METER ES-2 User manual

ES-2

Electrical Conductivity &

Temperature Sensor

Operator’s Manual

METER Group, Inc. USA

13890-01

ES-2

METER Group, Inc. USA

2365 NE Hopkins Court

Pullman WA 99163

Phone: 509-332-5600

Fax: 509-332-5158

Website: www.metergroup.com

sales.environmen[email protected]

Trademarks

c

2018 METER

All Rights Reserved

ii

ES-2 CONTENTS

Contents

1 Introduction 1

1.1 Customer Support . . . . . . . . . . . . . . . . . . . . 1

1.2 About This Manual . . . . . . . . . . . . . . . . . . . 1

1.3 Warranty ......................... 2

1.4 Seller’s Liability . . . . . . . . . . . . . . . . . . . . . . 2

2 About the ES-2 3

2.1 Specifications ....................... 3

3 Measurements 5

3.1 Temperature ....................... 5

3.2 Electrical Conductivity . . . . . . . . . . . . . . . . . . 5

4 Calibration 6

5 Connecting Sensors 7

5.1 Connecting to METER Logger . . . . . . . . . . . . . 7

5.2 Connecting to a Non-METER Logger . . . . . . . . . 8

5.3 Pigtail End Wiring . . . . . . . . . . . . . . . . . . . . 8

6 Installation 11

6.1 Pipe Water Monitoring . . . . . . . . . . . . . . . . . . 11

6.2 Tank Water Monitoring . . . . . . . . . . . . . . . . . 11

6.3 Cleaning Method . . . . . . . . . . . . . . . . . . . . . 12

7 Communication 13

7.1 SerialString........................ 13

7.2 SDI-12 Communication . . . . . . . . . . . . . . . . . 13

7.3 Common SDI-12 Commands . . . . . . . . . . . . . . . 14

7.4 SDI-12 Sensor Bus . . . . . . . . . . . . . . . . . . . . 14

7.5 SDI-12 Address . . . . . . . . . . . . . . . . . . . . . . 14

7.6 Power ........................... 15

7.7 Reading .......................... 15

8 Troubleshooting 16

9 Declaration of Conformity 17

iii

ES-2 1 INTRODUCTION

1 Introduction

METER designed the ES-2 sensor to measure pipe water, tank water

(when used with protective cap).A thermistor in thermal contact

with the probe provides water temperature, while the screws on the

surface of the sensor form a four-electrode array to measure electrical

conductivity. This manual should help you understand the sensor

features and how to use it successfully.

1.1 Customer Support

There are several ways to contact METER if you ever need assis-

tance with your product, have any questions, or feedback. METER

has Customer Service Representatives available to speak with you

Monday through Friday, between 7am and 5pm Pacific time.

Note: If you purchased your sensor through a distributor, please con-

tact them for assistance.

Email:

sales.environmen[email protected]

Phone:

509-332-5600

Fax:

509-332-5158

If contacting us by email or fax, please include as part of your mes-

sage your instrument serial number, your name, address, phone, fax

number, and a description of your problem or question.

1.2 About This Manual

Please read these instructions before operating your sensor to ensure

that it performs to its full potential.

1

1 INTRODUCTION ES-2

1.3 Warranty

This sensor has a 30-day satisfaction guarantee and a one-year war-

ranty on parts and labor. Your warranty is automatically validated

upon receipt of the instrument.

Note: The one year service plan activates when METER ships the

instrument and not at the time of purchase.

1.4 Seller’s Liability

Seller warrants new equipment of its own manufacture against de-

fective workmanship and materials for a period of one year from the

date of receipt of equipment.

Note: We do not consider the results of ordinary wear and tear,

neglect, misuse, or accident as defects.

The Seller’s liability for defective parts shall in no event exceed the

furnishing of replacement parts “freight on board” the factory where

originally manufactured. Material and equipment covered hereby

which is not manufactured by Seller shall be covered only by the

warranty of its manufacturer. Seller shall not be liable to Buyer for

loss, damage or injuries to persons (including death), or to property

or things of whatsoever kind (including, but not without limitation,

loss of anticipated profits), occasioned by or arising out of the instal-

lation, operation, use, misuse, nonuse, repair, or replacement of said

material and equipment, or out of the use of any method or process

for which the same may be employed. The use of this equipment con-

stitutes Buyer’s acceptance of the terms set forth in this warranty.

