Advanced Motion Controls 12A8 Assembly instructions

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Advanced Motion Controls 12A8E at our website: Click HERE

Everything’s possible.

www.a-m-c.com

Hardware

Installation Manual

AZ Analog Drives

for Servo Systems

MNALAZIN-02 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 ii

Preface

ADVANCED Motion Controls constantly strives to improve all of its products. We review the information in

this document regularly and we welcome any suggestions for improvement. We reserve the right to modify

equipment and documentation without prior notice.

For the most recent software, the latest revisions of this manual, and copies of compliance and

declarations of conformity, visit the company’s website at www.a-m-c.com. Otherwise, contact the

company directly at:

ADVANCED Motion Controls •3805 Calle Tecate Camarillo, CA •93012-5068 USA

Agency Compliances

The company holds original documents for the following:

•UL 508c, file number E140173

•Electromagnetic Compatibility, EMC Directive - 2004/108/EC

EN61000-6-2:2001

EN61000-6-4:2001

EN61000-3-2:2000

EN61000-3-3:1995/A1:2001

•Electrical Safety, Low Voltage Directive - 72/23/EEC

EN 60 204-1 (IEC 60 204-1)

•Reduction of Hazardous Substances (RoHS), 2002/95/EC

Trademarks

ADVANCED Motion Controls™, the combined isosceles trapezoid/right triangle logo, DIGIFLEX®,

DIGIFLEX® Performance™ and DriveWare™ are either registered trademarks or trademarks of

ADVANCED Motion Controls in the United States and/or other countries. All other trademarks are the

property of their respective owners.

Related Documentation

•Product datasheet specific for your drive, available for download at www.a-m-c.com.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

/

iii MNALAZIN-02

Attention Symbols

The following symbols are used throughout this document to draw attention to important operating

information, special instructions, and cautionary warnings. The section below outlines the overall directive

of each symbol and what type of information the accompanying text is relaying.

Revision History

Document ID Revision # Date Changes

MNALAZIN-01 19/2008 AZ Install Manual First Release

MNALAZIN-02 210/31/2008 - Updated Pads Layout Diagram, Figure 3.4

- Updated Pin Layout Diagram, Figure 2.4

- Added Tachometer Velocity information (also see page 10, page 30, and page 33)

© 2008 ADVANCED Motion Controls. All rights reserved.

Note - Pertinent information that clarifies a process, operation, or ease-

of-use preparations regarding the product.

Notice - Required instruction necessary to ensure successful completion

of a task or procedure.

Caution - Instructs and directs you to avoid damaging equipment.

Warning - Instructs and directs you to avoid harming yourself.

Danger - Presents information you must heed to avoid serious injury or

death.

Note

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 iv

Contents

1 Safety 1

General Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Products and System Requirements 4

AZ Drive Family Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Drive Datasheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Products Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Current (Torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Open Loop (PWM Duty Cycle) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hall Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Encoder Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Tachometer Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Feedback Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Feedback Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hall Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using a Single Phase Motor with a Three Phase Drive . . . . 9

Encoder Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tachometer Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pin Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Single Phase (Brushed, Voice Coil, Inductive Load) Drives . . . . . . . 12

AZxxA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

AZxxA8DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Three Phase (Brushless) Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 v

/

AZBxxA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AZBExxA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AZBDCxxA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AZBHxxA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Specifications Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Motor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ambient Temperature Range and Thermal Data . . . . . . 17

Shock/Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Integration in the Servo System 18

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wire Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Motor Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Supply Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Feedback Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Input Reference Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Noise Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Line Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ferrite Suppression Cores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Inductive Filter Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mounting Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PCB Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mating Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Screw Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

PCB Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Trace Width and Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Interface Circuitry Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DC Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Motor Power Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hall Sensor Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 vi

/

Encoder Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tachometer Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Offset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 Operation 31

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Input/Output Pin Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Current Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Current Reference Output . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fault Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Inhibit Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Low Power Supply Output for Hall Sensors . . . . . . . . . . . . 32

Velocity Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Tachometer Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Current (Torque) Mode Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connections Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Input Command Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Hall Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Applying a Command (Analog Input) . . . . . . . . . . . . . . . 35

