INSTRUCTIONS FOR USE ENGLISH

1465374000 - SW900 1

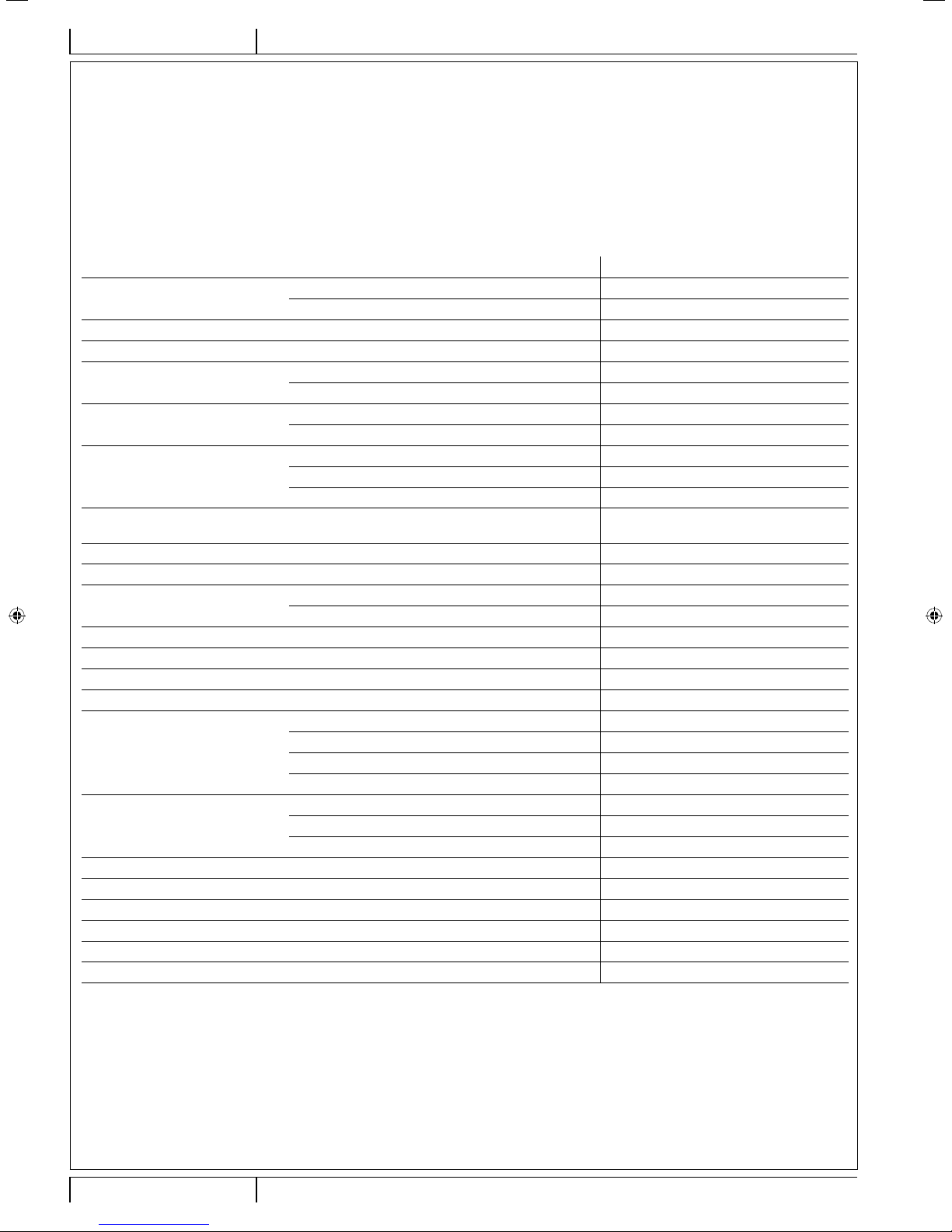

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................................................................. 2

MANUAL PURPOSE AND CONTENTS .......................................................................................................................................... 2

TARGET........................................................................................................................................................................................... 2

HOW TO KEEP THIS MANUAL....................................................................................................................................................... 2

IDENTIFICATION DATA................................................................................................................................................................... 2

OTHER REFERENCE MANUALS................................................................................................................................................... 2

SPARE PARTS AND MAINTENANCE............................................................................................................................................. 2

CHANGES AND IMPROVEMENTS ................................................................................................................................................ 2

OPERATION CAPABILITIES ........................................................................................................................................................... 3

CONVENTIONS .............................................................................................................................................................................. 3

UNPACKING/DELIVERY ................................................................................................................................................. 3

SAFETY ........................................................................................................................................................................... 3

VISIBLE SYMBOLS ON THE MACHINE......................................................................................................................................... 3

SYMBOLS THAT APPEAR ON THIS MANUAL............................................................................................................................... 4

GENERAL INSTRUCTIONS............................................................................................................................................................ 4

