INSTRUCTION FOR USE ENGLISH

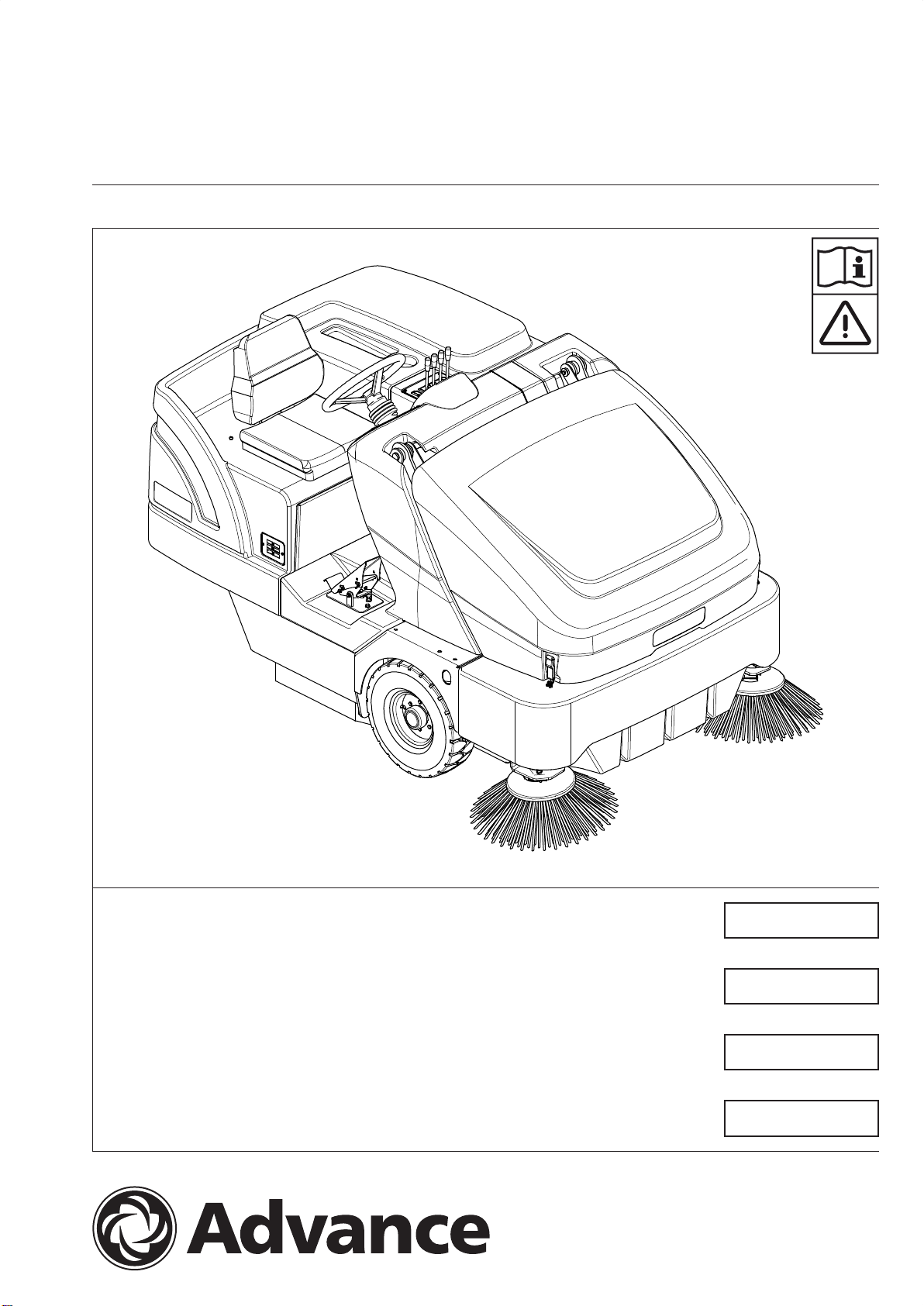

33019864 - Proterra™ 1

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................................................................. 2