A Specifications 38

Specifications Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

B Troubleshooting 41

Fault Conditions and Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Over-Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Over-Voltage Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Under-Voltage Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Short Circuit Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Invalid Hall Sensor State (Brushless Drives only) . . . . . . . . . 42

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 vii

/

Inhibit Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Power-On Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Over-Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Motor Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Causes of Erratic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Drive Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Product Label Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Warranty Returns and Factory Help . . . . . . . . . . . . . . . . . . . . . . 45

Index I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 1

1 Safety

ThissectiondiscussescharacteristicsofyourAZAnalogDrivetoraiseyourawarenessofpotentialrisksand

hazards.Theseverityofconsequencesrangesfromfrustrationofperformance,throughdamagetoequipment,

injuryordeath.Theseconsequences,ofcourse,canbeavoidedbygooddesignandproperinstallationintoyour

mechanism.

General Safety Overview

You must install and operate motion control equipment so that you meet

all applicable safety requirements. Ensure that you identify the relevant

standards and comply with them. Failure to do so may result in damage

to equipment and personal injury.

Read this entire manual prior to attempting to install or operate the drive.

Become familiar with practices and procedures that allow you to

operate these drives safely and effectively. You are responsible for

determining the suitability of this product for the intended application.

The manufacturer is neither responsible nor liable for indirect or

consequential damages resulting from the inappropriate use of this

product.

High-performance motion control equipment can move rapidly with

very high forces. Unexpected motion may occur especially during

product commissioning. Keep clear of any operational machinery and

never touch them while they are working.

InordertoinstallanAZdriveintoaservosystem,youmusthaveathoroughknowledgeand

understandingofbasicelectronics,computersandmechanicsaswellassafetyprecautionsand

practicesrequiredwhendealingwiththepossibilityofhighvoltagesorheavy,strong

equipment.

Observeyourfacility’slock‐out/tag‐outproceduressothatworkcanproceedwithoutresidual

powerstoredinthesystemorunexpectedmovementsbythemachine.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Keep clear of all exposed power terminals (motor, DC Bus, shunt, DC

power, transformer) when power is applied to the equipment. Follow

these safety guidelines:

•Always turn off the main power and allow sufficient time for

complete discharge before making any connections to the drive.

•Do not rotate the motor shaft without power. The motor acts as a

generator and will charge up the power supply capacitors through

the drive. Excessive speeds may cause over-voltage breakdown in

the power output stage. Note that a drive having an internal power

converter that operates from the high voltage supply will become

operative.

•Do not short the motor leads at high motor speeds. When the motor is

shorted, its own generated voltage may produce a current flow as

high as 10 times the drive current. The short itself may not damage

the drive but may damage the motor. If the connection arcs or

opens while the motor is spinning rapidly, this high voltage pulse flows

back into the drive (due to stored energy in the motor inductance)

and may damage the drive.

•Do not make any connections to any internal circuitry. Only

connections to designated connectors are allowed.

•Do not make any connections to the drive while power is applied.

MNALAZIN-02 2

Safety / General Safety Overview

Do not reverse the power supply leads!

Severe damage will result!

Use sufficient capacitance!

Pulse Width Modulation (PWM) drives require a capacitor on the high

voltage supply to store energy during the PWM switching process.

Insufficient power supply capacitance causes problems particularly with

high inductance motors. During braking much of the stored mechanical

energy is fed back into the power supply and charges its output

capacitor to a higher voltage. If the charge reaches the drive’s over-

voltage shutdown point, output current and braking will cease. At that

time energy stored in the motor inductance continues to flow through

diodes in the drive to further charge the power supply capacitance. The

voltage rise depends upon the power supply capacitance, motor

speed, and inductance.

A 2μH motor at 20 amps can charge a 2000 μF capacitor an additional

30 VDC. An appropriate capacitance is typically 2000 μF/A maximum

output current for a 50 VDC supply.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 3

Safety / General Safety Overview

Make sure minimum inductance requirements are met!

