ENGLISH / A-5

FORM NO. 56041986 - Condor™ - A-5

CONSIGNES DE PRUDENCE ET DE SÉCURITÉ

SYMBOLES

Les symboles reproduits ci-dessous sont utilisés pour attirer l’attention de l’opérateur sur des situations dangereuses. Il est donc conseillé de lire attentivement

ces indications et de prendre les mesures adéquates en vue de protéger le personnel et le matériel.

DANGER!

Ce symbole est utilisé pour mettre l’opérateur en garde contre les risques immédiats pouvant provoquer des dommages corporels graves, voire entraîner la mort.

ATTENTION!

Ce symbole est utilisé pour attirer l’attention sur une situation susceptible d’entraîner des dommages corporels graves.

PRUDENCE!

Ce symbole est utilisé pour attirer l’attention de l’opérateur sur une situation qui pourrait entraîner des dommages corporels minimes, ou des dommages à la

machine ou à d’autres équipements.

Lire toutes les instructions avant d’utiliser l’appareil.

CONSIGNES GENERALES DE SECURITE

Les consignes spécifiques de prudence et de sécurité mentionnées ici ont pour but de vous informer de la survenance de tout risque de dommages matériels ou

corporels.

ATTENTION!

•Cette machine ne pourra être utilisée que par du personnel parfaitement entraîné et dûment autorisé.

•Evitez les arrêts subits lorsque la machine est chargée et se trouve sur des rampes ou des plans inclinés. Evitez les virages serrés. Adoptez

une vitesse réduite lorsque la machine est en descente. Ne nettoyez que lorsque la machine monte la pente.

•Eloignez les batteries de toutes flammes, étincelles ou substance fumigène. Les gaz explosifs sont ventilés pendant le fonctionnement

normal.

•De plus, du gaz hydrogène explosif s’échappe des batteries lorsqu’elles sont en charge. Ne procédez au chargement des batteries que dans

une zone bien ventilée, loin de toute flamme. Ne fumez pas à proximité des batteries lorsqu’elles sont en charge.

•Otez tous vos bijoux lorsque vous travaillez à proximité de composants électriques.

•Positionnez la clé de contact sur off (O) et déconnectez les batteries avant de procéder à l’entretien des composants électriques.

•Ne travaillez jamais sous une machine sans y avoir placé, au préalable, des blocs de sécurité ou des étais destinés à soutenir la machine

•Ne déversez pas d’agents nettoyants inflammables, ne faites pas fonctionner la machine à proximité de ces agents ou d’autres liquides

inflammables.

•Ne nettoyez pas cette machine avec un nettoyeur à pression.