There are no understandings, representations, or warranties of any

kind, express, implied, statutory or otherwise (including, but with-

out limitation, the implied warranties of merchantability and fitness

for a particular purpose), not expressly set forth herein.

2

ES-2 2 ABOUT THE ES-2

2 About the ES-2

2.1 Specifications

Temperature

Accuracy: ±1◦C

Resolution: 0.1 ◦C

Range: −40 ◦C to 60 ◦C

Bulk Electrical Conductivity

Accuracy: ±0.01 dS/m or ±10% (whichever is greater)

Resolution: 0.001 dS/m

Range: 0 to 120 dS/m (bulk)

General

Dimensions:

•ES-2: 10.9 x 2.4 cm (4.3 x 0.95 in) with 1/2” NPT

Measurement Time: 300 ms (milliseconds)

Power Requirements: 3.6 to 15 VDC, 0.03 mA quiescent, 0.5 mA

during 300 ms measurement

Output: Serial (TTL), 3.6 voltage levels or SDI-12

Operating Temperature: −40 to 6 0◦C

Note: Sensors can be used at higher temperatures. Please contact

METER for assistance.

Connector types: 3.5 mm (stereo) plug or stripped and tinned lead

wires (Pigtail)

Cable Length: 5 m standard; custom cable length

Data logger Compatibility (not exclusive):

•METER: All METER Loggers cabable of reading digital

sensors

3

2 ABOUT THE ES-2 ES-2

•Campbell Scientific: Loggers with serial I.O includ-

ing CR10X, CR23X, or any CRBasic type logger (CR850,

1000, 3000, etc)

•Other: Any data acquisition system capable of 3.6 to 15

V excitation and serial or SDI-12 communication.

Handheld Reader Compatibility: ProCheck (rev 1.34+)

Software Compatibility: ECH2O Utility (rev 1.64+) and DataTrac

3 (rev 3.4+)

4

ES-2 3 MEASUREMENTS

3 Measurements

3.1 Temperature

A thermistor near the electrical conductivity (EC) sensor senses the

temperature of the water. The sensor uses this temperature to ad-

just the EC measurements to their 25 ◦C value, and provides the

temperature output for the data stream.

3.2 Electrical Conductivity

EC is useful for measuring the concentration of salts in water and

also gives information about dissolved solids. EC is measured by

applying an alternating electrical current to two electrodes, measur-

ing voltage drop with a separate set of electrodes. Then measuring

the current flow through those electrodes and measuring the current

with a separate set of electrodes. The conductance is the ratio of

current to voltage. Conductivity is conductance multiplied by a cell

constant based on common conductivity standards. It is important

to realize that a four electrode sensor gives unpredictable readings in

air because there is no connection between the voltage and current

electrodes.

5

4 CALIBRATION ES-2

4 Calibration

METER calibrates our EC sensors at the factory using KC1 solutions

of known concentration and calibration values are stored internally

in flash memory.

The following table relates EC at 25 ◦C to concentration for vari-

ous concentrations of KC1. Operators can verify ES-2 performance

using these solutions. The ES-2 internally corrects output value to

25 ◦C

Table 1: EC of KC1 solutions for testing ES-2 calibrations.

Electrical Conductivity g KC1 per kg of distilled

(µS/cm) water

100 0.0446

200 0.0930

500 0.2456

1,000 0.5120

2,000 1.0673

5,000 2.8186

10,000 5.8758

20,000 12.2490

6

ES-2 5 CONNECTING SENSORS

5 Connecting Sensors

The ES-2 Sensor was designed to work most efficiently with ME-

TER’s data loggers, or our ProCheck handheld reader. The stan-

dard sensor (with 3.5 mm stereo connector) quickly connects to and

is easily configured within a METER logger or ProCheck.

The ES-2 Sensor incorporates several features that also make it an

excellent sensor for use with third party loggers. The sensor may

be purchased with stripped and tinned wires (pigtail) for terminal

connections. Visit www.metergroup.com and search for the ES-2 In-

tegrator Guide to get extensive directions on integrating the ES-2

sensor into third party loggers.

The ES-2 Sensor comes standard with a five meter cable. Sensors

may be purchased with custom cable lengths for an additional fee

(on a per-meter basis). METER has tested its digital sensors suc-

cessfully with cable lengths up to 1,000 m (3,200 ft). Using a longer

cable eliminates the need for splicing the cable (a possible failure

point).