Pulse Width modulation (PWM) servo drives deliver a pulsed output that

requires a minimum amount of load inductance to ensure that the DC

motor current is properly filtered. The minimum inductance values for

different drive types are shown in the individual data sheet

specifications. If the drive is operated below its maximum rated voltage,

the minimum load inductance requirement may be reduced. Most

servo-motors have enough winding inductance. Some types of motors

(e.g. "basket-wound", "pancake", etc.) do not have a conventional iron

core rotor, so the winding inductance is usually less than 50 μH.

If the motor inductance value is less than the minimum required for the

selected drive, use an external filter card.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 4

2 Products and System Requirements

Thisdocumentisintendedasaguideandgeneraloverviewinselecting,installing,andoperatinganAZservo

drive.Containedwithinareinstructionsonsystemintegration,wiring,drive‐setup,andstandardoperating

methods.

AZ Drive Family Overview

ThefamilyofAZanalogdrivesaredesignedtoofferthesamehighperformanceandaccuracy

oflargerdrives,butinaspace‐savingPCB‐mountarchitecture.Byutilizinghighdensitypower

devices,dualsidedPCBboards,andcreativedesignAZdrivesareidealforapplicationswith

limitedsizeandweightconstraints.

TheAZdrivefamilycontainsdrivesthatcanpowerSinglePhase(brushed)andThreePhase

(brushless)motors.AZdrivesarepoweredoffasingleunregulatedDCpowersupply,and

provideavarietyofcontrolandfeedbackoptions.Thedrivesaccepteithera+/‐10Vanalog

signaloraPWMandDirectionsignalasinput.Adigitalcontrollercanbeusedtocommandand

interactwithAZdrives,andanumberofinput/outputpinsareavailableforparameter

observationanddriveconfiguration.

Drive Datasheet

EachAZanalogdrivehasaseparatedatasheetthatcontainsimportantinformationonthe

modesandproduct‐specificfeaturesavailablewiththatparticulardrive.Thedatasheetistobe

usedinconjunctionwiththismanualforsystemdesignandinstallation.

In order to avoid damage to equipment, only after a thorough reading

and understanding of this manual and the specific datasheet of the AZ

drive being used should you attempt to install and operate the drive.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FIGURE 2.1 AZ Part Numbering Structure

A

Revision

Peak Voltage

Peak Current

-

Additional Options

Blank: Current Mode only

E: Encoder Velocity Mode Available

Maximum peak current rating in Amps Peak voltage rating scaled 1:10 in Volts

Assigned a letter (A through Z) by manufacturer

PWM Command

H: Hall velocity Mode Available

Brushed DriveBlank:

AZ Analog Drive Series

AZ

Drive Type

DDC: Brushed Drive, PWM Command

B: Brushless drive

BDC: Brushless Drive, PWM Command

Feedback Supported

MNALAZIN-02 5

Products and System Requirements / Products Covered

Products Covered

Theproductscoveredinthismanualadheretothefollowingpartnumberingstructure.

However,additionalfeaturesand/oroptionsarereadilyavailableforOEM’swithsufficient

orderingvolume.FeelfreetocontactADVANCEDMotionControlsforfurtherinformation.

Ingeneral,theAZfamilyofanalogdrivescanbedividedintotop‐levelcategoriesbasedonthe

peakcurrentratingofthedrive.Thesecategoriescanbefurtherseparatedintosubdivisions

basedonspecificationssuchaswhetheradriveusesanalogorPWMinput,thetypeof

motor(s)supported,andthefeedbackavailableonthedrive.

