Advanced Power technologies TTC-1000 Installation instructions manual

V6.230 20131017

TTC

-

1000

Transformer Temperature Controller

Instruction & Operation Manual

1

-

3 Temperature Probes

4,

6

, or 8

Outputs

9

CT Input

s

14

Digital Inputs

Tap Position Monitoring

Firmware version 6.

23

X

215 State Route 10, Building 2

Randolph, NJ 0

7869

Phone: (973) 328

-

3300

Fax: (973) 328

-

0666

Website: advpowertech.com

e

-

mail: info@advpowertech.com

(T

his manual applies to firmware versions

6.

23

X

)

Advanced Power Technologies

Table of Contents

V6.230 20131017

i

1

INTRODUCTION

................................

................................

...........................

1

2

PRODUCT DESCRIPTION

................................

................................

............

3

2.1

Controls & Indicators

................................

................................

..............

3

2.2

Connection Overview

-

Panel Mount Unit

................................

................

4

2.3

Rear Layout

-

Panel Mount Unit

................................

..............................

5

2.4

Connections Overview

-

NEMA Enclo

sure

................................

.............

6

2.5

Rear Panel Layout

-

NEMA Enclosure

................................

....................

7

2.6

Specifications

................................

................................

.........................

8

2.7

Part Number Details

................................

................................

.............

10

3

INSTALLATION and CONNECTIONS

................................

.........................

11

3.1

Mounting the NEMA Enclosure

................................

.............................

11

3.2

Power Hookup

................................

................................

......................

1

2

3.3

Temperature Probes

................................

................................

.............

13

3.3.1

TTC

-

PROBE

-

01 Installation

................................

..........................

13

3.3.2

TTC

-

PROBE

-

11 Installation

................................

..........................

14

3.3.3

Magnetic Mount Probe (TTC

-

PROBE

-

02) Installation

...................

15

3.3.4

Probe Lead Connections

................................

...............................

16

3.3.5

Applying a Backup Temperature Pr

obe

................................

.........

18

3.4

Auxiliary CT Input for Calculated Winding Temperature

.......................

18

3.5

Cooling Control and Condition Alarm Connections

...............................

20

3.6

Unit Alarm Connections

................................

................................

........

21

3.7

Telemetry Connections

................................

................................

.........

22

3.7.1

RS

-

232 Terminal Connections

................................

......................

22

3.7.2

Analog Outputs

................................

................................

..............

22

3.7.3

RS

-

485 for DNP3.0 or MODBUS Communications

.......................

24

3.7.4

Fiber Optic Interface for DNP3.0 or MODBUS Communications

...

25

3.7.5

Setting Repeat Mode on Fiber Optic Channel

...............................

27

3.8

Optically Isolated Inputs

................................

................................

........

28

3.9

Heater Connections

................................

................................

..............

29

3.10

Shield Drain Wire Grounding

................................

................................

29

4

SETTINGS

................................

................................

................................

...

31

Table of Contents

V6.230 20131017

ii

4.1

Programming Settings Through the Front Panel

................................

..

31

4.2

Programming Settings Through a PC

................................

...................

32

4.3

Firmware Version from the Front Panel

................................

................

39

4.4

Settings for Calculated Winding Temperature

................................

......

39

4.4.1

CT RATIO

................................

................................

......................

41

4.4.2

Rated Load

................................

................................

....................

41

4.4.3

Hot Spot Rise over Top Oil

................................

............................

42

4.4.4

Winding Rise Time Constant

................................

.........................

42

4.4.5

Calculated Winding Exponent Setting

................................

...........

43

4.4.6

Checking Winding Temperature

................................

....................

43

4.5

Probe Names

................................

................................

........................

45

4.5.1

Setting Probe Names

................................

................................

....

45

4.5.2

Setting Winding Names

................................

................................

.

46

4.5.3

Setting Load Names

................................

................................

......

47

4.6

Temperature Set Points

................................

................................

........

48

4.6.1

Setting Liquid Pickup and Drop Out Temperatures

.......................

50

4.6.2

Setting Calculated Winding Pickup and Dropo

ut Temperatures

....

51

4.7

Load Pickup Set Points

................................

................................

.........

52

4.7.1

Setting Load Pickup Set Point

................................

.......................

54

4.7.2

Setting Load Pickup Timer

................................

............................

55

4.8

Optically

Isolated Input Settings

................................

...........................

55

4.9

Programmable Logic Settings

................................

...............................

58

4.9.1

Assigning Liquid Temperature Set Points

................................

......

59

4.9.2

Assigning Winding Temperature Set Points

................................

..

61

4.9.3

Assigning Load Pickup Set Points

................................

.................

62

4.9.4

Assigning IN1 through IN14

................................

...........................

63

4.9.5

Assigning Outputs

................................

................................

.........

65

4.9.6

Time Set Points

................................

................................

.............

66

4.9.6.1

Time Set Point Settings

................................

..........................

67

4.9.6.2

Time Set Point Counter Settings

................................

............

68

4.9.7

Setting Output Timers

................................

................................

....

68

Table of Contents

V6.230 20131017

iii

4.9.8

Setting Output Invert

................................

................................

......

69

4.9.9

Application Examples

................................

................................

....

70

4.9.9.1

Commanding the cooling fans:

................................

...............

71

4.9.9.2

Periodic exercise of cooling fans:

................................

...........

72

4.9.9.3

Cooling Fan Alarm:

................................

................................

.

72

4.10

Setting Output Control With Alarm

................................

........................

73

4.11

Alternate Fan Banks

................................

................................

.............

75

4.12

Auto and Manual Control

................................

................................

......

76

4.13

Setting Control of Unit A

larm

................................

................................

77

4.13.1

Device Alarm Setting

................................

................................

.....

77

4.13.2

Temperature Probe Alarm Setting

................................

.................

78

4.13.3

Manual Mode Alarm Setting

................................

..........................

79

4.13.4

Winding Circ

uit Alarm Setting

................................

........................

79

4.14

Setting Date and Time

................................

................................

..........

80

4.14.1

Setting Time and Date Via the Front Panel

................................

...

80

4.14.2

Setting Time and Date Via the PC

................................

.................

81

4.15

Setting Password

................................

................................

..................

81

4.16

Setting Unit ID

................................

................................

......................

82

5

TAP CHANGER POSITION MONITORING (TPM)

................................

......

83

5.1

Basic Operation

................................

................................

