Advantage Controls MicroTron A Series User manual

1

Manual

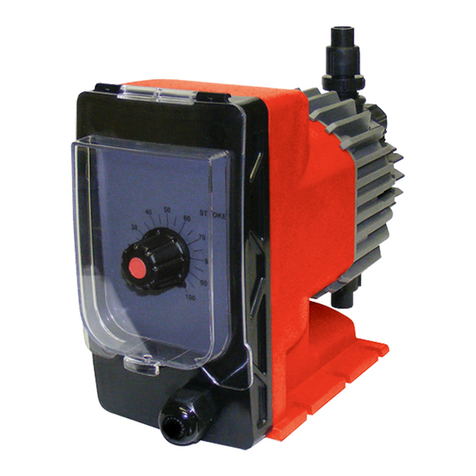

MicroTron

Series A

Chemical Metering Pump

Installation

Maintenance

Repair

Manual

Advantage Controls

4700 Harold Abitz Dr.

Muskogee, OK 74403

Phone: 800-743-7431

Fax: 888-686-6212

www.advantagecontrols.com

2

Series A Pump

Instruction & Maintenance Manual

Table of Contents

Contents Page

I. Introduction ................................................................................3

Model Numbering.......................................................................3

II. Unpacking ..................................................................................4

III. Safety Considerations................................................................4

A. Chemical Compatibility .....................................................4

B. Safety Equipment and Preparation...................................4

IV. Installation..................................................................................4

A. Location ............................................................................4

B. Electrical ...........................................................................5

C. Plumbing...........................................................................5

V. Start-Up......................................................................................7

A. Front Panel Description ....................................................7

B. Run Mode Explanation .....................................................8

C. Set-Up Mode Explanation.................................................8

D. Password Protection.........................................................8

E. Priming the Pump .............................................................8

F. Adjusting Feed Rate .........................................................8

G. Stroke Length ...................................................................9

H. Calculating Output ............................................................9

VI. Control Options ..........................................................................9

A. Standard Control...............................................................9

B. 4-20mA Input Programming..............................................9

C. Selectable Timers .............................................................9

1. Recycle Timer Programming ...................................9

2. Pulse Timer Programming .....................................10

3. Biocide Pump Programming..................................10

VII. Set-Up Menus ..........................................................................10

VIII. Maintenance ............................................................................13

A. Diaphragm Replacement ................................................13

B. Suction and Discharge Check Valve Replacement ........13

C. Liquid End Diagram ........................................................14

D. Pump Replacement Parts...............................................15

IX. Trouble Shooting Guide ...........................................................16

X. Warranty and Factory Service Policies ....................................17

3

I. Introduction

This manual covers all facets of operation of the Advantage MicroTron™ pump, including unpacking,

mounting, electrical and plumbing connection, and start-up. Safety, maintenance and repair, warranty, and

factory information is also provided. Please read this manual completely before proceeding. Observe safety

protocols and heed all warnings and precautions.

Model Numbering

particular pump. Your pump may be supplied with one or more of the options described in this manual.

To determine what features apply to your pump, check the model number label located on the pump.

Model Number Example A 1 30 X 1 – K V C 1 - S

Pressure Rating

1 = 110 and 150 psi

2 = 250 psi

Gallon Per Day Rating

30 = 30 gallons per day at 110 psi

15 = 15 gallons per day at 150 psi

17 = 17 gallons per day at 250 psi

Control Options

X = Strokes per minute or hour (standard)

M = 4-20mA Input

T = Selectable Timers - Pulse, 28-Day, Recycle

Voltage

1 = 120 volt - 50/60 Hz - .35A with USA plug (standard)

2 = 240 volt - 50/60 Hz - .65A no plug

3 =

4 = 12 volt dc

Pump Head Material

K = Kynar

S = Stainless

Seat Material

V = Viton (standard)

F =

H = Hypalon

Check Ball

C = Ceramic (standard)

D = Ceramic/single on discharge (pressure relief)

S=Stainless

Tubing Connections

1 = 3/8” PE, 75-200 psi (standard)

2 = ¼” PE, 250 psi models (standard)

P = ¼” MNPT

V =

Special Options

E = External Stop

H =

S = 3-function injection valve

R = No stroke length adjustment knob

4

II. Unpacking

The MicroTron™ pump has been shipped as a complete package, ready for installation.

If the shipping carton shows any signs of damage, notify the shipping company immediately

upon receipt. Advantage Controls cannot be held responsible for damage from shipping.

