Advanced 3320 User manual

3325SM Rev10 092515

Advanced®Micro-Osmometer Model 3320

Service Manual

3

1. Introduction

Specifications . . . . . . . . . . . . . . . . . . . . .7

General Description and Purpose . . . . .8

Service Assistance . . . . . . . . . . . . . . . . .8

Safety/Regulatory Information . . . . . . .9

Symbol Conventions . . . . . . . . . . . . . . .9

General Cautions . . . . . . . . . . . . . . . . . .9

Service & Maintenance Cautions . . . .10

Hazardous Material Cautions . . . . . . .11

Regulatory Notices . . . . . . . . . . . . . . .11

Symbol Conventions . . . . . . . . . . . . . .11

FCC Requirements . . . . . . . . . . . . . . . .11

2. General Overview

Overview . . . . . . . . . . . . . . . . . . . . . . .17

3320 Circuit Description . . . . . . . . . . .19

Power Supply . . . . . . . . . . . . . . . . . . . .19

Front End . . . . . . . . . . . . . . . . . . . . . . .19

332620 Control Board Set . . . . . . . . .19

PCB120 Processor Board . . . . . . . . . .19

PCB115 Application Board . . . . . . . . .21

Back Panel I/O Board . . . . . . . . . . . . .21

Instrument Software Updates . . . . . . .23

Design Changes . . . . . . . . . . . . . . . . . .24

Replacement Parts . . . . . . . . . . . . . . . .25

Supplies & Accessories . . . . . . . . . . . .25

3. Maintenance

Maintaining the Instrument . . . . . . . . .29

Solenoid Cleaning Procedure . . . . . . .31

4. Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . .35

Diagnostic Menu . . . . . . . . . . . . . . . . .35

A/D Tests . . . . . . . . . . . . . . . . . . . . . . .35

Probe Bin Test . . . . . . . . . . . . . . . . . . .35

Solenoid Test . . . . . . . . . . . . . . . . . . . .35

Display/Print Test . . . . . . . . . . . . . . . .35

Key/Beeper Test . . . . . . . . . . . . . . . . . .35

Barcode Test . . . . . . . . . . . . . . . . . . . .35

Troubleshooting Table . . . . . . . . . . . . .37

5. Replacement Instructions

Actuator Switch (332318R) . . .332P318

Back Panel I/O Board

(PCB140R) . . . . . . . . . . . . . .332P140

Block Probe (332340R) . . . . . . .332P340

Block Probe Cable (332341R) .332P341

Central Processor Board and

Application Board (332620R) 332P620

Cooling Assembly (332400R) . .332P400

Cooling Fan (330330R) . . . . . . .332P330

Display Module (330800R) . . . .332P800

Fuse (70013R) . . . . . . . . . . . . . .332P013

Keypad (202511R) . . . . . . . . . .332P511

NVRAM Battery (71027R) . . . .71P27R

Power Entry Module

(332149R) . . . . . . . . . . . . . . .332P149

Power Supply (332950R/

332951R) . . . . . . . . . . . . . . . .332P950

Sample Handling Assembly

(332310R) . . . . . . . . . . . . . . .332P310

Sample Probe (330700) . . . . . . .332P700

Sample Probe Cable

(240725R) . . . . . . . . . . . . . . .332P725

Secondary Cooling Fan

(332087R) . . . . . . . . . . . . . . .332P087

Solenoid Impactor (3M2353R) .332P353

Plunger Wire (3M0828) . . . . . .3MP825P

6. Schematics

PCB140_DWG Back Panel I/O Assembly

Drawing

PCB140_SCH Back Panel I/O Board

Schematic

PCB115 Application Board Assembly

Drawing

PCB117 Application Board Schematic

PCB120 CPU 80C186 Assembly Drawing

PCB122 CPU 80C186 Schematic

332000 3320 System Interconnect

APPENDICES

A: Event Record

B: Symbol Definitions

C: Product Disposal and Recycling

D: Service Log

Index

The Advanced®Osmometer Model 3320 Service Manual

Table of Contents

4

The Advanced®Osmometer Model 3320 Service Manual

Notes:

1. Introduction

7The Advanced®Osmometer Model 3320 Service Manual

Model 3320 Osmometer Specifications

Electrical:

Voltage: 100 to 240 VAC

Frequency: 50 or 60 Hz

Fuses: 250V time delay (Type T): 1.25 Amp

Power: 60 Watts

Memory Backup: integral lithium cell; 10-year life

(typical); (not user replaceable)

Sample Volume: 20 µL

Sample Capacity: single sample

Readout: 2 line by 24-character vacuum

fluorescent display

Units: mOsm/kg H2O

Range: 0 to 2000 mOsm/kg H2O

Resolution: 1 mOsm/kg H2O

Communications: DTE EIA-232/V.24 (RS-232)

serial port, parallel printer port

and optional barcode scanner

Performance at Reference Conditions1

Linearity: Less than ±1% from a straight line

over calibrated range

Repeatability:

0 to 400 mOsm: Std. Deviation < 2 mOsm/kg H2O

400 to 2000 mOsm: Std. Deviation < 0.5% of

value mOsm/kg H2O

Drift: Less than 1 mOsm/kg H2O per

month

Performance Over Operating Conditions

Temperature Effects: Less than 1 mOsm/kg H2O

for every 5°C (9°F) ambient

temperature change.

Operating Conditions

Temperature: 18°C to 35°C (64°F to 95°F)

Humidity: 5 to 80% relative humidity;

(non-condensing)

Storage Temperature: -40°C to +45°C

(-40°F to +113°F)

Start-up Time: 30 seconds from power-on

Test Time: 60 seconds

Dimensions inches centimeters

Width: 14.0 35.5

Depth: 15.0 38.1

Height: 14.0 35.5

Weight pounds kilograms

Net: 13.4 6.1

Shipping: 25.0 11.4

Warranty: One-year limited warranty on work-

manship and all parts except glass,

plastic and parts warranted by their

makers.

Certification:

Refer to Regulatory Notices (see page 11) for appli-

cable standards.

Installation Class: I

Over-Voltage Category: II

Pollution Degree: 2

Moisture Protection: IPXO (ordinary)

1Reference Conditions: 20 to 25°C (68 to 77°F); 40 to 60% Relative Humidity; tolerances of reference or calibration

solutions excluded.

The Advanced®Osmometer Model 3320 Service Manual 8

General Description and Purpose

The Advanced®Model 3320 Osmometer uses

the freezing-point depression method to meas-

ure the osmotic concentration of body fluids

such as blood, serum and urine. The Model

3320 automatically tests a single 20 µL sam-

ple.

This Service Manual contains:

• instructions for performing repairs.

• guides for troubleshooting operational and

mechanical problems.

• circuit system illustrations.

• information about replacement parts and

service repairs.

This manual is designed to assist

service technicians, and does not

imply a license to perform repairs

without proper qualifications.

Service Assistance

To contact Advanced Instruments Product

Service:

• Call (800) 225-4034 (toll-free within the

USA and Canada; after normal business

hours, dial extension 2191)

• Call +US (781) 320-9000 (elsewhere)

• Or fax (781) 320-0811

When calling Advanced Instruments, have the

model and serial number from the label on the

bottom of the instrument, and a description of

the problem. Use a telephone as close to the

instrument as possible in order to facilitate

making recommended diagnostic checks.

A service technician may assist in making

minor repairs over the phone, providing you

with recommended parts (or part numbers), or

may issue an authorization (RMA) to ship the

instrument for factory repair.

The RMA procedure is as follows:

1. Contact Advanced Instruments to obtain

an RMA.

2. Pack and ship the instrument in its origi-

nal carton. Do not send instrument supply

items.