TABLE 2.1 Power Specifications

Power Specifications

Description Units AZxx6A8 AZxx12A8 AZxx20A8

DC Supply Voltage Range VDC 20-80 10-80

DC Bus Over Voltage Limit VDC 88

DC Bus Under Voltage Limit VDC 18 9

Maximum Peak Output Current A 6 12 20

Maximum Continuous Output Current A 3 6 12

Maximum Power Dissipation at Continuous Current W12 24 48

Minimum Load Inductance μH100

Switching Frequency kHz 31

TABLE 2.2

Control Specifications

Description AZ AZB AZ_DDC AZBDC AZBE AZBH

Command Sources +/- 10V Analog +/- 10V Analog PWM and Direction PWM and Direction +/- 10V Analog +/- 10V Analog

Commutation Methods -Trapezoidal -Trapezoidal Trapezoidal Trapezoidal

Control Modes Current Current Current Current Current, Open Loop, Encoder

Velocity, Tachometer Velocity

Current, Open Loop, Hall

Velocity, Tachometer Velocity

Motors Supported Single Phase Three Phase

Single Phase Single Phase Three Phase

Single Phase

Three Phase

Single Phase

Three Phase

Single Phase

Control Specifications

The values and diagrams presented in this chapter are a general drive

"overview". For more detailed information, consult the datasheet for a

specific drive.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 6

Products and System Requirements / Control Modes

Control Modes

TheAZfamilyofanalogdrivesoffersavarietyofdifferentcontrolmethods.Whilesomedrives

intheseriesaredesignedtooperatesolelyinonemode,onotherdrivesitispossibletoselect

thecontrolmethodbyDIPswitchsettings.Consultthedatasheetforthedriveinusetosee

whichmodesareavailableforuse.

Thenameofthemodereferstowhichservoloopisbeingclosedinthedrive,nottheend‐result

oftheapplication.Forinstance,adriveoperatinginCurrent(Torque)Modemaybeusedfora

positioningapplicationiftheexternalcontrollerisclosingthepositionloop.Oftentimes,mode

selectionwillbedependentontherequirementsandcapabilitiesofthecontrollerbeingused

withthedriveaswellastheend‐resultapplication.

Current (Torque)

InCurrent(Torque)Mode,theinputcommandvoltagecontrolstheoutputcurrent.Thedrive

willadjusttheoutputdutycycletomaintainthecommandedoutputcurrent.Thismodeisused

tocontroltorqueforrotarymotors(forceforlinearmotors),butthemotorspeedisnot

controlled.Theoutputcurrentcanbemonitoredthroughananalogcurrentmonitoroutput

pin.Thevoltagevaluereadatthe“CurrentMonitorOutput”canbemultipliedbyascaling

factorfoundonthedrivedatasheettodeterminetheactualoutputcurrent.AllAZdrivesare

abletooperateinCurrent(Torque)Mode.

While in Current (Torque) Mode, the drive will maintain a commanded

torque output to the motor based on the input reference command.

Sudden changes in the motor load may cause the drive to be outputting

a high torque command with little load resistance, causing the motor to

spin rapidly. Therefore, Current (Torque) Mode is recommended for

applications using a digital position controller to maintain system stability.

Open Loop (PWM Duty Cycle)

InOpenLoop(PWMDutyCycle)Mode,theinputcommandvoltagecontrolstheoutputPWM

dutycycleofthedrive,indirectlycontrollingtheoutputvoltage.However,anyfluctuationsof

theDCpowersupplyvoltagewillaffectthevoltageoutputtothemotor.Thismodeisavailable

asaDIPswitchselectablemodeonAZBExxA8andAZBHxxA8drives.

This mode is recommended as a method of controlling the motor

velocity when precise velocity control is not critical to the application,

and when actual velocity feedback is unavailable.

Hall Velocity

InHallVelocityMode,theinputcommandvoltagecontrolsthemotorvelocity,withtheHall

Sensorfrequencyclosingthevelocityloop.Ananalogvelocitymonitoroutputallows

observationoftheactualmotorspeedthroughaHz/Vscalingfactorfoundonthedrive

datasheet.Thevoltagevaluereadatthevelocitymonitoroutputcanbeusedtodeterminethe

Note

Note

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 7

Products and System Requirements / Control Modes

motorRPMthroughthescalingfactor.See“VelocityMonitorOutput”onpage33forthemotor

RPMequation.ThismodeisavailableasaDIPswitchselectablemodeonAZBHxxA8drives.

