Advantech Automation1 XC4 User manual

Revision 2.01

Automation1 XC4 PWMDigital Drive

HARDWAREMANUAL

GLOBALTECHNICALSUPPORT

Go to the Global Technical Support Portal for information and support about your

Aerotech, Inc. products. The website supplies software, product manuals, Help files,

training schedules, and PC-to-PC remote technical support. If necessary, you can

complete Product Return (RMA) forms and get information about repairs and spare or

replacement parts. To get help immediately, contact a service office or your sales

representative. Include your customer order number in your email or have it available

before you call.

This manual contains proprietary information and may not be reproduced, disclosed, or

used in whole or in part without the express written permission of Aerotech, Inc.

Product names mentioned herein are used for identification purposes only and may be

trademarks of their respective companies.

Copyright © 2018-2021, Aerotech, Inc., All rights reserved.

Table of Contents

Automation1 XC4 PWMDigital Drive 1

Table of Contents 3

List of Figures 5

List of Tables 7

EU Declaration of Conformity 9

Agency Approvals 11

Safety Procedures and Warnings 13

Installation Overview 15

Chapter 1: Introduction 17

1.1. Electrical Specifications 20

1.1.1. System Power Requirements 21

1.2. Mechanical Specifications 22

1.2.1. Mounting and Cooling 22

1.2.2. Dimensions 23

1.3. Environmental Specifications 25

1.4. Drive and Software Compatibility 26

Chapter 2: Installation and Configuration 27

2.1. Input Power Connections 28

2.1.1. Control Supply Connector 28

2.1.2. Motor Supply Connector 29

2.1.3. Transformer Options 30

2.1.4. Minimizing Noise for EMC/CECompliance 37

2.2. Motor Power Output Connector 38

2.2.1. Brushless Motor Connections 39

2.2.1.1. Brushless Motor Powered Motor and Feedback Phasing 40

2.2.1.2. Brushless Motor Unpowered Motor and Feedback Phasing 41

2.2.2. DCBrush Motor Connections 42

2.2.2.1. DC Brush Motor Phasing 43

2.2.3. Stepper Motor Connections 44

2.2.3.1. Stepper Motor Phasing 45

2.3. Feedback Connector 46

2.3.1. Primary Encoder Inputs 47

2.3.1.1. Square WaveEncoder 48

2.3.1.2. Absolute Encoder 49