....................

83

5.1.1

Minim

al Configuration

................................

................................

....

83

5.1.2

Full Configuration

................................

................................

..........

84

5.2

Programming Items

................................

................................

..............

85

5.2.1

Inputs

................................

................................

.............................

85

5.2.2

Start Position

................................

................................

.................

85

5.2.3

Raise and Lower limits

................................

................................

..

85

5.2.4

TLIM

................................

................................

..............................

86

5.2.5

OFFTAP Timeout

................................

................................

..........

86

5.2.6

OFFT

................................

................................

.............................

86

5.2.7

OP FAIL TIMEOUT

................................

................................

........

86

5.2.8

OPFL

................................

................................

.............................

86

Table of Contents

V6.230 20131017

iv

5.2.9

Freq Alarm Counter

................................

................................

.......

86

5.2.10

Freq Alarm Per

................................

................................

..............

86

5.2.11

FREQ

................................

................................

............................

86

5.2.12

Offtap, Raise and Lower Inputs

................................

.....................

87

5.2.13

Upper Limit Input

................................

................................

...........

87

5.2.14

Lower Limit Input

................................

................................

...........

87

5.2.15

Reset Input

................................

................................

....................

87

5.2.16

Input Contacts

................................

................................

...............

87

5.2.17

Tap Info

................................

................................

.........................

88

5.3

Configuring TPM Settings through Front Panel

................................

....

88

5.4

Configuring TPM Settings through RS232 on PC

................................

.

89

5.4.1

Tap Changer Position Monitoring Status and

Statistics

.................

89

5.5

Tap Changer Position Monitoring Targets

................................

............

90

6

Dual Algorithm LTC Condition Monitoring

................................

....................

91

6.1

Detection of Slowly Evolving Problems

................................

.................

92

6.1.1

Setting LTCDIFF Set Point

................................

............................

94

6.1.2

Setting LTCDIFF Pickup Timer

................................

......................

95

6.1.3

Assigning LTCDIFF for LTC Condition Monitoring Alarm

..............

95

6.2

Detection of

Quickly Evolving Problems

................................

...............

97

6.2.1

Setting LTCDIFF Rise

................................

................................

...

98

6.2.2

Setting LTCDIFF Rate

................................

................................

...

98

7

TELEMETRY OPTIONS

................................

................................

..............

99

7.1

Analog Outputs

................................

................................

.....................

99

7.1.1

Setting the Analog Output Range

................................

................

102

7.1.2

Setting the Analog Source

................................

...........................

103

7.1.3

Enabling Negative Scaling

................................

...........................

104

7.2

DNP3.0 and MODBUS

................................

................................

.......

104

7.2.1

Setting BAUD Rate

................................

................................

......

106

7.2.2

Setting NODE Address

................................

................................

107

7.2.3

Setting Remote Blocking

................................

.............................

108

7.3

Telemetry Via RS232

................................

................................

..........

108

Table of Contents

V6.230 20131017

v

8

VIEW TEMPERATURES

................................

................................

...........

111

8.1

View Scrolling Display

................................

................................

........

111

8.2

Reset Min/Max

................................

................................

....................

111

8.3

Reset LTCDIFF Rate of Rise

................................

..............................

113

8.4

Re

set TPM Targets

................................

................................

............

113

8.5

Reset Overall TPM Counter

................................

................................

113

9

View Settings

................................

................................

.............................

115

9.1

View Settings Via Front Panel

................................

............................

11

5

9.2

View Settings Via PC

................................

................................

..........

116

10

STATUS

................................

................................

................................

.

123

10.1

View Status Via Front Panel

................................

...............................

123

10.2

View Status Via PC

................................

................................

............

123

11

SETTING FILES

................................

................................

.....................

125

1

1.1

Upload Setting Files

................................

................................

...........

125

11.1.1

Upload Settings Using HyperTerminal

................................

.........

125

11.1.2

Upload Settings Using HyperAccess

................................

...........

126

11.2

Download Setting Files

................................

................................

.......

127

11.2.1

Download Settings Using HyperTerminal

................................

....

127

11.2.2

Download Settings Using HyperAccess

................................

......

128

11.2.3

Download Settings Using a *.csv Template With HyperTerminal

128

11.2.4

Download Settings Using a *.csv Template With HyperAccess

...

129

12

DATA LOGGING

................................

................................

....................

131

12.1

Data Storage

................................

................................

......................

131

12.2

Data Points

................................

................................

.........................

132

12.3

Setting the Time Base

................................

................................

........

132

12.4

Selecting Data Points

................................

................................

.........

133

12.4.1

Add or Delete P1 From Log

................................

.........................

133

12.4.2

Add or Delete P2 From Log

................................

.........................

133

12.4.3

Add or Delete P3 From Log

................................

.........................

134

12.4.4

Add or Delete Calculated Winding 1 From Log

...........................

134

12.4.5

Add or Delete Load1 From Log

................................

...................

135

Table of Contents

V6.230 20131017

vi

12.4.6

Add or Delete

Tap Position From Log

................................

.........

135

12.5

Viewing the Data Log

................................

................................

.........

136

12.6

Import Data Log Using HyperTerminal

................................

...............

137

12.7

Import to Excel

................................

................................

....................

138

13

DOWNLO

AD PROGRAM UPDATES

................................

.....................

143

13.1

Download Firmware Using HyperTerminal

................................

.........

144

13.2

Download Firmware HyperAccess

................................

......................

145

14

FRONT PANEL SETTINGS WORKSHEETS

................................

.........

147

14.1

SETPOINT MENU FRONT PANEL SETTINGS WORKSHEET

.........

147

14.2

CFG MENU FRONT PANEL SETTINGS WORKSHEET

....................

164

14.3

TPM MENU FRONT PANEL SETTINGS WORKSHEET

....................

173

15

PC SETTINGS WORKSHEETS

................................

.............................

189

15.1

SETPOINT MENU SETTINGS WORKSHEET

................................

...

189

15.2

CONFIGURATION MENU SETTINGS WORKSHEET

.......................

209

15.3

DIGITAL INPUTS AND TAP POSITION MONITOR WOR

KSHEET

..

217

16

Creating Setting Using an Excel CSV file

................................

...............

235

17

DNP3.0 PROFILE DOCUMENTS and TTC

-

1000 DATA MAPS

.............

237

17.1

DNP3.0 Device Profile Document

................................

.......................