Due to the inherent low resolution of motor mounted Hall Sensors, Hall

Velocity Mode is not recommended for low-speed applications below

300 rpm for a 6-pole motor, 600 rpm for a 4-pole motor, or 900 rpm for a

2-pole motor. Hall Velocity Mode is better suited for velocity control

applications where the motor will be spinning at higher speeds.

Encoder Velocity

InEncoderVelocityMode,theinputcommandcontrolsthemotorvelocity,withthefrequency

oftheencoderpulsesclosingthevelocityloop.Ananalogvelocitymonitoroutputallows

observationoftheactualmotorspeedthroughakHz/Vscalingfactorfoundonthedrive

datasheet.Thevoltagevaluereadatthevelocitymonitoroutputcanbeusedtodeterminethe

motorRPMthroughthescalingfactor.See“VelocityMonitorOutput”onpage33forthemotor

RPMequation.ThismodeisavailableasaDIPswitchselectablemodeonAZBExxA8drives.

The high resolution of motor mounted encoders allows for excellent

velocity control and smooth motion at all speeds. Encoder Velocity

mode should be used for applications requiring precise and accurate

velocity control, and is especially useful in applications where low-speed

smoothness is the objective.

Tachometer Velocity

InTachometerVelocityMode,theinputcommandvoltagecontrolsthemotorvelocity.This

modeusesanexternalDCtachometertoclosethevelocityloop.ThedrivetranslatestheDC

voltagefromthetachometerintomotorspeedanddirectioninformation.Thismodeis

availableasaDIPswitchselectablemodeonAZBExxA8andAZBHxxA8drives.

DC Tachometers have infinite resolution, allowing for extremely accurate

velocity control. However, they also may be susceptible to electrical

noise, most notably at low speeds.

Note

Note

Note

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 8

Products and System Requirements / Feedback Supported

Feedback Supported

ThereareanumberofdifferentfeedbackoptionsavailableintheAZfamilyofanalogdrives.

Thefeedbackelementcanbeanydevicecapableofgeneratingavoltagesignalproportionalto

current,velocity,position,oranyparameterofinterest.Suchsignalscanbeprovideddirectly

byapotentiometerorindirectlybyotherfeedbackdevicessuchasHallSensorsorEncoders.

TheselatterdevicesmusthavetheirsignalsconvertedtoaDCvoltage,ataskperformedbythe

AZdrivecircuitry.

TABLE 2.3 Feedback Supported

Feedback Supported

Description AZ AZB AZ_DDC AZBDC AZBE AZBH

Hall Sensors for Commutation D D D D

Hall Sensors for Velocity Control D

Single- Ended Incremental Encoder D

Feedback Polarity

Thefeedbackelementmustbeconnectedfornegativefeedback.Thiswillcauseadifference

betweenthecommandsignalandthefeedbacksignal,calledtheerrorsignal.Thedrive

comparesthefeedbacksignaltothecommandsignaltoproducetherequiredoutputtothe

loadbycontinuallyreducingtheerrorsignaltozero.ForAZdrives,thisbecomesimportant

whenusing“EncoderFeedback”and“HallSensors”,asconnectingthesefeedbackelements

forpositivefeedbackwillleadtoamotor"run‐away"condition.Inacasewherethefeedback

linesareconnectedtothedrivewiththewrongpolarityineitherHallVelocityorEncoder

VelocityMode,thedrivewillattempttocorrectthe"errorsignal"byapplyingmorecommand

tothemotor.Withthewrongfeedbackpolarity,thiswillresultinapositivefeedbackrun‐away

condition.Tocorrectthis,eitherchangetheorderthatthefeedbacklinesareconnectedtothe

drive,orchangeSwitch4ontheDIPswitchbanktotheoppositesettingtoreversetheinternal

feedbackvelocitypolarity.SeethedrivedatasheetformoreinformationonDIPswitchsettings.