5.1 Connecting to METER Logger

METER designed the ES-2 to work specifically with METER data

loggers. Simply plug the 3.5 mm “stereo” connector directly into one

of the sensor ports.

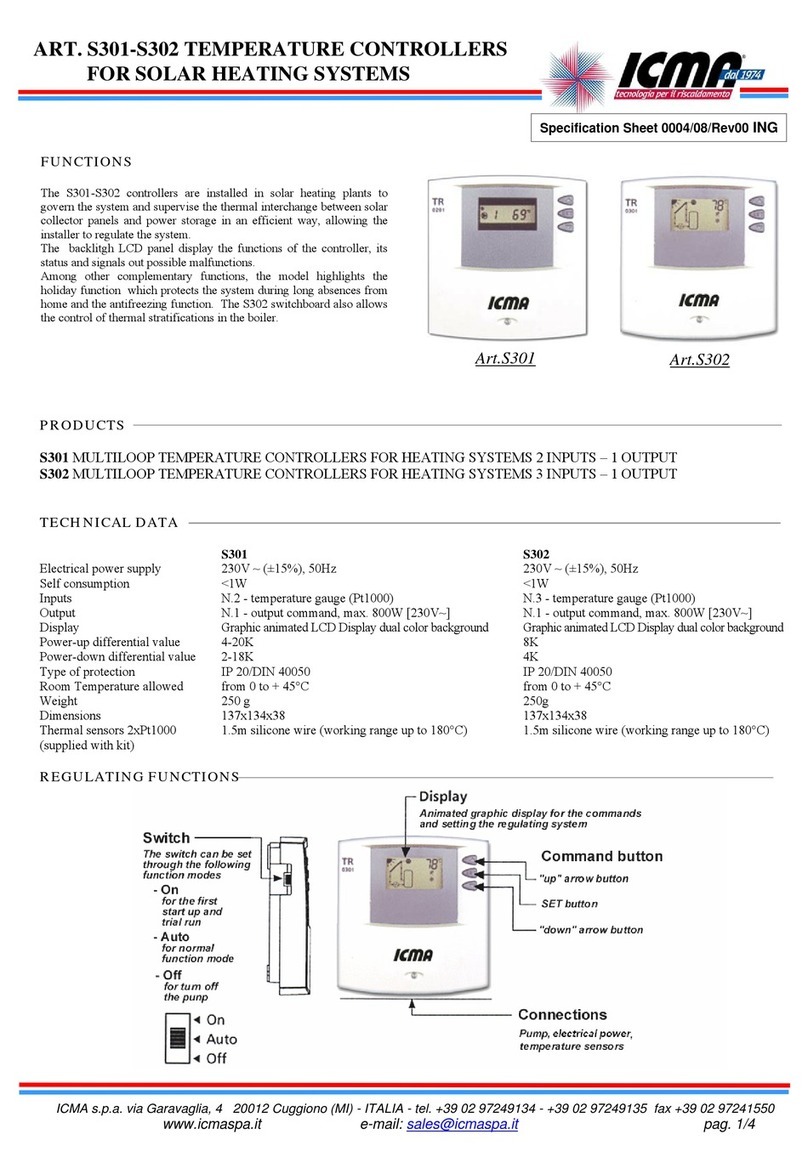

Figure 1: 3.5 mm Stereo Plug Wiring

The next step is to configure your logger port for the ES-2 Sen-

sor and set the measurement interval. This may be done using ei-

7

5 CONNECTING SENSORS ES-2

ther ECH2O Utility Mobile (see respective manuals). Please check

your software version to ensure it supports the ES-2 To upgrade

your software to the latest version, please visit METER’s website:

www.metergroup.com.

The following firmware and software supports the ES-2 Sensor:

Em50 Firmware version 2.09 or greater

ECH2O Utility 1.64 or greater

ECH2O DataTrac 3.4 or greater

To download data from the logger to your computer, you need to

use the ECH2O Utility, DataTrac 3 or a terminal program on your

computer.

5.2 Connecting to a Non-METER Logger

The ES-2 Sensor may be purchased for use with non-METER data

loggers. These sensors typically come configured with stripped and

tinned (pigtail) lead wires for use with screw terminals. Refer to

your logger manual for details on wiring. Our Integrator’s Guide

gives detailed instructions on connecting the ES-2 sensor to non-

METER loggers. Please visit www.metergroup.com for the complete

Integrator’s Guide.