237

17.2

TTC

-

1000 Data Map

................................

................................

...........

241

17.3

MODBUS RTU POINT MAP

................................

...............................

244

Table of Figures

V6.230 20131017

vii

Figure 2.1: Front Panel

................................

................................

.........................

3

Figure 2.2: Panel Mount Conn

ection Overview

................................

.....................

4

Figure 2.3: Panel Mount Rear Layout

................................

................................

...

5

Figure 2.4: NEMA Mount Connection Overview

................................

...................

6

Figure 2.5: NEMA Mount Rear Panel Layout

................................

........................

7

Table 2.1: Ordering Options

................................

................................

................

10

Figure 3.1: NEMA 4X Mounting

................................

................................

..........

11

Figure 3.2: Mounting Bracket

................................

................................

..............

12

Figure 3.3a: NEMA Power Connections

................................

............................

12

Figure 3.3b: Panel Power Connections

................................

..............................

12

Figure 3.4: PROBE

-

01 Installation

................................

................................

......

13

Figure 3.5: PROBE

-

11 Installation

................................

................................

......

14

Figure 3.6: Magnetic Mount, Application of

Thermal Compound

........................

15

Figure 3.7: Magnetic Mount, Side View

................................

..............................

16

Figure 3.8: Magnetic Mount, Application of RTV

................................

.................

16

Table 3.1: Probe Lead Connections

................................

................................

....

16

Figure 3.9a: NEMA Connections

................................

................................

.........

17

Figure 3.9b: Panel Connections

................................

................................

..........

17

Figure 3.10: Temperature Probe Shield Grounding

................................

............

17

Figure 3.11: Split Core CT Installat

ion

................................

................................

18

Figure 3.12a: NEMA CT Connections

................................

................................

.

19

Figure 3.12b: Panel CT Connections

................................

................................

..

19

Figure 3.13a: Relay Outputs

–

NEMA

................................

................................

.

20

Figure 3.13b: Re

lay Outputs

–

Panel

................................

................................

..

20

Figure 3.14a: NEMA Alarm Connections

................................

............................

21

Figure 3.14b: Panel Alarm Connection

................................

...............................

21

Table 3.2: RS

-

232 Pinout

................................

................................

....................

22

Figur

e 3.15a: TB5 Connections to Plug

-

In Analog Output Module

.....................

23

Figure 3.15b: TB5 Connections to Plug

-

In Analog Output Module

.....................

23

Figure 3.16 Jumper location and connection

................................

......................

24

Figure 3.17: Outline of Fiber Optic Interface

................................

.......................

26

Table of Figures

V6.230 20131017

viii

Figure 3.18a: NEMA Input Connections

................................

..............................

28

Figure 3.18b Panel Input Connections

................................

................................

28

Table 4.1: Setting Ranges

................................

................................

..................

39

Table 4.2: Probe Names

................................

................................

.....................

45

Table 4.3 Winding Names

................................

................................

...................

46

Table 4.4: Load Names

................................

................................

.......................

47

Figure 4.1: Over Temperature Operation

................................

............................

48

Figure 4.2: Under Temp Operation

................................

................................

.....

49

Figure 4.3: Load Pickup Set Point Operation

................................

......................

53

Figure 4.4: Input Set for LEVEL

................................

................................

..........

56

Figure 4.5: Input Set for PULSE

................................

................................

..........

56

Table 4.5: Programmable Logic Operands

................................

.........................

58

Figure 6.1: LTC Differential Set Point Operation

................................

.................

92

Figure 6.2: LTCDIFF Rate of Rise Method

................................

.........................

97

T

able 7.1: Tap Position Analog Ranges

................................

............................

101

Table 8.1: Display Scroll Sequence

................................

................................

..

112

Table 12.1: Maximum Records

................................

................................

.........

131

Warranty

V6.230 20131017

ix

All new products sold to customers are warranted a

gainst defects in design, materials, and

workmanship for the life of their use to the original end user. If it is determined that the new

product defect is covered under this warranty, Advanced Power Technologies, LLC (the

“Company”) will repair, replace,

or substitute an identical unit at its own discretion to the customer

at no charge. The Company requires the customer to ship the unit back to the factory for

diagnosis under all circumstances. In such event, the Company may, at its own discretion, decide

to provide the customer with a substitute unit which may be sent to the customer either from the

Company’s factory or from an authorized representative or distributor from their inventory. All

expenses related to the shipment of defective units back to the

Company or the provision of a

substitute unit to the customer are the responsibility of the customer. This expense may include,

but is not limited to, freight, insurance, Customs clearance, and duties. All expenses related to the

shipment of repaired unit

s back to customers (or the provision of a new unit to the customer) will

be borne by the Company.

Product Upgrade Policy

From time to time, the Company makes product upgrades to add or enhance the performance of

the products. Customers of a particular pr

oduct being issued an upgrade will be notified either by

the Company directly or through its authorized representatives or distributors. Customers who

have purchased an annual upgrade policy will receive all upgrades during the calendar year free

of charge

. Customers who did not purchase the annual upgrade policy may purchase each unit

upgrade individually. The annual upgrade policy can be purchased at any time. Regardless of

whether the upgrade policy is purchased, the Company will make reasonable efforts

to notify all

customers of all available upgrades.

Equipment Repair and Warranty

Repair costs of products not covered under this warranty are paid for by customers. Customers

are responsible for the cost of shipping the products to the Company located at:

215 State Route

10, BLDG 2, Randolph, NJ 07869, USA. All products repaired by the Company will continue to be

warranted against defects in material and workmanship for its installed life at the original end

user.

Limitations

The Company's warranty does n

ot extend to (A) The Company's products subject to (i) improper

installation, connection, operation, maintenance, or storage; (ii) accident, damage, abuse, or

misuse; (iii) abnormal or unusual operating conditions or applications outside the specifications

for the product; (iv) a purpose or application in any way different from that for which the products

were designed; (v) repairs conducted by persons other than the Company employees or an

authorized representative or distributor; or (vi) modifications mad

e to the product by the customer

or end user, (B) Equipment and products not manufactured by the Company. Such equipment

and products may be covered by a warranty issued by the respective manufacturer. This warranty

is in lieu of any other warranties, expr

ess or implied, including without limitation, any warranty of

merchantability or fitness for a particular purpose, and is in lieu of any and all other obligations or

liability of the Company. Under no circumstances shall the Company be liable for any accid

ental

or consequential damages or for any other loss, injury, damage, or expense of any kind including

loss of profits arising hereunder. To the extent any court, arbitration panel, or other governmental

body of competent jurisdiction shall declare any pro

vision of this warranty invalid or

unenforceable by reason of a rule of law or public policy, all the other provisions hereof shall

remain in full force and effect.

