Advanced Radiant Systems RS-30 Manual

Installation, Operation and Service Instructions

RS RANGE

RESIDENTIAL

INFRARED HEATERS

WARNINGS

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, injury

or death. Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance. If you smell gas:

1. Open windows

2. Don’t touch electrical switches

3. Extinguish any open flame

4. Immediately call your gas supplier

OWNER

Retain this Manual & ensure available for service.

Improper installation, adjustment, alteration, service

or maintenance can cause injury, death or property

damage.

Read the installation, operation and service

instructions thoroughly before installing or servicing

this equipment.

INSTALLER

Provide Manual to Owner upon completion of

installation!

Read and thoroughly understand these Instructions

before attempting any installation

CAUTION: FIRE OR EXPLOSION HAZARD

Maintain clearance to combustible constructions as

further specified in this manual. Failure to do so

could result in a serious fire hazard. Heaters should

not be located in hazardous atmospheres containing

flammable vapors or combustible dusts. Signs

should be provided in storage areas specifying

maximum safe stacking height.

CAUTION: MECHANCIAL HAZARD

This equipment expands and contracts with each

operating cycle. The gas connection, suspension

hardware and the installation itself must safely allow

this movement. Failure to do so could result in

serious fire or explosion hazard.

CAUTION: FIRE OR EXPLOSION HAZARD

This heater is equipped with an automatic ignition

device. Do not attempt to light the burner by hand.

Failure to comply could result in a serious fire and

personal injury hazard.

CAUTION: MECHANCIAL HAZARD

Do not use high pressure (above 1/2 psi) to test the

gas supply system with the burners connected,

doing so could result in damage to the burner and

its control components requiring replacement.

Do not install equipment in atmospheres containing

halogenated hydrocarbons or other corrosive

chemicals, doing so may lead to premature

equipment failure and invalidation of the warranty.

Additionally, it is recommended that the equipment

be installed with a slope downward and away from

the burner of ¼" (6mm) in 10' (3m) to allow start-up

condensate drainage.

CAUTION: SERVICE LIFE RISK

Due to continuous product innovations, we reserve the right to change product specifications without due notice.

CONTENTS

INTRODUCTION ............................................................................................................................. 1

Installation Codes.............................................................................................................................................1

GENERAL SPECIFICATIONS .......................................................................................................... 2

DIMENSIONAL CHART .................................................................................................................. 2

CLEARANCE TO COMBUSTIBLES ................................................................................................. 3

INSTALLATION .............................................................................................................................. 4

Installation Sequence.......................................................................................................................................4

Outdoor Installation..........................................................................................................................................5

Cover Installation Sequence............................................................................................................................7

DECORATIVE GRILLE .......................................................................................................................................9

VENTING AND COMBUSTION AIR DUCTING .............................................................................. 10

General Requirements ...................................................................................................................................10

Roof Venting ...................................................................................................................................................12

GAS PIPING.................................................................................................................................. 13

General Requirements ...................................................................................................................................13

ELECTRICAL WIRING................................................................................................................... 14

General Requirements ...................................................................................................................................14

Wiring Diagrams .............................................................................................................................................14

OPERATION AND MAINTENANCE............................................................................................... 15

Starting Sequence of Operation....................................................................................................................15

Maintenance ...................................................................................................................................................15

TROUBLESHOOTING ................................................................................................................... 16

Troubleshooting Chart ...................................................................................................................................17

REPLACEMENT PARTS ............................................................................................................... 18

WARRANTY.................................................................................................................................. 19

Page 1Residential Range RS_10062016al

Advanced Radiant Systems’ Residential Range (RS) is exactly what it sounds like; a residential grade,

unitary infrared heater. The RS is designed to optimize performance as well as aesthetics. The compact,

preassembled, unitary design and custom mounting brackets make for a simple and minimally invasive

installation. With lower output capacities, comfortable designs are easily maintained at lower hanging heights.

INTRODUCTION

IMPORTANT

These instructions, the layout drawing, local codes and ordinances, and applicable standards such as apply to

gas piping and electrical wiring comprise the basic information needed to complete the installation, and must

be thoroughly understood along with general building codes before proceeding.

Only personnel who have been trained and understand all applicable codes should undertake the installation.

Representatives that are Factory Certied in the service and application of this equipment and can be called on

for helpful suggestions about installation.

Installation Codes

Installations must comply with local building codes, or in their absence, the latest edition of the national

regulations and procedures as listed below.

General Installation and Gas Codes

Heaters must be installed only for use with the type of gas appearing on the rating plate, and the installation must

conform to the National Fuel Gas Code, ANSI Z223.1/NFPA 54 in the US and CSA B149.1 and B149.2 Installation

Codes in Canada. This heater may be approved for either indoor or outdoor installation. Not for use in residential

dwellings, refer to Rating plate.

Aircraft Hangar Installation

Installation in aircraft hangars must conform to the Standard for Aircraft Hangars, ANSI/NFPA 409 in the US and

CSA B149.1 and B149.2 Installation Codes in Canada.

Public Garage Installation

Installation in public garages must conform to the Standard for Parking Structures, NFPA-88A or Standard for

Repair Garages, NFPA 88B, in the US and CSA B149.1 and B149.2 Installation Codes in Canada.