2.3.1.3. Sine Wave Encoder [-MX1 Option] 50

2.3.1.4. Encoder Phasing 52

2.3.2. Hall-Effect Inputs 53

2.3.3. Thermistor Input 54

2.3.4. Encoder Fault Input 55

2.3.5. End of Travel and Home Limit Inputs 56

2.3.5.1. End of Travel and Home Limit Phasing 58

2.3.6. Brake Outputs 59

2.4. Safe Torque Off Input (STO) 60

2.4.1. STOStandards 62

2.4.2. STO Functional Description 63

2.4.3. STO Startup Validation Testing 64

2.4.4. STO Diagnostics 65

2.5. Auxiliary I/O Connector 66

2.5.1. Auxiliary Encoder Inputs 67

2.5.1.1. Square WaveEncoder 68

2.5.1.2. Absolute Encoder 69

2.5.2. Position Synchronized Output (PSO) 70

2.5.3. Digital Outputs 72

2.5.4. Digital Inputs 75

2.5.5. High-Speed Inputs 77

2.5.6. Analog Output 0 78

2.5.7. Analog Input 0 (Differential) 79

XC4 Hardware Manual Table of Contents

www.aerotech.com 3

2.6. Brake Power Supply Connector 80

2.7. HyperWire Interface 81

2.8. External Shunt Option [-SX1] 82

2.9. Sync Port 84

2.10. System Interconnection 85

2.11. PC Configuration and Operation Information 87

Chapter 3: -EB1 I/O Option Board 89

3.1. Digital Outputs [-EB1] 90

3.2. Digital Inputs [-EB1] 94

3.3. Analog Outputs [-EB1] 97

3.4. Analog Inputs [-EB1] 98

3.5. Position Synchronized Output Interface [-EB1] 99

Chapter 4: Cables and Accessories 101

4.1. Joystick Interface 102

4.2. Handwheel Interface 104

Chapter 5: Maintenance 105

5.1. Preventative Maintenance 106

5.2. Fuse Specifications 107

Appendix A: Warranty and Field Service 109

Appendix B: Revision History 111

Index 113

Table of Contents XC4 Hardware Manual

4 www.aerotech.com

List of Figures

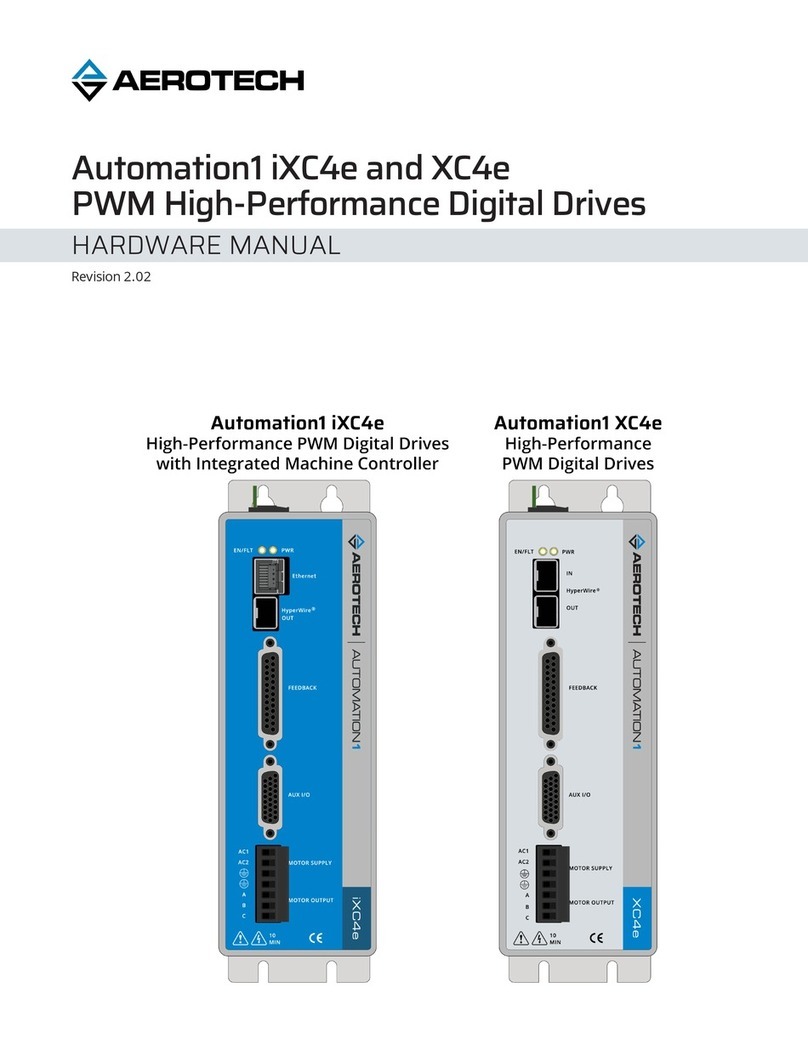

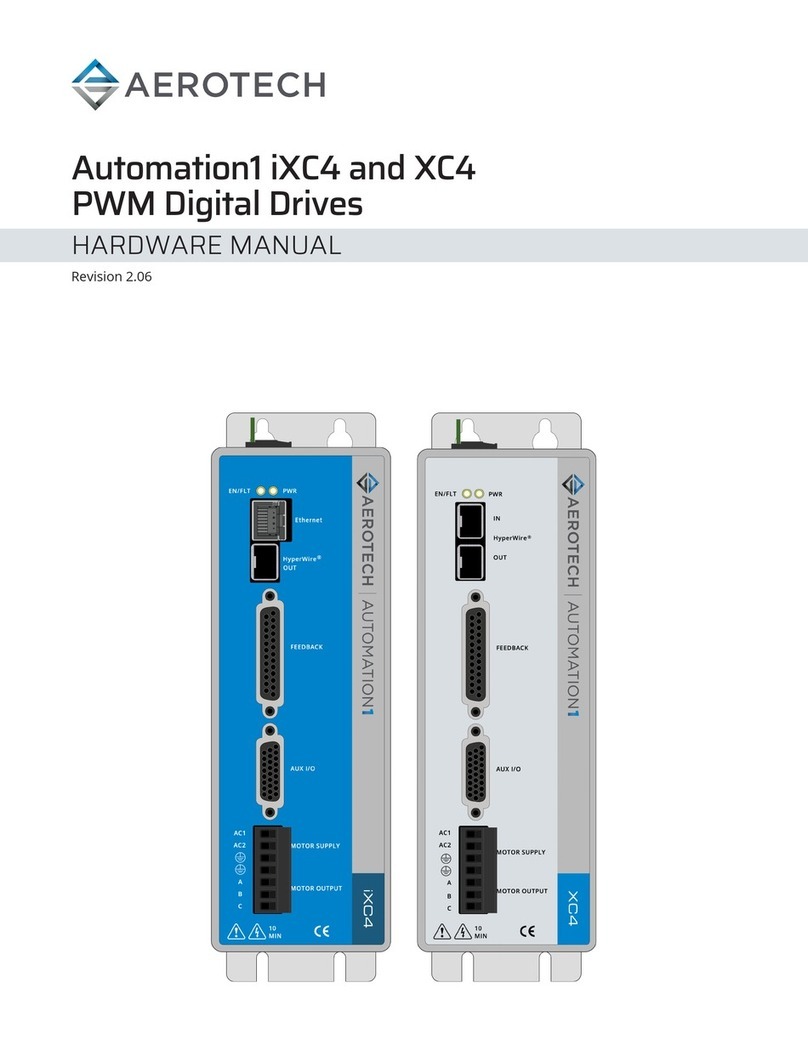

Figure 1-1: XC4 Digital Drive 17

Figure 1-2: Functional Diagram 19

Figure 1-3: Dimensions 23

Figure 1-4: Dimensions [-EB1] 24

Figure 2-1: Control Supply Connections 28

Figure 2-2: Motor Supply Connections 29

Figure 2-3: Transformer Examples 30

Figure 2-4: TV0.3-28-56-ST Transformer Control and Motor Power Wiring (40 VDC Bus) 31

Figure 2-5: TV0.3-28-56-ST Transformer Control and Motor Power Wiring (80 VDC Bus) 32

Figure 2-6: TV0.3-28-56-ST Transformer Control and Motor Power Wiring (160 VDC Bus) 33

