SW4000 USER’S MANUAL

VER5.13 1

Contents

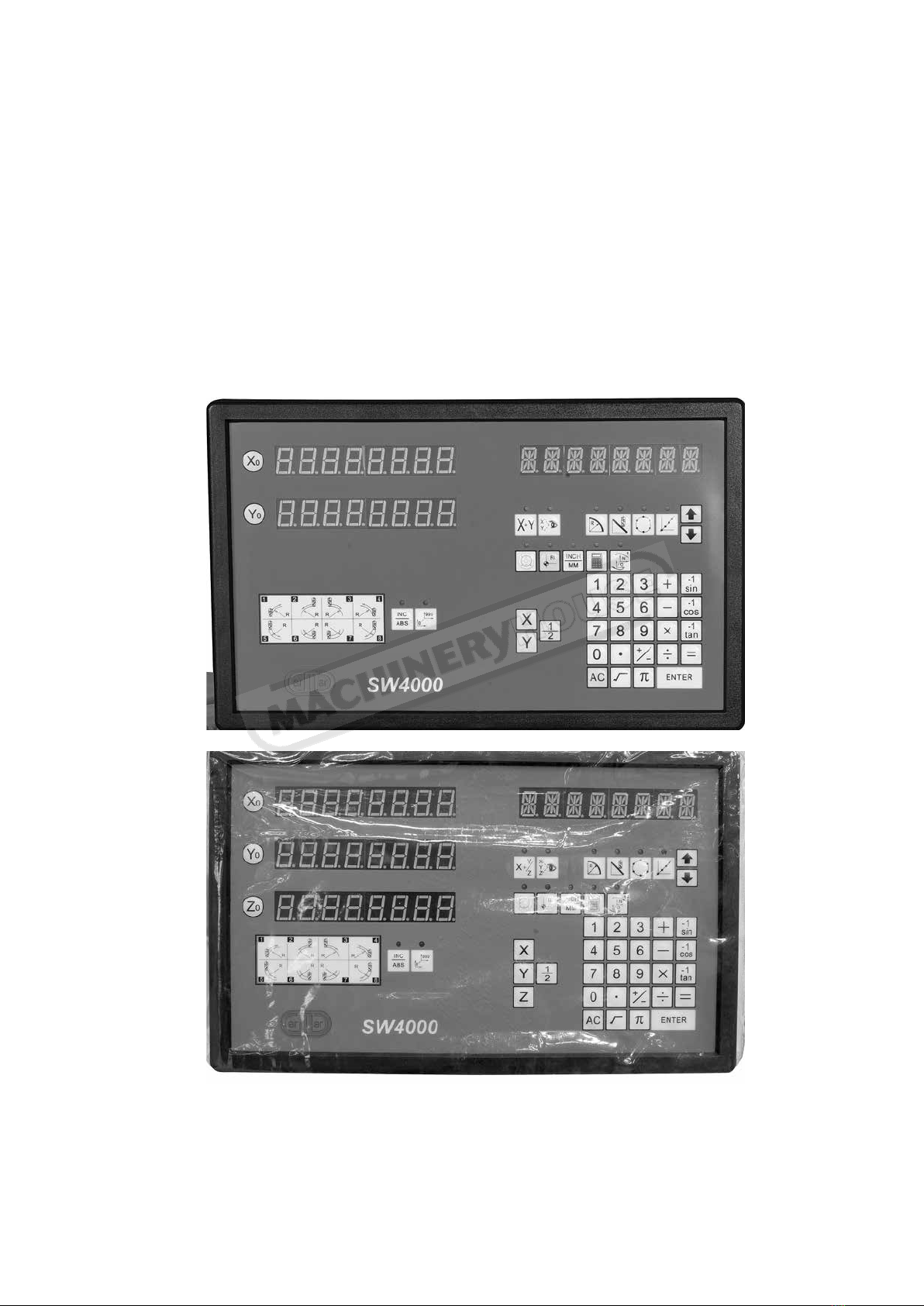

Chapter 1. INTRODUCTION.................................................................................................3