Parking Structures

Technical requirements are outlined in ANSI/NFPA 88B (USA)

Electrical

All heaters must be electrically grounded in accordance with the National Electric Code, ANSI/NFPA 70 in the US,

and the Canadian Electric Code, CSA C22.1 in Canada, and must comply with all local requirements.

Venting

Refer to the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) in the US and CSA B149.1 and B149.2 Installation

Codes in Canada, as well as all local requirements for general venting guidance.

High Altitude

When installing this appliance over 4500 ft. above sea level in Canada, the appliance must be properly derated

and installed according to local codes. In the absence of local codes the appliance must be derated in

accordance with the most recent CSA B149 code. In the United States for installations over 2000ft above sea

level the appliance must be installed in accordance with the Current National Fuel Gas Code, ANSI Z223.1/NFPA

54.

Safety Features

This heater utilizes an airow switch as blocked vent shut off system. This system is designed to prevent the

operation of the appliance if a fresh air supply is blocked or if the ue exhaust is blocked. If this system fails to

operate DO NOT ATTEMPT ADJUSTMENTS. Disconnect power to the appliance and contact a qualied service

person.

Page 2Residential Range RS_10062016al

GENERAL SPECIFICATIONS

DIMENSIONAL CHART

Gas Supply

Inlet Pressure

Natural Gas: Minimum 5.0" W.C.

Maximum 14.0" W.C.

Propane Gas: Minimum 11.5" W.C.

Maximum 14.0" W.C.

Manifold Pressure

Natural Gas: 3.5" W.C. Propane Gas: 10.5" W.C.

Inlet Connection

Natural Gas or Propane: 1/2" NPT female

Electric Supply

120 VAC, 60 HZ, 1 Amp: 36" cord with grounded 3 prong plug

Flue and Outside Air Connection

2" diameter (installed concentrically)

Figure 1: Overall Dimensional Information

RS-30 RS-45

30,000 45,000

109 LBS

REFER TO ANSI Z223.1 AND CSA B149.1 AND B149.2 FAN ASSISTED

APPLIANCES FOR CORRECT SIZING.

NOT TO SCALE

15.1"

7.5"

5

"

3.8"

1.8"

5.4"

113.0"

6.4"

1.0"

3.8

"

5.

Table 1: Heater Specications

Page 3Residential Range RS_10062016al

CLEARANCE TO COMBUSTIBLES

It is very important to observe the minimum clearance to combustibles at all times to avoid any possibility of

property damage or personal injury.

WARNING

Clearances as marked on the heater body must be maintained from vehicles parked beneath.

Signs should be posted identifying any possible violation of the clearance distances from the

heater in all vehicle areas.

appropriate markings adjacent to the thermostat or in a conspicuous location.

Table 2 lists the minimum clearance to combustible materials for various installation congurations. Note

that standard clearances also apply to installation above T-bar ceilings and above decorative grills. Additional

clearance may be required for glass, painted surfaces and other materials which maybe damaged by radiant or

convective heat.

Combustible materials are considered to be wood, compressed paper, plant bers, plastics, Plexiglas or other

materials capable of being ignited and burned. Such materials shall be considered combustible even though

ameproofed, re-retardant treated or plastered.

Reector miter kits are available for U-bends and elbows.

Adequate clearance to sprinkler heads must be maintained (NFPA 13: Standard for the Installation of Sprinkler

Systems).

The stated clearance to combustibles represents a surface temperature of 90°F (32°C) above room temperature.

Building materials with low heat tolerance (such as plastics, vinyl siding, canvas, tri-ply, etc…) maybe subject

to degradation at lower temperatures. It is the installer’s responsibility to assure that adjacent materials are

protected from degradation.

It is important to observe minimum clearance to combustibles at all times to avoid any possibility of property

damage or personal injury. Clearances must be maintained from vehicles parked beneath heaters. Signs should

be posted identifying any possible violation of the clearance distances from the heater in vehicle areas. Also

maximum allowable stacking height in storage areas should be identied with signs or appropriate markings.

Table 2 shows minimum clearance to combustible materials.

Table 2: Clearance to Combustibles

MODEL

NUMBER

DIMENSION

0° ANGLE 45° ANGLE VENTED

A B C D A B C D END

RS-30 18" 36" 18" 18" 50" 18" 5″

RS-45 2" 33" 33" 48" 48" 5″

C

D

A

B

D

A

B

C

in the U.S. and 7 feet in Canada.