5.3 Pigtail End Wiring

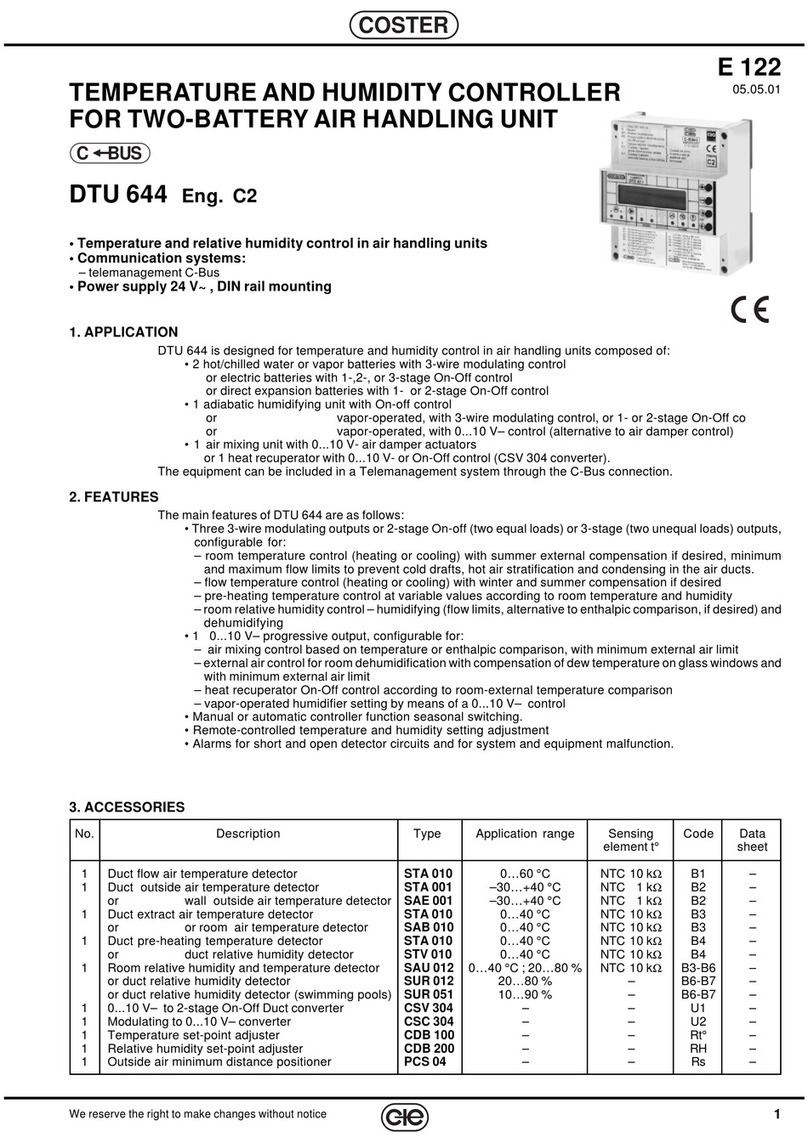

Figure 2: Cable Wiring

Connect the wires to the data logger as shown, with the supply wire

(brown) connected to the excitation (3.6 to 15 volts), the digital out

8

ES-2 5 CONNECTING SENSORS

wire (orange) to a digital input, the bare wire (ground) to ground.

NOTE: Some ES-2 sensors may have the older Decagon wiring scheme

where the power supply is white, the digital out is red, and the bare

wire is ground.

Figure 3: Wiring Diagram

Note: The acceptable range of excitation voltages is from 3.6 to 15

VDC. If you wish to read your METER sensor with the Campbell

Scientific Data Loggers, you will need to power the sensors off of the

switched 12V port.

If your ES-2 Sensor is equipped with the standard 3.5 mm plug,

and you wish to connect it to a non-METER data logger, you have

two options. The first option is to clip off the plug on the sensor ca-

ble, strip and tin the wires, and wire it directly into the data logger.