Unpack the carton and insure the following items are present:

2. Suction, discharge and priming tubing 5. Instruction manual

3. Foot valve and weight

III. Safety Considerations

NOTE: All MicroTron™ pumps are primed with water before leaving the factory. If the

solution to be pumped is not compatible with water, disassemble the pump uid end before

use. After disassembly, thoroughly dry the pump head, valves, and seals before pump is

reassembled and used.

A. Chemical Compatibility

MicroTron™ metering pumps are designed to work with most liquid chemicals depending upon

your pump’s liquid end materials of construction. A chemical resistance chart is available for

compatibility questions, contact Advantage Controls service department at 1-800-743-7431.

B. Safety and Preparation

Always wear the proper protective clothing and gear when working around chemicals and

chemical metering pumps. Safety glasses, gloves, and aprons are critical in preventing accidental

exposure to dangerous chemicals. Liquids under pressure can present a special hazard when

a line or seal is punctured resulting in the spraying of chemical many yards away. If a chemical

the chemical being used.

IV. Installation

A. Location

Select a mounting location convenient to the chemical supply as well as a source of power

for the pump. Do not install the pump in a location where the ambient temperature exceeds

120 degrees F (50o

the pump. While the MicroTron™ pump is suitable for most outdoor installations, do not use

the standard poly tubing in direct sunlight. If you must mount pump in direct sunlight or under

Accessory item R00225 (plastic mounting bracket) is recommend for a secure installation.

5

B. Electrical

1. The Standard MicroTron™ pump has a voltage regulated internal power supply capable

of operating in the range of approximately 95 to 135 VAC. Use a supply voltage of 100 to

120 VAC for best results. The 3-wire grounded plug must be used in a 3-wire wall plug.

2. With a 240-volt option, the MicroTron™ pump has a voltage regulated internal power

supply capable of operating in the range of approximately 195 to 260 VAC. Use a

supply voltage of 210 to 250 VAC for best results.

CAUTION: Never remove ground wire from plug!

C. Plumbing

1. Tubing Connections

The MicroTron™ pump uses carefully matched components to achieve a predictable

unaltered. Do not attempt to reduce tubing size. All tubing connections should be

double checked to insure against leakage. If hazardous chemicals are being pumped, use

shielding around discharge tubing.

NOTE: When cutting lengths of tubing for your installation, ensure a clean, square

cut. Use short lengths of tubing and as few connections as possible.

2. Tubing Nuts

Do not use a wrench or pliers

Be

sure to observe applicable local plumbing codes.

WARNING: Clear exible tubing is not intended for pressurized use.

3. Tubing Connections

3/8"

1/4"

TUBING MUST SLIP OVER NIPPLE

1/4" TUBING

ADAPTER

IMPORTANT

THE END OF THE TUBING

MUST EXTEND 1/4" BEYOND ADAPTOR

6

4. Suction Lift vs Flooded Suction Applications

Suction Lift Installation

Mount the MicroTron™ pump around the top of the solution tank, not to exceed 5 feet

from pump to bottom of tank.

Flooded Suction

This installation is recommended for very low outputs, solutions that gasify and/or high

viscosity solutions. Priming is easier and loss of prime is reduced. Failure of the pump

diaphragm or rupture of the solution tubing can cause loss of solution in the tank.

Suction lift Flooded Suction Not recommended

5. Wall Mounting

The pump head must be kept in a vertical position for proper operation. The head can

be removed and rotated 90oif needed to keep the inlet and outlet valves in a vertical

position.

6. Foot valve installation

A weight is provided to hold the tubing and foot valve in a vertical position at the

bottom of the tank. Do not allow the foot valve to lay horizontally in the chemical

container. This defeats the action of the valve and causes the pump to lose prime.

Keep suction tubing reasonably short and avoid high spots or bends.

7. Injection valve installation

line. To work properly, this valve must be mounted within 45 degrees of vertical (see

drawing). One end of the injection valve is 1/2” MNPT. Install this end into the piping

head.

7

8. Optional Three Function Valve.

Anti-siphon feature allows metering of liquids “downhill” or into the suction side of a

circulating pump. It provides protection against an accidental application of suction

anti-siphon action.

Back pressure function permits metering into atmospheric discharge (open container)

without overpumping.