Figure 2-7: TV0.3-28 Transformer Control and Motor Power Wiring (40 VDC Bus) 34

Figure 2-8: TV0.3-56 Transformer Control and Motor Power Wiring (80 VDC Bus) 35

Figure 2-9: TM3/TM5 Transformer Control and Motor Power Wiring 36

Figure 2-10: Brushless Motor Configuration 39

Figure 2-11: Positive Motor Direction 40

Figure 2-12: Encoder and Hall Signal Diagnostics 40

Figure 2-13: Brushless Motor Phasing Oscilloscope Example 41

Figure 2-14: Brushless Motor Phasing Goal 41

Figure 2-15: DC Brush Motor Configuration 42

Figure 2-16: Positive Motor Direction 43

Figure 2-17: Stepper Motor Configuration 44

Figure 2-18: Positive Motor Direction 45

Figure 2-19: Square Wave Encoder Schematic (Feedback Connector) 48

Figure 2-20: Absolute Encoder Schematic (Feedback Connector) 49

Figure 2-21: Sine Wave Encoder Phasing Reference Diagram 50

Figure 2-22: Sine Wave Encoder Schematic (Feedback Connector) 51

Figure 2-23: Encoder Phasing Reference Diagram (Standard) 52

Figure 2-24: Position Feedback in the DiagnosticDisplay 52

Figure 2-25: Hall-Effect Inputs Schematic (Feedback Connector) 53

Figure 2-26: Thermistor Input Schematic (Feedback Connector) 54

Figure 2-27: Encoder Fault Input Schematic (Feedback Connector) 55

Figure 2-28: End of Travel and Home Limit Input Connections 57

Figure 2-29: End of Travel and Home Limit Input Schematic (Feedback Connector) 57