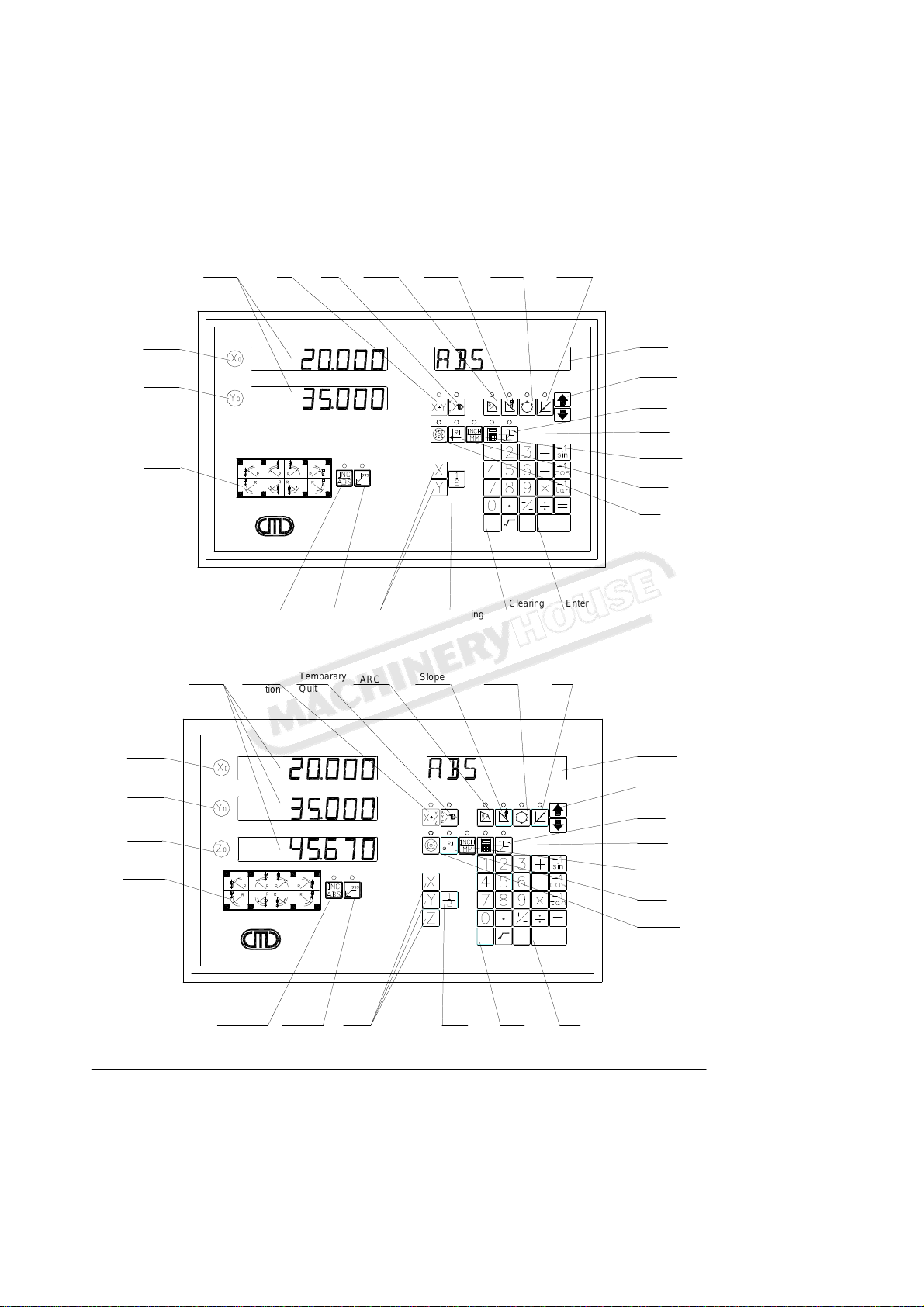

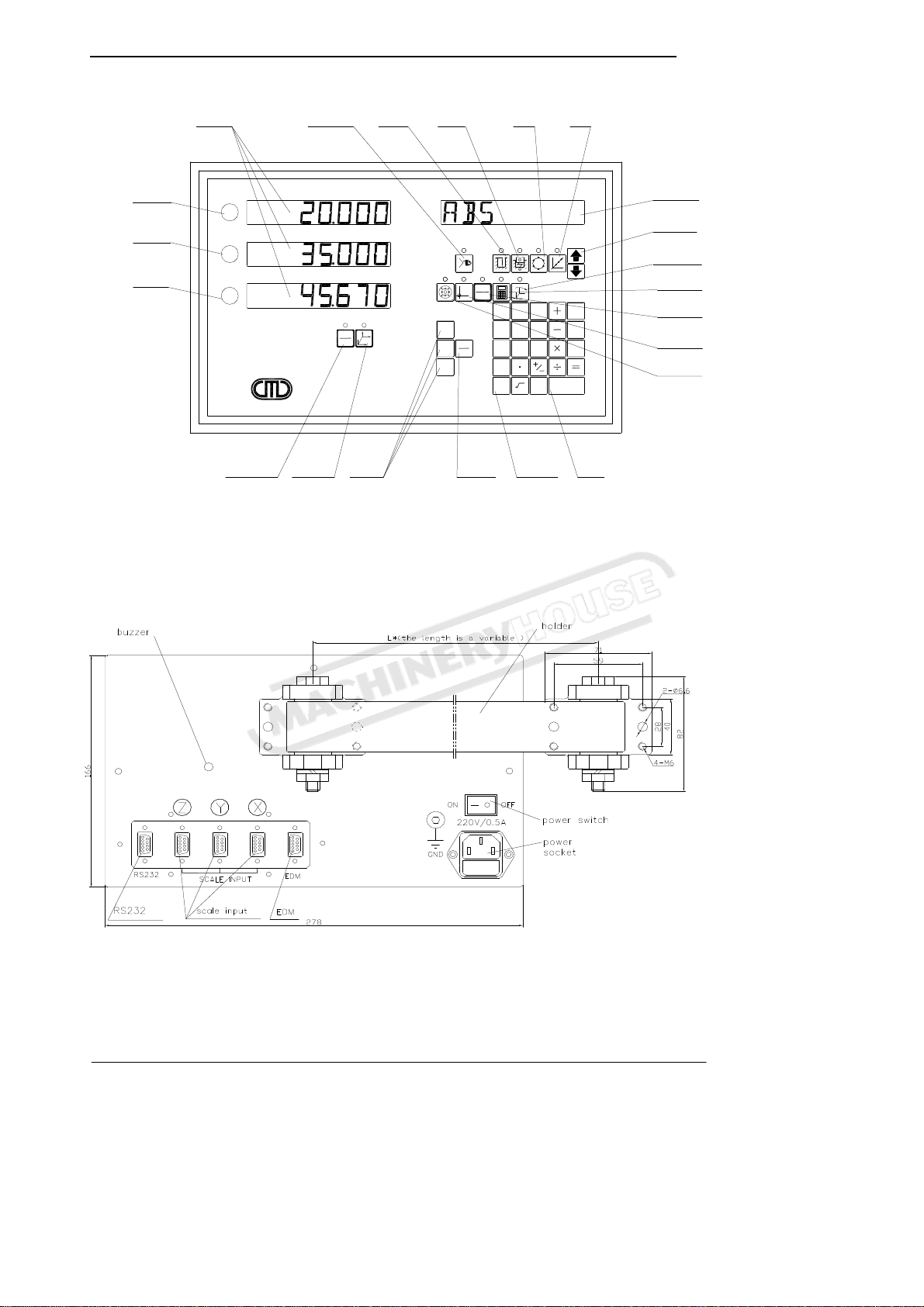

1.1 Front Panel.............................................................................................................3

1.2 Back Panel..............................................................................................................4

