Advantage Controls SFS Series Operating instructions

1

Manual

SFS Series

Solid Feed Systems

Installation

Maintenance

Repair

Manual

Advantage Controls

4700 Harold Abitz Dr.

Muskogee, OK 74403

Phone: 918-686-6211

Fax: 888-686-6212

www.advantagecontrols.com

2

SFS Series Manual

Table of Contents

Contents Page

I. Introduction ................................................................................3

Model Numbering.......................................................................3

Options.......................................................................................4

II. Installation..................................................................................5

Electric Models .................................................................5

Non-Electric Models..........................................................6

III. Operation ...................................................................................6

IV. Option C-2 Operation.................................................................7

A. Front Panel Display ..........................................................7

a. System Menu Functions .............................................7

b. Control Panel LED Lights ...........................................7

c. Control Panel Buttons.................................................7

B. Controller Set-Up ..............................................................7

C. System Operation .............................................................7

D. Resetting Bowls ................................................................8

E. C-2 Menu Display Options................................................8

V. Diagrams....................................................................................9

A. SFS-101............................................................................9

B. SFS-G01.........................................................................10

C. SFS-G02......................................................................... 11

D. SFS-105..........................................................................12

VI. Trouble Shooting Guide ...........................................................13

VII. Warranty and Factory Service Policies ....................................14

3

I. Introduction

The SFS system is engineered to inject city water into a bowl containing a solid chemical which will then be

dissolved and drained into a chemical solution tank based on high/low level switches. All systems primarily

consists of:

1. Liquid Level controller (except SFS-G01, SFS-G02, SFS-10 and SFS-20 models).

2. A Universal dissolving bowl.

3. ¼”plumbingmanifoldwithshut-o,solenoidvalve,pressureregulatorandpressuregauge.

4. Molded solution tank with pump mounting shelf.

5. Atwoleveloatswitchassembly(exceptSFS-G01,SFS-10andSFS-20models).

Note: Inlet water pressure needs to be at 45-50 psi for best disolution.

Model Numbering

SFS systems have two base controller models, a full featured 120 VAC controller or the mini 12 VDC control-

ler. Your unit may be supplied with one or more of the features described in this manual. To determine what

features apply to your unit, check the model number label located on the controller.

SFS-G01 - Single dissolving bowl in a tank with non-electric make-up valve.

SFS-G02 - Dual dissolving bowls in a tank with non-electric make-up valve

SFS-101 - Provides a mini 12 VDC controller, dissolving bowl and a supply water plumbing assembly mount-

ed on a molded solution tank.

SFS-201 - Provides two SFS-101 units mounted on a poly panel with one water inlet.

SFS-105 - Provides a 120 VAC Liquid Level Controller with one solution tank, liquid level controller, universal

dissolving bowl and a supply water plumbing assembly mounted on a poly panel.

SFS-205 - Provides a 120 VAC Liquid Level Controller, two universal dissolving bowls and a supply water

plumbingassembly,solenoidvalveandvegallonsolutiontankmountedonapolypanel.

SFS-305 - Provides a 120 VAC Liquid Level Controller, three universal dissolving bowls and a supply water

plumbingassembly,solenoidvalveandvegallonsolutiontankmountedonapolypanel.

SFS-10 - Dissolving bowl with 120 volt solenoid, pressure regulator, no tank or controller.

SFS-20 - Two dissolving bowls with one 120 volt solenoid, regulator, no tank or controller.

4

Options

AConduit connections

A2 240 volt with conduit connections

B1 Back check in pump suction line

D1” FNPT port on the top of the tank for conductivity probe (not needed with C2)

D2 Adjustable level wand for external monitoring

E 10’of3/4”I.D.cleartubingforoverow

GBlue back panel for 105 and 205

H Highlevelalarmwithrelayoutputandcut-o

H2 Highlevelcut-oforSFS-101withDCcontroller

H3 Highalarmwithcut-oandsecondbrasssolenoidN.O.on120voltunits

H4 Highlevelcut-osonSFS-201,120voltmodualandN.O.brassshut-ovalves

KGray dissolving tank

LProvide 120 volt level controller for remote mounting with SFS-101

PNon Advantage Controls metering pump mounting adapter

R1 Remove pressure regulator from 205, 305 & 405 (R2, R3 to remove more than one)

T2 Dual timer on SFS-205 instead of level controller (Includes MicroTron Timer manual)

WAdjustable wands

5

II. Installation

Non-Electric Model Installation

Step 1

• Remove the two screws on top

plate of solid feeder (Fig. A).