3. Prepay shipment to the factory. Advanced

Instruments cannot accept collect ship-

ments. Insure the shipment or accept the

damage risk.

The Advanced®Osmometer Model 3320 Service Manual

9

To reduce the risk of bodily injury,

electric shock, fire, and damage to

your instrument, please read and

observe the following precautions.

• If the product is used in a manner not in

accordance with the equipment design,

operating instructions or manufacturer's

recommendations, the operation of the

product may be impaired to the extent that

a safety hazard is created.

• Do not attempt to perform electrical work

if you are not fully qualified. This manual

is not a substitute for electrical training.

Symbol Conventions

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and maintenance

(servicing) instructions in the litera-

ture accompanying this product.

The lightning flash with arrowhead

symbol within an equilateral triangle

is intended to alert the user to the

presence of uninsulated dangerous

voltage within the product's enclo-

sure that may be of sufficient magni-

tude to constitute risk of electric

shock to persons.

The static symbol within an equilat-

eral triangle is intended to alert the

user to the presence of internal com-

ponents that could be damaged by

static electricity.

This static symbol is intended to

alert the user to the presence of a

specific component that could be

damaged by static electricity.

This symbol indicates the presence

of alternating current (AC).

This symbol indicates the presence

of a fuse.

This symbol indicates the presence

of protective earth ground.

This symbol indicates the power is

ON.

This symbol indicates the power is

OFF.

General Cautions

• This product should be operated only with

the type of power source indicated on the

product’s electrical ratings label. Refer to

the installation instructions included with

the product.

• If the power cord provided is replaced for

any reason or if an alternate cord is used,

the cord must be approved for use in the

local country. The power cord must be

approved for the product’s listed operating

voltage and be rated at least 20% greater

than the ampere ratings marked on the

product’s electrical ratings label. The cord

end that connects to the product must have

an IEC 60320 connector.

• Plug the product into an approved ground-

ed electrical outlet.

• Do not disable the power cord’s grounding

plug.

• If an extension cord or power strip is used,

make sure that the cord or strip is rated for

the product, and that the total ampere rat-

ings of all products plugged into the exten-

sion cord or strip do not exceed 80% of the

cord’s or strip’s rating limit.

• Route power cords so that they will not be

walked on, tripped on, or pinched by items

placed upon or against them. Pay particu-

lar attention to the plug, electrical outlet,

and the point where the cord exits the

product.

Safety / Regulatory Information

The Advanced®Osmometer Model 3320 Service Manual 10

• Do not pull on cords and cables. When

unplugging cords or cables, grasp the cor-

responding connector.

• Do not install or use this product in any

area subject to extreme short-term temper-

ature variations, or locations that exceed

the specified operating environment tem-

peratures.

• Never use this product in a wet area.

• To avoid injury or fire hazard, do not oper-

ate this product in an explosive atmos-

phere.

• Do not install or use the product on an

unstable, non-level work surface.

• Do not operate this product with the covers

removed or unsecured.

Service & Maintenance Cautions

•Unplug the power cord prior to opening or

removing covers, or else you may be

exposed to electric shock, excessive tem-

peratures, or mechanical hazards.

•Performing service or maintenance not

detailed in the User’s Guide, with or with-

out this Service Manual, should only be

done by a qualified service technician.

•Never restrict airflow into or out of the

product. Occasionally, check the air vents

for blockage.

•Wipe the exterior of the product with a

soft, damp cloth as needed. Using cleaning

products other than those specified, may

discolor or damage the finish.

•If the product requires service for any of

the following reasons, unplug the product

from the electrical outlet and refer service

to a qualified service technician.

- The power cord, extension cord, power

strip or power input module is damaged.

- Liquid has been spilled into the interior

of the product.

- A foreign object has fallen into the prod-

uct.

- The product has been dropped or dam-

aged by a falling object.

- There are noticeable signs of overheat-

ing or a burning odor.

- The product does not operate normally

when you follow the operating proce-

dures.

