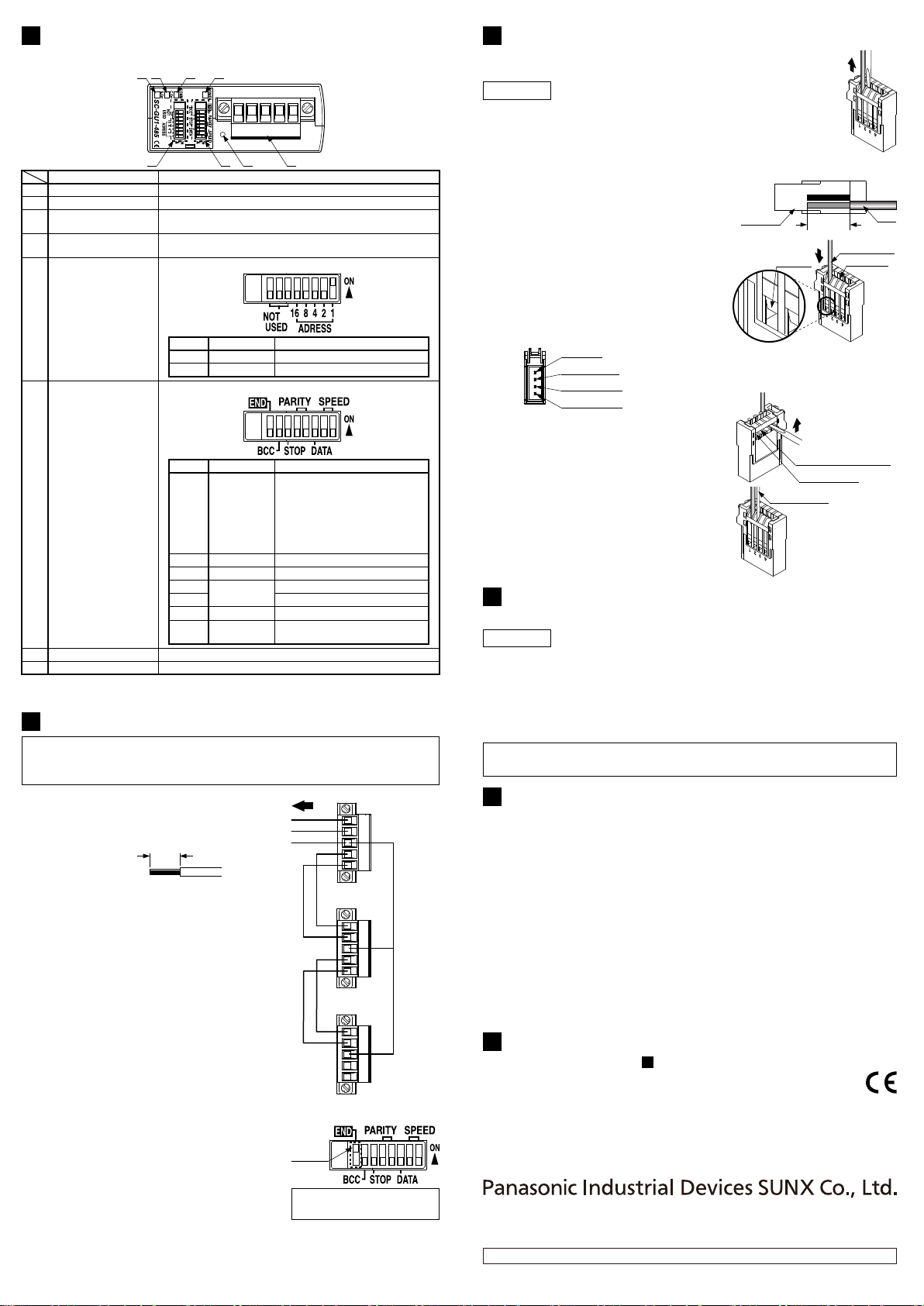

●The link cable (SC-GU1-CC02) can be shortened with the

desired length. However, the cable cannot be extended.

