Advanced Screenworks Mystic Series User manual

© Advanced Screenworks, LLC 2019

INSTALLATION INSTRUCTIONS

Tech Support Help Line:

678-926-9700

Send Tech Support Media to:

678-462-8928

®

2 | P a g e

1. IMPORTANT SAFETY INFORMATION

Read all instructions and the following safety information carefully prior to installation and use. Failure

to do so may result in serious injury or death.

Mystic Motorized Screens are heavy, require electric connection, and may be installed in applications

that require professional skilled workers. Ensure that installation is performed by suitably qualified,

trained, licensed and insured professionals in accordance with applicable local, County, State and

Federal governmental regulations, codes and other requirements.

The bottom weight bar of the Mystic Motorized Screen is heavy. Since movement of heavy objects can

cause serious injuries, your safety and the proper operation of the screen depend on you doing the

following:

-Keep the screen in full view and free of obstruction when in operation;

-Do not allow children to operate the screen;

-Do not close or operate the screen if people or pets are in the door opening;

-Do not hang or place force on the bottom weight bar under any circumstances;

-Do not place fingers, hand or other body parts in the rails or canister when in operation;

-Repairs and adjustments to the screen should be performed exclusively by trained

professionals;

-Do not paint the screen or frame of the unit.

2. TOOLS, EQUIPMENT, AND MATERIALS

-Scissors

-Level

-Blankets/mats

-Ladders (2 if installing

large screens)

-Square

-Dry Silicone Lube

Spray

-Power Drill and

Impact Wrench Set

-Measuring Tape

-Safety glasses or

goggles

-Drill Bit set for metal,

wood, concrete

-Plumb line or laser

level tool

-Saw Horses (optional)

-Hand Screwdriver set

-Pencil

-Fasteners

3. ANCHORS & FASTENERS NOT INCLUDED

Fasteners or anchors for securing the Mystic unit to the structure are not included with the unit.

Installers must furnish the appropriate type of fasteners/anchors depending on the structural material

on to which the unit will be secured.

4. ELECTRICAL REQUIREMENTS, REMOTE AND MOTOR

The Mystic Motorized Screen motor is a 120 VAC, 2.5 AMP, 60Hz unit. The electrical circuit should be

wired with 14 gauge wire, 110-120V AC, 15 AMP and grounded.

The unit may be plugged into an outlet or hard-wired directly to a circuit. If hard-wired, it is

recommended that an electrical switch be placed in the circuit, near to the unit.

For multi-unit applications, up to 5 units may be connected to a standard 15 AMP circuit.

The remote and motor communicate via RF. The remote and motor may stop communicating as a result

of power surges caused by a variety of circumstances. Follow instructions contained herein to reconnect

the motor and remote. The limits are mechanical and are generally not affected by power surges.

3 | P a g e

5. PREPARATION OF JOB SITE, OPENING PACKAGES

********** DO NOT USE A KNIFE OR UNPROTECTED BLADE TO OPEN PACKAGES **********

Each Mystic unit comes packaged in two sturdy cardboard tubes with metal caps screwed on to the ends

of the tubes.

If you are not using saw horses, spread blankets on floor or lawn to protect the painted metal frames

from scratches and the screen fabric from damage.

Using a power tool, remove the screws from one metal end-cap on each tube.

Using a sturdy screwdriver or other flat tool, remove the metal end-cap from the tubes.

Slide the contents of each tube out of the tube and carefully lay it on the saw horses or protective

blanket. Carefully remove the foam covering using scissors or by hand.

Remove the canister cover by undoing the screw that secures the cover to each end of the canister. Save

the screws in a safe location.

Remove the contents inside the canister. Depending on the dimensions of the unit, the canister will

either contain (a) the screen panel rolled up on the motorized metal tube or (b) the assembled side rails,

bottom weight bar, and hardware bag. Save any non-packaging items in a safe location.

Using a hand screwdriver, unscrew the inner rail from the outer rail of the 2 side rail assemblies. Save

the screws in a safe location.