Warranty

V6.230 20131017

x

PAGE INTENTIONALLY BLANK

V6.230 20131017

1

1

INTRODUCTION

The TTC

-

1000, 3 Probe Transformer Temperature Co

ntroller is a mission

specific programmable controller that measures up to three different probe

temperatures

and

three

calculated winding temperature

s

. The user can program

four (4)

, s

ix (6)

, or eight (8)

independent hardware outputs based on the state of

pre

-

programmed temperature set points, time set points, load set points or the

outputs themselves. The controller can measure any of the three probes to an

accuracy of ± 1 ºC and does not require calibration. Calculated winding

temperature is based on the

methods of ANSI C57.91 and uses measured top oil

temperature and load current.

The outputs can be used to:

Control cooling fans and pumps.

Provide high temperature, LTC condition, and cooling system performance

alarms.

Provide a trip output.

Send tempera

ture, load and status

to a master via DNP3.0

or MODBUS

The TTC

-

1000 is substation hardened and designed to operate over a wide

temperature range of

–

50

to 85 ºC suitable for installation in outdoor cabinets.

The TTC

-

1000 contains many features including:

M

easures temperature from

-

35 to 160 ºC.

Does not require calibration.

Up to four o

ptional 0

-

1 or 4

-

20 mA analog outputs.

Up to three temperature probes.

Up to 9

optional aux CT inputs for current measurements of fans, load and to

calculate winding temper

atures.

P

atented Load Pickup Cooling

™

set points for early activation of cooling

b

ased on sudden increases in load

.

Comprehensive Patented Dual Algorithm LTC Condition Monitoring

™

for the

detection of both slowly and quickly evolving problems.

Universal pr

obe kit includes thermo well fitting adapters and probe sleeves.

Optional m

agnetic mount temperature probe

when a thermo well is not

available.

Reports Min and

Max Temperatures, time stamped with date and time.

V6.230 20131017

2

Data logging.

Periodic exercise of cooling fa

ns.

Automatic swapping of lead and lag fan banks.

Four independent temperature set points per probe.

Redundant top oil capable. Operates on secondary top oil probe if one fails.

Cooling system performance monitor to alarm when cooling is commanded

but the

current draw of the cooling fans or pumps is outside a specified

range.

4, 6 or 8

scheme logic programmable form C rel

ay outputs, all trip duty rated.

Dedicated form “C” programmable alarm relay.

Remote/Local

C

omm

s

through RS

-

232, no special software requi

red.

Flash memory for convenient firmware upgrades.

Same unit operates from 38 to 29

0VDC or 120VAC and is immune to

reversal of battery voltage polarity.

Available in either compact panel mount or a 304 Stainless Steel NEMA 4X

enclosure.

Optional DNP3.0 Le

vel 1 or MODBUS communications for reading analogs

plus status and remotely commanding cooling via RS

-

485 wired connection

or Multi

-

Mode Fiber

Optics. V

-

Pin fiber available.

Up to 14

optional optically isolated inputs for reporting status from liquid level

or sudden pressure alarms over DNP3.0

or MODBUS

, or for selective

blocking of outputs.

Patented Sensorless

Tap Position Monitoring

™

and Reporting. Patent

Pending.

Each TTC

-

1000 is burnt

-

in for a total of 48 hours prior to shipping and comes

with a lifetime warranty.

U.S. Patents 6,222,714,

6,714,022,

7,323,852

, 7,417,411

and other Patents

Pending

V6.230 20131017

3

2

PRODUCT DESCRIPTION

The following

section describes the front panel display, indicators, and switches,

connection points, mounting, physical size and panel cutout requirements

2.1

Controls &

Indicators

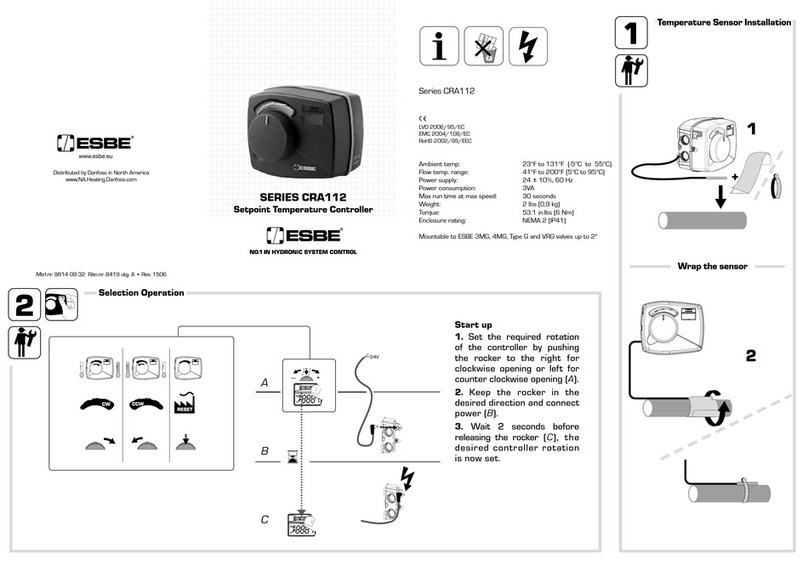

Figure 2.1 shows the front panel displays, indicators, and switches. Control

layout of NEM

A and panel units are identical other than panel size.

Figure

2

.1: Front Panel

1.

UP arrow button for navigating forward into menu categories and increasing settings.

2.

DOWN arrow button for navigating backward into menu categories and decreasing settings.

3.

LE

FT arrow button used for moving to the next character to the left when changing settings.

4.

RIGHT arrow button used for moving to the next character to the right when changing

settings.

5.

YES button is used to enter a menu category, request to change a setting

, and acknowledge

a setting change.

6.

NO button is used to leave a menu category or abort a setting change.

7.

ACTIVE indicator is a green LED that illuminates when power is applied.

8.

ALARM indicator is a red LED that illuminates whenever an alarm condition is p

resent.

Alarms can be caused by a failure detected in the electronics, or a broken temperature

probe. In NEMA 4 mounting models, this indicator will flash when using the light activated

Min/Max reset feature.