• Liftocoverandsetonit’sside.

Step 2

• Clipweightedoattobottomof

wire hanger via cutout (Fig. B).

Step 3

• Insertweightedoatbackinto

solid feeder (Fig. C).

Note:Makesureweightedoat

is centered on wire hanger and

that the hanger moves freely up

and down through cap.

Step 4

• Reattach the two screws

previously removed in Step 1.

WARNING:Transportingthefeederwiththeweightedoatattachedtothe

hangercandamagethehangerandcausethevalvetonotshut-ocorrectly.

Figure A

Figure B

Figure C

6

Electric Models

The standard units are designed to be free standing or wall mounted. The level controller, control solenoid

valveandleveloatassemblyareallprewiredforeasyinstallation.

Models with 120 VAC controllers are supplied with an 8 foot, 3-wire grounded power cord.

Models with 12 VDC controllers are supplied with a wall plug-in transformer.

A ¼” MNPT connection is supplied for the incoming water supply. The pressure of the incoming water should

not exceed 110 PSI.

The reservoir tank has a molded pump mounting shelf. Various pump mounting accessories will be included

dependinguponthemodelnumberforsecuringpumptotank.Aoodedsuctionconnectionisalsoprovided

for the chemical feed pump.

Notes: 1. Pressure regulators are preset to approximately 40 psi. If incoming water pressure is below 50

psi the regulator will need to be set to a lower level to insure proper valve operation. Turning the

small knob on regulator counter clockwise will reduce the incoming line pressure.

2.Allmodelshaveanairgapdesignutilizingtheoverowport(seepage8)thatprovidesa

positivebackowpreventionleavingnopressurizedpathfordissolvedsolutionbackintothe

fresh water supply line.

III. Operation

The electric level controller will activate a relay to power the make-up water solenoid when the solution level

inthereservoirtankbecomeslowandturnsotherelaywhenthesolutiontankbecomesfull,reachingthe

secondoator(high)point.Thestandardleveloatpositioningand1”MNPTconnectionforoverowto

be piped to drain are designed to maintain a maximum solution level of 2.5 gallons. Changing the pressure

regulator setting will change the dissolving rate.

An additional high-level override switch input can be added with the H option on models that operate on

120VAC.Ifthecontrollerdetectsacontactfromthehighalarmswitch,thecontrolrelayisturnedoand

the alarm relay is activated. Models operating on 12 VDC have the H2 option in which the high alarm simply

turnsothecontrolrelay.

Muti-bowl models are designed to eliminate valuable maintenance time and create easy upkeep.

Option C-2 will allow a feed system to operate 2 or more bowls sequentially switching automatically by using

a conductivity controller, increasing the jug replacement interval.

7

IV. Option C-2 Operation

A. Front Panel Display

a. System Menu Functions:

Calibrate - Conductivity of dissolved liquids.

Switch At - Conductivity value in which the system will advance to the next bowl.

Sprayingon#1-Identiesthebowlinuse.

ZeroCond-Identiesthezeroconductivityvalue.

b. Run Mode Explanation:

Power- Illuminates when the controller is supplied with 120/240VAC.

Relay - Illuminates when a relay is activated.

Alarm-Illuminateswhenthenalbowlhasbeenutilized.

c. Control Panel Buttons:

View- displays menu options screen and returns back to run mode.

Function Select- advances menu options.

Value Adjust- changes menu settings.

Test- activates relays and alarms on for 3 minutes.

B. Controller Set-up

1. Press VIEW then adjust the FUNCTION SELECT knob to view functions.

2. Stop on the desired function and use the VALUE ADJUST knob to change the value.

3. After setting a value, adjust FUNCTION SELECT knob again to advance to the next function.

4. Press VIEW after setting the controller to continue with the run mode.

Note: PresstheTESTbuttontoforceallrelayson,pressagaintoforceo,pressagaintoreturnto

normaloperation.Ifforcedonoro,theunitwillreturntonormalafter3minutes.