Your package contents should be:

-1 L-Shaped Canister back assembly with end-caps and mounting brackets installed; and

-1 Canister front - curved; and

-1 Screen panel assembly: screen panel rolled up on metal tube; motor on one end; idler

spring at other end; side zipper cutout on bottom right for weight bar installation; 3 zipper

teeth cut off the bottom zipper to allow for proper motion of screen panel; and

-1 bottom weight bar assembly; plastic end-caps on each end of bottom bar; and

-2 Inner side rails with plastic entry guide installed at the top; and

-2 Outer side rails (with predrilled access holes if unit is to be surface mounted); and

-1 Hardware bag containing:

Remote control(s)

Extra hood screw (2 pieces)

Yellow limit adjustment tool

Color Matched Hole Caps (if surface

mount)

Inner Side rail screws

Mystic Installation Instructions

Electrical plug

Mystic Motor & Remote Programming

Instructions

4 | P a g e

6. PREPARATION OF THE STRUCTURE: FLAT, LEVEL, PLUMB, AND SQUARE

***** THE UNIT WILL NOT OPERATE PROPERLY UNLESS IT IS FLAT, LEVEL, PLUMB, AND SQUARE *****

i. For Recessed Mount Applications, ensure that:

(a) FLAT & LEVEL:

a. The base surface of the header to which the canister back will be secured is flat and

level; and

b. The floor/base is flat and level; (the bottom weight bar is equipped with a brush pile

seal which is designed to conceal minor variations in the floor/base surface in

addition to impeding incursions by bugs; and

c. Take 3 measurements from header to floor/base; left, middle, and right. They

should be identical otherwise you may have to use shims; and

(b) PLUMB:

a. Take 3 measurements from side jamb to side jamb; top, center, bottom. They

should be identical otherwise you may have to use shims; and

b. Using a level or plumb line ensure that the side jambs are plumb; and

(c) SQUARE:

Measure the two diagonals: top left to bottom right corners; top right to bottom left

corners. The measurements should be identical.

ii. For Surface Mount Applications, ensure that:

(a) FLAT & LEVEL:

a. Using a laser line or level on the header, pencil in a line at the height at which the

top of the canister will be located; and

b. Check the floor/base to ensure that it is flat and level; (the bottom weight bar is

equipped with a brush pile seal which is designed to conceal minor variations in the

floor/base surface in addition to impeding incursions by bugs; and

(b) PLUMB:

Using a laser line or level on each side jamb, pencil in a line at the width at which the

outer edge of the side rails will be located; and

(c) SQUARE:

Measure the two diagonals: top left to bottom right corners; top right to bottom left

corners. The measurements should be identical.