- The main supply fuse(s) or any internal

fuse(s) continually fail.

•A discharge of static electricity from con-

tact with the human body or other conduc-

tor may damage system boards or static

sensitive devices. Never perform internal

maintenance without following recom-

mended static protection procedures.

• The product is equipped with operator

accessible fuses. If a fuse blows, it may be

due to a power surge or failure of a com-

ponent. Replace the fuse only once. If the

fuse blows a second time, it is probably

caused by failure of a component part. If

this occurs, refer service to qualified serv-

ice personnel. Always replace the fuse

with one of the same rating, voltage, and

type. Never replace the fuse with one of a

higher current rating.

• When servicing the product, use only fac-

tory-specified parts.

• WARNING: When returning this product

for service, or shipping this product to a

second location, remove all hazardous

specimens and decontaminate the product

before packaging for shipment. If the

product cannot be decontaminated, consult

with your shipping agent on appropriate

packaging and marking.

The Advanced®Osmometer Model 3320 Service Man al

11

Hazardo s Material

Ca tions

• WARNING: Handle all biohazardous

materials according to established good

laboratory practices and follow your insti-

tution’s exposure control plan. Persons

handling human blood and body fluid

samples must be trained in blood-borne

hazards and observe universal precautions.

Universal precautions is an approach to

infection control, where all human blood

and body fluids are treated as if known to

be infectious. Use personal protective

equipment such as gloves, gowns, etc., to

prevent exposure. Store biohazardous

materials in regulated waste containers and

dispose of these materials in a safe and

acceptable manner that is in compliance

with all country, state and local require-

ments.

• If a biohazardous material is spilled on or

inside the equipment, decontaminate the

equipment using a 1% bleach solution, or

as outlined by those policies and proce-

dures established within your institution.

• To avoid injury or fire hazard, do not oper-

ate this product in an explosive atmos-

phere.

Reg latory Notices

•This product has been designed and manu-

factured in accordance with U.S.,

Canadian, and European regulatory

requirements as outlined below. odifica-

tions made to this product that are not

expressly approved in writing by the man-

ufacturer will void the user’s authority to

operate this product, previously issued fac-

tory approvals, and the user’s rights under

the warranty.

•The distributor or dealer may have applied

additional local, national, or international

approvals to this product. Consult the dis-

tributor or dealer for more information and

documentation.

•Connections to this product must be made

with shielded cables. Use of non-shielded

cables may violate RFI/E I limits.

Symbol Conventions

This symbol indicates conformity to

relevant European directives.

This symbol indicates the product

was tested to conform to relevant

Canadian and U.S. safety standards

by Intertek Testing Services NA,

Inc. The ETL mark is approved in

the United States as a Nationally

Recognized Testing Lab (NRTL) by

OSHA, and in Canada by the

Standards Council of Canada.

In Vitro Diagnostic edical Device

complying with EU Directive

98/79/EC.

This symbol, depending upon its

location, indicates the assembly,

component, and/or product are free

of lead. In respect to its inclusion on

a circuit component or assembly, the

following must be adhered to when

servicing. Failure to do so may

result in defects caused by dissimilar

metals.

1. Do not repair or modify using a

lead-containing solder.

2. Do not repair or modify using any

soldering tools that have been in

contact with lead-containing sol-

ders.

3. Do not repair or modify with any

lead-free solder other than that

specified by the manufacturer or

as indicated by the symbology of

standard IPC-1066.

4. Do not repair or modify using any

soldering tools that have been in

contact with any other incompati-

ble lead-free solders.

5. Contact factory service for further

information.

The number in this symbol indicates

the type of lead-free solder used in the

assembly of printed circuit boards, per

standard IPC-1066. Repair or modifi-

cation must be performed using the

same or compatible type lead-free sol-

der and matching tools. Failure to do

so may result in defects caused by dis-

similar metals.

Contact factory service for further information.