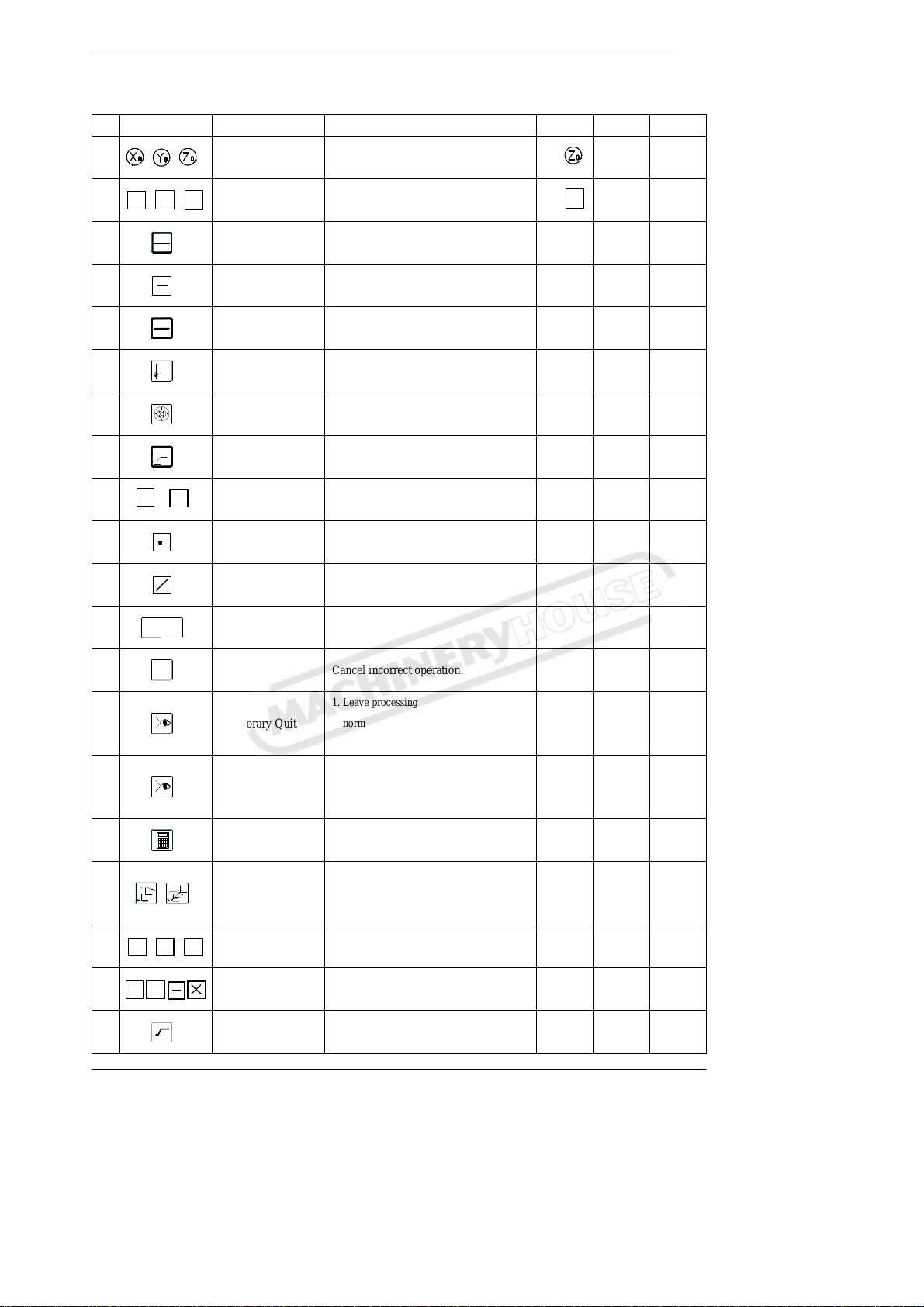

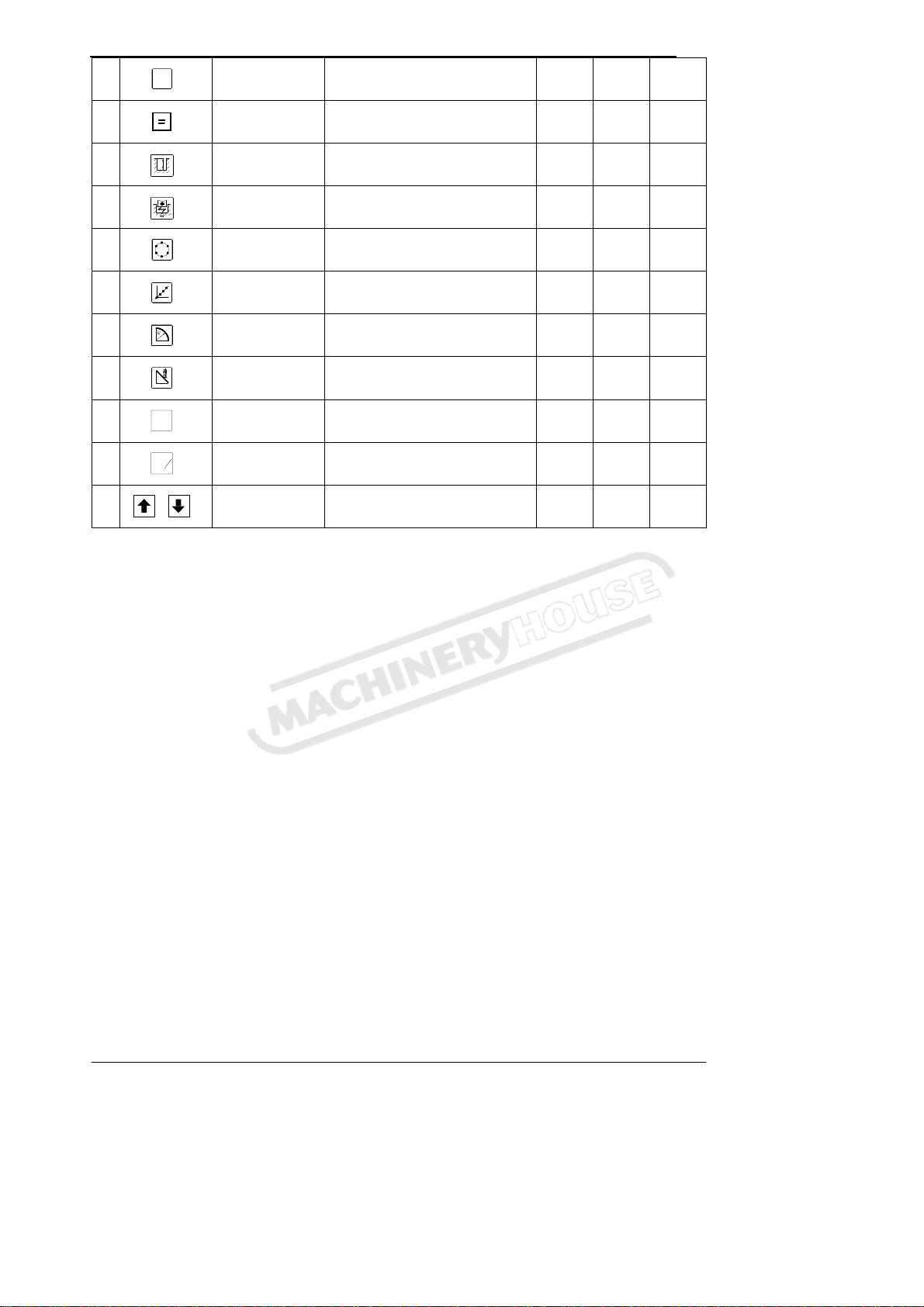

1.3 Description of Key Function..................................................................................5

1.4 Interface..................................................................................................................7