Page 4Residential Range RS_10062016al

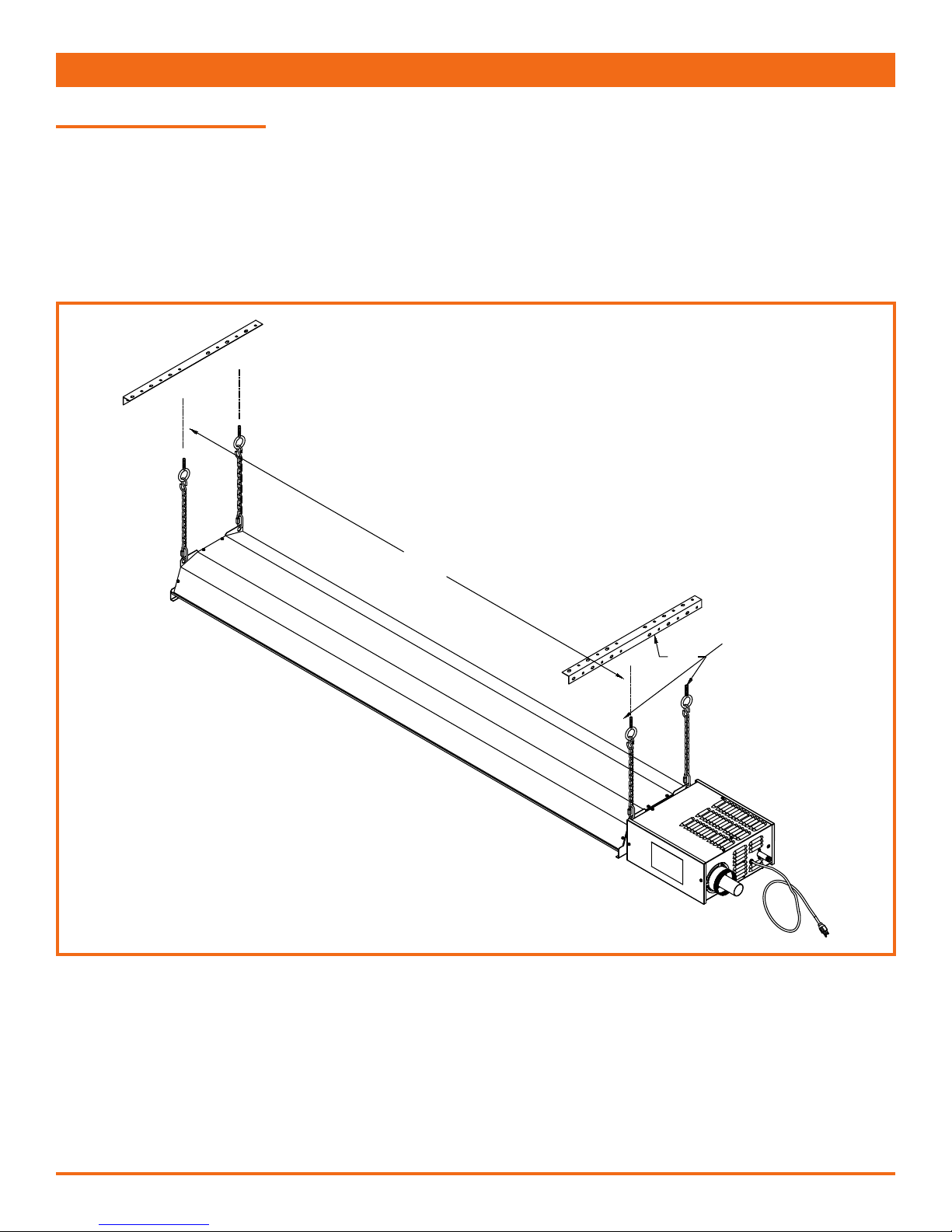

INSTALLATION

96.00"

Fasten Support Angle to Ceiling to

Accommodate Heater Hanging Points

OR

Note:

Close all open ended "S" hooks, chain links,

and turnbuckles or any open connection.