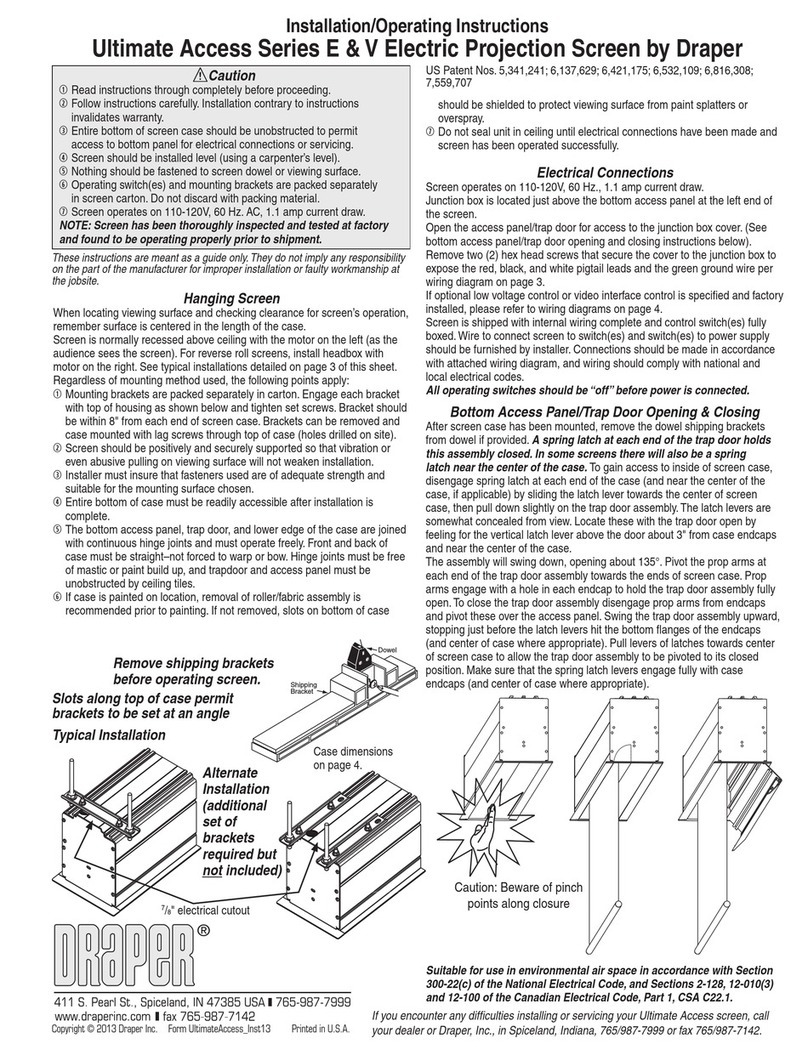

7. INSTALL THE CANISTER

**** Depending on the size of the unit, 2 persons may be needed for this step of the installation ****

Identify the location where the electrical cord will be located. Drill a 5/8” diameter hole on the canister

in the location where the electrical cord will exit the canister. The 5/8” diameter hole should be near to

the end of the canister with the U-bracket that receives the motor. Drill any additional holes needed in

the jamb structure through which the electrical cord will be passed to reach the circuit.

i. For Recessed Mount Applications: Secure the top of the canister to the underside of the

header jamb.

ii. For Surface Mount Applications: Secure the back of the canister to the surface of the

header jamb with the top edge along the line drawn in Instruction 6 ii. (a)

For units under 12’ wide use 2 fasteners positioned 1’from each end of the canister. For units over 12’

wide use a 3rd fastener in the center. Use a washer on each fastener if necessary.

5 | P a g e

8. INSTALL THE OUTER RAILS

For Recessed Mount Applications:

Place one outer rail directly under the edge of the canister and firmly along the side jamb of the

structure.

The face of the outer rail that is towards the back of the canister should be lined up with the

back of the canister and run plumb vertically to the floor/base of the structure.

The open side of the outer rail should be facing towards the interior of the opening.

Secure the outer rail to the side jamb using the appropriate fastener.

Repeat for 2nd outer rail.

For Surface Mount Applications:

Place one outer rail directly under the edge of the canister and firmly along the face of the side

jamb of the structure.

The outer edge of the outer rail should be exactly along the line drawn in Instruction 6 ii. (b).

The access holes for installing the fasteners should face outwards.

The open side of the outer rail should be facing towards the interior of the opening.

Secure the outer rail to the side jamb using the appropriate fastener.

Install the color-matched hole-caps in the access holes of the outer side rail.

Repeat for 2nd Outer rail.

9. INSTALL THE SCREEN PANEL, TUBE, MOTOR ASSEMBLY

**** Depending on the size of the unit, 2 persons may be needed for this step of the installation ****

Orient the screen tube assembly such that:

a. The motor end of the assembly is at the end of the canister with the 5/8” hole and at the end of

the canister with the U-bracket.

b. The spring idler end of the assembly is on the end of the canister with the starred bracket;

c. The bottom zipper is falling off the back of the screen motor tube assembly;

d. Turn tube so as to unroll the entire screen panel until you see the top zipper on the roll-tube;

e. The two limit adjustment switches on the end of the motor must be accessible from the front.

Place the spring idler end of the screen tube assembly in the bracket with the starred hole.

Pass the electrical cord through the 5/8” hole made for that purpose in Instruction 7 above. Loop and tie

the electrical cord with the loop below the motor, such that any water running along the cord will not

reach the head of the motor.

Place the square metal idler of the motor end of the screen tube assembly in the U-bracket and secure

the motor end to the U-bracket using the Cotter pin. Use the holes closest to the bottom of the U-

bracket.

Install the electrical plug to the end of the power cord and plug it in; OR Connect the power cord to the

circuit

With the screen panel hanging off the back of the metal roll-tube assembly and then continuing down

along the front of the two outer side rails, move the top zipper, secured on to the metal roll-tube, to the

left or right such that the side zippers of the screen panel line up with the lines down the center of the

outer side rails

6 | P a g e

10. INSTALL THE BOTTOM WEIGHT BAR ASSEMBLY

NOTE: to perform the instruction in this section, you may need to adjust the temporary factory set limits

on the motor by following the instructions found in the accompanying document entitled “Instructions

for the Mystic Classic Remote and Motor”

Using the UP button on the remote, raise the bottom zipper to a comfortable level so that you can slide

the bottom weight bar on to the bottom zipper. If the bottom zipper stops before it reaches a

satisfactory level when the UP button is pressed, then follow the instructions to INCREASE the

temporary factory set upper limit.