Line check

9. Priming / Degassing Valve Connection

Connect the clear poly tubing to the outlet of the bleed or priming valve. Position the

priming valve built into the head. Clear poly tubing should be connected to the outlet of

this valve, the other end of the tube should be placed in the chemical container above

V. Start-Up

A. Front Panel Description

80

20

30

40 50 60

70

90

100

PULSE POWER

Press ENTER to test

Press MENU to access settings

MENU

ENTER

80

20

30

40 50 60

70

90

100

POWER PULSE

Press ENTER to test

Press MENU to access settings

MENU

ENTER

All Model R pumps come with the following standard panel

features:

• 1x16-backlit LCD display

• Pulse or Stroke indicator light

• Up and Down arrow keys for setting

adjustments

• MENU key to enter and exit pump set-up

• ENTER key to save desired adjustments

NOTE: When installation is made into a

line with zero pressure or when

pumping into an open vessel, use the

optional three function injection valve

which provides back pressure and

anti-syphon capabilities.

8

B. Run Mode Explanation

The readout will display one of two modes, Run mode and Set-up mode. Run mode is

displayed only while the pump is in normal operation. The display will show the pump speed

setting.

Manual activation of the relay output and pump stroking can be activated by pressing the

ENTER key while the pump is in the run mode. This will manually activate both functions of

the unit for 3 minutes. After three minutes the unit goes back to automatic.

If the ENTER key is pressed during the 3-minute test, it will revert to automatic.

C. Set-Up Mode Explanation

To enter Set-up mode, press MENU. Notice that a cursor appears on the screen signifying that

keys until the desired setting appears, then press ENTER to advance. Continue pressing

ENTER to toggle past the other displays. When all settings are made, press MENU to return

to run mode, and save settings.

D. Password Protection

Option T allows for a built in four-digit password to prevent unauthorized changes.

Entering Setup Mode when a password has been set - Press Menu and enter the correct

four-digit password using the up and down arrow keys followed by Enter. Once the password has

been entered correctly the Setup Mode menus can be accessed. A code of 0000 disables the

password.

Set a new password by pressing the Menu key to enter the Setup Mode. Press ENTER until

the display shows “Password: 0000” then use the up and down keys followed by the ENTER

key to set each of the four digits to the desired value.

E. Priming the Pump

1. Settings

Plug in pump, set stroke knob to 100%.

2. Priming/Bleed valve

Do not over tighten bleed valve. Damage may occur.

3. To prime the Advantage A pump, simply press the ENTER key while the pump

is in Run mode. This allows the pump to stroke at the maximum STROKES/MIN

setting.

F. Adjusting Feed Rate

The A pump allows for an exact number of strokes to be set and read on the front panel

LCD meter. It is adjustable from 0 to 125 strokes per minute (0 to 160 for 55 GPD).

In addition, for applications requiring very low outputs the speed can be set in strokes per

hour from 1 to 125.

9

G. Stroke Length

The stroke length can be adjusted on all MicroTron™ pumps. This adjustment is a

mechanical adjustment made using the large knob on the control panel. To avoid damage to

the pump, this adjustment should only be made while the pump is running at a high stroking

rate.

Always start adjusting your pump’s output down by reducing the pump’s stroking speed or

frequency. By leaving the stroke length as long as possible you decrease any chance of

loosing prime.

H. Calculating Output

A pump’s output per minute can be determined by dividing the maximum rated gallons per

day by 1440 (minutes per day). For example, a 30 gallons per day (gpd) pump at a maximum

stroke length and speed setting of 125 strokes per minute (spm) will pump 0.000167 gallons

per stroke (gps).

30 ÷ 1440 = 0.0208 gpm ÷ 125 spm = 0.000167

With this value and the pump’s speed setting (strokes per minute) you can calculate your

pump’s output at it’s rated pressure. A 30 gpd pump set at 50 strokes per minute:

50spm x .000167gps x 1440 (minutes per day) = 12.02 gallons per day

Reducing the stroke length will reduce the pump’s output again. If the example pump above

had it’s stroke length reduced to 50% the 12.02 gallons per day output is reduced to 6.01.

(example: 12.02 gpd x 0.50 = 6.01 gpd)

A higher product viscosity will reduce the output. Pressures lower than the pump’s rating can

increase the output.

VI. Control Options

A. Standard Control (Basic A Pump) - See Menu Map on Page 10

Pumps continuously with speed and length adjustments.

B. 4-20mA Input (Option M) - See Menu Map on Page 12

Option M allows the pump to accept a 4-20mA signal input to control the pump’s stroking

rate or speed from an external control device. The pump can be programmed for number

of strokes per minute at two milli-amps points on a 4-20 scale. The maximum setting is 125

strokes per minute.