C. System Operation

In order to activate the conductivity on the controller both level wands must be down (closed) to start,

with the 1st relay on for spraying on bowl 1. Both level wands must be up (open) to stop, to turn the

“FILL”relayso.

1.Uponstartup,theconductivityofthesolutioninthetankhasnoeectonthecontroller.Thetank

mustbelledandemptiedonetimebeforethecontrollerwillconsidertheconductivity.Thissimply

means,thelevelwandsmustbothgouptostartllingthetankandthentheymustbothgodownto

show an empty tank. At this point the controller will accept the conductivity reading.

2. When the conductivity drops below the “Switch At” point, the system will switch from Bowl #1 (Relay

#1)toBowl#2(Relay#2),Bowl#1willhaveutilizedthesolidchemicalbythispoint.Thersttime

the controller switches to Bowl #2, it will not consider the conductivity; once again, until the tank has

beenlledandemptiedonetime.

3. The controller will continue operating on Bowl #2, even if the conductivity drops below the “Switch

At” point while utilizing Bowl #2 the ALARM led will activate. If the controller has option “H”, then a

relay will also activate for the alarm. This relay can be 120/240VAC or a dry contact.

8

D. Resetting Bowls

WhenAUTORESETisenabled,thiswillallowthecontrollertoautomaticallyresetitselftotherst

bowl after the last bowl has gone “low conductivity”. Set to Y will enable.

When disabled (Set to N), the controller will function as below:

When the controller is utilizing Bowl #2, it must be manually switched back to Bowl #1, presummably

after the solid chemical jugs have been changed. This can be done by:

1. Pressing the “VIEW” button and then rotating the “FUNCTION SELECT” knob two clicks clockwise.

The display will read “RESET TO BOWL #1”.

2. By rotating the “VALUE ADJUST” knob (either direction). The display will change to “SPRAYING

ON #1”. Chemical Bowl #1 will be used to start the new run cycle.

3. You may then press the “VIEW” button so the controller will return to the “run” mode.

(The controller will return to “run” mode after 3 minutes.)

E. C-2 Menu Display Options

Press

VIEW BUTTON

to view menu

options

Press

VIEW BUTTON

to return to

run mode

Turn VALUE

ADJUST to change setting

Turn FUNCTION

SELECT to change menu

CALIBRATION

Turn VALUE

ADJUST to change setting

Turn FUNCTION

SELECT to change menu

SWITCH AT

Turn VALUE

ADJUST to change setting

Turn FUNCTION

SELECT to change menu

SPRAYING ON #1

Turn VALUE

ADJUST to change setting

Turn FUNCTION

SELECT to change menu

ZERO COND

Turn VALUE

ADJUST to change setting

Turn FUNCTION

SELECT to change menu

AUTO RESET? Y

9

V. Diagrams

A. SFS-101

SFS-101 Parts List

1

6

2

3

4

57

8

9

10

11

13

12

1. SFS-DB-1

2. SFS-TANK-101

3. 2C4A000056

4. SFS-SUCTION

5. SFS-SB-12V

6. R00223

7. SFS-BV

8. SFS-PR

9. SFS-PG

10. SFS-C01

11. SFS-LF-2

12. 2C4A000059

13. SFS-DB-ARM-1

SFS-PA-101M includes #5, 7, 8, 9 & polyboard

Dissolving bowl (includes spray arm)

Replacement Tank

1” MNPT to 3/4” tubing barb overflow elbow

Outlet pump suction assembly

Brass solenoid valve with y-strainer 12 volt D.C.