The advantage of this method is that you create a direct connection

with no chance of the sensor becoming un-plugged. However, it then

cannot be easily used in the future with a METER readout unit or

data logger. (Figure 1)

The second option is to obtain an adapter cable from METER. The

3-wire sensor adapter cable has a connector for the sensor jack on one

end, and three wires on the other end for connection to a data logger

9

ES-2 6 INSTALLATION

6 Installation

METER designed the ES-2 sensor for installation in several different

applications. The ES-2 can be installed in line with an irrigation

pipe, in a water body or in a tank.

Note: Do not remove the protective cap from the sensor. This will

change the sensor calibration and result in erroneous data.

6.1 Pipe Water Monitoring

The threaded cap on the ES-2 allows for easy installation into a pipe

for monitoring the EC and temperature of water flowing through a

pipe.

To integrate the ES-2 into an irrigation pipe, begin by ensuring the

white threaded plug is installed on the side of the protective screw

cap. Then screw the end of the ES-2 sensor into a 3/4” NPT Tee

pipe fitting. If necessary, use a pipe converter to convert from the

3/4” NPT thread size to a size more appropriate for your system.

Orient the sensor with the cable end facing down or to the side.

This will allow air to escape from the sensing area.

6.2 Tank Water Monitoring

The ES-2 can be used to monitor water in a storage tank or water

body. When used in a tank or water body, the ES-2 should be used

with the attached protective screw-on cap. It is best to suspend the

sensor in the tank, but if this is not possible, make sure that the

sensor is placed away from the sides of the tank as much as possible.

After the sensor is installed in the correct location, follow the in-

structions in Cleaning Method.

11

6 INSTALLATION ES-2

A four electrode conductivity measurement is less sensitive to sensor

fouling than a two electrode sensor, but contamination of the elec-

trodes can still affect the measurement. The electrodes are stainless

steel.

6.3 Cleaning Method

1. Insert swab into slot on side of sensor housing. Rug the screws

vigorously with swab.

2. Rinse the sensor and screws thoroughly with tap or DI water

Note: Do not touch the screws without gloves or contact them

with any source of oil or other non-conducting residue.

12

ES-2 7 COMMUNICATION

7 Communication

The ES-2 sensor can communicate using two different methods: 1)

Serial String or 2) SDI-12 communication protocol. This section dis-

cusses the specifics of each of these communication methods. Please

visit www.metergroup.com for the complete Integrator’s Guide, which

gives more detailed explanations and instructions.

7.1 Serial String

When you apply excitation voltage to the ES-2 sensor it makes a

measurement. Within about 140 ms of excitation, three measure-

ment values transmit to the data logger as a serial stream of ASCII

characters. The serial out is 1,200 baud asynchronous with 8 data

bits, no parity, and one stop bit. The voltage levels are 0 to 3.6 V and

the logic levels are TTL (active low). The power must be removed

and reapplied for a new set of clues to be transmitted.; The ASCII

stream contains two numbers separated by spaces. The first number

is EC in µS/cm with a resolution of 1 µS/cm and the second num-

ber is temperature in Celsius with a resolution of 0.1 ◦C a carriage

return follows the three numbers, then the character “t,” indicating

that this is a ES-2 sensor, then a checksum character, and finally a

carriage return and line feed.

7.2 SDI-12 Communication

The ES-2 sensor also communicates using SDI-12 protocol, a three-

wire interface where all sensors are powered (brown wire), grounded

(bare wire and black wire), and communicate (orange wire) on shared

nodes ( for more information on the SDI-12 protocol, visit www.sdi-

12.org). Below is a brief description of SDI-12 for communication. If

you plan on using SDI-12 for communication with the ES-2 Sensor,

please see our integrator’s guide at www.metergroup.com for detailed

instruction.

13

7 COMMUNICATION ES-2

7.3 Common SDI-12 Commands

Table 2 shows common SDI-12 commands that the ES-2 Sensor re-

sponds to. The ES-2 can respond to any SDI-12 command under the

SDI-12 specification version 1.3. The sensor addresses shown an ‘a.’

If a ‘?’ is substituted for ‘a’ all addresses respond.

