Cello Installation Guide Table of Contents

MAN-CELIG (Ver. 1.6) 6

3.4.8. I/O Cables ................................................................................................. 46

3.4.8.1. General I/O Port (J1)................................................................ 46

3.4.8.2. General Input Port (J2) ............................................................ 48

3.4.9. Communication Cables............................................................................. 50

3.4.9.1. RS-232 Communication ........................................................... 50

3.4.9.2. CANopen Communication ....................................................... 51

3.5. Powering Up ............................................................................................................ 53

3.6. Initializing the System.............................................................................................. 53

Chapter 4: Technical Specifications ............................................................................ 54

4.1. Features................................................................................................................... 54

4.1.1. Motion Control Modes ............................................................................. 54

4.1.2. Advanced Positioning Motion Control Modes ......................................... 54

4.1.3. Advanced Filters and Gain Scheduling...................................................... 54

4.1.4. Fully Programmable.................................................................................. 54

4.1.5. Feedback Options ..................................................................................... 55

4.1.6. Input/Output ............................................................................................ 55

4.1.7. Built-In Protection .................................................................................... 56

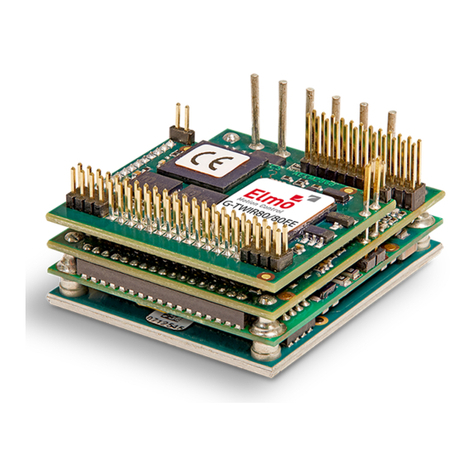

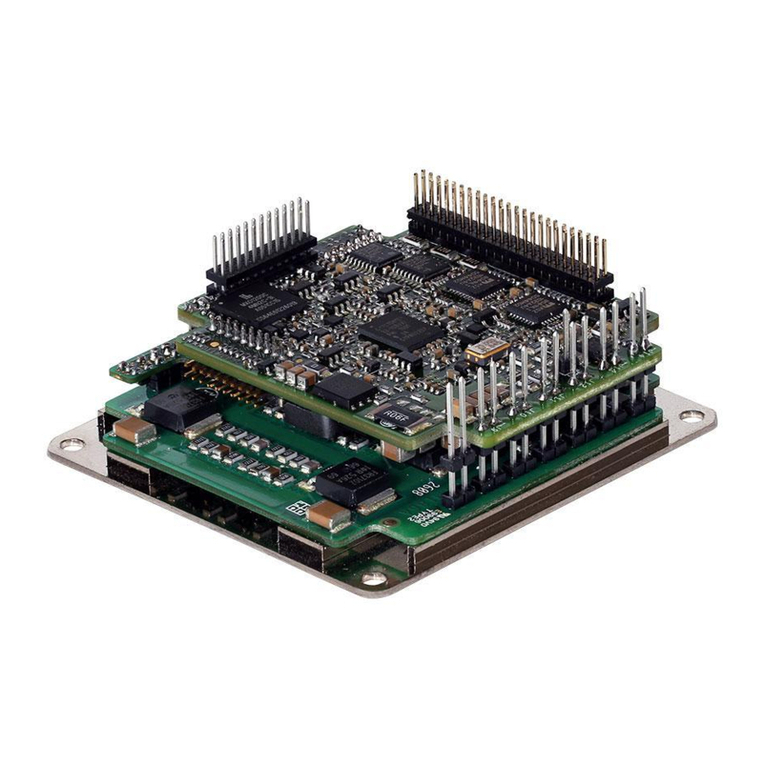

4.2. Cello Dimensions ..................................................................................................... 57

4.3. Power Ratings.......................................................................................................... 58

4.4. Environmental Conditions....................................................................................... 58

4.5. Cello Connections.................................................................................................... 59

4.5.1. Backup Supply (Optional) ......................................................................... 60

4.6. Control Specifications.............................................................................................. 60

4.6.1. Current Loop............................................................................................. 60

4.6.2. Velocity Loop ............................................................................................ 61

4.6.3. Position Loop ............................................................................................ 61

4.7. Feedbacks ................................................................................................................ 62

4.7.1. Feedback Supply Voltage.......................................................................... 62

4.7.2. Incremental Encoder Input....................................................................... 62

4.7.3. Digital Halls ............................................................................................... 63

4.7.4. Interpolated Analog (Sine/Cosine) Encoder ............................................. 63

4.7.5. Resolver .................................................................................................... 64

4.7.6. Tachometer............................................................................................... 64

4.7.7. Potentiometer .......................................................................................... 65

4.7.8. Encoder Outputs....................................................................................... 65

4.8. I/Os .......................................................................................................................... 65

4.8.1. Digital Input Interfaces ............................................................................. 66

4.8.2. Digital Output Interface............................................................................ 67

4.8.3. Analog Input ............................................................................................. 68

4.9. Communications...................................................................................................... 68

4.10. Pulse-Width Modulation (PWM)............................................................................. 68

4.11. Mechanical Specifications ....................................................................................... 68

4.12. Compliance with Standards..................................................................................... 69