HOW TO CHANGE THE LENGTH OF LINK CABLE (SC-GU1-CC02)

7

Procedure

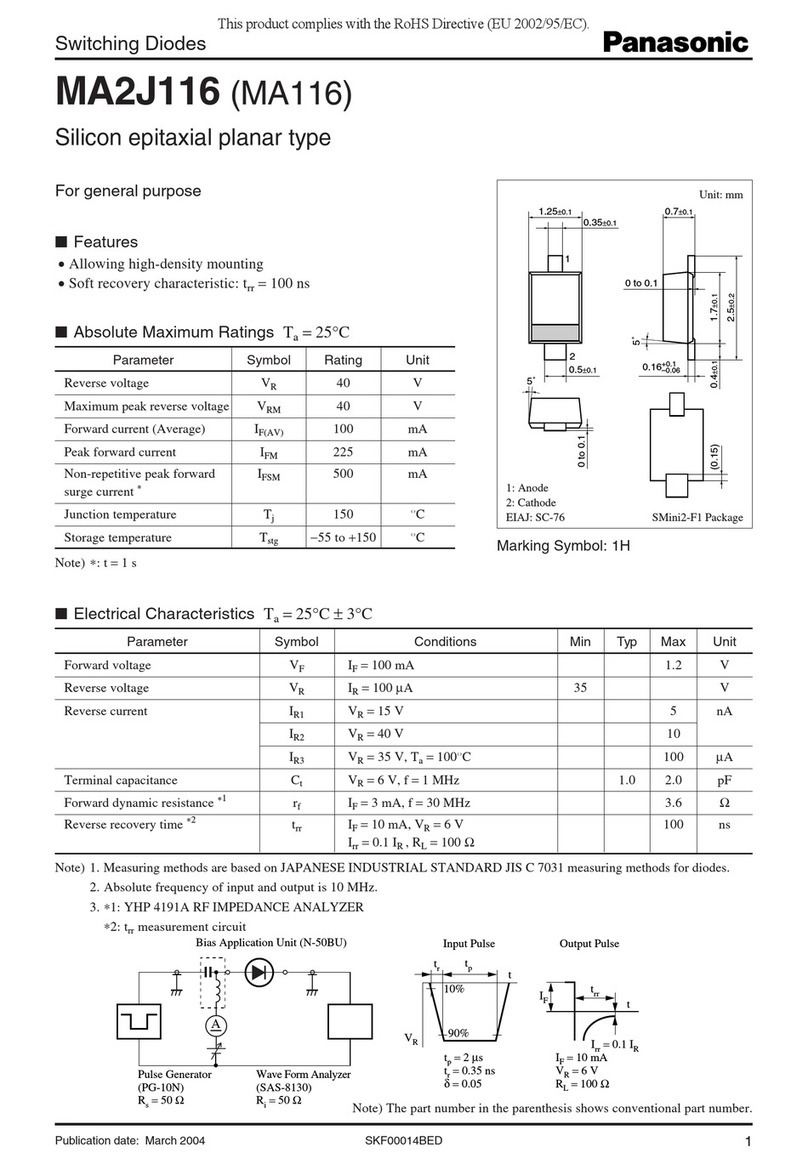

①Use a flathead screwdriver (Blade width: 2mm or less) to push

the operating lever (white) located at the wire inlet on the main

unit side connector of the link cable until it is locked.

②

③

Cut the link cable at the desired length.

Process the core length to 7 to 8mm in accordance with 'STRIP GAUGE' indicated

on the side of the connector, and twist the core

several times.

When using shielded wires, be sure to twist

the wire to a diameter of φ1.2mm or less.

④Insert the wire to the bottom of the wire inlet.

Check that the shielded part of the wire is

properly inserted into the wire inlet as well

as that the core end has passed through

the wire connection area as shown in the

right figure.

STRIP GAUGE

Core length:

7 to 8mm

Connector

Wire

Wire

connection

area

Shielded part

of wire

Wire inlet

Operating lever (white)

Releasing slot

Shielded wire

<Connector pin arrangement>

Core wire

Shielded wire

Not connected

Not connected

⑤Place the head of a flathead screwdriver

underneath the operating lever (white)

through the releasing slot, and lift the

screwdriver head.

If you hear a snap, the operating lever

(white) is returned and the wire is fixed.

