Testing Strategies:

¾During assembly of the mold check the sensors at each step that might apply pre-loading or side

loads to the sensor; e.g. just after the clamp plate is assembled.

¾After assembling the mold, press on each sensor or ejector pin to ensure that the force can be

appliedtothesensor.Whiletheforceisapplied,thegreenoryellowLEDwillash.Whenthe

forcereaches10%(2%forpiezo)theredLEDwillstayon.Ifnolightsash,thelackof

clearance is preventing movement.

¾Piezo sensors will start with the green LED on. If you see a change to yellow or red without

pressing on the sensor then the sensor wire is damaged or the connections are dirty. If the green

lightdoesnotashwhenyouapplyforcetothepiezosensorthenthesensorwireisprobably

broken or disconnected.

¾If a sensor is “suspect” (yellow LED is On) it may have side loading which can cause it to fail in

operation. If it passes when removed from the mold check the pocket for improper radius or

bending of the sensor stem. If it remains suspect when removed from the mold then it should be

returned for re-calibration.

¾If a sensor is “failed” (red LED is On) remove it from the mold assembly and check it again. If it

passes (green) out of the mold then it is being preloaded or side loaded when installed. If it does

not pass then it is permanently damaged and must be returned for repair.

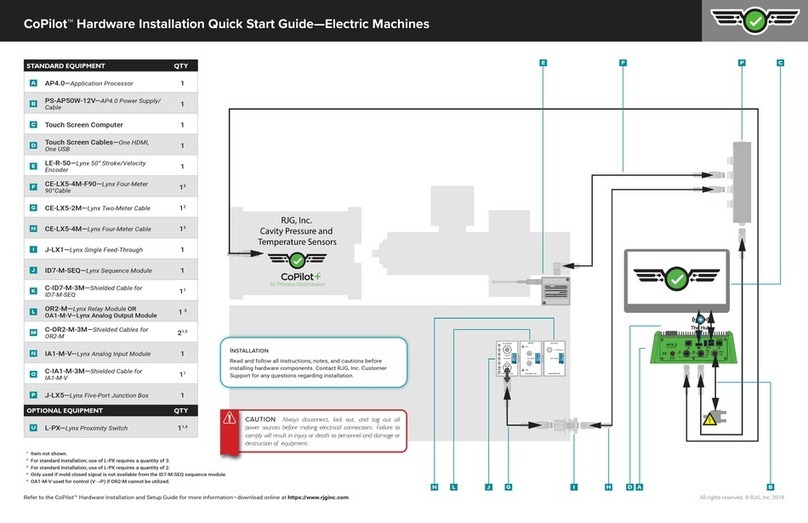

RJG, Inc. 11/20/12 Lynx Sensor Tester

The Lynx Sensor

Tester works with

RJG Lynx, strain

gage, and piezo force

sensors only.

All LEDs Flashing

Together: Sensor is not

communicating. Electronics

may be damaged

Green LED On:

Sensor is OK.

Green Flashing:

Pressure is changing

Yellow LED On:

Sensor offset is ± 5% to ±

10% (± 1% to ± 2% for piezo)

Yellow Flashing:

Pressure is changing

Red LED On:

Sensor offset is over ± 10%

(± 2% piezo).

Red LED is Flashing:

Sensor is reporting an

“invalid” condition. Sensor

wire damaged (pinched

or cut) or sensor head

damaged.

Lynx Sensor Tester Operating Instructions

Pass Suspect Fail

Pass Suspect Fail

Pass Suspect Fail

Pass Suspect Fail

Pass Suspect Fail

Pass Suspect Fail

If the LEDs are ashing in

sequence, the tester is thinking

Push and

hold for

duration of

the test

Connect directly to each

sensor to be tested.