FCC Req irements

• WARNING: Changes or modifications to

this unit not expressly approved by

Advanced Instruments could void the user’s

authority to operate the equipment.

• This equipment has been tested and found

to comply with the limits for a Class A dig-

ital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful inter-

ference in a commercial environment. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the instruc-

tions, may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference, in which case

the user will be required to correct the

interference at his own expense.

The Advanced®Osmometer Model 3320 Service Man al 12

U.S. Safety This product has been listed by

ETL testing laboratories as being in

compliance with the requirements

of UL 61010-1, Second Edition,

“Safety Requirements for Electrical

Equipment for easurement,

Control and Laboratory Use; Part

1: General Requirements". The

"US" in the lower right of the ETL

mark demonstrates this listing.

Canadian Safety This product has been listed by

ETL testing laboratories as being in

compliance with the requirements

of CAN/CSA C22.2 No. 61010-1,

"Second Edition, “Safety Require-

ments for Electrical Equipment for

easurement, Control and Labora-

tory Use; Part 1: General Require-

ments". The "C" in the lower left of

the ETL mark demonstrates this

listing.

EC Declaration of: This product meets the intent of

Conformity - Low Directive 2006/95/EC, the Low

Voltage Voltage Directive. Compliance was

demonstrated using the following

standards as listed in the Official

Journal of the European Communi-

ties: Consult the Declaration of

Conformance certificate shipped

with the product (if required) for

the latest update.

·EN 61010-1, "Safety Require-

ments for Electrical Equipment

for easurement, Control and

Laboratory Use - Part 1:

General Requirements".

·IEC 61010-2-101, “Safety

Requirements for Electrical

Equipment for easurement,

Control, and Laboratory Use;

Part 2-101: Particular Require-

ments for In Vitro Diagnostic

(IVD) edical Equipment, First

Edition”.

EC Declaration of This product meets the intent of

Conformity - E C Directive 2004/108/EC for Electro-

magnetic Compatibility. Compli-

ance was demonstrated using the

following standards, as listed in the

Official Journal of the European

Communities: Consult the Declara-

tion of Conformance certificate

shipped with the product (if

required) for the latest update.

• EN 61326-1, Group 1, Class B,

"Electrical Equipment for

easurement, Control, and

Laboratory Use".

Reg latory

approval type Description

EXAMPLES

ONLY

13 The Advanced®Osmometer Model 3320 Service Man al

Reg latory

approval type Description

EC Declaration of This product meets the intent of

Conformity - IVD Directive 98/79/EC for In Vitro

Diagnostic edical Devices.

Consult the Declaration of

Conformance certificate shipped

with the product (if required) for

the latest update.

CB Report A CB report to standard IEC

Available upon 61010-1 and IEC 61010-2-101 has

request been prepared by Intertek Testing

Services. A certificate is available

upon request.

FCC - Part 15 This device complies with Part 15

Subpart B, Class A of the FCC Rules. Operation is

subject to the following two condi-

tions: (1) this device may not

cause harmful interference, and (2)

this device must accept any inter-

ference received, including inter-

ference that may cause undesired

operation.

Canadian ICES-003 This Class A digital apparatus

complies with Canadian ICES-003.

Cet appareil numérique de la

classe A est conforme à la norme

NMB-003 du Canada.

U.S. FDA Listing The osmometer, along with the

calibrators and controls manufac-

tured by Advanced Instruments,

are listed with a U.S. Department

of Health and Human Services,

Food and Drug Administration, as:

Osmometer Class 1

Calibrators Class 2

Controls Class 1

Reg latory

approval type Description

Health Canada The osmometer, along with the

License calibrators and controls manufac-

tured by Advanced Instruments,

are licensed with Health Canada,

Therapeutic Products Directorate,

edical Devices Bureau, as:

Osmometer Class 2

Calibrators Class 2

Controls Class 2

EC Declaration of This product meets the intent of

Conformity - WEEE Directive 2002/96/EC as amended

by 2003/108/EC for Waste

Electrical and Electronic

Equipment (WEEE). Consult the

Declaration of Conformance cer-

tificate shipped with the product

(if required) for the latest update.