Hall Sensors

DCThreePhase(Brushless)AZdrivesusesingle‐endedHallSensorsforcommutation

feedback,andinthespecialcaseoftheAZBHxxA8drives,forvelocitycontrol.TheHallSensors

(typicallythree)arebuiltintothemotortodetectthepositionoftherotormagneticfield.These

sensorsaremountedsuchthattheyeachgenerateasquarewavewith120‐degreephase

differenceoveroneelectricalcycleofthemotor.Dependingonthemotorpolecount,there

maybemorethanoneelectricalcycleforeverymotorrevolution.Foreveryactualmechanical

motorrevolution,thenumberofelectricalcycleswillbethenumberofmotorpolesdividedby

2.Forexample:

•a6‐polemotorcontains3electricalcyclespermotorrevolution

•a4‐polemotorcontains2electricalcyclespermotorrevolution

•a2‐polemotorcontains1electricalcyclepermotorrevolution.

ThedrivepowerstwoofthethreemotorphaseswithDCcurrentduringeachspecificHall

Sensorstate:

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FIGURE 2.2 Hall Sensor Commutation and Motor Phase Current for 120-Degree Phasing

Electrical Degrees

Motor Phase

Current

060 120 180 240 300 360

Hall A

Hall B

Hall C

High (1)

Low (0)

High (1)

Low (0)

High (1)

Low (0)

Phase A

Phase B

Phase C

Hall Sensor

Commutation

Electrical Degrees

060 120 180 240 300 360

High

Low

High

Low

High

Low

MNALAZIN-02 9

Products and System Requirements / Feedback Supported

Thetablebelowshowsthevalidcommutationstatesforboth120‐degreeand60‐degree

phasing.

TABLE 2.4 Commutation Sequence Table

60 Degree 120 Degree Motor

Hall 1 Hall 2 Hall 3 Hall 1 Hall 2 Hall 3 Phase A Phase B Phase C

Valid

1 0 0 1 0 0 HIGH -LOW

1 1 0 1 1 0 - HIGH LOW

1 1 1 0 1 0 LOW HIGH -

0 1 1 0 1 1 LOW -HIGH

0 0 1 0 0 1 - LOW HIGH

0 0 0 1 0 1 HIGH LOW -

Invalid 1 0 1 1 1 1 - - -

0 1 0 0 0 0 - - -

Bydefault,AZdrivesarealwayssetto120‐degreephasing.Threephase(Brushless)drivesdo

howeverhaveasurface‐mountjumper(JE2)onthedrivePCBthatcanberemovedto

manuallysetthedriveto60‐degreephasing.

Using a Single Phase Motor with a Three Phase Drive ThreePhase(Brushless)

drivesarealsocompatiblewithSinglePhase(Brushed)motors.However,becausethereareno

HallSensorsonabrushedmotor,oneofthefollowingcourseofactionsmustbetakento

properlycommutatethedrive:

•RemovetheJE2jumpertosetthedrivefor60‐degreephasing.LeavealltheHallSensor

inputsonthedriveopen.Theseinputsareinternallypulledhighto+5V,creatinga"1‐1‐1"

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 10

Products and System Requirements / Feedback Supported

commutationstate(seeTable2.4above)whichisavalidstatein60‐degreephasing.

Connectonlytwoofthemotoroutputwires,MotorAandMotorB.

or:

•TieoneoftheHallSensorinputsontheAZdrivetosignalground.SincetheHallSensor

inputsarebydefaultinternallybroughthighto+5V,thiswillputtheAZdriveina

commutationstatewheretwoHallinputsarehigh,andoneislow(asshowninTable2.4,

havingallthreeHallinputspulledhighisaninvalidcommutationstatein120‐degree

phasing).DependingonwhichHallSensorinputistiedtoground,consultTable2.4above

todeterminewhichtwomotoroutputwireswillbeconductingcurrentforthatspecific

commutationstate.

FIGURE 2.3 Encoder Feedback Signals

Encoder-A

Encoder-B

Encoder-A

Encoder-B

Example 1: Encoder-A precedes

Encoder-B. The pulses arrive at

a certain frequency, providing

speed and directional

information to the drive.