MANUAL PURPOSE AND CONTENTS .......................................................................................................................................... 2

TARGET........................................................................................................................................................................................... 2

HOW TO STORE THIS MANUAL.................................................................................................................................................... 2

IDENTIFICATION DATA................................................................................................................................................................... 2

OTHER REFERENCE MANUALS................................................................................................................................................... 2

SPARE PARTS AND MAINTENANCE............................................................................................................................................. 2

CHANGES AND IMPROVEMENTS ................................................................................................................................................ 2

OPERATION CAPABILITIES ........................................................................................................................................................... 3

CONVENTIONS .............................................................................................................................................................................. 3

UNPACKING/DELIVERY ................................................................................................................................................. 3

SAFETY ........................................................................................................................................................................... 3

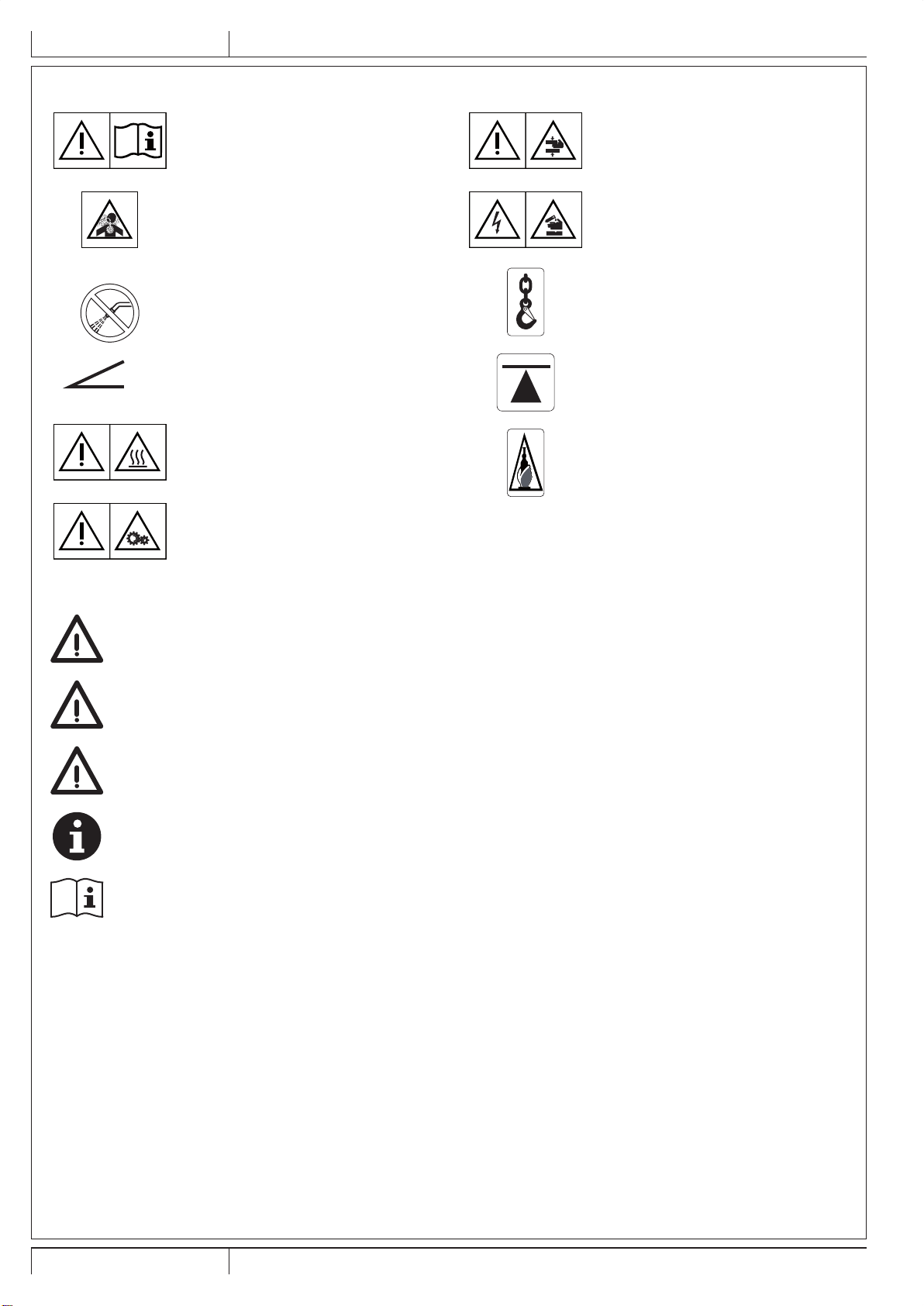

VISIBLE SYMBOLS ON THE MACHINE......................................................................................................................................... 4

SYMBOLS THAT APPEAR ON THIS MANUAL............................................................................................................................... 4

GENERAL INSTRUCTIONS............................................................................................................................................................ 5

HOPPER SAFETY SUPPORT ........................................................................................................................................................ 8

JACKING THE MACHINE................................................................................................................................................................ 8

MACHINE TRANSPORT ................................................................................................................................................................. 8

PUSHING/TOWING THE MACHINE............................................................................................................................................... 8

KNOW YOUR MACHINE ................................................................................................................................................. 9

MACHINE NOMENCLATURE ......................................................................................................................................................... 9

OPERATING CONTROLS..............................................................................................................................................................11

ACCESSORIES/OPTIONS............................................................................................................................................................ 12

TECHNICAL DATA......................................................................................................................................................................... 12

WIRING DIAGRAM........................................................................................................................................................................ 13

HYDRAULIC DIAGRAM ................................................................................................................................................................ 15

PREPARING THE MACHINE FOR USE ....................................................................................................................... 16