Figure 2-30: End of Travel and Home Limit Input Diagnostic Display 58

Figure 2-31: Brake Connected to the 25-Pin Feedback Connector (Typical) 59

Figure 2-32: Typical Configuration 61

Figure 2-33: STO Timing 65

Figure 2-34: Square Wave Encoder Interface (Aux I/OConnector) 68

Figure 2-35: Absolute Encoder Schematic (Auxiliary I/O Connector) 69

Figure 2-36: PSOInterface 71

Figure 2-37: Digital Output Schematic (Aux I/OConnector) 73

Figure 2-38: Digital Outputs Connected in Current Sourcing Mode 74

Figure 2-39: Digital Outputs Connected in Current Sinking Mode 74

Figure 2-40: Digital Inputs Schematic (Aux I/OConnector) 75

Figure 2-41: Digital Inputs Connected to Current Sinking Devices 76

Figure 2-42: Digital Inputs Connected to Current Sourcing Devices 76

Figure 2-43: High-Speed Inputs 77

Figure 2-44: Analog Output 0 Schematic 78

XC4 Hardware Manual List of Figures

www.aerotech.com 5

Figure 2-45: Analog Input 0 Schematic 79

Figure 2-46: System Wiring Drawing (Best Practice) 85

Figure 2-47: PC-Based Controller System Interconnection (Best Practice) 86

Figure 3-1: XC4 with -EB1 I/O Option Board Connectors 89

Figure 3-2: Digital Outputs Schematic [-EB1] 92

Figure 3-3: Digital Outputs Connected in Current Sourcing Mode [-EB1] 93

Figure 3-4: Digital Outputs Connected in Current Sinking Mode [-EB1] 93

Figure 3-5: Digital Inputs Schematic [-EB1] 95

Figure 3-6: Digital Inputs Connected to Current Sourcing (PNP) Devices [-EB1] 96

Figure 3-7: Digital Inputs Connected to Current Sinking (NPN) Devices [-EB1] 96

Figure 3-8: Analog Output Typical Connection [-EB1] 97

Figure 3-9: Analog Input Typical Connection [-EB1] 98

Figure 3-10: PSO Output Sources Current 100

Figure 3-11: PSOOutput Sinks Current 100

Figure 3-12: PSO TTLOutputs Schematic 100

Figure 4-1: Two Axis Joystick Interface (to the Aux I/O of two drives) 102

Figure 4-2: Two Axis Joystick Interface (to the I/Oboard) 103

Figure 4-3: Handwheel Interconnection to Aux I/O Connector 104

Figure 4-4: Handwheel Interconnection to the Aux I/O through a BBA32 Module 104

List of Figures XC4 Hardware Manual

6 www.aerotech.com

List of Tables

Table 1-1: Features and Options 18

Table 1-2: Electrical Specifications 20

Table 1-3: Mounting Specifications 22

Table 1-4: Environmental Specifications 25

Table 1-5: Drive and Software Compatibility 26

Table 2-1: Control Supply Wiring Specifications 28

Table 2-2: Mating Connector Part Numbers for the Control Supply Connector 28

Table 2-3: Motor Supply Connector Wiring Specifications 29

Table 2-4: Mating Connector Part Numbers for the Motor Supply Connector 29

Table 2-5: Nominal Motor Operating Voltages / Required ACVoltages 30

Table 2-6: TransformerOptions 30

Table 2-7: Motor Power Output Connector Pinout 38

Table 2-8: Mating Connector Part Numbers for the Motor Power Output Connector 38

Table 2-9: Wire Colors for Aerotech-Supplied Brushless Motor Cables 39

Table 2-10: Hall Signal Diagnostics 40

Table 2-11: Wire Colors for Aerotech-Supplied DCBrush Motor Cables 42