⑥

⑦

Slightly pull the wire to ensure that the wire

is not loose.

Also, check that they are not in contact with

each other.

Fit the cover to the connector.

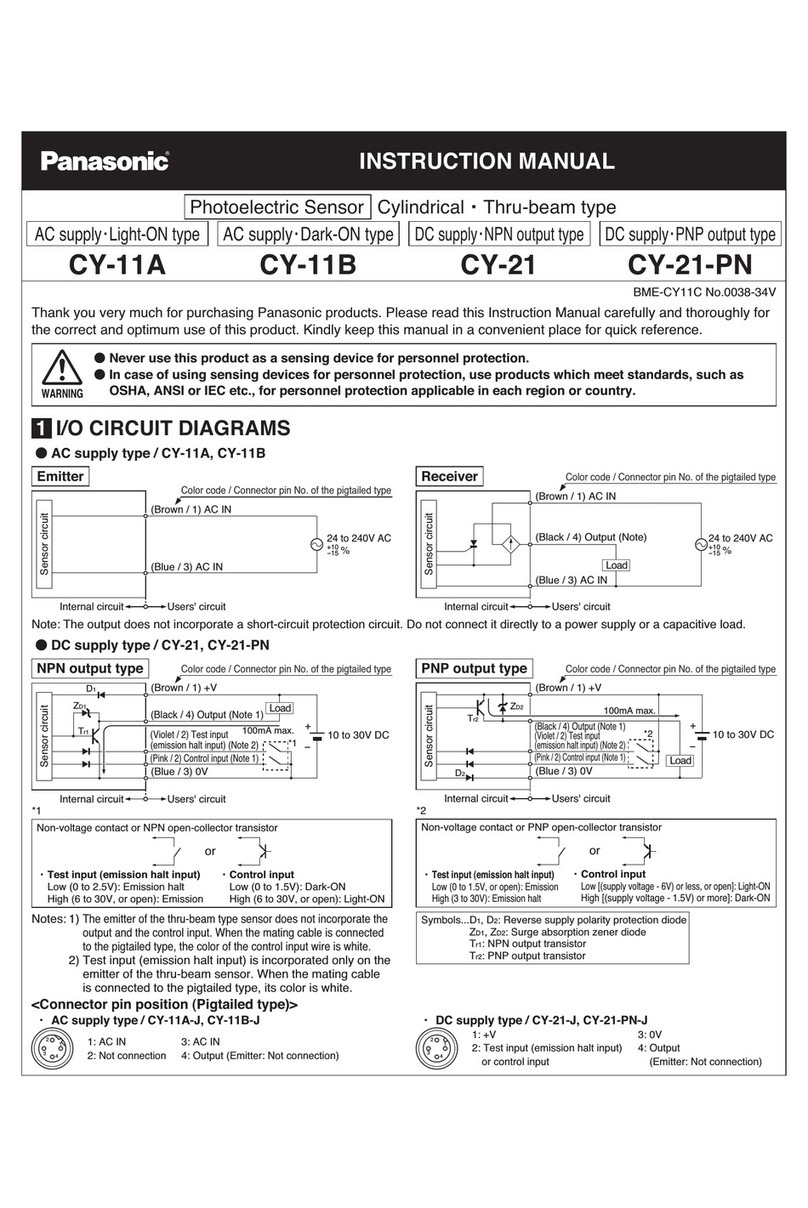

SETTING

8

●Follow the procedure given below for setting.

①

②

③

④

Mount this product and carry out wiring.

Carry out the address setting by using the DIP switch for address setting.

Carry out the communication-related setting by using the DIP switch for

communication setting.

Turn the power on.

Procedure

For communication conditions and commands, refer to 'Product specification'

and 'Communication command specification'.

Note: When the setting is changed after the power was turned on, be sure to press the reset switch.

Note: In case the upper communication error indicator (red) and the lower communication error

indicator (red) are mixed, each indicator blinks alternatively.