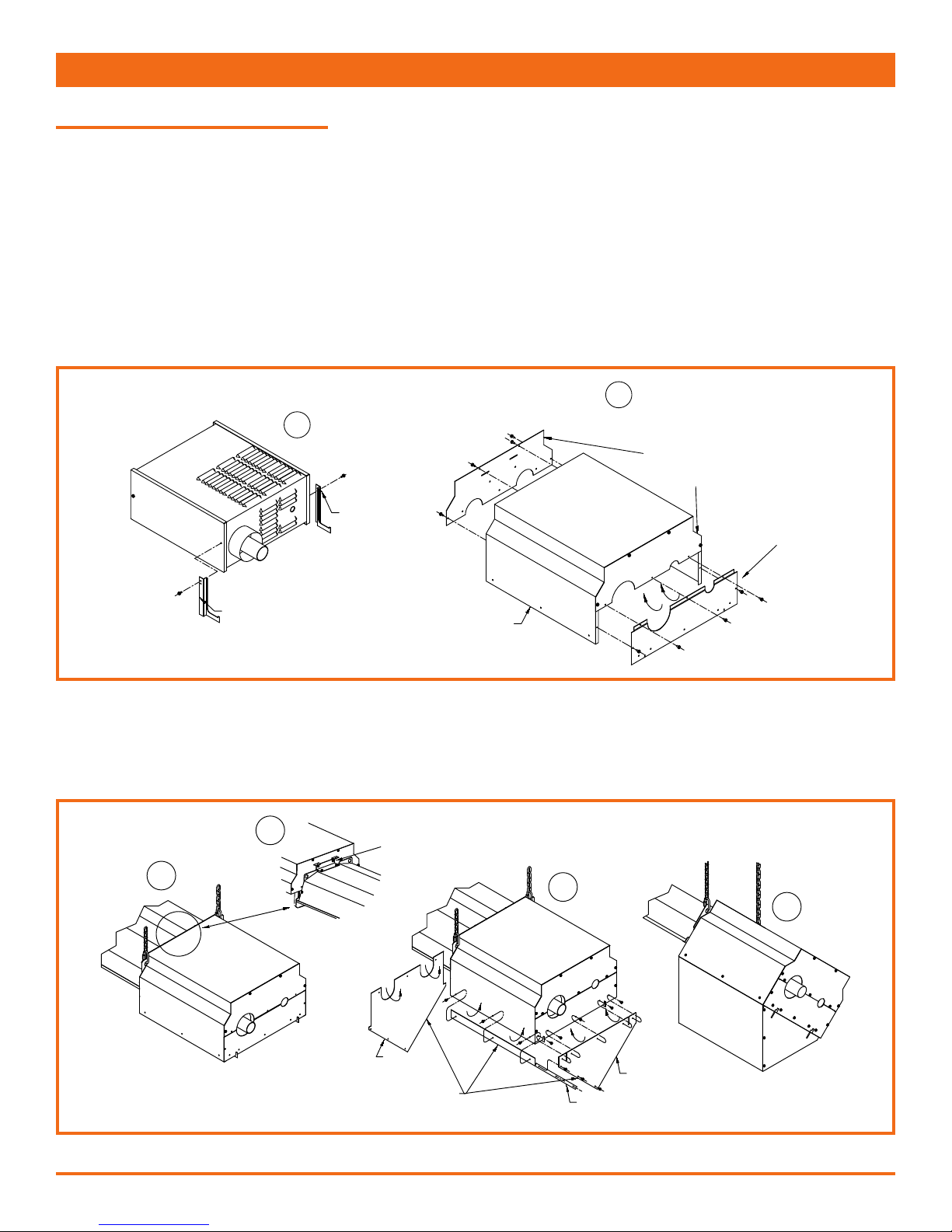

Figure 2: General Overview of Components Utilized in the Installation

Installation Sequence

The heater is sent with all parts necessary for installation with the exception of chain.

It is recommended that the heater be hung as high as possible and along an uncluttered wall to give the reector

a widest possible “view” of the space to be heated. Avoid installation directly over vehicle parking, over cabinets, or

where an open door will interfere. Adhere to minimum clearances on the rating plate.

Leave adequate space around the burner box for future servicing.

Choose a location that permits easy installation of exterior venting. A horizontal vent length up to 10' feet is

allowed. For vertical venting adhere to local venting tables and methods.

As required, fasten hanging angles to ceiling such that heater-hanging points can be accommodated.

Each hanging point must be able to hold at least 150 lbs.

Allow for movement of heater during expansion and contraction during operating cycle.

Heater must re horizontally. To tilt reector at 45°, lengthen two of the hanging points to an appropriate length

using chain. (Each chain length will be approximately 12" inches longer than the high side of the heater. “Quick

hooks and turnbuckles are used, the open ends must be closed to avoid unhooking chain with inadvertent

contact.

Page 5Residential Range RS_10062016al

24"

24"

SIDE

BACK

TOP 8"

Note:

Close all open ended "S" hooks, chain links,

and turnbuckles or any open connection.

Figure 3: Outdoor Heater Installation

INSTALLATION

Outdoor Installation

For outdoor installations the heater must be installed not more than 8” from beneath awnings, and not less

than 24” from back and side as shown in Figure 4. If the heater cannot be protected from the elements by an

overhang, then a protective cover must be installed as shown in Figure 7, Figure 8 and Figure 9.

When the heater is installed with back and side dimensions greater than the minimum of 24” then the

clearance.

Example:

Given: Side dimension = 36"

Back dimension = 48"

A ratio of 3:1 must be maintained

The side dimension gives us a maximum Top dimension of (36/3)" = 12"

The back dimension gives us a maximum Top dimension of (48/3)" = 16"

The new Top dimension is 12", the lesser of the two.

Page 6Residential Range RS_10062016al

INSTALLATION

24.00" Min. or ("B") 8.39" or ("B/3") Max.

28.00" Min. or ("B") 8.00" Max. or ("B/3") 28.00" Min. or ("B") 8.00" Max. or ("B/3")

Figure 4: Mounting Distances for Outdoor Installations under Eaves

Figure 5: Mounting Distances for Tilted (45°) Outdoor Installations under Eaves.

In the case where the heater is installed at a 45° angle, the minimum dimension inside the overhang is 28"

from both the back and side of the burner box and 8" maximum on the top. If the side or back dimensions are

increased then the top clearance may be increased using the same rules as for a horizontal installation.

NOTE: These dimensions are only for satisfying outdoor heater positioning. Clearance to combustible must

Page 7Residential Range RS_10062016al

INSTALLATION

Cover

2

Right Support

Bracket, Install

Screw on

Bottom Hole

Left Support

Bracket, Install

Screw on

Top Hole

1Install Both

Top Covers

As Shown,

Then Install

Assembly on

to Heater

Install Bottom

Cover As Shown

Back

Side

Front

5

4

3

Install 45°

Extension

Covers

As Shown

Attach Cover

Bracket

3

A

B

Note:

Close all open ended "S" hooks, chain links,

and turnbuckles or any open connection.

Figure 6: Cover Installation Sequence Steps 1 and 2

Figure 7: Cover Installation Sequence Steps 3 to 5

Cover Installation Sequence

When a heater is installed outdoors without the presence of an adequate eave, then a protective cover must be

installed as illustrated below. This cover is available from your local dealer (Part # RS020).