SS wall mounting bracket

Brass inlet valve

Pressure regulator

Pressure gauge

12 vold controller

2 level float assembly

Replacement spray nozzle

Spray arm (includes spray nozzle)

10

B. SFS-G01

SFS-G01 Parts List

1

10

2

3

8

12

11

1. SFS-DB-1

2. SFS-TANK-G01

3. SFS-SUCTION

4. 2C4A000056

5. SFS-BV

6. SFS-Y

7. SFS-PR

8. SFS-PG

9. SFS-LF-G01

9a. SFS-FV-G01

10. R00223

11. 2C4A000059

12. SFS-DB-ARM-1

13. SFS-FLOAT

SFS-PA-G01 includes #5, 6, 7, & 8

Dissolving bowl (includes spray arm)

Replacement Tank

Outlet pump suction assembly

1” MNPT to 3/4” tubing barb overflow elbow

Brass inlet valve

Y-strainer

Pressure regulator

Pressure gauge

Level float & inlet valve assembly (includes weight & polyboard)

Fill valve assembly only - no float

SS wall mounting bracket

Replacement spray nozzle

Spray arm (includes spray nozzle)

Float bottle

4

5

7

9

6

9

13

9a

11

C. SFS-G02

1

5

8

7

6

4

3

SFS-G02 Parts List

1. SFS-BV

2. SFS-TANK-G02

3. SFS-DB-1

4. 2C4A000056

5. SFS-SUCTION

6. SFS-LF-G02

7. SFS-PR

8. SFS-Y

9. SFS-PG

10. 2C4A000059

11. R00339

Brass inlet valve

Tank

Dissolving bowl

1” MNPT to 3/4” tubing barb overflow elbow

Outlet pump suction assembly

Level float & inlet valve assembly (includes weight & polyboard)

Pressure regulator

Y-strainer

Pressure gauge

Replacement spray nozzle (not shown)

SS wall mounting bracket (not shown)

9

2

12

D. SFS-105

SFS-105 Parts List

1. SFS-DB-1

2. SFS-TANK-101

3. 2C4A000056

4. SFS-SUCTION

5. SFS-SB-120V

6. R00223

7. SFS-BV

8. SFS-PR

9. SFS-PG

10. SFS-C105

11. SFS-LF-2

12. 2C4A000059

13. SFS-DB-ARM-1

SFS-PA-101M includes #5, 7, 8, 9 & polyboard

Dissolving bowl (includes spray arm)

Replacement Tank

1” MNPT to 3/4” tubing barb overflow elbow

Outlet pump suction assembly (left or right)

Brass solenoid valve with y-strainer 120 volt A.C.

SS wall mounting bracket (not shown)

Brass inlet valve

Pressure regulator

Pressure gauge

Level controller

2 level float assembly

Replacement spray nozzle (not shown)

Spray arm (includes spray nozzle)

1

2

3

4

11

13

5 7

9

10

8

13

VI. Trouble Shooting

PROBLEM CAUSE REMEDY

Solenoids not

activating

Power Source

Output Power

Bad or Dirty Level Floats

Faulty Wiring to Level Floats

Check power source

Check or replace fuse

Clean or replace as needed

Leveloatsasneeded

System not spraying Dirty Bowl Injection Nozzle

Clogged Y-Strainer Screen

Low Water Pressure

Clean as needed

Clean as needed

Lower regulator setting

No system power Power Source

Check Fuse

Check power source

Replace as needed

No output power Check Ribbon (120/240V Controller)

Check Fuse

Make sure connection is fully seated on

both ends

Replace as needed

(C-2 Option)

False reading Bad or Dirty Electrode

Out of Calibration

Clean as needed

Calibrate unit

Will not calibrate Dirty Electrode

Faulty Electrode

Faulty Wiring to Electrode

Out of Calibration

Clean electrode

Replace controller or

Replace as needed

Calibrate unit

Alarm Lights ON System has utilized all bowls Reset to bowl #1

14

VII. Manufacturer’s Product Warranty

Advantage Controls warrants control systems of its manufacture to be free of defects in material or workman-

ship. Liability under this policy extends for 24 months from date of installation (sensors are not included).

Liability is limited to repair or replacement of any failed equipment or part proven defective in material or

workmanship upon manufacturer’s examination. Removal and installation costs are not included under this

warranty. Manufacturer’s liability shall never exceed the selling price of equipment or part in question. Ad-

vantage disclaims all liability for damage caused by its products by improper installation, maintenance, use

or attempts to operate products beyond their intended functionality, intentionally or otherwise, or any unau-

thorized repair. Advantage is not responsible for damages, injuries or expense incurred through the use of

its products. The above warranty is in lieu of other warranties, either expressed or implied. No agent of ours

is authorized to provide any warranty other than the above.

