Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installing and servicing of heating and air conditioning equipment can be

hazardous due to system pressures and electrical components. Only

trained personnel should install or service heating and air conditioning

equipment.

Untrained personnel can perform basic maintenance functions such as

cleaning coils, or cleaning and replacing filters. All other operations

should be performed by trained personnel. When working on heating

and air conditioning equipment, observe precautions in literature, on

tags, and on labels attached to the unit.

Follow all safety codes. Wear safety glasses and work gloves. Have a

fire extinguisher available.

Recognize safety information. This is the safety-alert symbol . When

you see this symbol on the unit and in instructions or manuals, be alert to

the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION.

These words are used with the safety-alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury or

death. WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices, which

may result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

NOTE: Use an accessory downflow base to maintain proper clearance

on downflow installations.

EHC

Electric Heater Packages

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Before beginning any installation or modification, be sure the main

electrical disconnect switch(es) is in the OFF position. There may be

more than one power supply. Tag the disconnect switch(es) with a

suitable warning label.

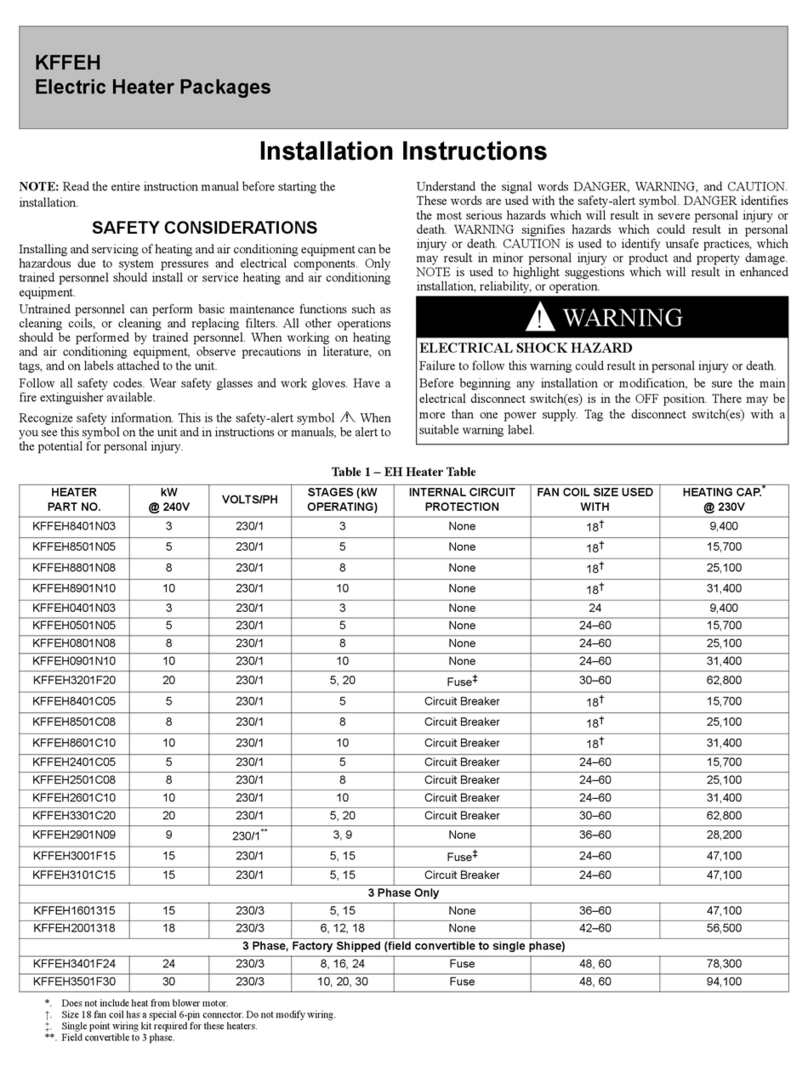

Table 1 – EH Heater Table

HEATER

PART NO.

kW

@ 240V VOLTS/PH STAGES (kW

OPERATING)

INTERNAL CIRCUIT

PROTECTION

FAN COIL SIZE USED

WITH

HEATING CAP.*

@ 230V

*. Does not include heat from blower motor.

EHC05CKN 5 230/1 5 None 18†

†. Size 18 fan coil has a special 6-pin connector. Do not modify wiring.

15,700

EHC07CKN 8 230/1 8 None 18†25,100

EHC10CKN 10 230/1 10 None 18†31,400

EHC05BKN 5 230/1 5 None 24–60 15,700

EHC07BKN 8 230/1 8 None 24–60 25,100

EHC10BKN 10 230/1 10 None 24–60 31,400

EHC20BKF 20 230/1 5, 20 Fuse‡

‡. Single point wiring kit required for these heaters.

30–60 62,800

EHC05CKB 5 230/1 5 Circuit Breaker 18†15,700

EHC07CKB 8 230/1 8 Circuit Breaker 18†25,100

EHC10CKB 10 230/1 10 Circuit Breaker 18†31,400

EHC05BKB 5 230/1 5 Circuit Breaker 24–60 15,700

EHC07BKB 8 230/1 8 Circuit Breaker 24–60 25,100

EHC10BKB 10 230/1 10 Circuit Breaker 24–60 31,400

EHC20BKB 20 230/1 5, 20 Circuit Breaker 30–60 62,800

EHC09BKCN 9 230/1**

**. Field convertible to 3 phase.

3, 9 None 36–60 28,200

EHC15BKF 15 230/1 5, 15 Fuse‡24–60 47,100

EHC15BKB 15 230/1 5, 15 Circuit Breaker 24–60 47,100

3 Phase Only

EHC15BHN 15 230/3 5, 15 None 36–60 47,100

EHC18BHN 18 230/3 6, 12, 18 None 42–60 56,500

3 Phase, Factory Shipped (field convertible to single phase)

EHC25BHCF 24 230/3 8, 16, 24 Fuse 48, 60 78,300

EHC30BHCF 30 230/3 10, 20, 30 Fuse 48, 60 94,100