Table 2-12: Wire Colors for Aerotech-Supplied Stepper Motor Cables 44

Table 2-13: Feedback Connector Pinout 46

Table 2-14: Mating Connector Part Numbers for the Feedback Connector 46

Table 2-15: Multiplier Options 47

Table 2-16: Primary Encoder Input Pins on the Feedback Connector 47

Table 2-17: Square Wave Encoder Specifications 48

Table 2-18: Sine Wave Encoder Specifications 50

Table 2-19: Hall-Effect Feedback Pins on the Feedback Connector 53

Table 2-20: Thermistor Input Pin on the Feedback Connector 54

Table 2-21: Encoder Fault Input Pin on the Feedback Connector 55

Table 2-22: End of Travel and Home Limit Pins on the Feedback Connector 56

Table 2-23: Brake Output Pins on the Feedback Connector 59

Table 2-24: Brake Control Specifications 59

Table 2-25: STO Connector Pinout 60

Table 2-26: Mating Connector Part Numbers for the STOConnector 60

Table 2-27: STOElectrical Specifications 61

Table 2-28: STOStandards 62

Table 2-29: STOStandards Data 62

Table 2-30: STOSignal Delay 64

Table 2-31: Motor Function Relative to STOInput State 64

Table 2-32: STOTiming 65

Table 2-33: Auxiliary I/O Connector Pinout 66

Table 2-34: Mating Connector Part Numbers for the Auxiliary I/OConnector 66

Table 2-35: Auxiliary Encoder Pins on the Auxiliary I/OConnector 67

Table 2-36: Square Wave Encoder Specifications 68

Table 2-37: PSO Specifications 70

Table 2-38: PSOPins on the Auxiliary I/OConnector 70

Table 2-39: Digital Output Specifications 72

Table 2-40: Digital Output Pins on the Auxiliary I/O Connector 72

Table 2-41: Digital Input Specifications 75

Table 2-42: Digital Input Pins on the Auxiliary I/O Connector 75

Table 2-43: High-Speed Input Specifications 77

XC4 Hardware Manual List of Tables

www.aerotech.com 7

Table 2-44: High-Speed Input Pins on the Auxiliary I/O Connector 77

Table 2-45: Analog Output Specifications 78

Table 2-46: Analog Output Pins on the Auxiliary I/O Connector 78

Table 2-47: Analog Input Specifications 79

Table 2-48: Analog Input Pins on the Auxiliary I/O Connector 79

Table 2-49: Brake Power Supply Connector Pinout 80

Table 2-50: Mating Connector Part Numbers for the Brake Power Supply Connector 80

Table 2-51: HyperWire Card Part Number 81

Table 2-52: HyperWire Cable Part Numbers 81

Table 2-53: -SX1Component Information 82

Table 2-54: Maximum Additional Storage Energy for a Standard XC4 83

Table 2-55: Sync-Related Functions 84

Table 2-56: SyncPort Cables 84

Table 3-1: Digital Output Specifications [-EB1] 90

Table 3-2: Digital Output 1 Connector Pinout [-EB1] 91

Table 3-3: Mating Connector Part Numbers for the Digital Output 1 Connector [-EB1] 91

Table 3-4: Digital Output 2 Connector Pinout [-EB1] 91

Table 3-5: Mating Connector Part Numbers for the Digital Output 2 Connector [-EB1] 91

Table 3-6: Digital Input Specifications [-EB1] 94

Table 3-7: Digital Input 1 Connector Pinout [-EB1] 94

Table 3-8: Mating Connector Part Numbers for the Digital Input 1 Connector [-EB1] 94

