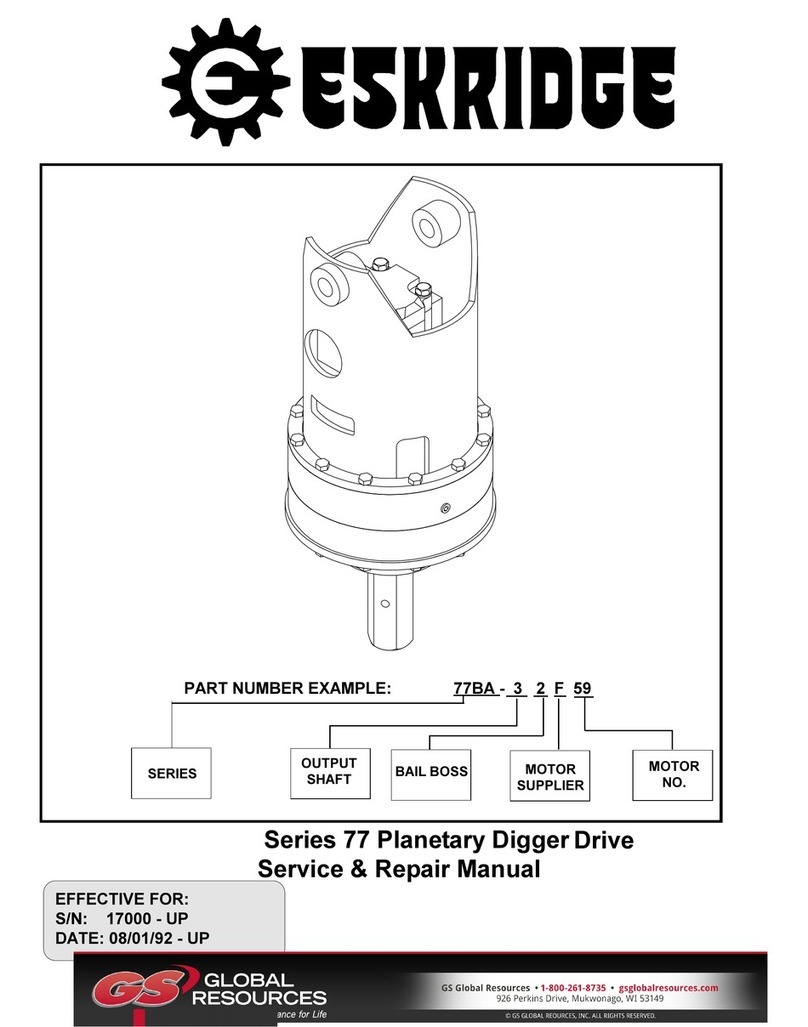

Eskridge 1400 User manual

M

O

D

E

L

1400

TR

IP

L

E P

LAN

E

TAR

Y

S

HAFT

DR

IVE SE

R

VI

C

E

MANUAL

TH

I

S SE

R

VI

C

E

MANUAL

IS E

FF

E

CT

IVE

:

S/

N:

74362

T

O

CURR

E

NT

DAT

E

:

10/01/2007

T

O

CURR

E

NT

VE

R

SIO

N:

S

M

1400

KD

3

-AA

!

WARN

I

N

G

:

Wh

ile w

o

rki

ng

on

th

is e

qu

i

p

me

nt

,

u

se sa

f

e li

ft

i

ng

p

r

o

ce

du

res,

wear a

d

e

qu

a

t

e cl

oth

i

ng

a

nd

wear

h

eari

ng

, eye a

nd

res

p

ira

to

ry

p

r

ot

ec

t

i

on

.

N

O

T

E

:

Ind

ivi

dua

l

c

u

s

to

m

e

r

s

pe

ci

f

ic

at

i

on

s

(m

ount

i

ng

c

a

s

e, output

s

haft, b

r

a

k

e a

ss

e

m

b

ly

, et

c

.