FUNCTIONAL DESCRIPTION

5

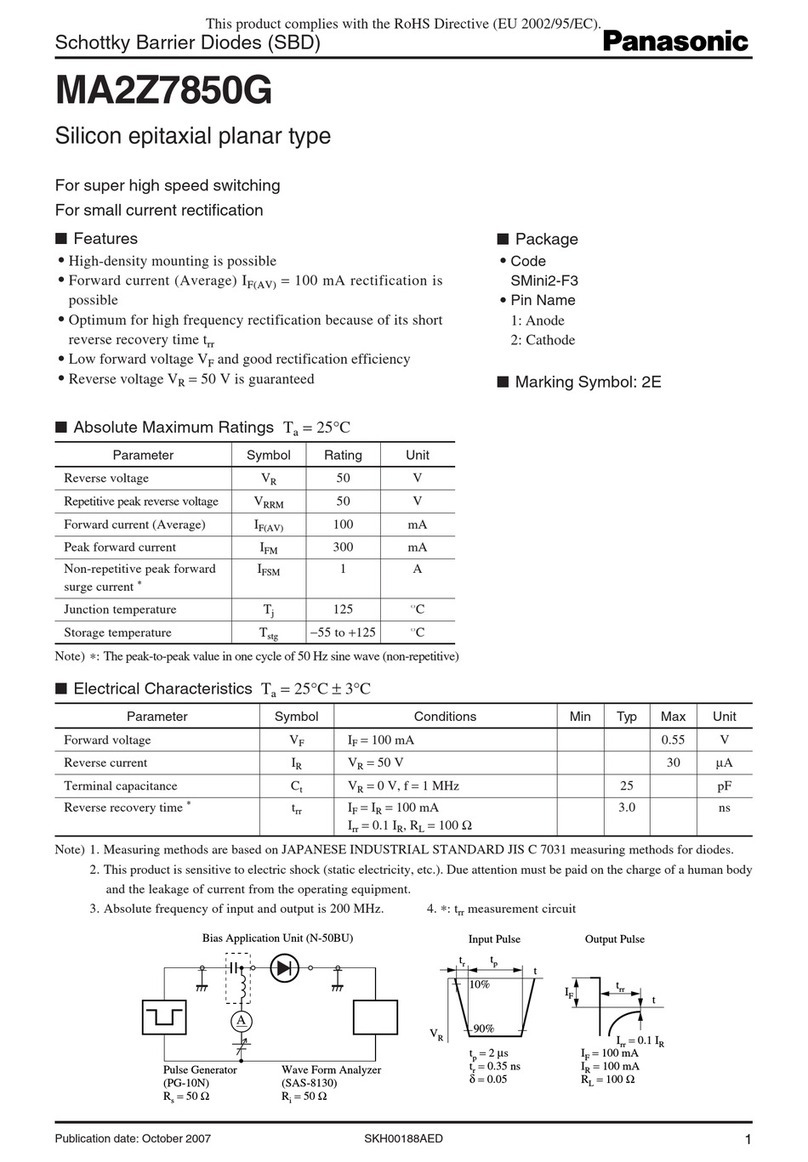

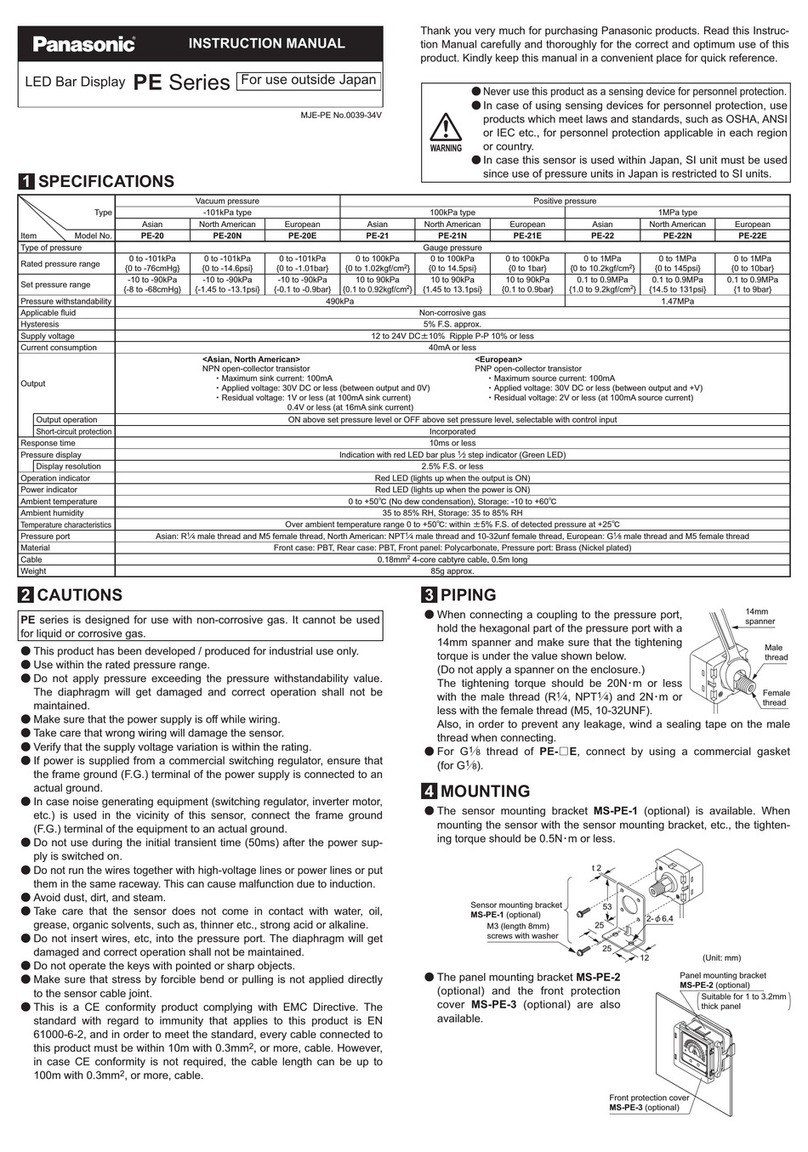

●Main unit / SC-GU1-485

①

⑦ ⑧⑥⑤

②③④

This is used when the upper controller or the main unit is mounted.

⑧

Terminal block connector

Makes the setting change valid.⑦Reset switch

⑥

DIP switch for

communication setting

0: Invalid, 1: Valid

0: Even number, 1: Odd number

5

4

8

Be sure to set the DIP switch

on the main unit at the

termination node to ON.

Be sure to set the DIP switch

on the main units other than the

termination node to OFF.

*:

0:

-

, 1: Termination

Termination

change

7 0: Invalid, 1: Valid

BCC check

6 0: 1bit, 1: 2 bitStop bit

Parity check

00: 9.6kbps, 01: 19.2kbps

10: 38.4kbps, 11: 57.6kbps

Communication

speed

2 to 1

3 0: 7 bit, 1: 8 bitData length

Description (0: OFF, 1: ON)Namebit No.

12347 6 58 bit No.

⑤

DIP switch for address

setting

Blinks when communication error between the main unit and

sensor amplifers occur.

④

Lower communication

error indicator (Red) (Note)

Blinks when communication error between PLC (Programmable Logic

Controller) and Master or Master and Slave, or command error occurs.

③

Upper communication

error indicator (Red) (Note)

Lights up during communication.②

Communication indicator (Green)

Lights up when the power is ON.①Power indicator (Green)

Designation Description

They are used for address setting.

Address setting

8 to 6

5 to 1

Not used.

-

DescriptionNamebit No.

12347 6 58 bit No.