9.

16 character by 2 line Liquid Crystal Display.

10.

9 pin 15KV ESD protected RS

-

232 interface.

YES

NO

ACTIVE

ALARM

RS-232

CLEAR WINDOW NO TEXTURE

Advanced Power Technologies

TTC-1000

6

5

4

3

2

1

7

8

10

9

V6.230 20131017

4

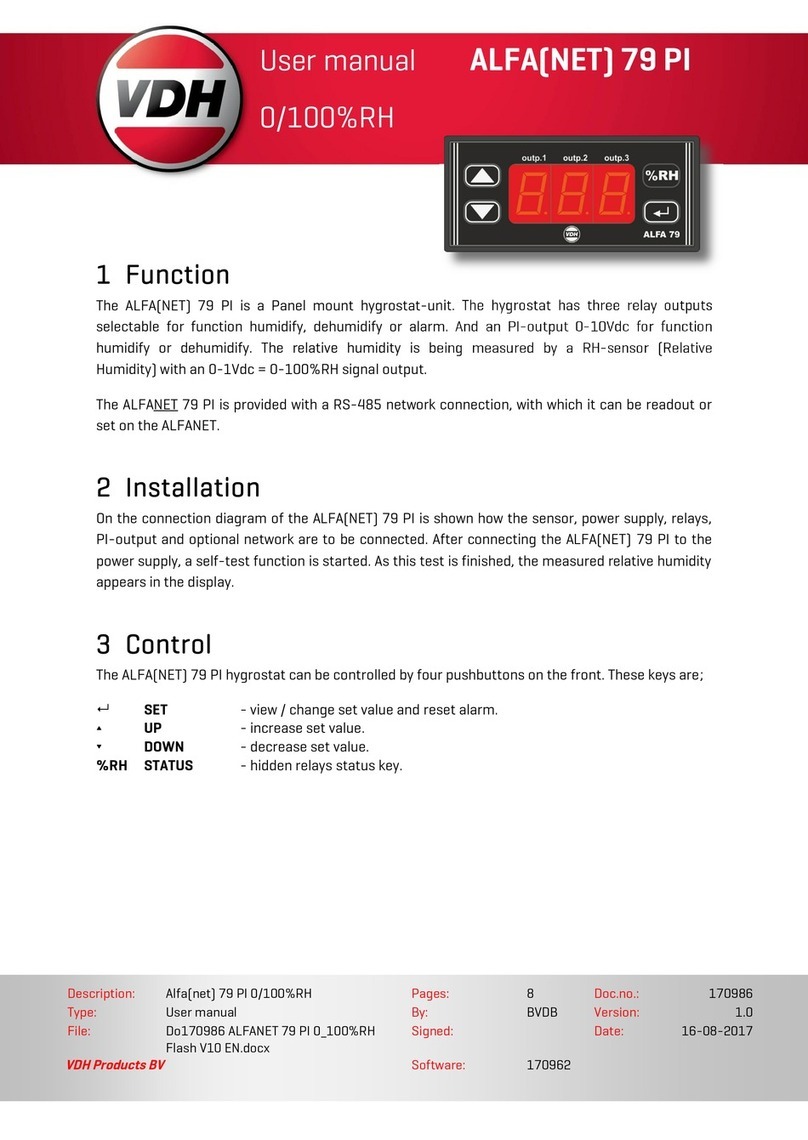

2.2

Connection Overview

-

Panel

Mount

Unit

Figure 2.2: Panel Mount Connection Overview

CHASSIS

GROUND

A

u

x

C

T

I

n

p

u

t

M

u

s

t

u

s

e

E

X

T

E

R

N

A

L

C

T

S

u

p

p

l

i

e

d

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

TB

8

TB

7

IN

3

IN

4

IN

5

IN

6

IN

7

IN

8

IN

9

IN

10

IN

11

IN

12

IN

13

IN

14

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

13

CT

2

CT

3

CT

4

CT

5

CT

6

CT

7

CT

8

CT

9

Optional For

Winding or

Load

TB

6

Front Panel

DB

-

9

RS

-

232

1

2

3

4

5

6

7

8

9

GROUND

Rx

Tx

N

/

C

N

/

C

N

/

C

RTS

CTS

N

/

C

Optional

for Load

Only

TB

7

&

TB

8

are

optional AC or DC

digital inputs

.

These

terminals will not be

present if the

additional input option

is not selected

.

TB

6

is for optional

extra CT inputs

.

These terminals will

not be present if the

extra CT option is not

selected

.

Pendant Rear

Panel RS

232

(

Optional

)

GROUND

Rx

Tx

N

/

C

N

/

C

N

/

C

RTS

CTS

N

/

C

1

2

3

4

5

6

7

8

9

Power In

38

to

160

VDC or

120

VAC

TB

3

Optional

Heater Option

Open

@

75

Deg F

CT

1

1

2

3

4

1

2

3

4

5

6

TB

5

A

3

A

2

A

1

Analog

Outputs

Used for units with up to

3

isolated or non

-

isolated

analog outputs

.

TB

5

is a

6

position plug

-

in style block

.

Used for units with

4

isolated or non

-

isolated

analog outputs

.

TB

5

is

an

8

position plug

-

in

style block

.

Analog Output Options Note

:

Not present if the analog output option is not selected

1

2

3

4

5

6

A

3

A

2

A

1

TB

5

7

8

A

4

1

2

3

4

5

6

TB

5

A

3

A

2

A

1

Rear Panel

Marked As

CT

1

-

CT

8

Shield

Connect to ground

REF

RTD

WHT

RED

BLK

Probe

2

TB

2

COM

REF

TMP

COM

REF

TMP

1

2

3

4

5

6

7

8

9

10

11

12

COM

REF

TMP

Optional

Optional

REF

RTD

WHT

RED

BLK

Probe

1

REF

RTD

WHT

RED

BLK

Probe

3

If PROBE

2

and

/

or PROBE

3

channels are not ordered

,

no

connections will be made to

those terminals

.

RS

-

485

For DNP

3

.