30 Day Billing Memo Policy

Advantage Controls maintains a unique factory exchange program to ensure uninterrupted service with

minimum downtime. If your controller malfunctions, call 1-918-686-6211 (international customers dial +1918

686-6211), and provide our technician with Model and Serial Number information. If they are unable to di-

agnose and solve your problem over the phone, a fully warranted replacement unit will be shipped, usually

within 48 hours, on a 30 Day Billing Memo. This service requires a purchase order and the replacement unit

is billed to your regular account for payment. The replacement unit will be billed at current list price for that

model less any applicable resale discount. Upon return of your old unit, credit will be issued to your account

if the unit is in warranty. If the unit is out of warranty or the damage not covered, a partial credit will be applied

based upon a prorated replacement price schedule dependent on the age of the unit. Any exchange covers

only the controller or pump. Electrodes and other external accessories are not included.

15

- Notes -

16

Get the Advantage in Water Treatment Equipment

Advantage Controls can give you the Advantage in products, knowledge

and support on all of your water treatment equipment needs.

Cooling Tower Controllers

Boiler Blow Down Controllers

Blow Down Valve Packages

Solenoid Valves

Water Meters

Chemical Metering Pumps

Corrosion Coupon Racks

Chemical Solution Tanks

Solid Feed Systems

Feed Timers

Filter Equipment

Glycol Feed Systems

Pre Fabricated Systems

Get the Advantage

5

4

3

2

1

0

9

8

7

6

BACK

HOME

HELP

ENTER

CANCEL

SET UP

RUN

5

4

3

2

1

ENTER

HELP

5

4

3

CHANGE

RUN

SET UP

0

9

8

2

1

7

6

HOME

BACK

This manual suits for next models

9

Table of contents

Other Advantage Controls Water System manuals

Popular Water System manuals by other brands

Solarbayer

Solarbayer FRIWA 65 Kaskade KL2 Product information

Jung Pumpen

Jung Pumpen compli 300 instruction manual

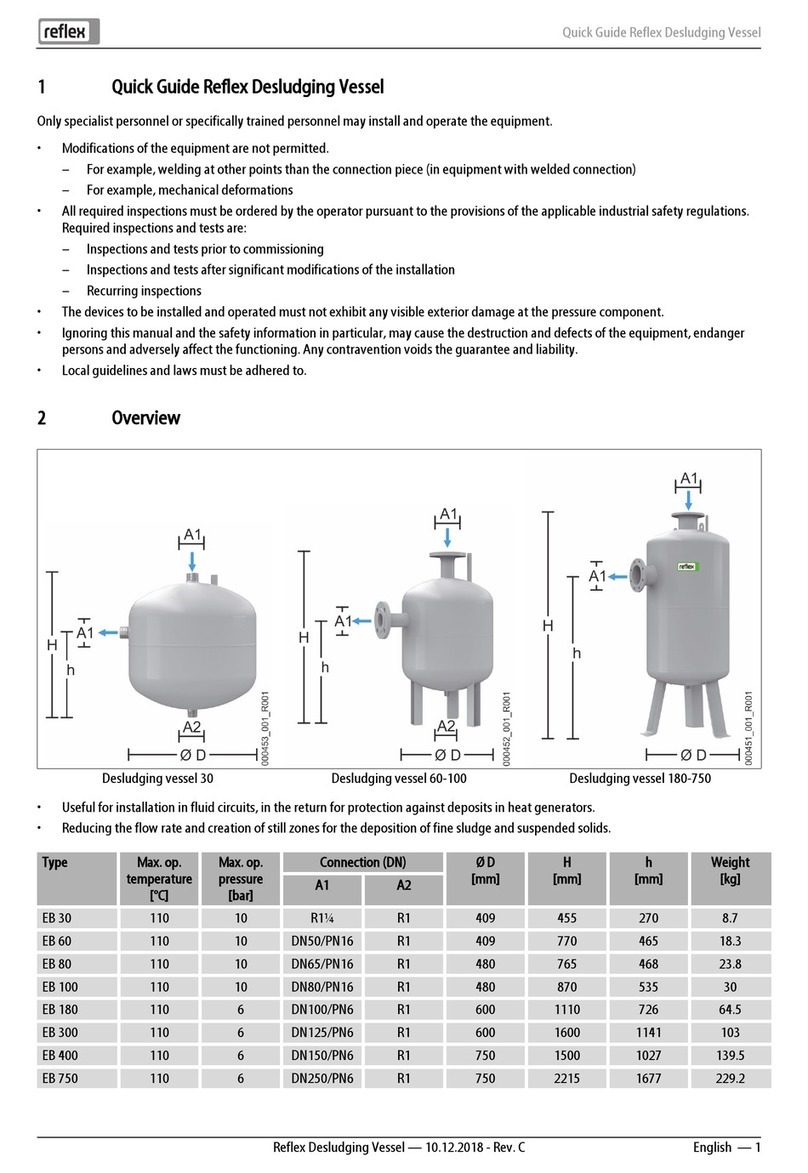

Reflex

Reflex EB 30 quick guide

Watts Premier

Watts Premier 5 SV DELUXE Installation, operation and maintenance manual

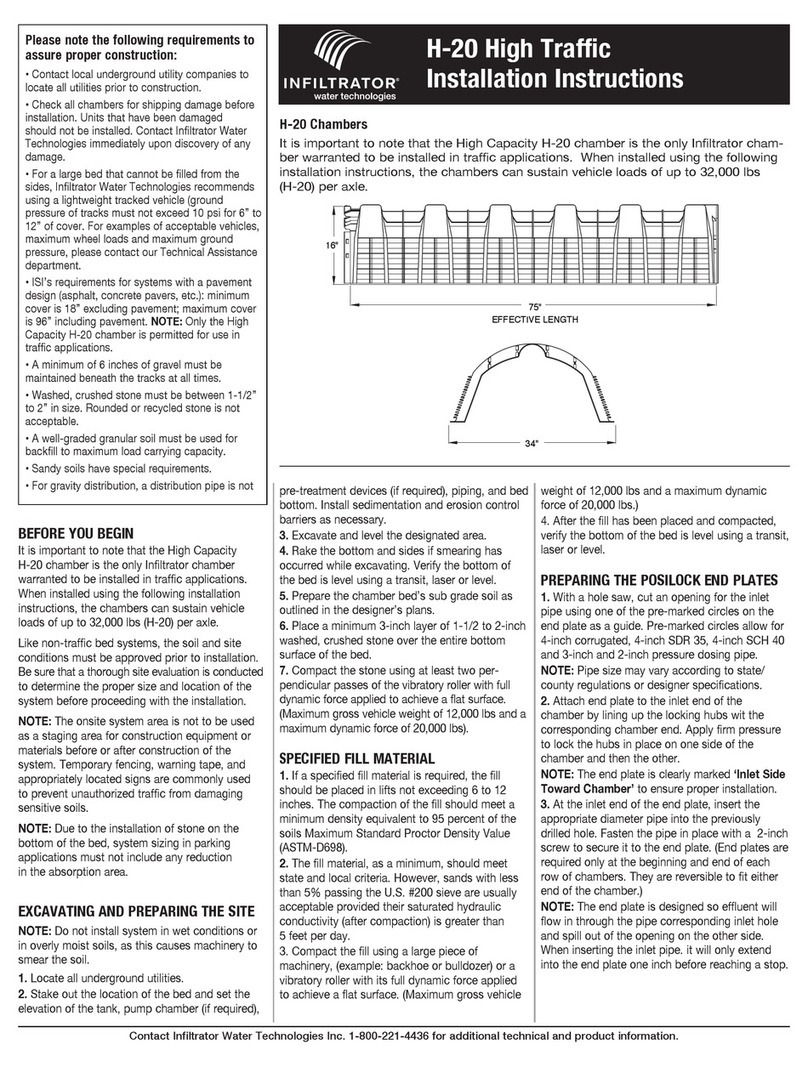

Infiltrator

Infiltrator H-20 installation instructions

Reverse Osmosis

Reverse Osmosis Economy RO75 owner's manual