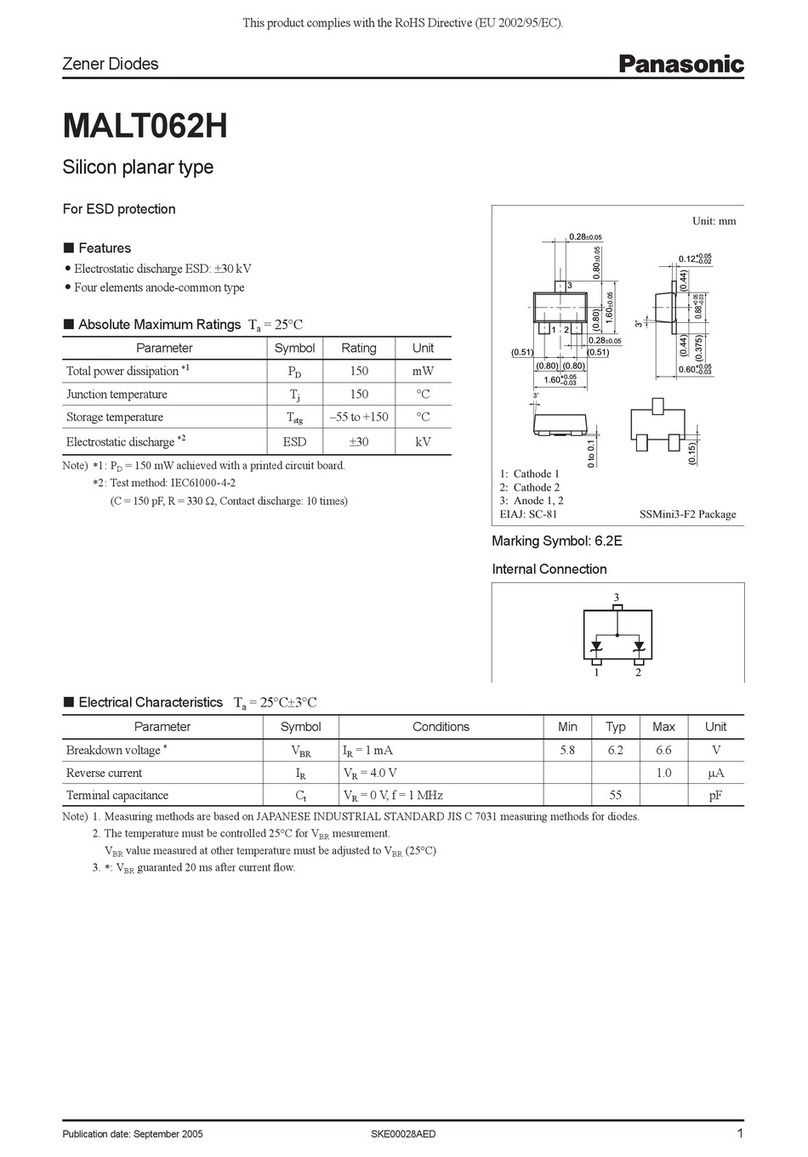

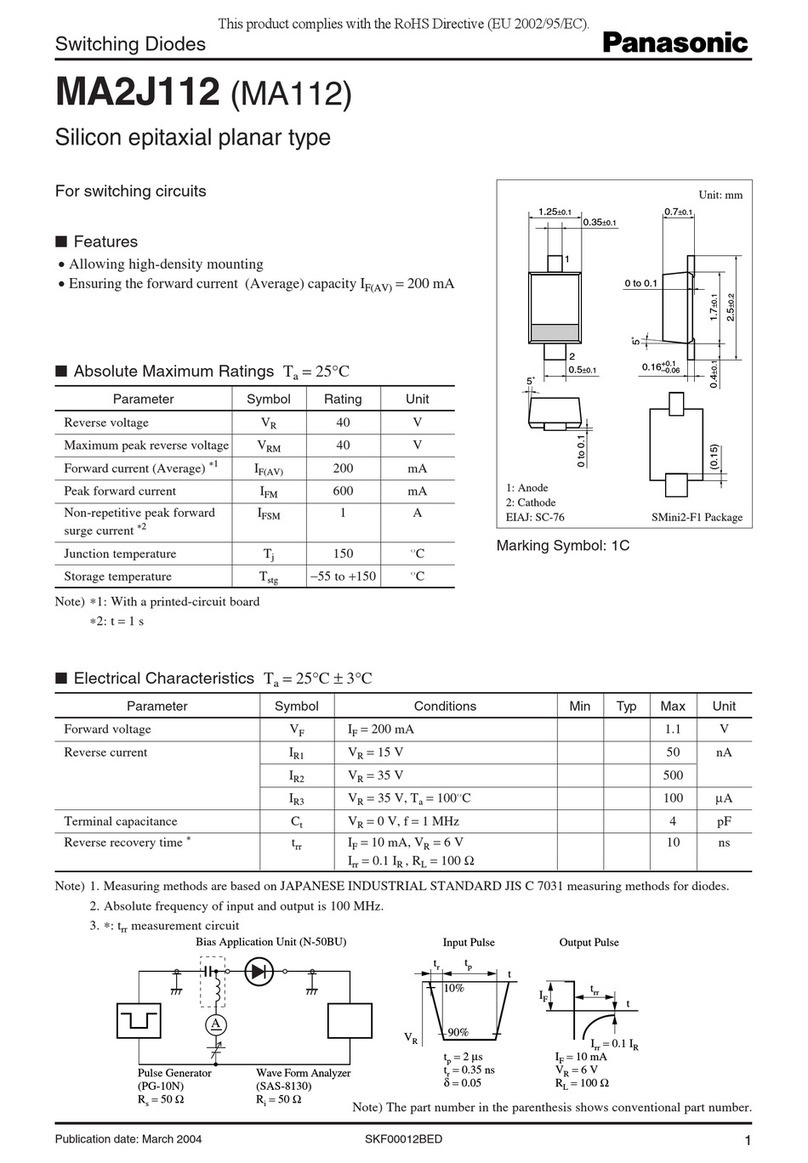

CONNECTION WITH UPPER COMMUNICATION CABLE

6

Make sure that the power is off while wiring.

Be sure to use the specified communication cable.

The communication distance should be within the specification.

●

●

●

●

●

When the main units (SC-GU1-485)are

connected to each other, max. 31 nodes can be

connected. Wire them as shown in the right figure.

The wire process length should be 7mm.

●

●

●

●

Do not plate the wire connected to the terminal

block connector with solder etc., since the

connected wire may come off by loosening screws.

The tightening torque of the screws for wire

fixing should be 0.5N・m or less.

The screws of the flange part should be tighten

as well so that the terminal block connector

does not come off from the main body. The

tightening torque should be 0.5N・m or less.

For the communication cable, use a shielded

twist-pair cable. Furthermore, the shield should

be connect to the frame ground (F.G.).

To upper controller

A

B

A

B

F.G.

A

B

A

B

F.G.

A

B

A

B

F.G.

<1st node>

<2nd node>

<Termination node>

7mm

Note: The termination resistance is fit in the main unit.

Be sure that the DIP switch/termination select on the main unit in the termination node is set

to ON side, and the DIP switch/termination select on the main units other than the termination

node is set to OFF side.

●

●

●

Note that the frame ground (F.G.) terminal has

not been connected to inside the unit.

Be sure that the DIP switch/termination select

on the main unit in the termination node is set

to ON side, and the DIP switch/termination

select on the main units other than the