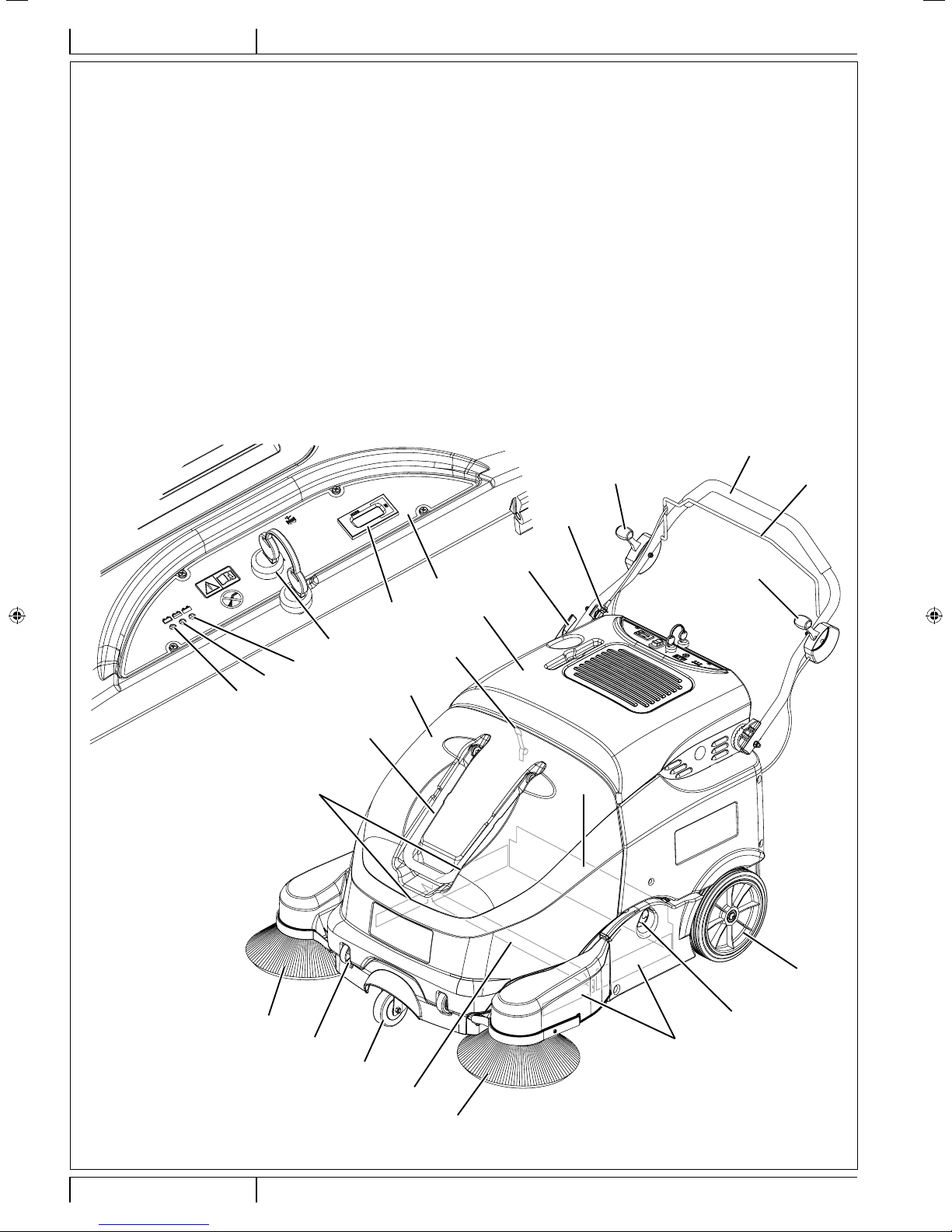

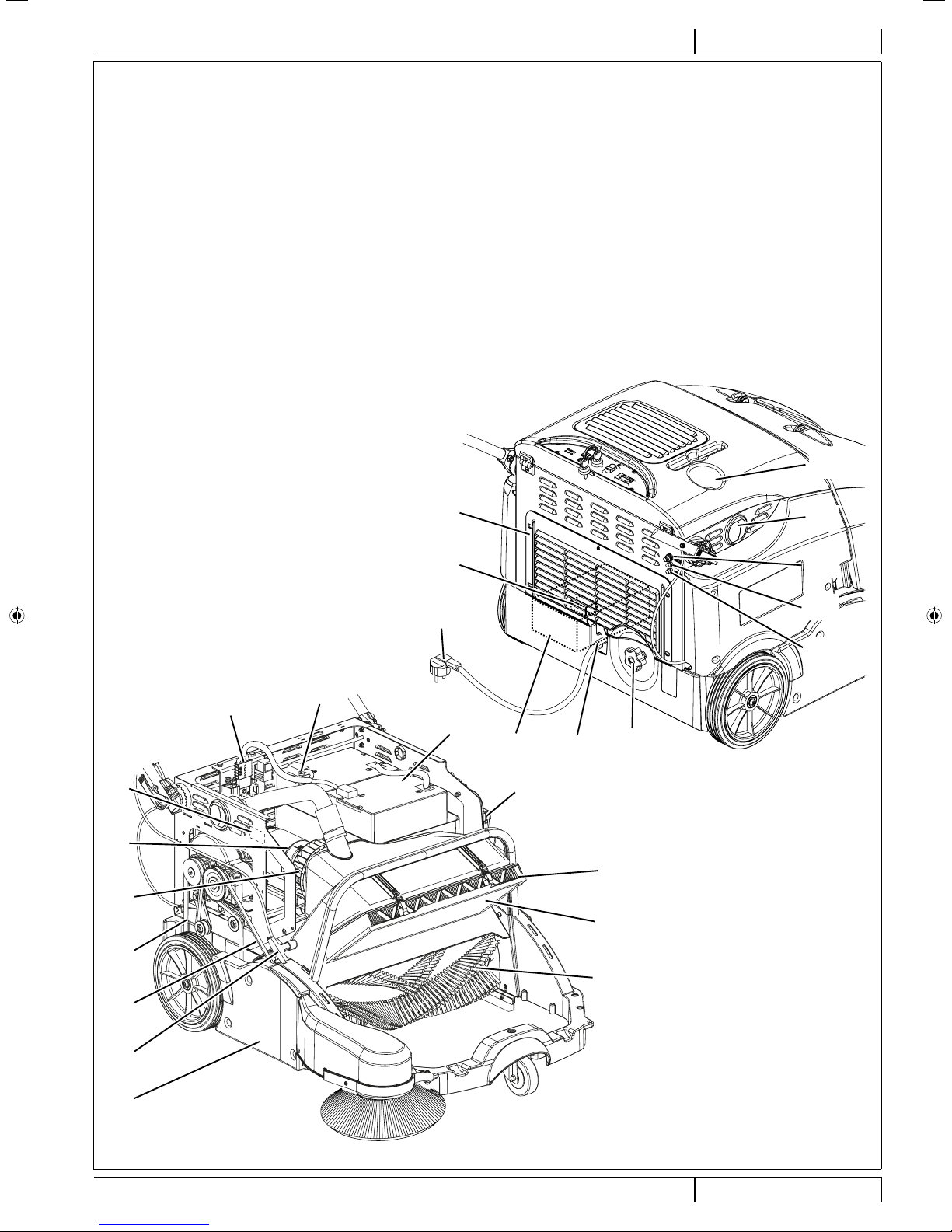

MACHINE DESCRIPTION ............................................................................................................................................... 6

MACHINE STRUCTURE ................................................................................................................................................................. 6

ACCESSORIES/OPTIONS.............................................................................................................................................................. 8

TECHNICAL DATA........................................................................................................................................................................... 8

WIRING DIAGRAM.......................................................................................................................................................................... 9

USE ................................................................................................................................................................................ 10

BATTERY CHECK/SETTING ON A NEW MACHINE.....................................................................................................................11

BEFORE MACHINE START-UP .................................................................................................................................................... 12

STARTING AND STOPPING THE MACHINE ............................................................................................................................... 12

MACHINE OPERATION ................................................................................................................................................................ 12

HOPPER DUMPING...................................................................................................................................................................... 13

AFTER USING THE MACHINE..................................................................................................................................................... 13

PUSHING THE MACHINE............................................................................................................................................................. 13

MACHINE LONG INACTIVITY ...................................................................................................................................................... 13

MAINTENANCE............................................................................................................................................................. 13

SCHEDULED MAINTENANCE TABLE ......................................................................................................................................... 14

BATTERY CHARGER CABLE CHECK ......................................................................................................................................... 14

BATTERY CHARGING .................................................................................................................................................................. 14

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT.................................................................................................................. 15

MAIN BROOM REPLACEMENT ................................................................................................................................................... 16

SIDE BROOM HEIGHT CHECK AND ADJUSTMENT .................................................................................................................. 17

SIDE BROOM DISASSEMBLY/ASSEMBLY.................................................................................................................................. 17

SKIRT CHECK AND ADJUSTMENT ............................................................................................................................................. 18

DUST FILTER CLEANING AND INTEGRITY CHECK .................................................................................................................. 19

HOPPER POSITION MICROSWITCH OPERATION CHECK....................................................................................................... 20

FUSE CHECK/REPLACEMENT/RESET....................................................................................................................................... 20

BATTERY ELECTROLYTE LEVEL CHECK (FOR WET BATTERIES ONLY) ............................................................................... 20

TROUBLESHOOTING................................................................................................................................................... 21

SCRAPPING .................................................................................................................................................................. 22

1465374000(B)10-2013.indb 1 01/12/2017 15:00:05