1. Install support brackets on to heater covers as shown in step 1 in Figure 6.

2. Preassembled the cover and its top covers and bottom cover as shown in step 2 in Figure 6.

3. Remove the two top screws holding the reector in place.

4. Slide cover onto burner making sure the support brackets slide into slots on the bottom cover.

5. Secure cover to heater by screwing in the cover bracket in step 3B in Figure 7.

6. Install the extension covers (Front, Back, and Side) as shown in step 4 in Figure 7 if needed

When a heater is to be installed outdoors at 45° without the presence of an adequate eave, an extension cover

must be used to protect the heater, refer to step 4 in Figure 7. This extension cover is available through your local

Dealer (Part # RS021). Note that both the cover and extension cover must be used in this case (refer to Figure 8

for completed assembly)..

Page 8Residential Range RS_10062016al

INSTALLATION

Extension Cover

Note:

Close all open ended "chain links,

and turnbuckles or any open connection.

Figure 8: Extension Cover for 45° Outdoor Installations

Page 9Residential Range RS_10062016al

INSTALLATION

DECORATIVE GRILLE

Follow these steps for the installation of the optional decorative grille.

1. Screw Decorative Grille

supports (4) to the outside of

2. Maneuver grille (2) inside the

supports lip.

3. Butt the two grates together.

4. Install and screw support strip

into side supports.

Page 10Residential Range RS_10062016al

VENTING AND COMBUSTION AIR DUCTING

General Requirements

•Refer to the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) in the USA and CSA B149.1 and B149.2

Installation Codes in Canada, as well as all local requirements for vertical venting and general guidance

for minimum distances to openings to the building.

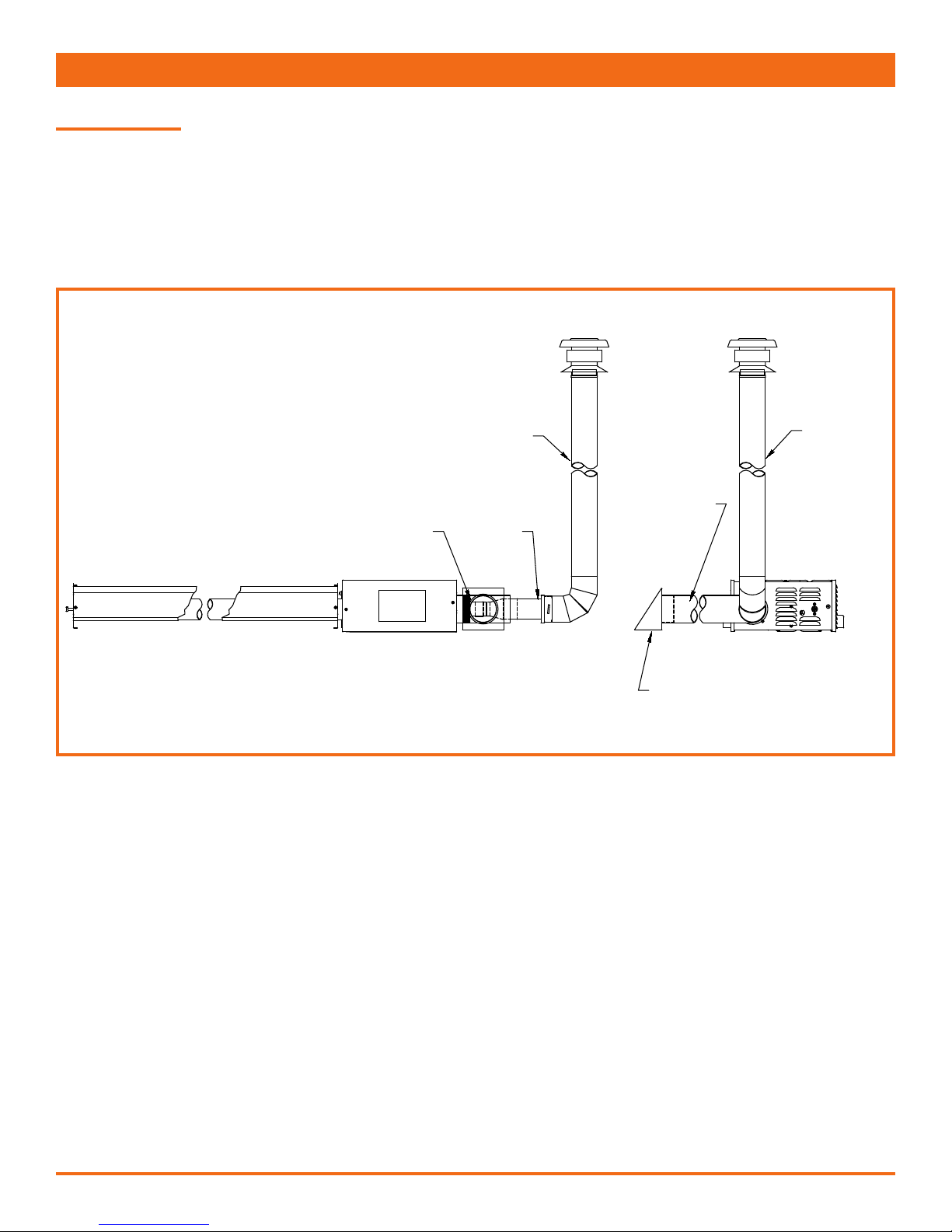

•This equipment is of balanced ue construction and must be horizontally vented (see Figure 9). Vertical

venting is permitted, but not as a balanced ue assembly. (See roof venting)

Wall Thickness

(Max. 10")

(Min. 1")

NOTES:

1- This Heater may be rotated at 45° Tilt, but both ends of the heater must be kept at the same elevation.

