SERVICE MANUAL ENGLISH

Terra™ 5200 1463546000(1)2008-07 1

TABLE OF CONTENTS

GENERAL INFORMATION.............................................................................................................................................. 3

CONVENTIONS .............................................................................................................................................................................. 3

MACHINE LIFTING ......................................................................................................................................................................... 3

MACHINE TRANSPORT ................................................................................................................................................................. 3

PUSHING OR TOWING THE MACHINE......................................................................................................................................... 3

OTHER REFERENCE MANUALS................................................................................................................................................... 3

SAFETY........................................................................................................................................................................................... 3

SYMBOLS ....................................................................................................................................................................................... 3

GENERAL INSTRUCTIONS............................................................................................................................................................ 4

TECHNICAL DATA........................................................................................................................................................................... 5

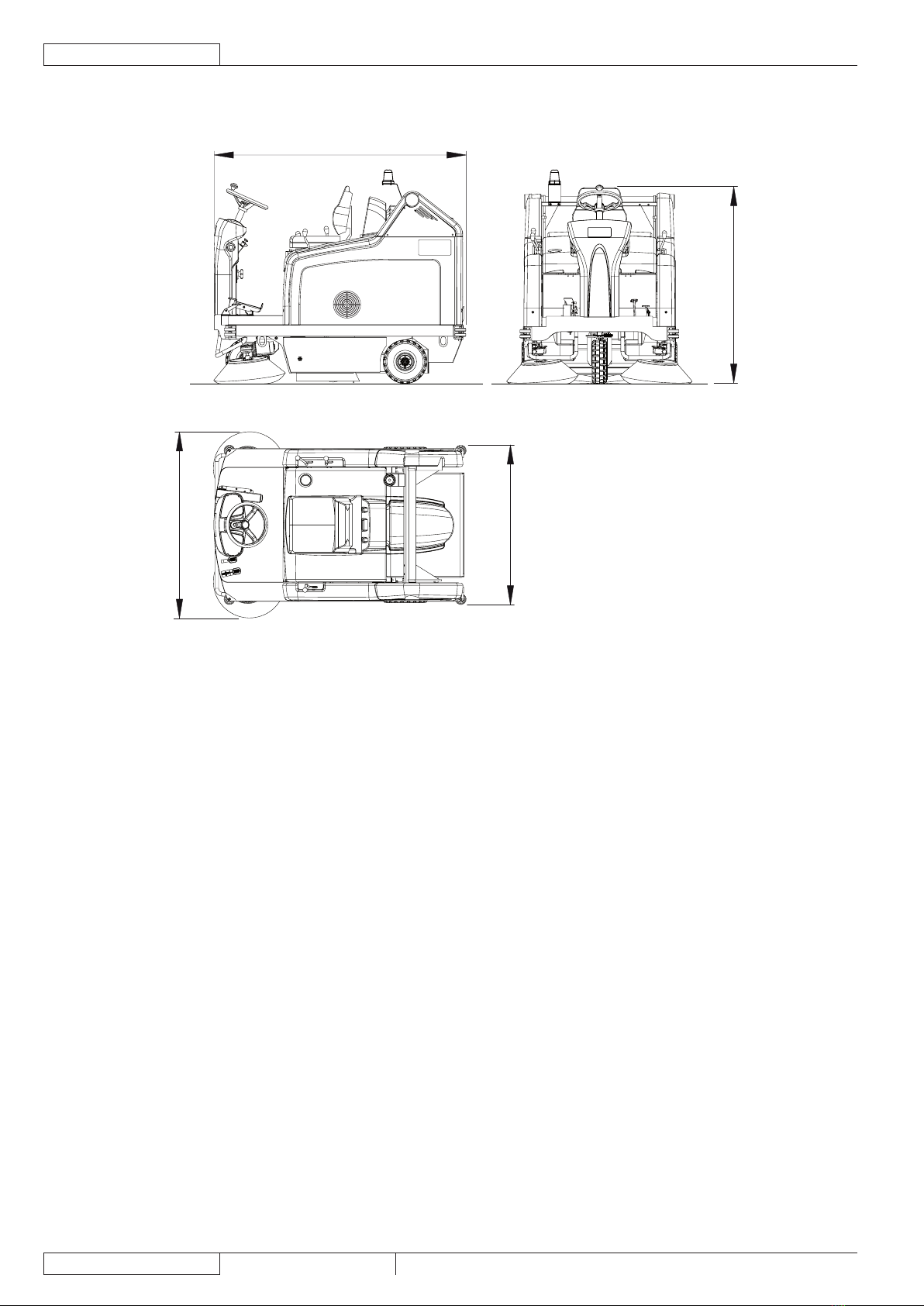

DIMENSIONS .................................................................................................................................................................................. 8