C. Selectable Timers

1. Recycle Timer - See Menu Map on Page 11

The recycle timer allows the pump to run based on set cycle times. The on time is adjustable

10

2. Pulse Timer and Flowmeter Input - See Menu Map on Page 11

Pulse timer allows the pump to run based on signals from an external dry contact switch closure.

Incoming pulse rate must not exceed 1,800 pulses per minute. There are four selections for a

pump with this option selectable on the MENU page EXT= which is short for external. Press

to select the desired external pulse function from the selections below. Press the ENTER key

to set the desired pulse function.

With screen showing Timer: MLTIPL BY the pump strokes based on multiplying each

incoming pulse by 1 to 9999. With the screen set for Timer: DIVIDE BY it strokes based

The pump will store strokes (a maximum of 65,000 divided by the set multiply factor) to be

made if contacts come in faster than the pumps stroking. If the stored number of strokes

exceeds the maximum any additional strokes are lost.

3. Biocide or Event Timer - See Menu Map on Page 11

Biocide or event timers allow the pump to feed chemical based on a 28-day timer for the daily,

weekly, or monthly addition of chemicals. The unit has four programmable timers labeled P1,

P2, P3, and P4.

VII. Set-Up Menus

10

hours and 59 minutes. Ex. An on time of 15 minutes and an off time of 15 minutes will cycle

the pump on 15 minutes and off 15 minutes repeatedly.

2. Pulse Timer and Flowmeter Input - See Menu Map on Page 11

Pulse timer allows the pump to run based on signals from an external dry contact switch

closure. There are four selections for a pump with this option selectable on the MENU page

EXT= which is short for external. Press to select the desired external pulse function from

the selections below. Press the ENTER key to set the desired pulse function.

With screen showing Timer: MLTIPL BY the pump strokes based on multiplying each

incoming pulse by 1to 9999. With the screen set for Timer: DIVIDE BY it strokes based

on dividing each in coming pulse. For example, if the pump is told to divide by five it will

count five incoming external pulses and then stroke one time.

The pump will store strokes (a maximum of 65,000 divided by the set multiply factor) to be

made if contacts come in faster than the pumps stroking. If the stored number of strokes

exceeds the maximum any additional strokes are lost.

3. Biocide or Event Timer - See Menu Map on Page 11

Biocide or event timers allow the pump to feed chemical based on a 28-day timer for the daily,

weekly, or monthly addition of chemicals. The unit has four programmable timers labeled P1,

P2, P3, and P4.

VII. Set-Up Menus

125 Strokes/Min

Reset Counter? N

Model Axxx

MENU MAP

Use the ARROW keys to change

options and the ENTER key to

continue to next menu item.

Software version 8.2.a

Prime ALM:020STR

Grayed out menu items are

available only when FloTracker

option is enabled.

FT: 003.33 ML/P

11

11

125 Strokes/Min

Set Clock? N

Reset Counter? N

Model AxxxT

MENU MAP

Timer: No Timer

New Pass: 0000

Use the ARROW keys to change

options and the ENTER key to

continue to next menu item.

Software version 8.1.h

FT: 003.33 ML/P

Grayed out menu items are

available only when FloTracker

option is enabled.

Prime ALM: 020STR

Other Timer Options

Timer: Pulse

WM: 00000 Gal/P

WM: Gals/Pulse

Timer Mode: VOL

Accum:000 Pulses

Tmr Mode: Timed

Accum:000 Pulses

On Time mm:ss

Reset Meter: No

Duration 0000 ML

Limit mm:ss

Timer: Mltipl by

Mltiply by: 0000

Timer: Divide by

Divide by: 0000

Timer: Recycle

On Time mm:ss

Duration 0000 ML

Off Time hh:mm

Timer: 28 Day

P1 All Days

P1 All Weeks

P1 Strt 12:00 pm

P1 Mode: Timed

P1 Length hh:mm

P1 Mode: Volume

P1 Length 000 mL

P1 Limit hh:mm

12

12

125 Strokes/Min

Length = 100%

Pressure = 150PSI

Reset Counter? N

Calibrate? No

Calibrate? Yes

60 Strks = 00.0mL

Model A Option M (4-20mA Input)

MENU MAP

4-20mA= ON

Low Input = 04

Hi Input = 20

04mA = OFF Str

20mA = 125 Str

Use the ARROW keys to change

options and the ENTER key to

continue to next menu item.