Table 2: SDI-12 Commands

Send

Identification aI! a13DECAGON ES-2 316<CR><LF>

Change Address aAb! b<CR><LF>(b is new address)

Address Query ?! a<CR><LF>

Start

Measurement aM! 00013<CR><LF>

Send Data aD0! a+9+22.2+0<CR><LF>(3 values)

7.4 SDI-12 Sensor Bus

Up to 62 sensors can be connected to the same 12 V supply and

communication port on a data logger. This simplifies wiring because

no multiplexer is necessary. However, a problem with one sensor can

bring down the entire array (though a short circuit or incorrect ad-

dress settings). If you do use a SDI-12 sensor bus, we recommend that

you make an independent junction box with wire harnesses where all

sensor wires attach to lugs so sensors can be disconnected individu-

ally if a problem arises. A single three-wire cable can be run from the

junction box to the data logger. While this method minimizes the

number of data loggers needed, it maximizes the need for personnel

to monitor the set-up.

7.5 SDI-12 Address

The SDI-12 protocol requires that all sensors have a unique sensor

address. ES-2 sensors come from the factory with a SDI-12 address

of 0. To add SDI-12 sensors to a system, the sensor address must

14

ES-2 7 COMMUNICATION

be changed for each additional sensor. Address options include 0...9,

A...Z, a...z. The best and easiest way to change an address is to use

METER’s ProCheck (if this option is not available on your ProCheck,

please upgrade to the latest version of firmware). SDI-12 addressing

can be accessed in the ProCheck CONFIG menu by selecting “SDI-

12 Address.” You may then change addresses may then be changed

by simply pressing the up or down arrows until you see the desired

address and pushing Enter.

The SDI-12 communication protocol is supported by Campbell Sci-

entific data loggers like the CR10X, CR200, CR1000, CR3000, etc.

Direct SDI-12 communication is supported in the “Terminal Emula-

tor” mode under the “Tools” menu on the “Connect” screen.Detailed

information on setting the address using CSI data loggers can be

found on our website at http://www.metergroup.com.

7.6 Power

The ES-2 can be powered using any voltage from 3.6 to 15 VDC,

but 12 V is optimal. Although SDI-12 protocol allows the sensors to

be continuously powered, it is often best to connect the power wire

(brown) to a switched source. This reduces power usage (although

the ES-2 Sensor uses very little power) and reset the sensor from

time to time.

7.7 Reading

Example programs from Edlog and CRBasic can be found in our

software section online at www.metergroup.com. As with the Serial

String, the water depth is the first number output by the sensor

in mm. The second number is temperature in Celsius. The third

number is EC, in µS/cm.

15

8 TROUBLESHOOTING ES-2

8 Troubleshooting

Problems with the ES-2 sensor generally manifest as incorrect or er-

roneous readings. Before contacting METER about the sensor, try

the following:

Data Logger

1. Check to make sure the connections to the data logger are both

correct and secure.

2. Verify that your data logger batteries are not dead or weakened.

3. Check the configuration of your data logger in ECH2O Utility

or DataTrac to make sure you have selected the ES-2 sensor on

the correct port.

4. Verify that you are using the most up to date software and

firmware. You can find the most up to date version of the

software and firmware at www.metergroup.com/contact/.

Sensors

1. Verify that your sensors are installed according to the “Instal-

lation” section of this manual

2. Check sensor cables for nicks or cuts the could cause a mal-

function

3. Check the pressure transducer tube to ensure that it is not

clogged or damaged.

16

ES-2 9 DECLARATION OF CONFORMITY

9 Declaration of Conformity

Application of Council Directive: 2004/108/EC and 2011/65/EU

Standards to which conformity EN61326-1: 2013

is Declared EN50581: 2012

Manufacturer’s Name: METER Group, Inc. USA

2365 NE Hopkins Court

Pullman, WA 99163 USA

Type of Equipment: Water Depth Sensor

Model Number: ES-2

Year of First Manufacture: 2012

This is to certify that the ES-2 manufactured by METER Group,

a corporation based in Pullman, Washington, USA meets or exceed

the standards for CE compliance as per the Council Directives noted

above. All instruments are built at the factory. Pertinent testing

documentation is freely available for verification.

17

Other manuals for ES-2

1

Table of contents

Other METER Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

RKC INSTRUMENT

RKC INSTRUMENT RB100 Communication quick manual

Auber Instruments

Auber Instruments WS-1211GPH quick guide

La Crosse Technology

La Crosse Technology TX141TH-Bv3 quick start guide

Clas Ohlson

Clas Ohlson WTH450H instruction manual

Elko

Elko iNELS RFTC-150/G manual

Nibe

Nibe ECS 40 Installer manual