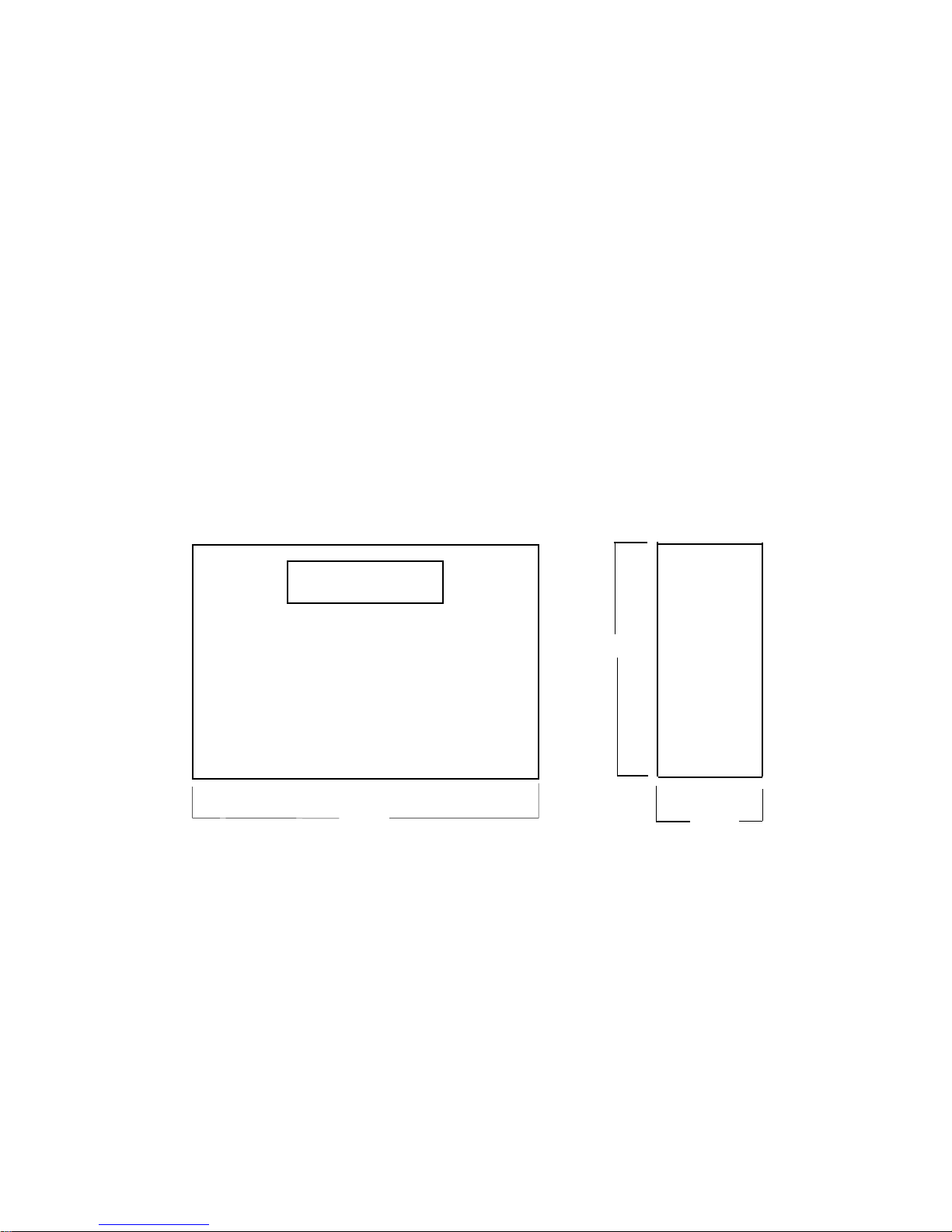

Figure 7.1.1 - Gauge Buster 2 Rear Connection Panel.

7.1 User Connections

Power

Switch

GaugeSafe Communication Port

Load/Enc Channel

Strain Channel

Not used

Not used

Printer

Port

(Optional))

Flashdrive

Port

(Optional))

-21-

Gauge Buster 2 Operations Manual ADMET, Inc.

7.4 Dimensions

9.25" 3.00"

8.50"

7.2 USB Port

7.3 Power (AC) Input

The USB port is used to transmit exchange data with either an HP compatible USB printer, GageSafe Data

Exchange software, or a Flash (Thumb) drive.

The Gauge Buster 2 Power requirements: 85 to 265 VAC (50 - 60Hz).

Table of contents

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started