CONTENTS

INTRODUCTION ............................................................................................................................. 1

Installation Codes.............................................................................................................................................1

GENERAL SPECIFICATIONS.......................................................................................................... 2

DIMENSIONAL CHARTS ................................................................................................................ 3

...............................................................................................................................4

................................................................................................4

.....................................................................................................................................6

CLEARANCE TO COMBUSTIBLES ................................................................................................. 7

INSTALLATION ............................................................................................................................ 10

.....................................................................................................................................10

...................................................................................................11

...............................................................................................12

.............................................................................................................................................13

........................................................................................................................15

......................................................................................................................................17

...................................................................................................................... 20

....................................................................................................................... 20

.................................................................................................................21

............................................................................................................ 22

........................................................................................................................... 23

VENTING AND COMBUSTION AIR DUCTING .............................................................................. 24

.................................................................................................................................. 24

..................................................................................................................................... 24

........................................................................................................................................... 25

......................................................................................................................................... 25

........................................................................................................................ 26

............................................................................................................................................. 27

............................................................................................................................. 27

................................................................................................................ 28

................................................................................................. 29

GAS PIPING.................................................................................................................................. 29

.................................................................................................................................. 29

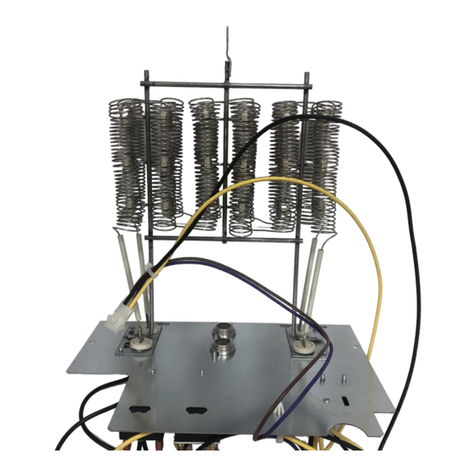

ELECTRICAL WIRING................................................................................................................... 30

.................................................................................................................................. 30

........................................................................... 30

...............................................................................................................31

............................................................................................................. 32

BURNER OPERATION................................................................................................................... 33

................................................................................................................... 33

.................................................................................................................................................. 33

INSTALLATION CHECKLIST ........................................................................................................ 34

TROUBLESHOOTING ................................................................................................................... 35

.................................................................................................................................. 36

REPLACEMENT PARTS ............................................................................................................... 37

WARRANTY.................................................................................................................................. 38