termination node is set to OFF side.

Connect a termination resistance (100Ω) in

the termination node.

<Recommended>

KPEV-S 0.5SQ×1P manufactured by Sumitomo Electric

Industries, Ltd.

Termina-

tion select

<DIP switch for communication setting>

Only the main unit of the

termination node is

ON.

This figure shows the

factory setting.

(

(

This figure shows the

factory setting.

(

(

INTENDED PRODUCTS FOR CE MARKING

10

●

●

The models listed under 'SPECIFICATIONS' come with CE Marking.

As for all other models, please contact our office.

Contact for CE

Panasonic Marketing Europe GmbH Panasonic Testing Center

Winsbergring 15, 22525 Hamburg,Germany

2

CAUTIONS

9

●

●

●

●

●

●

●

●

●

●

●

This product has been developed / produced for industrial use only.

Make sure that the power supply is off while wiring and adding the units.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within the rating including the

sensor amplifer.

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

Do not use during the initial transient time (1 sec.) after the power supply is switched on.

This sensor is suitable for indoor use only.

Do not use this sensor in places having excessive vapor, dust, etc.

Take care that the product does not come in contact with water, oil, grease,

organic solvents, such as, thinner, etc., or strong acid and alkaline.

This sensor cannot be used in an environment containing inflammable or explosive gases.

Never disassemble or modify the sensor.

http://panasonic.net/id/pidsx/global

PRINTED IN JAPAN

Overseas Sales Division (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

About our sale network, please visit our website.

© Panasonic Industrial Devices SUNX Co., Ltd. 2014