2- Total Vent Length (Including One (1) Elbow) = 10'

Each Additional Elbow = 4'

Max. Number Of Elbows = 2

Wall Thimble

P/N RS006

Wall Thickness

(Max. 10")

(Min. 1")

Ø4" Combustion

Air Inlet Duct Ø2" Flue

Pipe Wall Thimble

P/N RS006

Wall Thimble

P/N RS006

Wall Thickness

(Max. 10")

(Min. 1")

Ø4" Combustion

Air Inlet Duct

Ø2" Flue Pipe

Ø4" Combustion

Air Inlet Duct

Ø2" Flue Pipe

Heater may be sloped 1

4" in 10 '

Vent Elbow Kit

P/N RT013

Vent Elbow Kit

P/N RT013

6 6 6

Figure 9: Various Venting Orientations

•A ue/air vent length of 8 feet or less is recommended, although a maximum of 10' feet is allowable

(including one elbow).

•An approved Wall Terminal that allows the air duct to pass through the wall is required. This is included

with your heater. The Wall Thimble is a zero clearance terminal for both combustible and non-combustible

walls.

•For horizontal venting where an elbow is utilized an elbow kit (Part No. RT013) must be used, refer to

Figure 9 for more details.

•The 2" inch ue pipe should extend a minimum of 6" inches beyond the end of the 4" inch wall terminal (for

horizontally vented heaters only see Figure 11). Where the vent is under an eave the 2" vent pipe must have

a minimum clearance of 7" from the centerline of the vent to the bottom of the eave, refer to

•Figure 10. However, when the 2" pipe is less than 18" from the bottom of the eave, we recommend the 2"

inch ue extend just beyond the eave to prevent the possibility of frost. (Adhere to any code requirements

for clearances to opening in the building).

•The 2”-inch ue vent is inside (concentric with) the 4” inch combustion air inlet duct. Each of the

former must be seamless and all joints must be fastened with screws and sealed with GE RTV-106 high

temperature sealant (or equivalent) refer to Figure 11. The exposed 4” combustion air intake pipe is zero

clearance throughout its length.

Page 11Residential Range RS_10062016al

Fasten Screws (Min. one "1" Screw for 2" Flue Pipe)

2" Flue Pipe

(Flue Vent)

4" Combustion Air Inlet Duct

Maximum 10 Feet of Venting

With One (1) Elbow

2" Flue Pipe Should be

Concentric with the 4"

Combustion Air Inlet Duct

Seal Joints With RTV Silicone

Fasten Screws

(Min. 2 Screws

for 4" Duct)

Seal Joints

With RTV Silicone

6.0"

Extension

Wall Thimble

Figure 10: Minimum Clearance under an Eave

Figure 11: Venting & Combustion Air Ducting

VENTING AND COMBUSTION AIR DUCTING

Page 12Residential Range RS_10062016al

VENTING AND COMBUSTION AIR DUCTING

Roof Venting

When heater is to be vented through a roof (Vertical Venting), a B-Vent adapter kit (Part # RS022) must be used.

The B-vent must be installed in accordance to the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) in the USA

and CSA B149.1 and B149.2 Installation Codes in Canada. Refer to the former for correct sizing. Refer to Figure 12

for general overview.

Combustion air may be supplied from the outdoors using the material provided in the vent adapter kit (Part #

RS022) available from your local dealer. Maximum length of fresh air is 10 feet including one elbow. Fresh air

ducting is not provided in the kit.

Vertical Vent Kit

P/N RS022

For Vertical Venting Refer To

ANSI Z223.1 and CAN/CSA B149.1

and B149.2 for Fan Assisted Appliances

for Correct Sizing, Clearance and

Penetration Requirements.

B-Vent

Adapter

4" Combustion

Air Inlet Duct

4" Fresh Air Terminal

(included in vertical vent kit)

B-Vent

Flue Pipe

(Flue Vent)

The B-vent adapter must be secured with screws and sealed with high temperature silicone

sealant.

Install B-vent as per local code requirements.

Figure 12: Roof Venting / Combustion Air Ducting

Page 13Residential Range RS_10062016al

GAS PIPING

•The gas meter and service must be sufciently large to supply gas to the connected building gas load

including the heating equipment and any other gas red equipment. Additionally, the gas distribution

piping must be designed according to local and national ordinances. Generally (low pressure) systems

designed with a maximum ½ in W.C. total pressure drop meet this requirement

•Gas supply pipe sizing must be in accordance with the National Fuel Gas Code, ANSI Z223.1 (NFPA 54)

in the US and CSA B149.1 and B149.2 Installation Codes in Canada.

•Before connecting burners to the gas supply system, verify that high pressure testing of the system

has been completed. Failure to do so may expose the burner components to damaging high pressure,

requiring replacement of key components.