0

or MODBUS

(

Not Available if Fiber Optic Provided

)

OUT

4

TB

1

A

OUT

3

OUT

2

OUT

1

1

2

3

4

5

6

7

8

9

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

2

3

4

1

IN

1

IN

2

OUT

6

OUT

5

NO

NC

COM

NO

NC

COM

1

2

3

4

5

6

7

8

9

TB

1

B

TB

4

Digital Inputs and Relay Output Options

OUT

4

TB

1

A

OUT

3

OUT

2

OUT

1

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

2

3

4

1

OUT

6

OUT

5

NO

NC

COM

NO

NC

COM

TB

1

B

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

OUT

7

NO

NC

COM

OUT

8

NO

NC

COM

OUT

4

TB

1

A

OUT

3

OUT

2

OUT

1

1

2

3

4

5

6

7

8

9

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

2

3

4

1

IN

1

IN

2

OUT

6

OUT

5

NO

NC

COM

NO

NC

COM

1

2

3

4

5

6

7

8

9

TB

1

B

TB

4

Tx

Rx

Multi

-

Mode Fiber Optic

DNP

3

.

0

or MODBUS Interface

(

Not Available if RS

-

485

provided

)

Used for units with up to

6

outputs

&

2

digital inputs

.

I

/

O

terminals are labeled TB

1

A

,

TB

1

B and TB

4

.

If only four

outputs are ordered

,

TB

1

B has no connections in the

OUT

5

&

6

positions

.

If no inputs are ordered

,

there are

no connections to TB

4

.

Used for units with

8

outputs

.

I

/

O

terminals are labeled TB

1

A and TB

1

B

.

5

6

7

NC

NO

COM

To Alarm

V6.230 20131017

5

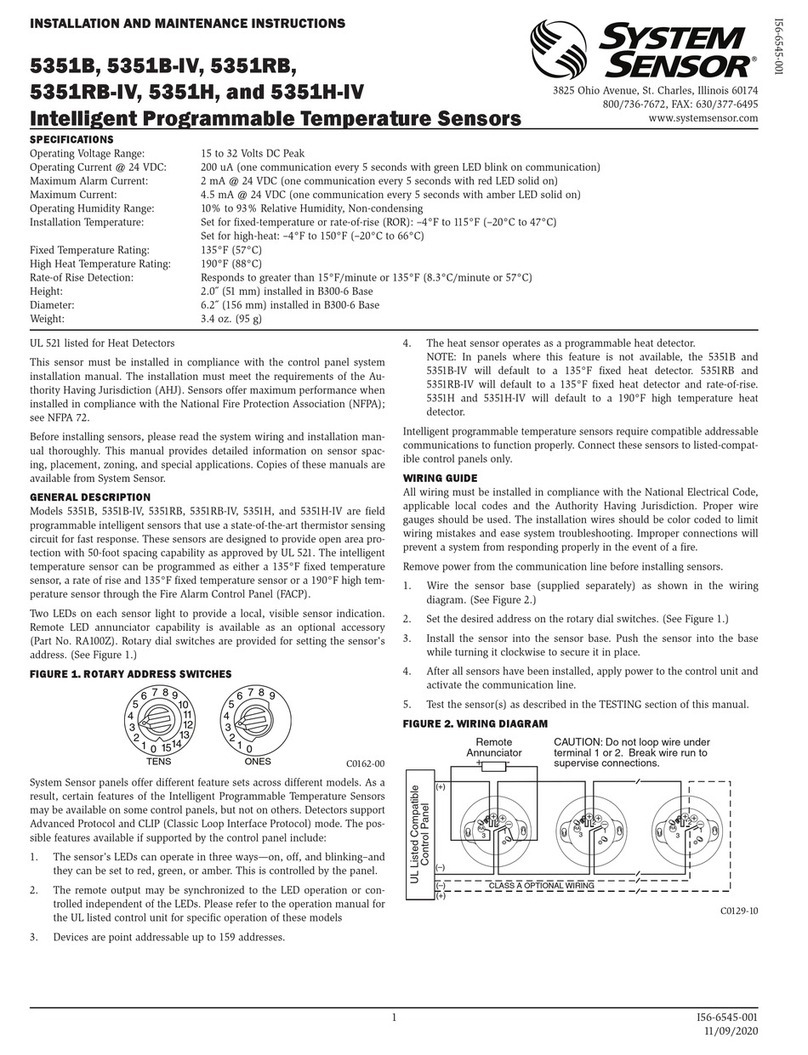

2.3

Rear Layout

-

Panel

Mount

Unit

Figure 2.3: Panel Mount Rear Layout

7

.

3

Panel Cutout

3

.

7

Panel

Cutout

3

.

558

Case

7

.

20

Case

C

O

M

T

M

P

R

E

F

C

O

M

T

M

P

R

E

F

C

O

M

T

M

P

R

E

F

A

B

DNP

Rx

Rx

Tx

Tx

Rpt

AUX CT

ALARM

POWER

PROBE

1

PROBE

2

PROBE

3

TB

2

TB

3

TB

5

A

1

A

2

A

3

GROUND

SHIELD

CT

8

TB

6

CT

7

TB

7

TB

8

CT

2

CT

3

CT

4

CT

5

CT

6

CT

1

IN

14

IN

13

IN

12

IN

11

IN

10

IN

9

IN

8

IN

7

IN

6

IN

5

IN

4

IN

3

TB

1

A

OUT

3

N

C

C

N

O

OUT

2

N

C

C

N

O

OUT

1

N

C

C

N

O

OUT

6

N

C

C

N

O

OUT

5

N

C

C

N

O

OUT

4

N

C

C

N

O

OUT

7

N

C

C

N

O

OUT

8

N

C

C

N

O

TB

7

&

TB

8

are optional digital inputs

.

These terminals will not be present if the

additional input option is not selected

.

TB

6

is for optional extra CT inputs

.

These

terminals will not be present if the extra

CT option is not selected

.

TB

1

B

Used for units with up to

6

outputs

&

2

digital inputs

.

I

/

O terminals are labeled

TB

1

A

,

TB

1

B and TB

4

.

If only four outputs

are ordered

,

TB

1

B has no connections in

the OUT

5

&

6

positions

.

If no inputs are

ordered

,

there are no connections to TB

4

.

Used for units with

8

outputs

.

I

/

O

terminals are labeled TB

1

A and TB

1

B

.