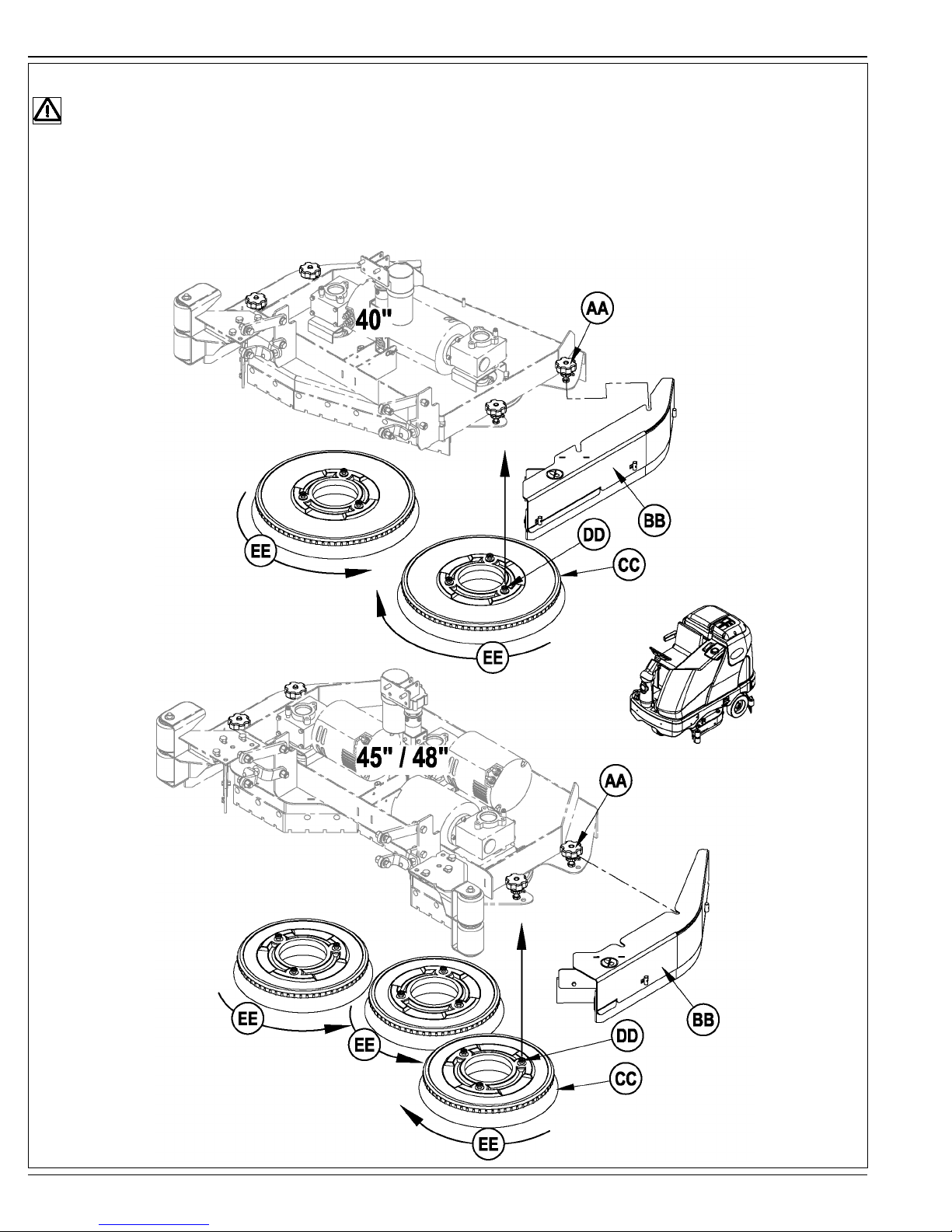

•Utilisez uniquement les brosses fournies avec l’appareil ou celles spécifiées dans le manuel d’instructions. L’utilisation d’autres brosses peut

mettre la sécurité en péril.

PRUDENCE!

•Cette machine n’est pas conçue pour une utilisation sur les chemins ou voies publics.

•Cette machine n’est pas conçue pour le ramassage des poussières dangereuses.

•N’utilisez pas de disques de scarificateur ni de meules. Advance ne pourra en aucun cas être tenue pour responsable des dommages

occasionnés à vos sols par ce type d’équipement (vous risquez également d’endommager le système d’entraînement des brosses).

•Lors de l’utilisation de cette machine, assurez-vous que des tiers, et notamment des enfants, ne courent pas le moindre risque.

•Avant de procéder à toute opération d’entretien, veuillez lire attentivement toutes les instructions qui s’y rapportent.

•Ne laissez pas la machine sans surveillance sans avoir, au préalable, coupé le contact, enlevé la clé de contact (O) et tiré le frein à main.

•Positionnez la clé de contact sur off (O) avant de remplacer les brosses ou d’ouvrir tout panneau d’accès.

•Prenez toutes les mesures nécessaires pour éviter que les cheveux, les bijoux ou les vêtements amples ne soient entraînés dans les parties

mobiles de la machine.

•Faites attention lorsque vous déplacez cette machine dans un endroit où la température peut descendre sous 0°. L’eau contenue dans les

réservoirs de détergent, de récupération ou de solution ou dans les conduites risquerait de geler et par là même d’endommager les valves et

raccords de la machine. Rincez avec un liquide de lave-glace.

•Prenez soin d’enlever les batteries de la machine avant de mettre cette dernière au rebut. Pour ce qui est de l’élimination des batteries,

conformez-vous aux réglementations locales en matière d’environnement.

•N’utilisez pas sur des surfaces dont la pente dépasse celle mentionnée sur la machine.

•Toutes les portes et couvercles doivent être dans la position mentionnée dans le manuel d’instruction avant de mettre la machine en service.

CONSERVEZ SOIGNEUSEMENT CES INSTRUCTIONS