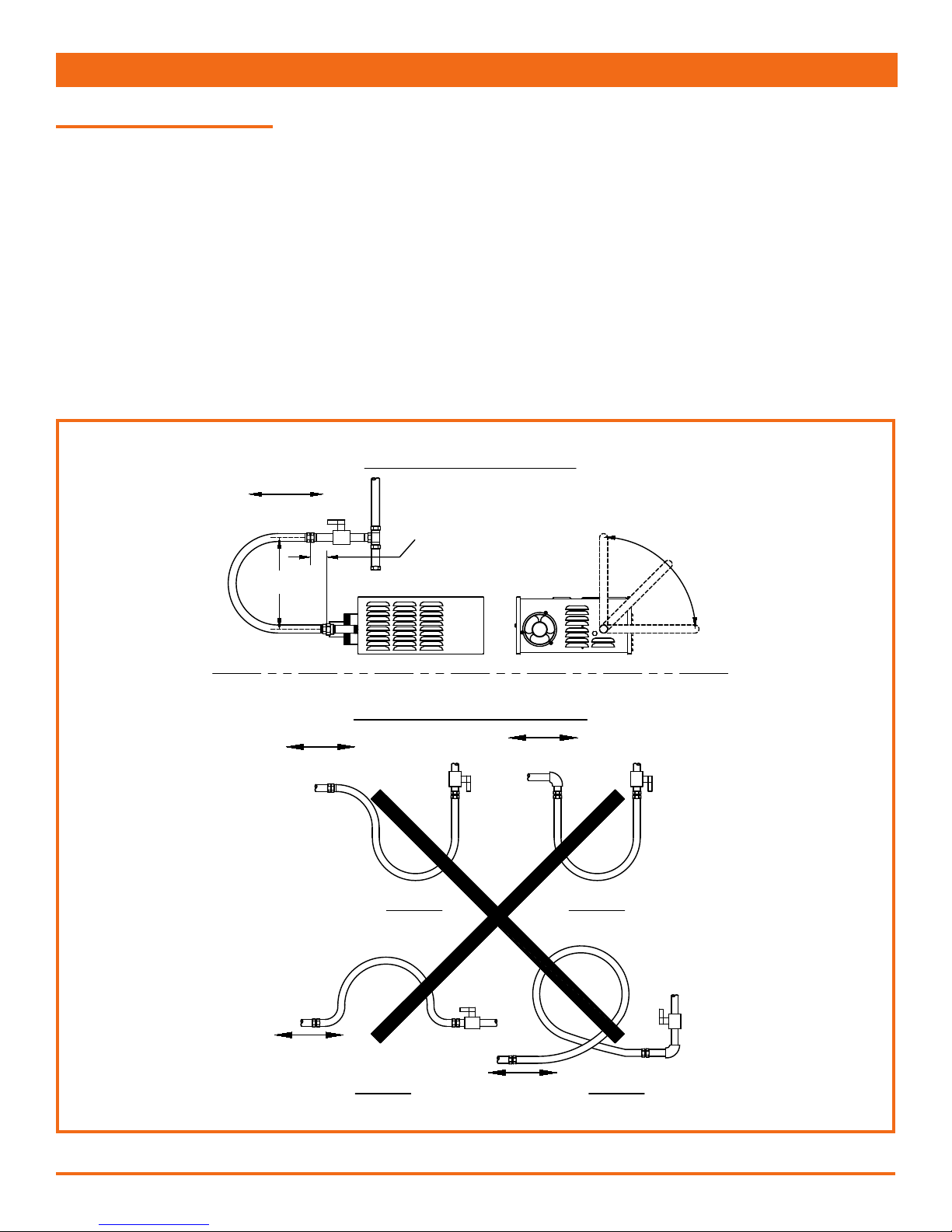

•Flexible gas connectors of approved type must be installed as shown in Figure 30, in one plane, and

without sharp bends, kinks or twists. A smooth loop of approximately 12 in (30 cm) in diameter is best.

Failure to install the gas connection in the approved manner will result in a hazardous and potentially

deadly situation due to the movement of the heat exchanger and burner in the normal course of operation.

General Requirements

3" (7.62 cm) Max.

Displacement

12"

(30 cm)

Heater Movement Vertical

(As Shown Below)

Alternate

Positions

Okay

CORRECT POSITIONS

INCORRECT POSITIONS

WRONG

WRONG WRONG

WRONG

Heater Movement

Heater

Movement

Heater Movement

Heater

Movement

Figure 13: Flexible Gas Connections

Page 14Residential Range RS_10062016al

ELECTRICAL WIRING

General Requirements

Wiring Diagrams

Heaters are normally controlled with the thermostat that is included with your equipment. A 24V signal is supplied

by the heater control module for thermostat connection. Refer to wiring diagram, Figure 14. A bulkhead tting

in the back panel of the control box is provided for the appropriate wire. In all cases, heaters must be grounded

in accordance with the National Electric Code, ANSI/NFPA 70 in the USA, and the Canadian Electric Code, CSA

C22.1 in Canada, and must comply with all local requirements.

If any of the original wire as supplied with the heater must be replaced, it must be replaced with wiring having a

rating of at least 105°C temperature service and 600 volts capability.