Digital Inputs and Relay Output Options

TB

1

A

TB

1

B

TB

4

OUT

3

N

C

C

N

O

OUT

2

N

C

C

N

O

OUT

1

N

C

C

N

O

OUT

6

N

C

C

N

O

OUT

5

N

C

C

N

O

OUT

4

N

C

C

N

O

IN

1

IN

2

1

2

3

4

TB

1

A

OUT

3

N

C

C

N

O

OUT

2

N

C

C

N

O

OUT

1

N

C

C

N

O

OUT

6

N

C

C

N

O

OUT

5

N

C

C

N

O

OUT

4

N

C

C

N

O

OUT

7

N

C

C

N

O

OUT

8

N

C

C

N

O

TB

1

B

If PROBE

2

and

/

or PROBE

3

channels are

not ordered

,

no connections will be made

to those terminals

.

Used for units with up to

3

isolated or non

-

isolated analog outputs

.

Used for units with

4

isolated or non

-

isolated analog outputs

.

Analog Output Options

A

1

A

2

A

3

A

1

A

2

A

3

A

4

TB

5

TB

5

If the fiber optic option is not ordered

,

fiber

connections will not be present

.

V6.230 20131017

6

2.4

Connections Overview

-

NEMA Enclosure

Figure 2.4: NEMA Mo

unt Connection Overview

CHASSIS

GROUND

A

u

x

C

T

I

n

p

u

t

M

u

s

t

u

s

e

E

X

T

E

R

N

A

L

C

T

S

u

p

p

l

i

e

d

OUT

4

TB

1

A

OUT

3

OUT

2

OUT

1

1

2

3

4

5

6

7

8

9

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

2

3

4

1

IN

1

IN

2

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

TB

7

TB

6

IN

3

IN

4

IN

5

IN

6

IN

7

IN

8

IN

9

IN

10

IN

11

IN

12

IN

13

IN

14

OUT

6

OUT

5

NO

NC

COM

NO

NC

COM

1

2

3

4

5

6

7

8

9

TB

1

B

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

13

CT

2

CT

3

CT

4

CT

5

CT

6

CT

7

CT

8

CT

9

Optional For

Winding or

Load

TB

8

TB

5

Front Panel

DB

-

9

RS

-

232

1

2

3

4

5

6

7

8

9

GROUND

Rx

Tx

N

/

C

N

/

C

N

/

C

RTS

CTS

N

/

C

Optional

for Load

Only

TB

6

&

TB

7

are

optional AC or DC

digital inputs

.

These

terminals will not be

present if the

additional input option

is not selected

.

TB

8

is for optional

extra CT inputs

.

These terminals will

not be present if the

extra CT option is not

selected

.

Digital Inputs and Relay Output Options

Shield

Connect to ground

REF

RTD

WHT

RED

BLK

Probe

2

TB

2

COM

REF

TMP

COM

REF

TMP

1

2

3

4

5

6

7

8

9

10

11

12

NO

NC

COM

COM

REF

TMP

To Alarm

Optional

Optional

REF

RTD

WHT

RED

BLK

Probe

1

REF

RTD

WHT

RED

BLK

Probe

3

Power In

38

to

160

VDC or

120

VAC

TB

3

Optional

Heater Option

Open

@

75

Deg F

CT

1

1

2

3

4

1

2

3

4

5

6

TB

4

A

3

A

2

A

1

Analog

Outputs

For qty

.

1

-

3

non

-

isolated

analog outputs

,

TB

4

is a

6

position plug

-

in style block

.

For all isolated analog options

,

TB

4

is

a

9

position plug

-

in style block

.

For

the

4

(

quad

)

non

-

isolated analog

output option

,

this block is also used

.

Analog Daughter Card Options Note

:

Card not present if the analog output option is not selected

1

2

3

4

5

6

A

3

A

2

A

1

TB

4

7

8

9

A

4

G

1

2

3

4

5

6

TB

4

A

3

A

2

A

1

TB

4

RS

-

485

DNP

3

.

0

Interface

1

2

Fiber Optic terminations for units with

the fiber option installed

.

Terminal will

be labeled TB

4

if no analogs are

present and TB

5

A if analogs are

present

.

DNP or MODBUS EIA

-

485

terminal

.

Labeled TB

5

when

there are no digital inputs

installed

.

DNP or MODBUS EIA

-

485

terminals

.

Labeled TB

5

A when

there are at least two digital inputs

installed in the unit

.

DNP Daughter Card Options

Tx

Rx

TB

5

TB

5

A

1

2

1

2

OUT

4

TB

1

A

OUT

3

OUT

2

OUT

1

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

2

3

4

1

OUT

6

OUT

5

NO

NC

COM

NO

NC

COM

TB

1

B

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

OUT

7

NO

NC

COM

OUT

8

NO

NC

COM

Used for units with

8

outputs

.

I

/

O

terminals are on plug

-

in style blocks labeled

TB

1

A and TB

1

B

.

OUT

4

TB

1

A

OUT

3

OUT

2

OUT

1

1

2

3

4

5

6

7

8

9

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

2

3

4

1

IN

1

IN

2

OUT

6

OUT

5

NO

NC

COM

NO

NC

COM

1

2

3

4

5

6

7

8

9

TB

1

B

TB

5

Used for units with

6

outputs

&

2

digital inputs

.

I

/

O terminals are on plug

-

in style blocks labeled

TB

1

A

,

TB

1

B and TB

5

.

OUT

4

TB

1

OUT

3

OUT

2

OUT

1

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

1

2

3

4

5

6

7

8

9

10

11

12

Used for units with

4

outputs

&

no digital inputs

&

no extra

CTs

.

I

/

O block is a

12

-

position

barrier style screw terminal

block and is labeled TB

1

.

NO

NC

COM

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

13

OUT

3

OUT

2

OUT

1

NO

NC

COM

NO

NC

COM

NO

NC

COM

OUT

4

IN

1

IN

2

TB

1

Used for units with

4

outputs

&

2

digital inputs

.

I

/

O terminals are on a

16

-

position plug

-

in style

block labeled TB

1

.

Pendant Rear

Panel RS

232

(

Optional

)

GROUND

Rx

Tx

N

/

C

N

/

C

N

/

C

RTS

CTS

N

/

C

1

2

3

4

5

6

7

8

9

If PROBE

2

and

/

or PROBE

3

channels are not ordered

,

no

connections will be made to

those terminals

.