)

m

a

y

v

a

ry

f

r

o

m

e

x

p

l

oded d

r

a

wi

ng and

s

tanda

r

d pa

r

t nu

m

be

rs

s

ho

w

n.

If app

lic

ab

l

e,

r

efe

r

to

c

u

s

to

m

e

r

d

r

a

wi

ng fo

r

deta

ils

.

Mod

el 1400

S

h

a

ft

D

rive service

ma

nu

al, S

M

1400

KD

3

-AA

Pa

g

e 1

Eskri

dg

e, I

n

c. Ola

th

e,

K

s. 913

-

782

-

1238 www.eskri

dg

ei

n

c.c

o

m

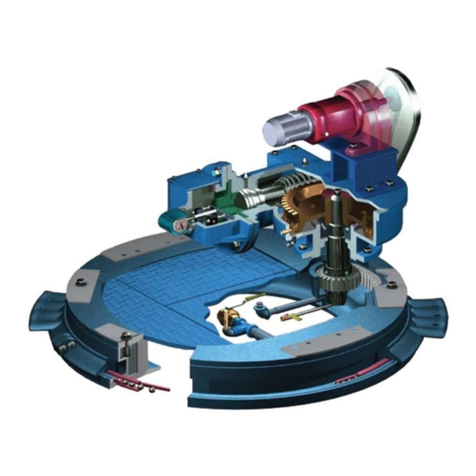

X

1400K

D3-AA

DATE: 04/01/08

12

16

C

6

7F

1

20D

14

B4

12A

5C

25A

35C

35A 35B

20C

2

20A

20B

25B

16A

13

16B

14A

35D

85

14C

52

3

62

66 55E

54

64A

64B

80C

80B 53

80A

75A

75B

25C

25D

55A

55C

55D

55E 55F

55B

55D

66

16C

7C

7D

7E

7F

7E

7H

7E

7B

7E

7D

5L

5A

5D

5E

5

G

5B

5G

5E

5D

5K

5F

16C

30

30

55H

55G

7G

30B

5J 5H

7A

X

1400

KD

3

-AA

,

Pa

g

e 1

of

3

E

ff

ec

t

ive

d

a

t

e 04/01/2008

E

ff

ec

t

ive se

rial # 74362

Mod

el 1400 S

h

a

ft

D

rive service ma

nu

al, S

M

1400

KD

3

-AA

Pa

g

e 2

Eskri

dg

e, I

n

c. Ola

th

e,

K

s. 913

-

782

-

1238 www.eskri

dg

ei

n

c.c

o

m

X1400

LD

3

-AA

Pa

g

e 2

of

3

E

ff

ec

t

ive

d

a

t

e 07/01/2007

E

ff

ec

t

ive serial # 74362

Mod

el 1400

S

h

a

ft

/S

p

i

nd

le

D

rive

R

a

t

i

o

b

reak

do

w

n

Un

i

t

104 155 201 163 243 314

S

tg

I 3.95 5.87 7.59 3.95 5.87 7.59

S

tg

II 4.96 4.96 4.96 7.76 7.76 7.76

S

tg

III 5.33 5.33 5.33 5.33 5.33 5.33

C

O

R

E

UN

I

T:

1400

-

26 1400

-

41

2

-

S

TA

GE

+3r

d-

S

TA

GE

C

O

R

E

M

O

D

E

L

1400 S

HAFT

DR

IVE

26.48

:

1

4.96

:

1

5.33

:

1

41.41

:

1

7.76

:

1

5.33

:

1

EI

TH

E

R

RAT

IO

+ 3

RD

S

TA

GE

I

t

e

m # Q

T

Y.