PRE-OPERATIONAL CHECKLIST................................................................................................................................................ 16

MAIN BROOM ............................................................................................................................................................................... 16

FUEL.............................................................................................................................................................................................. 16

OPERATING THE MACHINE ........................................................................................................................................ 17

BEFORE STARTING THE MACHINE ........................................................................................................................................... 17

STARTING AND STOPPING THE MACHINE ............................................................................................................................... 17

PARKING BRAKE.......................................................................................................................................................................... 18

SWEEPING ................................................................................................................................................................................... 18

HOPPER DUMPING...................................................................................................................................................................... 19

AFTER USING THE MACHINE..................................................................................................................................................... 20

MACHINE STORAGE.................................................................................................................................................................... 20

FIRST PERIOD OF USE ............................................................................................................................................................... 20

MAINTENANCE............................................................................................................................................................. 20

SCHEDULED MAINTENANCE TABLE ......................................................................................................................................... 21

MAIN BROOM MAINTENANCE .................................................................................................................................................... 22

SIDE BROOM MAINTENANCE..................................................................................................................................................... 24

DUST FILTER MAINTENANCE (PANEL FILTER)......................................................................................................................... 26

SKIRT MAINTENANCE ................................................................................................................................................................. 27

DUSTGUARD SYSTEM WATER FILTER CLEANING (OPTIONAL)............................................................................................. 27

HYDRAULIC OIL ........................................................................................................................................................................... 28

ENGINE OIL .................................................................................................................................................................................. 28

ENGINE AIR FILTER CLEANING.................................................................................................................................................. 29

ENGINE COOLANT....................................................................................................................................................................... 29

FUSE CHECK/REPLACEMENT/RESET....................................................................................................................................... 30

TROUBLESHOOTING................................................................................................................................................... 31

SCRAPPING .................................................................................................................................................................. 32

33019864(3)2012-03.indb 1 16/04/2012 12:40:50