SCHEDULED MAINTENANCE ....................................................................................................................................................... 9

SCHEDULED MAINTENANCE TABLE ........................................................................................................................................... 9

MACHINE NOMENCLATURE ....................................................................................................................................................... 10

SWEEPING SYSTEM .................................................................................................................................................... 13

MAIN BROOM DRIVING BELT VISUAL INSPECTION................................................................................................................. 13

MAIN BROOM DRIVING BELT DISASSEMBLY/ASSEMBLY ....................................................................................................... 14

MAIN BROOM PULLEY BEARING REPLACEMENT ................................................................................................................... 15

MAIN BROOM GAS SPRING DISASSEMBLY/ASSEMBLY]......................................................................................................... 16

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT.................................................................................................................. 17

MAIN BROOM REPLACEMENT ................................................................................................................................................... 19

MAIN BROOM HEIGHT ADJUSTMENT CABLE REPLACEMENT ............................................................................................... 20

SIDE BROOM HEIGHT ADJUSTMENT ........................................................................................................................................ 21

SIDE BROOM REPLACEMENT.................................................................................................................................................... 23

SIDE BROOM LIFTING CABLE REMOVAL .................................................................................................................................. 24

MICROSWITCH REPLACEMENT ON THE SIDE AND MAIN BROOMS LIFTING LEVERS ....................................................... 25

MAIN BROOM MOTOR ELECTRICAL INPUT CHECK................................................................................................................. 26

MAIN BROOM MOTOR CARBON BRUSH CHECK AND REPLACEMENT ................................................................................. 27

MAIN BROOM MOTOR DISASSEMBLY/ASSEMBLY................................................................................................................... 28

SIDE BROOM MOTOR ELECTRICAL INPUT CHECK ................................................................................................................. 29

SIDE BROOM MOTOR CARBON BRUSH CHECK AND REPLACEMENT.................................................................................. 30

SIDE BROOM MOTOR REMOVAL ............................................................................................................................................... 31

TROUBLESHOOTING................................................................................................................................................................... 32

SKIRT............................................................................................................................................................................. 33

SKIRT HEIGHT AND OPERATION CHECK .................................................................................................................................. 33

SIDE SKIRT REPLACEMENT ....................................................................................................................................................... 35

REAR SKIRT REPLACEMENT ..................................................................................................................................................... 35

FRONT SKIRT REPLACEMENT ................................................................................................................................................... 36

FRONT SKIRT CONTROL CABLE REPLACEMENT.................................................................................................................... 37

DUST AND DEBRIS COLLECTION SYSTEM .............................................................................................................. 39

PANEL DUST FILTER CLEANING AND INTEGRITY CHECK] ..................................................................................................... 39

CLOSED POCKET FILTER CLEANING AND INTEGRITY CHECK]............................................................................................. 41

VACUUM FAN MOTOR ELECTRICAL INPUT CHECK]................................................................................................................ 43

VACUUM FAN MOTOR REMOVAL/REPLACEMENT].................................................................................................................. 44

FILTER SHAKER OPERATION CHECK ....................................................................................................................................... 45

FILTER SHAKER MOTOR REMOVAL .......................................................................................................................................... 45

HOPPER GASKET CHECK AND REPLACEMENT ...................................................................................................................... 46

HORIZONTAL HOPPER CONTROL MICROSWITCH CHECK AND ADJUSTMENT ................................................................... 48

HORIZONTAL HOPPER CONTROL MICROSWITCH REPLACEMENT ...................................................................................... 49

LIFTED HOPPER CONTROL MICROSWITCH CHECK AND ADJUSTMENT.............................................................................. 50

LIFTED HOPPER CONTROL MICROSWITCH REPLACEMENT................................................................................................. 52

HOPPER ROTATION ACTUATOR CHECK AND ADJUSTMENT ................................................................................................. 53

HOPPER ROTATION ACTUATOR REPLACEMENT .................................................................................................................... 55

HOPPER MECHANICAL STABILIZER CHECK AND ADJUSTMENT ........................................................................................... 56

HOPPER REMOVAL ..................................................................................................................................................................... 57

ADJUSTMENT HOPPER END-OF-STROKE [SR 1301 B/SR 1301 P]......................................................................................... 58

HOPPER LIFTING LEVER ASSEMBLY REMOVAL...................................................................................................................... 60

TROUBLESHOOTING................................................................................................................................................................... 62