On the screen panel, a small section of the bottom of the RIGHT SIDE ZIPPER is cut out so that the

bottom weight bar may be easily slid on to the bottom zipper. On the bottom weight bar, there is a

channel that receives the bottom zipper of the screen panel. Slide the bottom weight bar from right to

left on to the bottom zipper of the screen panel. Line up the T-ends of the bottom weight bar end-caps

with the center lines of the outer side rails.

Using the remote control, raise the bottom weight bar to approximately 2 inches from the top of the

outer side rail and let it hang there. Again, you will need to adjust the upper limit if the screen panel

does not roll up sufficiently.

11. INSTALL THE INNER RAILS ASSEMBLY

****** DO NOT SCREW THE INNER RAIL TO THE OUTER RAIL UNTIL INSTRUCTION# 12 BELOW *******

Orient the inner rails, so that the black plastic entry guides installed on the inner rail is at the top.

For one of the inner rails, pass the T-end of the bottom weight bar end-cap into the rectangular channel

of the black plastic entry guide. Also, allow the teeth of side zipper of the screen panel to follow the T-

end of bottom weight bar end-cap into the same rectangular channel of the entry guide. Insert the inner

side rail firmly into the outer side rail.

Repeat the above instruction for the 2nd inner rail.

Allow the inner rail to stay loose inside of the outer rail. Do not attach any screws as yet.

12. SET YOUR FINAL UPPER AND LOWER LIMITS FOR THE SCREEN PANEL

Follow the instructions in the accompanying “Instructions for the Mystic Classic Remote and Motor” to

set your final upper and lower limits for the screen panel.

NOTE: At its upper limit, the bottom weight bar must hang into the side rails such that the side zippers

are always contained below the plastic entry guides at the top of the inner side rails. The bottom weight

bar does not store in the canister. It hangs below the canister.

Test the motion of the screen panel by running it up and down once. Do not do this too many times as

the motor will shut down if it overheats. If this occurs, wait approximately 20 minutes for the motor to

cool down before proceeding.

7 | P a g e

13. SECURE SCREWS ATTACHING INNER SIDE RAIL TO OUTER SIDE RAIL

************* IMPORTANT: DO NOT USE POWER TOOLS IN THIS STEP. **************

Using a hand screwdriver, secure the inner rail to the outer rail using the screws supplied. These screws

should not be tightened to the maximum. They should be turned enough so that (a) the screw head

does not interfere with the bottom bar end-caps, and (b) the screen panel is sufficiently taut from side

to side, and (c) the bottom weight bar can move ¼” to ½” side-to-side.

Test the motion of the screen panel to verify that the screw heads do not obstruct the bottom bar by

using the remote control to raise and lower the screen panel.

14. INSTALL COVER ON CANISTER BACK ASSEMBLY

Hang the canister cover in the groove at the front top of the canister and secure it to the bottom using

the two screws that were removed in Instruction 5.

Measure the distance from the bottom edge of the canister cover and the bottom of the metal section

of the bottom weight bar. This dimension should be no less than 2 ¼”. If it is less than 2 ¼” it means that

the side zippers will not reliably stay in the entry guide and inner side rails. To fix this problem, follow

the instructions to reduce the upper limit so that the bottom weight bar hangs lower such that this

dimension is 2 ¼” or more.

15. FINAL CHECKS

It is recommended that, with the bottom weight bar in the fully up position, a light spray of Dry Silicone

Lube be applied to the length of the inner side rail. This will assist with the smooth functioning of the

unit. Test the motion of the unit.

Leave the Yellow Limit Adjustment Tool with the customer for safekeeping and for use in the event that

the limits need to be adjusted.

16. MAINTENANCE, CARE, AND USE

On a quarterly basis, a light spray of Dry Silicone Lube be applied to the length of the inner side rail. This

will assist with the smooth functioning of the unit.