Table 3-9: Digital Input 2 Connector Pinout [-EB1] 95

Table 3-10: Mating Connector Part Numbers for the Digital Input 2 Connector [-EB1] 95

Table 3-11: Analog Output Specifications [-EB1] 97

Table 3-12: Analog Output Connector Pinout [-EB1] 97

Table 3-13: Mating Connector Part Numbers for the Analog Output Connector [-EB1] 97

Table 3-14: Differential Analog Input Specifications [-EB1] 98

Table 3-15: Analog Input Connector Pinout [-EB1] 98

Table 3-16: Mating Connector Part Numbers for the Analog Input Connector [-EB1] 98

Table 3-17: PSO Specifications [-EB1] 99

Table 3-18: PSO Interface Connector Pinout [-EB1] 99

Table 3-19: Mating Connector Part Numbers for the PSO Interface Connector [-EB1] 99

Table 4-1: Standard Interconnection Cables 101

Table 5-1: LEDDescription 105

Table 5-2: Troubleshooting 105

Table 5-3: Preventative Maintenance 106

Table 5-4: Control Board Fuse Specifications 107

List of Tables XC4 Hardware Manual

8 www.aerotech.com

EU Declaration of Conformity

Manufacturer Aerotech, Inc.

Address 101 Zeta Drive

Pittsburgh, PA 15238-2811

USA

Product XC4

Model/Types All

This is to certify that the aforementioned product is in accordance with the applicable requirements of

the following Directive(s):

2014/30/EU Electromagnetic Compatibility (EMC)

2014/35/EU Low Voltage Directive

2006/42/EC Machinery Directive

EU 2015/863 Directive, Restricted Substances (RoHS 3)

and has been designed to be in conformity with the applicable requirements of the following Standard(s)

when installed and used in accordance with the manufacturer’s supplied installation instructions.

EN 61326-1:2013 EMCRequirements for Electrical Equipment

EN 61010-1:2010/A1:2019 Safety Requirements for Electrical Equipment

EN ISO 13849-1:2015 SafetyRelated Parts of Control Systems

Authorized Representative: Simon Smith, European Director

Address: Aerotech Ltd

The Old Brick Kiln, Ramsdell, Tadley

Hampshire RG26 5PR

UK

Name / Alex Weibel

Position Engineer Verifying Compliance

Location Pittsburgh, PA

Date 3/24/2021

XC4 Hardware Manual EU Declaration of Conformity

www.aerotech.com 9

This page intentionally left blank.

EU Declaration of Conformity XC4 Hardware Manual

10 www.aerotech.com

Agency Approvals

Aerotech tested its XC4 drives and found that they obey the standards that follow:

Approval: CUS NRTL

Approving Agency: TUV SUD America Inc.

Certificate #: U8V 068995 0028 Rev. 02

Standards: CAN/CSA-C22.2 No. 61010-1:2012/U2:2016-04; EN 61010-

1:2010/A1:2019; UL 61010-1:2012/R:2016-04

Approval: Safety Components (STO)

Approving Agency: TUVSUD

Certificate #: Z10 068995 0030 Rev. 00

Standards: IEC61508-1:2010 (up to SIL3)

Visit https://www.tuev-sued.de/product-testing/certificates to view Aerotech's TÜV SÜD certificates.

Type the certificate number listed above in the search bar or type "Aerotech" for a list of all Aerotech

certificates.

XC4 Hardware Manual Agency Approvals

www.aerotech.com 11

This page intentionally left blank.

Agency Approvals XC4 Hardware Manual

12 www.aerotech.com

Safety Procedures and Warnings

IMPORTANT: This manual tells you how to carefully and correctly use and operate the XC4

drive.

lRead all parts of this manual before you install or operate the XC4 drive or before

you do maintenance to your system.

lTo prevent injury to you and damage to the equipment, obey the precautions in this

manual.

lAll specifications and illustrations are for reference only and were complete and

accurate as of the release of this manual. To find the newest information about this

product, refer to www.aerotech.com.