Prime ALM:020STR

FT:003.33 ML/P

Grayed outmenu items are

available only when FloTracker

option is enabled.

13

VIII. Maintenance

The Advantage MicroTron™ pump is designed for long service life with minimum maintenance.

If for any reason, maintenance is necessary or desireable, the MicroTron™ pump is easily

maintained.

Before any maintenance or service is performed, observe the following precautions:

1. Disconnect the MicroTron™ pump from power source.

2. Drain chemical from discharge tubing.

3. Disconnect discharge tubing from pump.

from chemical container.

5. Observe relevant safety protocols when handling parts which have been in contact with

hazardous chemicals.

A. Diaphragm Replacement

4. Unscrew the diaphragm from the pump shaft in a counter-clockwise direction.

Be careful that diaphragm support ring does not fall out.

5. Do not allow sharp or abrasive objects to come in contact with pump parts.

6. Inspect end of shaft to assure that threads are in good condition. Replace shaft bellows

if necessary. No further disassembly is recommended.

7. Screw new diaphragm onto pump shaft until it bottoms out on shoulder of shaft.

It is not necessary to tighten further.

9. Reconnect plumbing and power. Prime the pump.

B. Suction and Discharge Check Valve Replacement

1. Disconnect suction tubing from pump.

5. Remove check valve from suction side pump and replace.

9. Reconnect plumbing and power. Prime the pump.

NOTES: 1. Tighten pump head screws after pump’s initial week of operation.

2. When installing check valves, remember that the seats are always installed

at the bottom.

14

C. Liquid End Diagram

OR

2

OR

OR

5

14

8

9

10

4

3

OR

15

13

12

6

11

1

7

Item Description

1 Complete Head Kit

2 Injection Valve

3 Foot Valve

4 Suction Valve

5 Discharge Valve

6 Bleed Valve Assembly

7 Pump Head

8 Pump Diaphragm

9 Support Ring

10 Shaft Seal

11 Head Bolts

12 Priming Tube

13 Suction Tubing

14 Discharge Tubing

15 Weight

Complete Head Kit

includes items:

4,5,6,7,8, and 11

15

D. Replacement Parts

Getting the right materials of construction for your spare parts is easy. Using positions 7-10 of the

pump model number, example: A130X1-KFCV.Find the assembly needed and add the codes of

Part Assemblies

Item Description Part Number

1....................... Complete Head Assembly 110 psi....................................... CKR-1- __ __ __ __

......................... Complete Head Assembly 150 & 250 psi ............................... CKR-2- __ __ __ __

2....................... Injection Valve Assembly .............................................................. INJ- __ __ __ __

Optional ....... 3-Function Injection Valve............................................................ 3FV- __ __ __ __

3....................... Foot Valve Assembly .................................................................. FTV- __ __ __ __

4....................... Suction Valve Assembly.............................................................. SUC- __ __ __ __

5....................... Discharge Valve Assembly............................................................DIS- __ __ __ __

6....................... Priming Valve Assembly ...............................................................PRI- __ __ __ __

Body Seat Ball Connection

K- Kynar V- Viton C- Ceramic 1

S- 316 Stainless F D- Single 2

H- Hypalon S- Stainless 3

K

P

U

V

Single Parts

12...............Priming Tubing ....................................................................... R00255

13........................................................................ R00255

................... ............................................................. R00122

................... ............................................................ R00097

14............... ......................................................... R00122

................... ......................................................... R00267

15...............Weight, Suction Tubing ........................................................... R00139

16

IX. Trouble Shooting

PROBLEM CAUSE REMEDY

Pump does not achieve

or maintain prime

Air trapped in suction line

Foot valve contaminated or improperly

installed

Excessive lift

Worn or contaminated check valves

Split or pinch in suction tube

Low chemical level

Straighten suction line so as to eliminate

high spots.

Inspect foot valve screen and assure that

foot valve is in a vertical position below

Maximum suction lift is 5 feet with water or

heavier liquids such as acids. Mount pump

in a lower position relative to the chemical

container.

restriction. Conversely, if any leakage occurs,

pump will suck air and fail to prime.

Clean or replace as necessary.

Inspect suction tube through its full length

to assure that there are no splits at the

connections or other restrictions. Move

any objects or equipment which impinges

upon suction tube or reroute as required to

assure a smooth transition from foot valve

to pump.