RoHS This product meets the intent of

Directive 2002/95/EC for the

Restriction of Use of Certain

Hazardous Substances. This prod-

uct is exempt under the terms of

Article 2, paragraph 1 due to its

listing in Category 8 and/or 9 of

Directive 2002/96/EC.

14

The Advanced®Osmometer Model 3320 Service Manual

Notes:

2. General Overview

The Advanced®Osmometer Model 3320 Service Manual

17

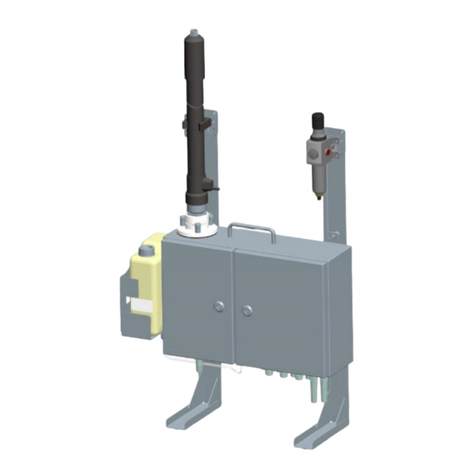

Overview

A. Power Entry Module

B. Secondary Cooling Fan

C. RS-232 Port

D. Printer Port

E. Barcode Port

F. Cooling Fan

G. Sample Probe Bin Number

H. Sample Probe

I. Block Probe

A

B

DC

H

F

M

E

P

K

Q

O

L

J. Block Probe Bin Number

K. Solenoid

L. Solenoid Retainer

M. Sample Handling Assembly

N. Actuator Switch Cable

O. Central Processor Board

P. Application Board

Q. Power Supply

J

G

I

N

The Advanced®Osmometer Model 3320 Service Manual 18

Notes:

The 3320 is comprised of the following func-

tional blocks:

Power Supply - Part No. 332950

The power entry assembly interfaces the AC

voltage presented to the instrument with the

power supply. The power supply provides

+15VDC to the main printed circuit board.

The thermoelectric cooling well fan and sole-

noid operate at +15VDC. The secondary cool-

ing fan operates at +12VDC via a drop-down

resistor.

Front End (sample handling assembly)

The sample thermistor measures the tempera-

ture of the sample. The thermoelectric

(whose duty cycle is controlled through the

block probe/thermistor) supercools the sam-

ple. When the supercooled sample reaches a

set temperature (3200 mOsm), the impactor

strikes the sample, causing the sample to

freeze. The main cooling fan remains on as

long as the thermoelectric is running.

The sample handling assembly also includes a

mechanical slide for holding and introducing

the sampler. Under this slide is a microswitch

connected to the application PCB, to automat-

ically start and stop the test routine.

332620 Control Board Set

General: The control board set is made up of

two printed circuit boards in a motherboard/

daughterboard configuration.

PCB120 Processor Board

Processor: The processor used is an Intel

80C186 16-bit embedded processor. The

80C186 contains three programmable 16-bit

timers, two serial ports, programmable inter-

rupts, 1 megabyte of memory address space,

and 64 kilobytes of input/output (I/O) address

space. The processor uses an external 32

MHz crystal to generate the internal 16 MHz

system clock. The processor controls access

to all memory and all I/O.

Memory Map: The 1 megabyte of memory

address space contains read-only memory

(Flash EPROM), read/write memory (static

RAM), and the real time clock. About half of

the address space is unused, allowing for

3320 Circuit Description

Processor

Board

Serial Port Applications

Board

Cooling

System

Power

Supply

Printer

Port

KeypadDisplay

Barcode

Port

19 The Advanced®Osmometer Model 3320 Service Manual

The Advanced®Osmometer Model 3320 Service Manual 20

future expansion. The read-only memory is

divided into four sections: reset vector, boot

code, parameter blocks (unused), and appli-

caiton code. The reset vector tells the proces-

sor where to first start executing code; in this

case, the boot code is executed first after

reset. The boot code determines if new soft-

ware will be downloaded by checking if the

program switch or dip switch is in the “PRO-

GRAM” position. If it is, the boot code waits

for new software to be downloaded through

the serial port. If not, the application code

starts.