If you do not understand the information in this manual, contact Aerotech Global

Technical Support.

IMPORTANT: This product has been designed for light industrial manufacturing or

laboratory environments. If the product is used in a manner not specified by the

manufacturer:

lThe protection provided by the equipment could be impaired.

lThe life expectancy of the product could be decreased.

DANGER: To decrease the risk of electrical shock, injury, death, and damage to the

equipment, obey the precautions that follow.

1. Before you do maintenance to the equipment, disconnect the electrical power.

2. Restrict access to the XC4 when it is connected to a power source.

3. Do not connect or disconnect electrical components, wires, and cables while this

product is connected to a power source.

4. Wait at least ten (10) minutes after removing the power supply before doing main-

tenance or an inspection. Otherwise, there is the danger of electric shock.

5. Supply each operator with the necessary protection from live electrical circuits.

6. Make sure that all components are grounded correctly and that they obey the local

electrical safety requirements.

7. Install the necessary precautions to supply safety and protection to the operator.

DANGER: System travel can cause crush, shear, or pinch injuries. Restrict access to all

motor and stage parts while your system is connected to a power source.

WARNING: To prevent damage to the equipment and decrease the risk of electrical shock

and injury, obey the precautions that follow.

1. Make sure that all system cables are correctly attached and positioned.

2. Do not use the cables or the connectors to lift or move this product.

3. Use this product only in environments and operating conditions that are approved

in this manual.

4. Only trained operators should operate this equipment.

XC4 Hardware Manual Safety Procedures and Warnings

www.aerotech.com 13

This page intentionally left blank.

Safety Procedures and Warnings XC4 Hardware Manual

14 www.aerotech.com

Installation Overview

This image shows the order in which to make connections and settings that are typical to the XC4. If a

custom interconnect drawing was supplied with your system, that drawing is on your Storage Device and

shows as a line item on your Sales Order in the Integration section.

1Connect the motor to the amplifier Motor Output connector. Section 2.2.

Connect the motor to the amplifier Feedback connector. Section 2.3.

2Connect a PCHyperWire port to the HyperWire In port. Section 2.7.

3Connect additional I/O as required by your application

(if you purchased the I/O option).

Section 2.5./

Chapter 3

4Connect the Safe Torque Off (STO). Section 2.4.

5Connect the power supply to the Control Supply connector. Section 2.1.1.

6Connect the motor power to the Motor Supply connector. Section 2.1.2.

Figure 1: Installation ConnectionOverview

XC4 Hardware Manual Installation Overview

www.aerotech.com 15

This page intentionally left blank.

Installation Overview XC4 Hardware Manual

16 www.aerotech.com

Chapter 1: Introduction

The XC4 is a high performance digital drive based on the HyperWire communication protocol. The drive

provides deterministic behavior, auto-identification, is fully software configurable. A double precision

floating point DSP controls the digital PID and current loops in the XC4.

The XC4 offers standard Safe Torque Off (STO) inputs and optional Position Synchronized Output (PSO)

outputs. The XC4 is offered with an optional encoder interpolation feature (-MX1), an auxiliary encoder

input for dual loop control, dedicated analog and digital I/O (expandable with the -EB1 option), and

separate power connections for motor and control supply voltages.

Figure 1-1: XC4 Digital Drive

XC4 Hardware Manual Chapter 1: Introduction

www.aerotech.com 17

Table 1-1: Features and Options

Standard Features

l100-240 VAC control supply inputs Section 2.1.1.

l0-240 VAC motor supply inputs (producing 340 VDC) Section 2.1.2.

lLine driver square wave quadrature encoder input for position and velocity

feedback Section 2.3.1.

lAbsolute Encoder support on the Feedback connector Section 2.3.1.2.

lOne fail-safe brake output Section 2.3.6.

lTwo STOsense inputs Section 2.4.

lLine driver square wave auxiliary quadrature encoder input or output for PSO Section 2.5.1.

lAbsolute Encoder support on the Auxiliary I/O connector Section 2.5.1.2.

lFour digital user outputs Section 2.5.3.

lSix digital user inputs

nFour Digital Inputs Section 2.5.4.

nTwo High-Speed Inputs Section 2.5.5.

lOne 16-bit analog output (±10 V) Section 2.5.6.

lOne 16-bit differential analog input (±10 V) Section 2.5.7.