Stroke adjustment set too low

Worn or contaminated check valves

Obstruction in suction line

Clogged foot valve screen

Output (system) pressure too high

Diaphragm worn or torn

Electronic failure

Check operation of stroke limiter knob.

If pump delivers too low adjustable rate,

check settings. Readjust as required.

Inspect, clean or replace as necessary.

Check suction line for obstructions, clogging,

kinks or pinch points.

Clean or replace foot valve screen.

Relocate the injector to a lower pressure part

of the the system.

Replace diaphragm, making sure that it is

screwed on fully to shoulder of shaft.

Consult dealer or factory.

17

Failure or lack of antisiphon valve

Excessive stroke rate

Improper stroke length

Inspect or add anti-siphon valve. This is

caused when system is in a vacuum condition

suction which feeds systems at very low

pressures.

Lower the stroke rate if adjustable on your

pump.

Reduce stroke length.

Pump will not pump System pressure too high

Diaphragm improperly installed

Check valves worn or clogged

Check system pressure to assure that it

is within system rated paramaters of the

pressure.

Make sure that diaphragm is screwed fully

unto shaft.

Clean or replace as required.

Pump will not run not

plugged in

Pump not turned on or not plugged in

Electronic failure

Check outlet with meter to assure that correct

or voltage is present and that power supply

cord is in good condition and plugged in.

Consult dealer or factory.

Excessive noise Pump not primed

No output pressure

Prime pump.

Add an anti-siphon valve to provide 25 PSI

restriction on pump discharge.

X. Manufacturer’s Product Warranty

Advantage Controls warrants units of its manufacture to be free of defects in material or

workmanship. Liability under this policy extends for 24 months from date of installation. Liability is limited

to repair or replacement of any failed equipment or part proven defective in material or workmanship upon

manufacturer’s examination. Removal and installation costs are not included under this warranty.

Manufacturer’s liability shall never exceed the selling price of equipment or part in question.

Advantage disclaims all liability for damage caused by its products by improper installation,

maintenance, use or attempts to operate products beyond their intended functionality, intentionally or

otherwise, or any unauthorized repair. Advantage is not responsible for damages, injuries or expense

incurred through the use of its products.

The above warranty is in lieu of other warranties, either expressed or implied. No agent of ours is

authorized to provide any warranty other than the above.

30 Day Billing Memo Policy

Advantage Controls maintains a unique factory exchange program to ensure uninterrupted service

with minimum downtime. If your unit malfunctions, call 1-800-743-7431, and provide our technician with

Model and Serial Number information. If we are unable to diagnose and solve your problem over the phone,

a fully warranted replacement unit will be shipped, usually within 48 hours, on a 30-Day Billing Memo.

This service requires a purchase order and the replacement unit is billed to your regular account for

payment. The replacement unit will be billed at current list price for that model less any applicable resale

discount. Upon return of your old unit, credit will be issued to your account if the unit is in warranty. If the unit

is out of warranty or the damage not covered, a partial credit will be applied based upon a prorated

replacement price schedule dependent on the age of the unit. Any exchange covers only the controller

or pump. Electrodes, liquid end components and other external accessories are not included.

18

19

20

Get the Advantage in Water Treatment Equipment

Advantage Controls can give you the Advantage in products, knowledge

and support on all of your water treatment equipment needs.

Cooling Tower Controllers

Boiler Blow Down Controllers

Blow Down Valve Packages

Solenoid Valves

Water Meters

Chemical Metering Pumps

Corrosion Coupon Racks

Chemical Solution Tanks

Solid Feed Systems

Feed Timers

Filter Equipment

Glycol Feed Systems

Pre-Fabricated Systems

Get the Advantage

5

4

3

2

1

0

9

8

7

6

BACK

HOME

HELP

ENTER

CANCEL

SET UP

RUN

5

4

3

2

1

ENTER

HELP

5

4

3

CHANGE

RUN

SET UP

0

9

8

2

1

7

6

HOME

BACK

Table of contents

Other Advantage Controls Water Pump manuals

Advantage Controls

Advantage Controls MicroTron G Series User manual

Advantage Controls

Advantage Controls RT Operating instructions

Advantage Controls

Advantage Controls MicroTron C Series Operating instructions

Advantage Controls

Advantage Controls MicroLinx L Series User manual

Advantage Controls

Advantage Controls GF Manual

Advantage Controls

Advantage Controls MicroTron O Series User manual

Advantage Controls

Advantage Controls MicroTron R Series User manual