D

escri

pt

i

on

Par

t

Nu

m

b

er Par

t

Nu

m

b

er Par

t

Nu

m

b

er

11

BASE

C

O

D

E A

-

F

LA

N

GE

D

60

-

004

-

3024

C

O

D

E A

-

F

LA

N

GE

D

W

/ B

R

G G

R

EASE

Z

E

R

K60

-

004

-

3024

Z

C

O

D

E

F

-

F

LA

N

GELESS 60

-

004

-

3137

C

O

D

E

F

-

F

LA

N

GELESS

W

/ B

R

G G

R

EASE

Z

E

R

K60

-

004

-

3137

Z

C

O

D

E

C

A o

r

CF

-

CU

S

T

O

M(CU

S

T

O

M

P/

N)

21

O

UT

P

UT

S

H

A

FT

C

O

D

E

D

1

-

4

”

LO

N

G, 40

T

8/16 SPLI

N

E60

-

004

-

4012

C

O

D

E

D

3

-

5

”

LO

N

G, 40

T

8/16 SPLI

N

E60

-

004

-

4082

C

O

D

E

C

1

-

CU

S

T

O

M(CU

S

T

O

M

P/

N)

31

C

OVE

R

#1

C

O

D

E

D

-

SAE

‘D’

(

4 BOL

T)

60

-

004

-

1074

60

-

004

-

1934

C

O

D

E E

-

SAE

‘

E

’

(

4 BOL

T)

60

-

004

-

1564

41

I

N

P

UT

GEA

R

#1

C

O

D

E 9

(

13

T

, 8/16 SPLI

N

E

)

60

-

004

-

1122 60

-

004

-

1142

---

C

O

D

E 5

(

15

T

, 8/16 SPLI

N

E

)

P

NN

YA 60

-

004

-

1552

---

C

O

D

E 8

(

16

T

, 8/16 SPLI

N

E

)

R

EQ

’D

f/

R

A

T

IOS

≥

50:1 60

-

004

-

1402 60

-

004

-

1492

SEE

2

-

S

T

A

GE

51SE

C

CARR

A

SSY

-

5.33

:

1

(

1400

)