Example 2: Encoder-B precedes

Encoder-A, meaning the direction

is opposite from Example 1. The

signal frequency is also higher,

meaning the speed is greater

than in Example 1.

Encoder Feedback

AZBExxA8drivesutilizetwosingle‐endedincrementalencoderinputsforvelocitycontrol.The

encoderprovidesincrementalpositionfeedbackthatcanbeextrapolatedintoveryprecise

velocityinformation.Theencodersignalsarereadas"pulses"thattheAZdriveusesto

essentiallykeeptrackofthemotor’spositionanddirectionofrotation.Basedonthespeedand

orderinwhichthesepulsesarereceivedfromthetwoencodersignals,thedrivecaninterpret

themotorvelocity.Thediagrambelowrepresentsencoder"pulse"signals,showinghow

dependentonwhichsignalisreadfirstandatwhatfrequencythe"pulses"arrive,thespeed

anddirectionofthemotorshaftcanbeextrapolated.

Tachometer Feedback

AZBExxA8andAZBHxxA8drivesoffertheoptionofusingaDCTachometerforvelocitycontrol.

ThetachometerprovidesananalogDCvoltagefeedbacksignalthatisrelatedtotheactual

motorspeedanddirection.Thedrivesubsequentlyadjuststheoutputcurrentbasedonthe

errorbetweenthetachometerfeedbackandtheinputcommandvoltage.Themaximumrange

ofthetachometerfeedbacksignalis±60VDC.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FIGURE 2.4 AZ-series Pin Layouts

PIN 1b PIN 1a

PIN 11a

PIN 11b

PIN 1

PIN 16

P1 - Signal

Connector

P2 - Power

Connector

0.10in [2.54mm]

[55.88mm]

2.20in

0.10in [2.54mm]

PIN 1

PIN 11

PIN 16

P1 - Signal

Connector

P2 - Power

Connector

PIN 1

[2.54mm]

[55.88mm]

2.20in

0.10in

AZ6andAZ12Drives AZ20Drives

MNALAZIN-02 11

Products and System Requirements / Pin Layout

Pin Layout

ThediagramsbelowshowthepinlayoutandlocationonAZdrives,asseenfromthePCB

wherethedriveismounted.NotethatAZ20drivesusesadoublerowforthepowerheader.

Moredetaileddimensionalinformationcanbefoundin“PhysicalDimensions”onpage39and

in“MatingConnectors”onpage24.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MNALAZIN-02 12

Products and System Requirements / Single Phase (Brushed, Voice Coil, Inductive Load) Drives

Single Phase (Brushed, Voice Coil, Inductive Load) Drives

AZxxA8

•Designedtodrivebrush‐typemotors

witha+/‐10Vanaloginput.

•Current(Torque)Mode

AZxxA8DDC

•Designedtodrivebrush‐typemotors

withaPWMinputcommand.

•Current(Torque)Mode

Block Diagrams

+/-10 V Analog

Input

Current Feedback

Motor Feedback

Brushed

Motor

Current Command

Drive

Logic

Power Stage

AZ SERVO DRIVE

Controller

PWM Input

Current Feedback

Current Command

Drive

Logic

Power Stage

Brushed

Motor

AZ Servo Drive

Controller

FIGURE 2.5.1 AZxxA8DDC Drive Structure

FIGURE 2.5 AZxxA8 Drive Structure

Pinouts

AZ6/AZ12/AZ20

Analog Command

AZ6/AZ12/AZ20

PWM Command

Pin Description Description

1 +REF IN PWM IN

2 SIGNAL GROUND SIGNAL GROUND

3−REF IN DIR IN

4 CURRENT MONITOR CURRENT MONITOR

5 INHIBIT IN INHIBIT IN

6 RESERVED RESERVED

7 SIGNAL GROUND SIGNAL GROUND

8 RESERVED RESERVED

9 RESERVED RESERVED

10 RESERVED RESERVED

11 CURRENT REF OUT CURRENT REF OUT

12 FAULT OUT FAULT OUT

13 RESERVED RESERVED

14 RESERVED RESERVED

15 RESERVED RESERVED

16 RESERVED RESERVED

AZ6 / AZ12

All Configurations

Pin Description

1HIGH VOLTAGE

2

3 NC (KEY)

4POWER

GROUND

5

6RESERVED

7

8MOTOR B

9

10 MOTOR A

11

AZ20

All Configurations

Pin Description

1b 1a HIGH VOLTAGE

2b 2a

3b 3a RESERVED (3B)