FENWALL DSI

TH

PSW

V1

IND

L1

24V

V2

GND

S1

RED

BLACK

BLACK

GREEN

PINK

BLUE

YELLOW

SENSOR

IGNITER

24V

L1

NEUTRAL

TRANSFORMER 120V

RED

BLUE

BLUEPURPLE

PURPLE

BROWNYELLOW

AIR

SWITCH

BLOWER

GAS VALVE

BLACK

BURNER

24 STAT

THERMOSTAT IS

MOUNTED EXTERNALLY

24 VAC THERMOSTAT

FENWALL DSI

TH

PSW

V1

IND

L1

24V

V2

GND

S1

RED

BLACK

BLACK

GREEN

PINK

BLUE

YELLOW

SENSOR

IGNITER

24V

L1

NEUTRAL

TRANSFORMER 120V

RED

BLUE

BLUEPURPLE

PURPLE

BROWNYELLOW

AIR

SWITCH

BLOWER

24 STAT

GAS VALVE

THERMOSTAT IS

MOUNTED EXTERNALLY

BLACK

WHEN CONNECTING 120 VAC STAT,

THE TWO BLUE WIRES USED FOR

THE 24 VAC STAT MUST BE

CONNECTED INTERNALLY.

BURNER

NOTE: THE POST PURGE FEATURE

IS NOT UTILIZED WITH THE

THERMOSTAT WIRED ON THE 120

VAC CIRCUIT. THIS OPTION ONLY

WORKS IF THE HEATER IS WIRED

WITH THE THERMOSTAT ON THE 24

VAC CIRCUIT ABOVE.

120 VAC THERMOSTAT

Figure 14: Internal Wiring

Page 15Residential Range RS_10062016al

OPERATION AND MAINTENANCE

Starting Sequence of Operation

••Turn the thermostat up. When the thermostat calls for heat, the blower motor will energize.

••When the motor approaches nominal running RPM, the air-proving switch closes and activates the ignition

module.

••The ignition module, after a pre-purge period of approximately 30 seconds, energizes the igniter. Additionally,

the gas valve is energized for this ignition trial period of 15 seconds.

••If a ame is detected, the ignition sensing rod “reads” a rectication signal and the gas valve remains

open. The sparking stops when the ame signal is established.

••If no ame is detected, the gas valve closes and a 30 sec inter-purge period begins. After the inter-purge,

the module repeats the trial for ignition period. If ame is still not established, a third and nal inter-purge

followed by a nal ignition trial cycle begins. After three trials, the module will lockout for a period of

approximately 1 hour or until reset. (Reset is accomplished by removing power from the module for at

least 5 seconds.) After this 1-hour period, the module re-attempts the full ignition sequence.

••When using a 24V thermostat and the heat requirement has been met and the thermostat opens, the burner

shuts off but the fan continues to run for approximately 30 seconds. This is referred to as a post purge. This

allows the products of combustion to be removed from the heat exchanger to avoid nuisance condensation

and increase heat exchanger life.

••When using a line voltage thermostat and the heat requirement has been met and the thermostat opens, the

burner and fan shut off with no post purge.

Maintenance

For best performance, the following minimal maintenance procedures should be performed before each heating

season:

••Before performing any service or maintenance, shut off gas and electrical supply to heater.

••Check condition of forced air blower scroll and motor. Dirt and dust may be blown or vacuumed from the

blower.

••Check condition of burner. Remove any foreign objects or debris from inside the burner box or burner cup.

••Inspect the igniter. Replace igniter if there is excessive wear or erosion, breakage or other defects.

••Check inside the heat exchanger tube visually with a ashlight. If carbon or scale are present, scrape or

otherwise remove deposits (a wire brush works well).

••Be sure the burner observation window is clean and free of cracks or holes. Clean or replace as necessary.

••Check the ue pipe for soot or dirt and reattach to the heater after cleaning as necessary.

••The heat exchanger reector sections may be cleaned by wiping with a damp cloth.

••A service agency qualied to adjust and repair infrared heaters should be engaged for service other than

routine maintenance.

••Be sure vent terminal and fresh air inlet are free from obstructions. If either pipe is restricted, the safety air

switch will not operate properly, and the heater could fail to operate.

Page 16Residential Range RS_10062016al

TROUBLESHOOTING

Blower Motor Fails To Run

•Is the thermostat calling for heat? Is there 115V at the burner receptacle?

•Check blower side door for seal. Repair if necessary

•Check blower for obstructions. Replace blower if necessary.

No Gas Supply

•Check to see if manual supply valve to heater is ON.

•Check to see if gas valve knob on heater gas control is ON.

•Supply gas pressure can be checked at 1/8” NPT pressure tapping in gas supply system.

•Is combination gas control opening? No manifold pressure indicates valve is closed. Gas pressure

downstream of gas control can be measured by connecting a manometer to pressure tap on control. If

the valve is closed, either the gas valve or the ignition module is faulty.

Burner Does Not Light

•Is spark visible through site glass during ignition trial? If no, further electrical checks by a qualied service

person are probably necessary.

•Check to see if gas lines were properly purged of air.

•Check inlet and outlet gas pressure during ignition period.

•Check for orice and air plate obstruction.

Burner Does Not Stay Lit

•Check ground wire continuity.

•Check insulation on the igniter leads.

•Measure ame signal current; it should be above 0.8 micro amps DC.

•Replace module if necessary.

This manual suits for next models

1

Table of contents

Other Advanced Radiant Systems Heater manuals