60

-

005

-

2133

5A 1

C

A

RR

IE

R

SE

C

; 4

-

PLA

N

E

T

60

-

004

-

1774

5B 4 PLA

N

E

T

GEA

R

; SE

C

60

-

004

-

1232

5

C

4PLA

N

E

T

S

H

A

FT

; SE

C

60

-

004

-

1262

5

D

8

C

O

N

E; SE

C

. PL

NT

5E 8

CU

P; SE

C

.PL

NT

5

F

4

R

E

T

AI

N

I

N

G

R

I

N

G; PLA

N

E

T

S

H

A

FT

01

-

160

-

0490

5G 8

R

E

T

AI

N

I

N

G

R

I

N

G; PLA

N

E

T

BO

R

E01

-

160

-

0500

5

H

8

W

AS

H

E

R

; SE

C

60

-

004

-

1291

5

J

8S

H

I

M

; SE

C

. PL

NT

60

-

004

-

1321

5K 4

R

OLL PI

N

; 1/4

x

1 3/8 01

-

153

-

0150

5L 1 PLA

T

E; SE

C

C

A

RR

IE

R

R

E

T

AI

N

E

R

60

-

004

-

1352

61S

UN

GEA

R

-

SE

C

O

ND

A

R

Y60

-

004

-

1792

71P

R

I

MAR

Y

CARR

IE

R

A

SSY

-

1400 60

-

005

-

2113 60

-

005

-

2123

SEE 2

-

S

T

AGE

7A 1

C

A

RR

IE

R

; P

R

I

M

A

R

Y60

-

004

-

1372 60

-

004

-

1722

SEE 2

-

S

T

AGE

7B 3 PLA

N

E

T

GEA

R

; P

R

I

M

A

R

Y60

-

004

-

1862 60

-

004

-

1872

SEE 2

-

S

T

AGE

7

C

3PLA

N

E

T

S

H

A

FT

; P

R

I

M

A

R

Y60

-

004

-

1272

7

D

6

THRU

S

T

W

AS

H

E

R

; P

R

I

M

A

R

Y PLA

N

E

T

60

-

004

-

1881

7E 12 SPA

C

E

R

W

AS

H

E

R

; P

R

I

R

OLLE

R

; 4 PE

R

S

H

A

FT

60

-

004

-

1891

7

F

168 LOOSE

R

OLLE

R

; 2 X 28 PE

R

S

H

A

FT

3/16 X 1.12 01

-

106

-

0050

7G 3

R

OLL PI

N

; 1/4

x

1 3/8 01

-

153

-

0150

7

H

3

R

E

T

AI

N

I

N

G

R

I

N

G; PLA

N

E

T

BO

R

E01

-

160

-

0750

12A 1

R

I

N

G GEA

R

; SE

C

.60

-

004

-

1243

12B 1

R

I

N

G GEA

R

; SI

M

PLE P

R

I60

-

004

-

1193

13 1 SEAL

C

A

RR

IE

R

60

-

004

-

1333

14A 2

THRU

S

T

R

A

C

E; P

R

I

C

A

RR

01

-

112

-

0350

14B 1

THRU

S

T

B

R

G; P

R

I

C

A

RR

01

-

112

-

0340

14

C

1

THRU

S

T

R

A

C

E; I

N

P

UT

GEA

R

01

-

112

-

0060

16A 1 SEAL; O

UT

P

UT

S

H

A

FT

01

-

405

-

0630

16B 1 O

-R

I

N

G; SEAL

C

A

RR

IE

R

01

-

402

-

0670

16

C

3O

-R

I

N

G;

R

I

N

G GEA

R

01

-

402

-

0660

20A 1 B

R

G

C

O

N

E; O

UT

E

R

01

-

102

-

0190

20B 1 B

R

G

CU

P; O

UT

E

R

01

-

103

-

0190

20

C

1B

R

G

C

O

N

E; I

NN

E

R

01

-

102

-

0220

20

D

1B

R

G

CU

P; I

NN

E

R

01

-

103

-

0220

25A 3

F

LA

T

HD

SO

C

C

.S.; SE

C

C

A

RR

R

E

T

.

(

3/8

-

24X1 G

R-

8

)

01

-

150

-

1590

Mod

el 1400 S

h

a

ft

D

rive service ma

nu

al, S

M

1400

KD

3

-AA

Pa

g

e 3

Eskri

dg

e, I

n

c. Ola

th

e,

K

s. 913

-

782

-

1238 www.eskri

dg

ei

n

c.c

o

m

X1400

LD

3

-AA

Pa

g

e 3

of

3

E

ff

ec

t

ive

d

a

t

e 07/01/2007

E

ff

ec

t

ive serial # 74362

Mod

el 1400 S

h

a

ft

/S

p

i

nd

le

D

rive

R

a

t

i

o

b

reak

do

w

n

Un

i

t

104 155 201 163 243 314

S

tg

I 3.95 5.87 7.59 3.95 5.87 7.59

S

tg

II 4.96 4.96 4.96 7.76 7.76 7.76

S

tg

III 5.33 5.33 5.33 5.33 5.33 5.33

25B 6 S

HC

S; 3/8

-

16 X 1 G

R

8; SEAL

C

A

RR

IE

R

01

-

150

-

1110

25

C

20

HHC

S

(

3/4

-

10

x

10.5 G

RD

8

)

01

-

150

-

1580

25

D

20

H

A

RDW

AS

H

E

R

; 3/4; 1.25 O.

D

.01

-

166

-

0350

30A 4 PIPE PL

U

G

(

3/4

N

P

T

M

AG

N

E

T

I

C)

01

-

207

-

0100

30B

(

2

)

PIPE PL

U

G; 1/8

N

P

T

(

Q

T

Y O

F

1

W

I

TH

‘Z’

OP

T

IO

N)

01

-

207

-

0030

30

C(

1

)

G

R

.

F

I

T

; S

TR

.1/8

N

P

T

(‘Z’

OP

T

IO

N)

SEAL

C

A

RR

IE

R

O.