NC - KEY (3a)

4b 4a POWER

GROUND

5b 5a

6b 6a RESERVED

7b 7a

8a 8b MOTOR B

9b 9a

10b 10a MOTOR A

11b 11a

TABLE 2.5.1 Single Phase Power Connector

TABLE 2.5 Single Phase Signal Connector

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents

Popular Servo Drive manuals by other brands

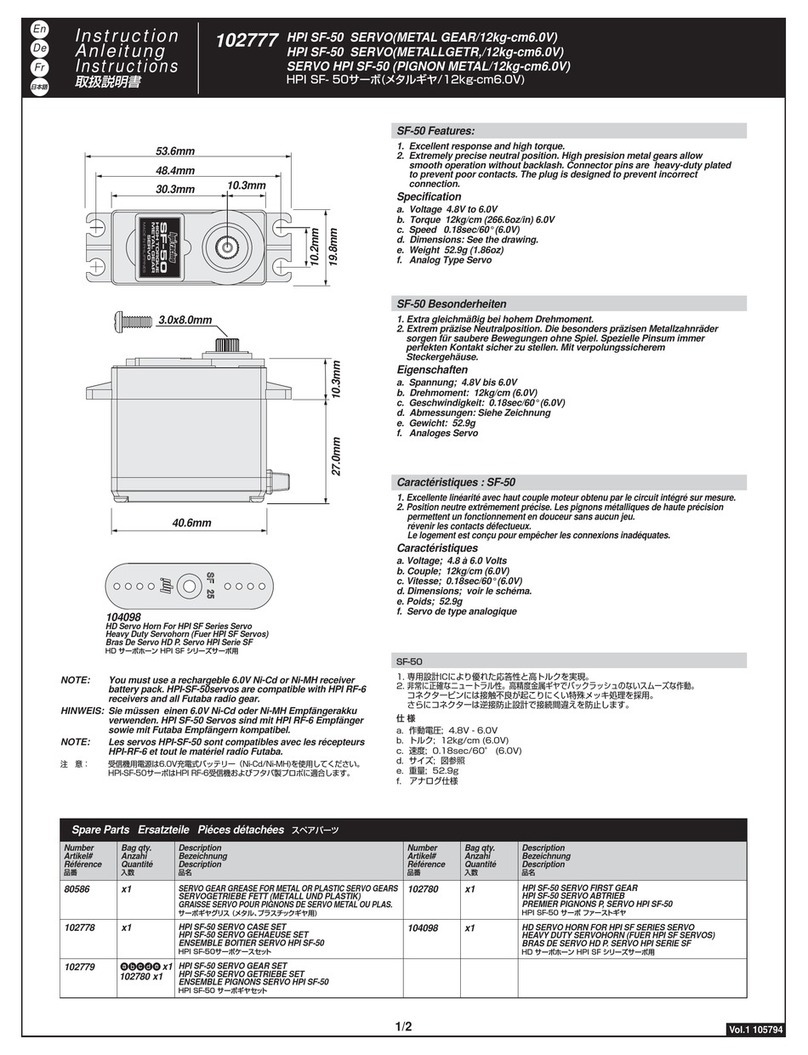

HPI Racing

HPI Racing SF-50 instructions

Dongbu Robot

Dongbu Robot HERKULEX DRS-0101 user manual

Leadshine Technology Co.

Leadshine Technology Co. DCS303 user manual

Kinco

Kinco CD420 user manual

NTI AG

NTI AG LinMot C1250 Series installation guide

Mitsubishi Electric

Mitsubishi Electric MR-JET- G Series user manual