Should the screen fabric become dirty, it may be washed using a mild detergent spray, e.g. Downy in a

spray container. Spray on detergent and wash down using a hose. Leave screen panel in the down

position to air dry.

Should the remote and motor become decoupled as a result of a power surge caused by inclement

weather or other circumstances, follow the instructions found in the accompanying document entitled

“Instructions for the Mystic Classic Remote and Motor” to re-couple the motor and remote.

8 | P a g e

This page is intentionally blank.

INSTRUCTIONS FOR THE MYSTIC CLASSIC MOTORS & REMOTE

IMPORTANT NOTES BEFORE YOU START:

1. THE MOTOR AND REMOTE ARE SYNCHRONIZED AND PRE-PROGRAMMED AT THE FACTORY.

2. PLEASE READ EACH INSTRUCTION CAREFULLY AND COMPLETELY BEFORE PERFORMING THE

ACTIONS DESCRIBED IN THE INSTRUCTION.

3. The Celtic Motor used in the Mystic Classic Motorized Screen is equipped with an AUTOMATIC

THERMAL CUTOFF MECHANISM that acts to prevent the motor from overheating. Depending

on the outdoor temperature, if the motor is run continuously for 3-5 minutes it will shut down

automatically. If this occurs, it will require approximately 20 minutes to cool down.

4. FOR EACH INSTRUCTION, IT IS ASSUMED THAT YOU HAVE SELECTED THE APPROPRIATE

CHANNEL ON THE REMOTE THAT IS TO BE PROGRAMMED. IT IS EXTREMELY IMPORTANT THAT

YOU FOLLOW THE STEPS AND BUTTON SEQUENCES EXACTLY AS DESCRIBED OTHERWISE THE

PROGRAMMING WILL NOT BE ACCEPTED. THIS IS BECAUSE THE MOTOR IS SET TO ACCEPT ONLY

EXACT SEQUENCES OF BUTTON COMBINATIONS FROM THE REMOTE. IF YOU DO NOT PERFORM

THE STEPS EXACTLY, YOU MAY HAVE TO RESET THE MOTOR/REMOTE AND START OVER FROM

THE BEGINNING. THE INSTRUCTION TO RESET THE MOTOR/REMOTE IS THE LAST INSTRUCTION

BELOW.

5. ONLY ONE motor/remote combination can be programmed at any point in time. If you are

installing MULTIPLE UNITS at the same job site, you will have to turn off power to all units

except the one that you are programming.

6. Power surges or static electric discharges caused by bad weather or other circumstances may

cause the motor and remote to become unpaired. The Mystic Classic motor has mechanical

limits, these limits are unlikely to be lost during a power surge. In the event that this occurs

simply follow the instruction to re-synchronize the motor and remote. Ensuring that the unit is

properly grounded may help to prevent this from occurring.

7. If you are hard-wiring the motor to the electric circuit, it is recommended that you install a

switch in that circuit and in the vicinity of the Mystic unit so that the power to the unit may be

turned on and off in the event that the unit has to be reprogrammed because of power surges

caused by bad weather or other circumstances.

8. It is recommended that you leave the Limit Adjustment Tool with the homeowner and instruct

him/her to keep it in a safe place so that it is available in the event that it becomes necessary to

reprogram the unit. A 5/32” or 4mm Allen Wrench or Hex Screwdriver may be used in place of

the Limit Adjustment Tool, if it is lost or misplaced.

955 Patrick Industrial Ct

Winder, GA 30680

Phone: 678-926-9700

Fax: 678-288-7924

A. THE MOTOR AND SIX CHANNEL REMOTE COMES FROM THE FACTORY WITH CHANNEL ONE

SYNCHRONIZED.

B. TEMPORARY UPPER AND LOWER LIMITS HAVE BEEN SET AT THE FACTORY. THE SCREEN PANEL IS

ROLLED UP ON THE TUBE SO THAT WHEN YOU POSITION IT CORRECTLY IN THE HOOD WITH THE

LIMIT ADJUSTMENT SWITCHES FACING FORWARD THE SCREEN PANEL WILL BE AT ITS UPPER

LIMIT. YOU WILL NEED TO ADJUST THE LOWER LIMIT TO ITS PERMANENT POSITION. YOU WILL

ALSO NEED TO FINE TUNE THE UPPER LIMIT.