V6.230 20131017

7

2.5

Rear Panel Layout

-

NEMA Enclosure

Figure 2.5: NEMA Mount Rear Panel Layout

CT

2

CT

3

CT

4

CT

5

CT

6

CT

7

CT

8

CT

9

TB

8

Connection Layout

1

2

3

4

TB

3

TB

2

2

1

Probe

1

Probe

2

Alarm

Aux CT

Power

COM

TMP

REF

10

11

12

7

8

9

5

6

4

Probe

3

COM

TMP

REF

COM

TMP

REF

3

TB

x

TB

x

TB

x

1

2

3

4

7

8

9

5

6

4

2

1

3

7

8

9

5

6

4

2

1

3

10

11

12

7

8

9

5

6

4

2

1

3

14

15

16

13

TB

4

4

5

6

2

3

1

A

1

+

+

-

-

-

A

2

A

3

+

TB

4

7

8

9

4

5

6

2

3

1

A

1

+

+

+

+

-

-

-

-

A

2

A

3

A

4

G

Tx

Rx

TB

5

TB

5

A

Analog Daughter Card

DNP

Daughter

Card

TB

4

7

8

9

4

5

6

2

3

1

TBxx

Fiber Optic terminations for

units with the fiber option

installed

.

Terminal will be

labeled TB

4

if no analogs are

present and TB

5

A if analogs

are present

.

DNP or MODBUS EIA

-

485

terminal

.

Labeled TB

5

when

there are no digital inputs

installed

.

DNP or MODBUS EIA

-

485

terminals

.

Labeled TB

5

A

when there are at least two

digital inputs installed in the

unit

.

For qty

.

1

-

3

non

-

isolated

analog outputs

,

TB

4

is a

6

position plug

-

in style block

.

For all isolated analog options

,

TB

4

is a

9

position plug

-

in style block

.

For the

4

(

quad

)

non

-

isolated analog

output option

,

this block is also used

.

DNP Daughter Card Options

Analog Daughter Card Options

TB

1

B

OUT

5

OUT

6

OUT

4

OUT

2

OUT

3

OUT

1

TB

1

A

TB

5

1

2

3

4

7

8

9

5

6

4

2

1

3

7

8

9

5

6

4

2

1

3

IN

2

IN

1

OUT

4

OUT

2

OUT

3

OUT

1

TB

1

TB

1

OUT

4

OUT

2

OUT

3

OUT

1

IN

2

IN

1

OUT

7

OUT

8

OUT

5

OUT

6

OUT

4

OUT

2

OUT

3

OUT

1

TB

1

A

TB

1

B

IN

3

IN

4

IN

5

IN

6

IN

7

IN

8

TB

7

IN

9

IN

10

IN

11

IN

12

IN

13

IN

14

TB

6

TB

6

&

TB

7

are optional digital inputs

.

These terminals will not be present if the

additional input option is not selected

.

TB

8

is for optional extra CT inputs

.

These

terminals will not be present if the extra

CT option is not selected

.

Used for units with

4

outputs

&

no digital

inputs

&

no extra CTs

.

I

/

O block is a

12

-

position barrier style screw terminal block

and is labeled TB

1

.

Used for units with

4

outputs

&

2

digital

inputs

.

I

/

O terminals are on a

16

-

position

plug

-

in style block labeled TB

1

.

Used for units with

6

outputs

&

2

digital

inputs

.

I

/

O terminals are on plug

-

in style

blocks labeled TB

1

A

,

TB

1

B and TB

5

.

Used for units with

8

outputs

.

I

/

O

terminals are on plug

-

in style blocks

labeled TB

1

A and TB

1

B

.

Digital Inputs and Relay Output Options

Note

:

Card not present if the analog

output option is not selected

A

B

A

B

A

B

7

8

9

4

5

6

2

3

1

10

11

12

7

8

9

4

5

6

2

3

1

10

11

12

10

11

12

7

8

9

5

6

4

2

1

3

14

15

16

13

10

11

12

7

8

9

5

6

4

2

1

3

10

11

12

7

8

9

5

6

4

2

1

3

1

2

3

4

5

6

7

8

9

10

11

12

V6.230 20131017

8

2.6

Specifications

Power Supply Input Operating Range:

38 VDC to 290 VDC or 120 VAC +/

-

10%, 3 Watts Max

Operating Temperature Range:

-

50 °C to +85 °C, 95% R

elative Humidity (non condensing)

Liquid Temperature Measurement Range:

-

35 to +160 °C

LTC Differential Temperature Measurement Range:

-

20 to +20 °C

Winding Temperature Measurement Range:

-

35 °C to +180 °C

Temperature Measurement Accuracy:

Avg error over

e

ntire measurement range ± 1 °C

Absolute er

ror at any temperature ± 1.5 °C

for temperatures within the range of

23

°C

-

160

°C. Below

23

˚C

the error is

±

3.5

°C.

Current Measurement Range:

Main CT:

Serial numbers ending in A through F:

0 to 10 A

Ser

ial numbers ending in G or later: 0 to 15 A

Extra CT Inputs: 0 to 50 A

Output Contact Rating:

30 amps make for 250 msec

10 amps continuous at 250VAC

0.4 amps break at 160VDC

Alarm Contact Rating:

0.4 a

mp continuous at 290 VDC (NEMA)

0.15 amp continuous at

290 VDC (Panel)

Analog Output:

Sele

ctable, 0 to 1 mA or 4 to 20 mA

Maximum load 10,000 ohms (0 to 1mA), 510 ohms (4 to 20 mA)

V6.230 20131017

9

Dimensions:

Panel Mount: 7.20” W x 3.558” H x 6.0”D Aluminum

NEMA 4X:

15.25

” H x

7

” W x

5

.25” D. 304 Stainless Steel

Surge Withsta

nd/Fast Transient:

Relay outputs, and station battery inputs: ANSI C37.90.1

EMI Withstand:

ANSI C37.90.2

Electrostatic Discharge:

IEC 801

-

2

Timers:

Output and Load Pick Up Timer: 0 to 255 seconds (actual minimum delay 32

msec)

Optically Isolated Inputs:

Op

erates from 38 to 290 VDC or 24 VAC to 260 VAC. External wetting voltage

required

. 5000 Volts of isolation.

Fiber Optic Interface:

Multi

-

Mode Transmit/Receive Wavelength 850nm. Supports 50 or 62.5 micron

multi

-

mode fiber. Optical budget is 9.1 dB.

V

-

Pin i

nterface supports HSC (recommended) or POF (not recommended for

distances greater than 70 feet) fiber. Optical budget 8.7 dBm.

Modulation is Non Return to Zero (NRZ).

Other manuals for TTC-1000

2

Table of contents

Other Advanced Power technologies Temperature Controllers manuals