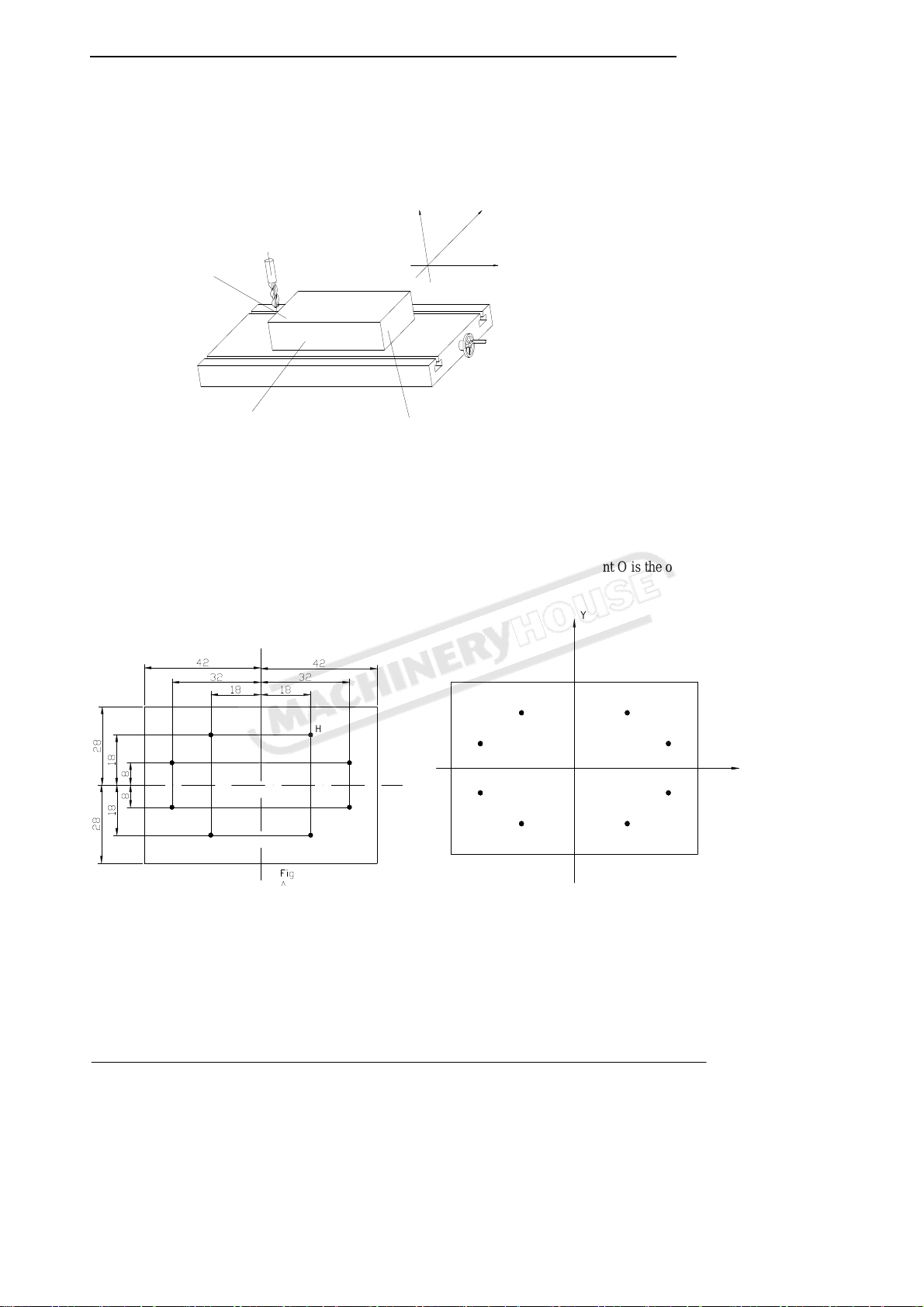

1.5 Coordinate System .................................................................................................8

Chapter 2. BASIC OPERATION............................................................................................9

2.1 Power on.................................................................................................................9

2.2 Zeroing...................................................................................................................9

2.3 Preset Data to Designated Axis............................................................................10

2.4 Toggle display unit between mm and inch...........................................................11

2.5 Mid-point Calculation..........................................................................................11

2.6 Set the Shrinkage Mode.......................................................................................12

2.7 Absolute / Incremental / 1000 groups SDM ........................................................13

2.8 Clear All SDM Datum..........................................................................................14

2.9 Search the Absolute Reference Point of Scale (RI) .............................................15

2.10 Clear the Error message .......................................................................................16

2.11 Lathe Function .....................................................................................................16

2.12 Filter display value...............................................................................................17

Chapter 3 1000 groups SDM coordinate...............................................................................18

3.1 Zeroing at the Current Point.................................................................................18

3.2 Preset datum of SDM Coordinate ........................................................................20

Chapter 4 SPECIAL FUNCTION.........................................................................................22

4.1 Bolt Hole Circle ...................................................................................................22

4.2 Bolt Hole Line......................................................................................................24

4.3 ARC Processing...................................................................................................26

4.4 Slope Processing..................................................................................................30

4.5 Auto Edge Detection............................................................................................33

Chapter 5. EDM....................................................................................................................35

5.1 Setting EDM Parameters......................................................................................36

5.2 EDM machining...................................................................................................37

5.2.1 Example for Mode 1 with Plus Depth..................................................................37

5.2.2 Example for Mode 1 with Minus Depth ..............................................................38

5.2.3 Example for Mode 2.............................................................................................40

5.2.4 Example for Mode 3.............................................................................................41

5.2.5 Example for Mode 4 with Minus Depth ..............................................................42

5.2.6 Example for Mode 6.............................................................................................44

5.2.7 Example for Mode 7.............................................................................................45

5.3 Combination of BHC: BHL and EDM Function .................................................47

Chapter 6 CALCULATOR FUNCTION ............................................................................49

6.1 Enter and exit Calculator Function ......................................................................49

6.2 Calculating Example............................................................................................49

6.3 Transferring the Calculated Results to Selected Axis..........................................49

6.4 Transferring the Current Display Value in Window to Calculator.......................50

Chapter 7 INITIAL SYSTEM SETTINGS...........................................................................51

7.1 Enter/Exit Initial System Settings........................................................................51