C. THERE WILL BE NO NEED TO CHANGE ANY OTHER PROGRAMMING IN THE REMOTE UNLESS

SIGNIFICANT CHANGES ARE MADE TO THE UNIT, SUCH AS CUTTING THE VERTICAL SIDE RAILS.

D. HOW TO: SWITCH THE MOTOR BETWEEN CONTINUOUS AND MANUAL MODE

Prior to adjusting any of the factory settings of the motor and remote, be sure to place the

motor in manual mode.

In manual mode, when you press & release the UP or DOWN buttons the screen moves

approximately 3” and stops. In manual mode, if you press & hold the UP or DOWN button for 3

seconds then the screen will run continuously.

Being in manual mode will reduce the chance of damage occurring to the unit while settings are

being changed. To do this:

1. PRESS & HOLD the STOP BUTTON until the motor jogs up and down or sounds 5

beeps

2. Within the 5 beeps, release the STOP BUTTON, THEN PRESS & RELEASE the STOP

BUTTON. The motor will jog up and down or sound 3 beeps

To take the motor out of manual mode and back into continuous mode repeat steps 1 & 2

above.

E. HOW TO: REVERSE THE DIRECTION OF THE MOTOR

Should the motor be in a state where the UP button on the remote lowers the screen panel and

the DOWN button raises the screen panel, you will need to reverse the direction of the motor.

To do this:

1. PRESS & HOLD the STOP BUTTON until the motor jogs up and down or sounds 5

short beeps.

2. Within the 5 beeps, PRESS & RELEASE the DOWN BUTTON. The motor will jog

up and down or sound 3 short beeps.

F. HOW TO: SET AND ADJUST UPPER AND LOWER LIMITS

1. ALWAYS SET THE LOWER LIMIT FIRST

2. USE THE DOWN ARROW ON THE REMOTE TO MOVE THE BOTTOM BAR DOWN. IF THE BOTTOM

BAR DOES NOT STOP BEFORE 1’ FROM THE BOTTOM, PRESS THE STOP BUTTON TO STOP IT 1’

FROM THE BOTTOM.

3. THE WHITE RECTANGULAR BLOCK ON THE VISIBLE END OF THE MOTOR HAS TWO HOLES

CONTAINING THE LIMIT ADJUSTMENT SWITCHES. THE LIMIT ADJUSTMENT SWITCH THAT

CONTROLS THE LOWER LIMIT IS ALWAYS IN THE TOP HOLE REGARDLESS OF WHICH SIDE (left or

right) THE MOTOR IS MOUNTED. ABOVE THE TOP HOLE, THERE IS AN ARROW ABOVE THE PLUS

(+) SIGN AND THERE IS AN ARROW ABOVE THE MINUS (-) SIGN. TURNING THE LIMIT

ADJUSTMENT TOOL IN THE DIRECTION OF THE PLUS (+) ARROW or the counter-clockwise

DIRECTION INCREASES THAT LIMIT AND TURNING THE LIMIT ADJUSTMENT TOOL IN THE

DIRECTION OF THE MINUS (-) ARROW or the clockwise DIRECTION REDUCES THAT LIMIT.

4. NOW ADJUST THE LOWER LIMIT:

1. IF THE SCREEN STOPPED BEFORE IT GOT TO

WITHIN 1' OF THE BOTTOM

2. IF YOU HAD TO STOP THE SCREEN BEFORE

IT GOT TO WITHIN 1' OF THE BOTTOM

1-A. YOU HAVE FOUND THE FACTORY-SET

TEMPORARY LOWER LIMIT. HOWEVER, THE

FACTORY-SET TEMPORARY LOWER LIMIT IS

TOO SHORT. SO, YOU NEED TO INCREASE THE

LOWER LIMIT POSITION

2-A. THE FACTORY-SET TEMPORARY LOWER

LIMIT IS SET TOO LONG. THEREFORE, YOU

NEED TO REDUCE THE LOWER LIMIT POSITION.

1-B. PLACE THE LIMIT ADJUSTMENT TOOL

INTO THE TOP HOLE ON THE END OF THE

MOTOR. TURN THAT LIMIT ADJUSTMENT

SWITCH IN THE DIRECTION OF THE PLUS (+)

ARROW or the counter-clockwise DIRECTION.