Options

Peak Current Section 1.1.

-10 10 A Peak, 5 A Continuous Current

-20 20 A Peak, 10 A Continuous Current

-30 30 A Peak, 10 A Continuous Current

Expansion Board Chapter 3

-EB0 No expansion board

-EB1

I/Oexpansion board

lThree 16-bit analog outputs (±10 V)

lThree 16-bit differential analog inputs (±10 V)

l16 digital logic inputs (5 - 24 VDC), may be connected to current sourcing or sinking

devices

l16 digital logic outputs (5 - 24 VDC), user defined as current sourcing or sinking

lDigital logic laser firing (PSO) output

Multiplier Section 2.3.1.3.

-MX0 No encoder multiplier

-MX1 Interpolation circuit allowing for analog sine wave input on the primary encoder channel

with an interpolation factor of 16,384.

PSO Section 2.5.2.

-PSO1 One-axis PSO firing (includes One-axis Part-Speed PSO)

External Shunt Section 2.8.

-SX0 No connector for the External Shunt

-SX1 Connection provided for an external shunt resistor network

Version

-DEFAULT Firmware Matches Software Line

-LEGACY Legacy Firmware Version X.XX.XXX

Chapter 1: Introduction XC4 Hardware Manual

18 www.aerotech.com

The block diagram that follows shows a summary of the connector signals.

Figure 1-2: Functional Diagram

XC4 Hardware Manual Chapter 1: Introduction

www.aerotech.com 19

1.1. Electrical Specifications

Table 1-2: Electrical Specifications

Description -10 Option -20 Option -30Option

Motor Supply

Input Voltage 0-240 VAC

Input Frequency 50-60 Hz

Inrush Current 34 Apk @ 240 V

Maximum

Continuous Input

Current

5 Arms 10 Arms 10 Arms

Input Current Refer to Section 1.1.1. System Power Requirements

Control Supply

Input Voltage 100-240 VAC

Input Frequency 50-60 Hz

Inrush Current 68 Apk @ 240 V

Input Power 10 W

Output Voltage (1) 340 VDC

Peak Output Current (1 second) (3) 10 A 20 A 30 A

Continuous Output Current (3) 5 A 10 A 10 A

Power Amplifier Bandwidth 2500 Hz maximum (software selectable)

Power Amplifier Efficiency 85% - 95% (2)

PWM Switching Frequency 20 kHz

Minimum Load Inductance 0.1 mH @160 VDC (1 mH @ 320 VDC)

User Power Supply Output 5 VDC (@ 500 mA)

Modes of Operation Brushless; Brush; Stepper

Protective Features

Output short circuit; Peak over current; DC bus over voltage;

RMS over current; Over temperature; Control power supply

under voltage; Power stage bias supply under voltage

Isolation Optical and transformer isolation between control and

power stages.

(1) AC input voltage and load dependent.

(2) Dependent on total output power: efficiency increases with increasing output power.

(3) Current is measured as the peak amplitude in any motor phase

1.1. Electrical Specifications XC4 Hardware Manual

20 www.aerotech.com

Table of contents

Other Advantech DC Drive manuals

Popular DC Drive manuals by other brands

Festo

Festo DRRD-12 operating instructions

Dorner

Dorner eDrive 3200 Series Installation, maintenance & parts manual

Parker

Parker Compumotor ZETA6 Series installation guide

Emerson

Emerson E Series installation manual

ABB

ABB ACS280 Hardware manual

Rockwell Automation

Rockwell Automation Allen-Bradley DRIVES HEADQUARTERS Flying Start PowerFlex... manual