contents

Rapid 220 Site Preparation Guide

i

CONTENTS

Using This Manual..............................................................................................1

Overview ...................................................................................................................................................... 1

Audience....................................................................................................................................................... 1

Assumptions ................................................................................................................................................ 1

Symbols and Syntax.................................................................................................................................. 2

Provisions for the work area.......................................................................3

Characteristics of the floor ....................................................................................................................... 4

Examples of suitable floors ...................................................................................................................... 5

Examples of non-suitable floors.............................................................................................................. 6

Technical floor ......................................................................................................................................... 6

Sound deadening floor........................................................................................................................... 6

Rubber ESD floor/sheet......................................................................................................................... 7

Fitted carpet............................................................................................................................................. 7

Requirements for Correct Operation......................................................9

Safety recommendations........................................................................................................................ 10

Project criteria ....................................................................................................................................... 10

Safety devices ....................................................................................................................................... 10

Safety devices location........................................................................................................................ 11

Requirements for correct operation ..................................................................................................... 13

Operating environment ....................................................................................................................... 13

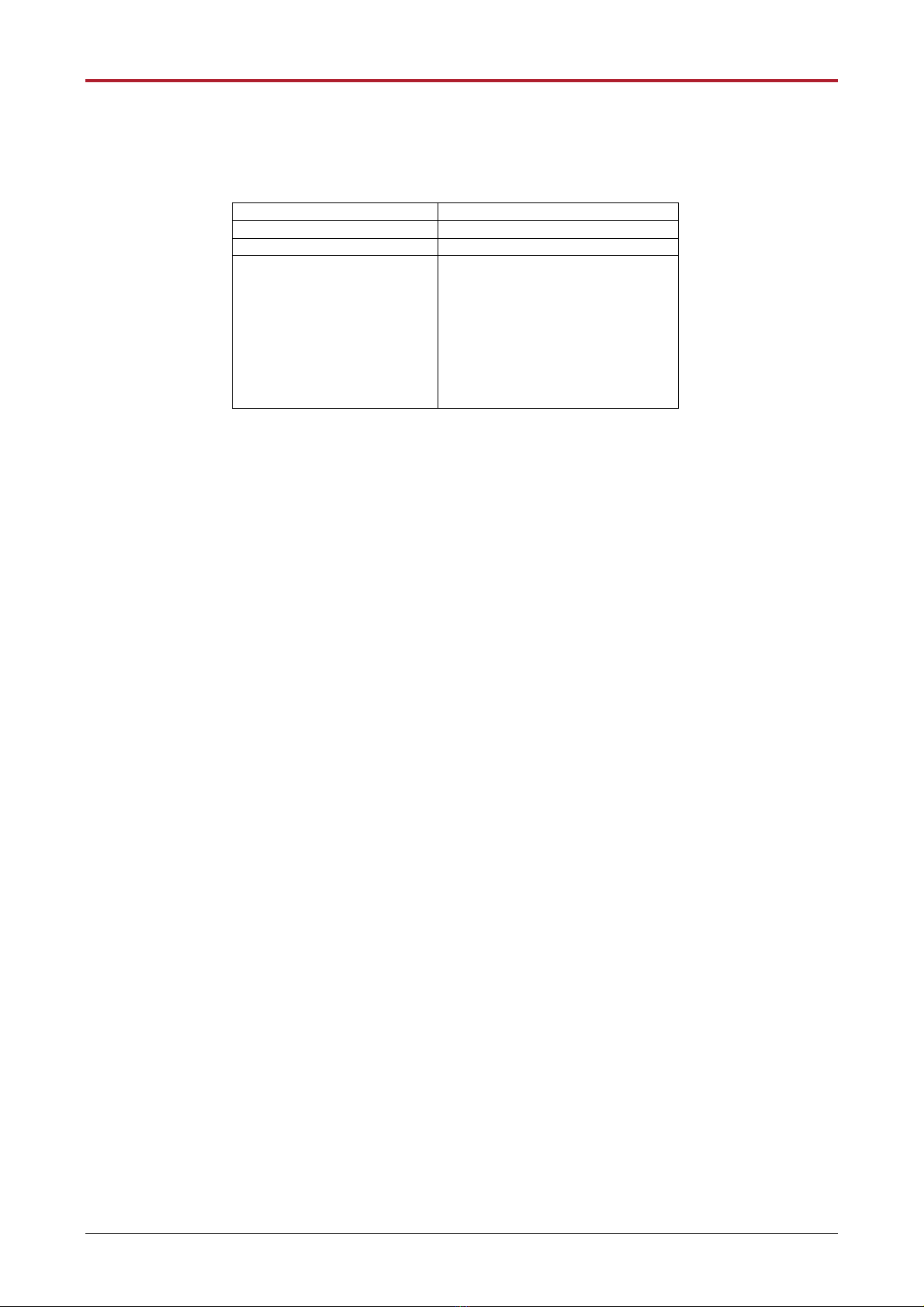

Technical specifications ....................................................................................................................... 14

Weight ..................................................................................................................................................... 15

Noise........................................................................................................................................................ 15

System dimensions .............................................................................................................................. 16

Work area............................................................................................................................................... 17

Carriage instructions......................................................................................19

Receiving inspections .............................................................................................................................. 20

Instructions for carriage ......................................................................................................................... 21

General precautions ............................................................................................................................. 22

Before transporting the system......................................................................................................... 22

Unpacking............................................................................................................................................... 23

Removing the shipment crate............................................................................................................ 24