THE BOTTOM BAR WILL JOG DOWN WITH

EACH TURN. CONTINUE TO TURN UNTIL THE

BOTTOM BAR REACHES THE DESIRED LOWER

POSITION. AT THAT POINT YOUR LOWER LIMIT

IS SET.

2-B. PLACE THE LIMIT ADJUSTMENT TOOL

INTO THE TOP HOLE ON THE END OF THE

MOTOR. TURN THAT LIMIT ADJUSTMENT

SWITCH IN THE DIRECTION OF THE MINUS (-)

ARROW or the clockwise DIRECTION FOR 25

COMPLETE TURNS.

Note: 7 complete turns of the Limit

Adjustment Tool results in one complete

rotation of the screen tube.

2-C. USING THE REMOTE, RAISE THE BOTTOM

BAR 2 FEET AND THEN LOWER IT. IF IT DOES

NOT STOP BEFORE IT REACHES 1' FROM THE

BOTTOM, STOP IT 1' FROM THE BOTTOM.

2-D. REPEAT STEPS 2-B AND 2-C UNTIL THE

BOTTOM BAR STOPS BY ITSELF. WHEN THE

BOTTOM BAR STOPS BY ITSELF YOU HAVE

FOUND THE TEMPORARY LOWER LIMIT.

2-E. PERFORM INSTRUCTION 1. (1-A AND 1-B)

ON THE LEFT COLUMN OF THIS TABLE OF

INSTRUCTIONS TO FINE TUNE THE LOWER

LIMIT.

5. NEXT, WE WILL SET THE UPPER LIMIT. USE THE UP ARROW ON THE REMOTE TO MOVE THE

BOTTOM BAR UP. IF THE BOTTOM BAR DOES NOT STOP BEFORE 1’ FROM THE TOP, PRESS THE

STOP BUTTON TO STOP IT 1’ FROM THE TOP.

CAUTION#1: Do not allow the bottom bar to rise too far so as to run up into the hood.

CAUTION#2: Do not set your upper limit too high. The guides of the bottom bar and a short

length of the side zippers should be completely contained in the side rails.

6. THE WHITE RECTANGULAR BLOCK ON THE VISIBLE END OF THE MOTOR HAS TWO HOLES

CONTAINING THE LIMIT ADJUSTMENT SWITCHES. THE LIMIT ADJUSTMENT SWITCH THAT

CONTROLS THE UPPER LIMIT IS ALWAYS IN THE LOWER HOLE REGARDLESS OF WHICH SIDE (left

or right) THE MOTOR IS MOUNTED. BELOW THE LOWER HOLE, THERE IS AN ARROW BELOW THE

PLUS (+) SIGN AND AN ARROW BELOW THE MINUS (-) SIGN. TURNING THE LIMIT ADJUSTMENT

TOOL IN THE DIRECTION OF THE PLUS (+) ARROW or the counter-clockwise DIRECTION

INCREASES THAT LIMIT AND TURNING THE LIMIT ADJUSTMENT TOOL IN THE DIRECTION OF THE

MINUS (-) ARROW or the clockwise DIRECTION REDUCES THAT LIMIT.

7. NOW, WE WILL ADJUST THE UPPER LIMIT.

3. IF THE SCREEN STOPPED BEFORE IT GOT TO

WITHIN 1' OF THE TOP

4. IF YOU HAD TO STOP THE SCREEN BEFORE

IT GOT TO WITHIN 1' OF THE TOP

3-A. YOU HAVE FOUND THE FACTORY-SET

TEMPORARY UPPER LIMIT. HOWEVER, THE

FACTORY-SET TEMPORARY UPPER LIMIT IS

TOO LOW. SO, YOU NEED TO INCREASE THE

UPPER LIMIT POSITION

4-A. THE FACTORY-SET TEMPORARY UPPER

LIMIT IS SET TOO HIGH. NOW YOU NEED TO

REDUCE THE UPPER LIMIT POSITION.

3-B. PLACE THE LIMIT ADJUSTMENT TOOL

INTO THE LOWER HOLE ON THE END OF THE

MOTOR. TURN THAT LIMIT ADJUSTMENT

SWITCH IN THE DIRECTION OF THE PLUS (+)

ARROW or the counter-clockwise DIRECTION.