The real time clock maintains the current date

and time, and contains nonvolatile memory

where the instrument’s operation parameters

are stored. A internal lithium battery pre-

serves the contents of the nonvolatile memory

when the instrument is turned off. Finally, the

read-write memory is used for stacks, vari-

ables, etc., except for the small section allo-

cated for the interrupt vectors. The interrupt

vectors tell the processor what code to run

when an interrupt occurs, and functions simi-

larly to the reset vector.

Please note that all memory addresses and

sizes are always defined in terms of bytes,

even though the processor handles words (1

word = 2 bytes, 1 byte = 8 bits; therefore, 16

bits = 1 word).

Input/Output Map: The 64 kilobytes of I/O

address space control access to all peripherals

such as the serial ports, application board, etc.

The processor uses 256 bytes, called the

Peripheral Control Block, to control the inte-

grated serial ports, timers, interrupts, chip

selects, and I/O pins. The Peripheral Control

Block is fully described in the

80C186EB/80C188EB Microprocessor User’s

Manual. The application board’s registers and

the CPU board’s registers control access to

various functions and are described later.

Memory: Two types of memory are avail-

able: read-only and read/write. The chips

used here have 8-bit wide data buses. Used in

pairs, the memory becomes compatible with

the processor’s 16-bit wide data bus. The

read-only memory is implemented using two

128 kilobytes x 8 bits Flash EPROMs. Flash

memory is only programmable when a pro-

gramming voltage (in this case, 12 volts DC)

is applied to the memory; otherwise, it

behaves like read-only memory. The boot

code controls the programming voltage, since

this is the only place where new software can

be downloaded. The read/write memory is

implemented using two 128 kilobytes x 8 bits

static RAMs.

Watchdog Timer: The watchdog timer pro-

vides a mechanism to reset the processor

when the software is not behaving normally.

The software “pets” the watchdog every 100 -

200 milliseconds. As long as the watchdog is

“petted”, nothing happens. However, if the

software stops “petting” the watchdog, the

watchdog “bites” the processor by activating

the processor’s RESET pin, causing the

processor to reset. The watchdog will also

reset the processor if the power supply falls

below 4.75 VDC. These two features allow

the instrument to recover from abnormal soft-

ware and hardware conditions.

Real Time Clock (RTC): The real time

clock maintains the current date and time.

The RTC uses an internal clock circuit with

an internal, 10-year life, lithium battery to

perform timekeeping. The battery also pre-

serves the contents of internal memory.

Dip Switch: The four-position dip switch

allows the user to download new software via

one switch. The other three switches are

available for selecting different operating

modes. These operating modes and the

process for downloading software are

described later in this manual.

Voltages: Three voltages are present on the

CPU board: +5 VDC, +12 VDC, and VPP.

+5 VDC powers all the logic. +12 VDC is

switched on and off to create the flash memo-

ry’s programming voltage, VPP.

Glue Logic: The glue logic performs the

functions of creating the RAM memory chip

selects, the Flash memory write signals, the

Table of contents

Other Advanced Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Siargo

Siargo MF4003 user manual

Sper scientific

Sper scientific 850068 instruction manual

Rice Lake

Rice Lake Healthweigh Adjusting instructions

Smart Tweezers

Smart Tweezers ST5SBT user manual

Maico

Maico LW 9 Mounting and operating instructions

MULTI MEASURING INSTRUMENTS CO.,LTD.

MULTI MEASURING INSTRUMENTS CO.,LTD. MCL-4000F instruction manual