THE BOTTOM BAR WILL JOG UP WITH EACH

TURN. CONTINUE TO TURN UNTIL THE

BOTTOM BAR REACHES THE DESIRED UPPER

POSITION. AT THAT POINT YOUR UPPER LIMIT

IS SET.

4-B. PLACE THE LIMIT ADJUSTMENT TOOL

INTO THE LOWER HOLE ON THE END OF THE

MOTOR. TURN THAT LIMIT ADJUSTMENT

SWITCH IN THE DIRECTION OF THE MINUS (-)

ARROW or the clockwise DIRECTION FOR 25

COMPLETE TURNS.

Note: 7 complete turns of the Limit

Adjustment Tool results in one complete

rotation of the screen tube.

4-C. USING THE REMOTE, LOWER THE

BOTTOM BAR 2 FEET AND THEN RAISE IT. IF IT

DOES NOT STOP BEFORE IT REACHES 1' FROM

THE TOP, STOP IT 1' FROM THE TOP.

4-D. REPEAT STEPS 4-B AND 4-C UNTIL THE

BOTTOM BAR STOPS BY ITSELF. WHEN THE

BOTTOM BAR STOPS BY ITSELF YOU HAVE

FOUND THE TEMPORARY UPPER LIMIT.

4-E. PERFORM INSTRUCTION 3. (3-A AND 3-B)

ON THE LEFT COLUMN OF THIS TABLE OF

INSTRUCTIONS TO FINE TUNE THE UPPER

LIMIT.

G. HOW TO: SYNCHRONIZE A 2ND REMOTE (EITHER A 2ND HAND HELD OR WALL MOUNT) TO THE

MOTOR:

1. PRESS AND HOLD THE STOP BUTTON ON THE PRIMARY HAND HELD REMOTE. THE MOTOR

WILL JOG OR BEEP 5 TIMES. RELEASE THE STOP BUTTON.

2. PRESS AND RELEASE THE UP BUTTON ON THE 2ND REMOTE. THE MOTOR WILL JOG OR BEEP

3 TIMES TO CONFIRM THAT THE 2 REMOTES ARE SYNCHRONIZED.

H. HOW TO: PAIR A REMOTE TO A MOTOR OR RE-SYNCHRONIZE A MOTOR AND REMOTE THAT

HAVE BECOME DELINKED

1. DISCONNECT THE POWER FROM THE MOTOR; UNPLUG IF IT IS PLUGGED IN OR TURN OFF

BREAKER IF THE MOTOR IS HARD-WIRED.

2. PRESS & HOLD THE UP BUTTON UNTIL THE LIGHT ON THE REMOTE GOES SOLID.

3. WHILE CONTINUING TO HOLD DOWN THE UP BUTTON, TURN THE POWER BACK ON TO THE

MOTOR: PLUG IT BACK IN IF PLUGGED, TURN ON BREAKER IF HARD WIRED

4. RELEASE THE UP BUTTON AND THEN IMMEDIATELY PRESS & RELEASE THE UP BUTTON

ONCE.

I. HOW TO: RESET MOTOR & REMOTE; DECOUPLE REMOTE FROM MOTOR; DELETE

PROGRAMMING

1. PRESS AND HOLD THE STOP BUTTON. THE MOTOR WILL JOG OR BEEP 5 TIMES. RELEASE

THE STOP BUTTON.

2. TURN TO THE BACK OF THE REMOTE AND USING A PAPER CLIP/TOOTH PICK/PIN PRESS

THE PROGRAM BUTTON, WHICH IS LOCATED IN THE HOLE FOUND IN THE BACK OF THE

REMOTE. THE MOTOR WILL JOG OR BEEP 3 TIMES TO CONFIRM THAT PROGRAMMING

HAS BEEN DELETED.

Table of contents

Popular Projection Screen manuals by other brands

Grandview

Grandview Pull Up Portable Screen user manual

DecisionVision

DecisionVision DV-15 Operator's manual

Screen Research

Screen Research SolidPix installation manual

Elite Screens

Elite Screens EVANESCE TAB-TENSION Series Replacement instructions

AVstumpfl

AVstumpfl DECOFRAME manual

AVstumpfl

AVstumpfl INLINE 90 manual