D

.01

-

215

-

0010

35A 2 S

H

I

M

; O

UT

P

UT

S

H

A

FT

60

-

004

-

1311

35B 1 S

U

PPO

RT

R

I

N

G; S

H

A

FT

B

R

G60

-

004

-

1281

35

C

1

R

E

T

AI

N

I

N

G

R

I

N

G; O

UT

P

UT

S

H

A

FT

01

-

160

-

0480

35

D

1

R

E

T

AI

N

I

N

G

R

I

N

G; I

N

P

UT

01

-

160

-

0510

M

O

D

E

L

440

TH

I

RD

S

TA

GE

(RAT

IOS > 50

:

1

)C

O

R

E

UN

I

T:

1400

-

440

-

41400

-

440

-

51400

-

440

-

7

3

RD-

S

TA

GE

RAT

IO

:

3.95 5.87 7.59

52 1 SPLI

N

E

D

A

D

AP

T

E

R

S

H

A

FT

60

-

004

-

1902

53 1

C

OVE

R

#2

SAE

‘C’

2 BOL

T

A

ND

4 BOL

T

42

-

004

-

2012

SAE

‘D’

4 BOL

T

42

-

004

-

2022

SAE

‘

E

’

4 BOL

T

42

-

004

-

2032

54A 1

I

N

P

UT

GEA

R

I

N

P

UT

GEA

R

13

T

OO

TH

, 8/16 42

-

004

-

1152 42

-

004

-

1162 42

-

004

-

1172

54B

(

1

)F

O

R

14

T

OO

TH

, 12/24,

U

SE A

D

AP

T

E

R

98

-

005

-

1141

55 1

CARR

IE

R

A

SSY

-

TH

I

RD

S

TA

GE 42

-

005

-

0101 42

-

005

-

0111 42

-

005

-

0121

55A 1

C

A

RR

IE

R

-

3

RD

S

T

AGE 42

-

004

-

1062 42

-

004

-

1072 42

-

004

-

12102

55B 3 PLA

N

E

T

GEA

R

-

3

RD

S

T

AGE 42

-

004

-

1102 42

-

004

-

1112 42

-

004

-

1272

55

C

3PLA

N

E

T

S

H

A

FT

-

3

RD

S

T

AGE 42

-

004

-

1342

55

D

6

THRU

S

T

W

AS

H

E

R

-

3

RD

S

T

AGE PLA

N

E

T

42

-

004

-

1362

55E 6 SPA

C

E

R

W

AS

H

E

R

-

3

RD

S

T

AGE

R

OLLE

R

42

-

004

-

1352

55

F

60 LOOSE

R

OLLE

R

; 20 PE

R

S

H

A

FT

01

-

106

-

0040

55G 3

R

OLL PI

N

; 3/16 X 1

-

3/4 01

-

153

-

0220

55

H

1

R

E

T

AI

N

I

N

G

R

I

N

G

-

A

D

AP

T

E

R

S

H

A

FT

01

-

160

-

0690

62 1

R

I

N

G GEA

R

-

P

R

I

M

A

R

Y42

-

004

-

1042

64A 2

THRU

S

T

W

AS

H

E

R

01

-

112

-

0400

64B 1

THRU

S

T

BEA

R

I

N

G01

-

112

-

0410

66 2 O

-R

I

N

G

-

R

I

N

G GEA

R

01

-

402

-

0840

75A 20

H

EX

H

EA

D

C

APS

CR

E

W

5/8

-

11 X 4.5 G

R

8 01

-

150

-

0870

75B 20 LO

C

K

W

AS

H

E

R

5/8 01

-

166

-

0040

80 2 PL

U

G

-

C

OVE

R

#2 01

-

208

-

0030

85 1

R

E

T

AI

N

I

N

G

R

I

N

G

-

A

D

AP

T

E

R

S

H

A

FT

01

-

160

-

0690

Mod

el 1400 S

h

a

ft

D

rive service ma

nu

al, S

M

1400

KD

3

-AA

Pa

g

e 4

Eskri

dg

e, I

n

c. Ola

th

e,

K

s. 913

-

782

-

1238 www.eskri

dg

ei

n

c.c

o

m

LUBR

I

CAT

I

O

N

&

MA

I

NT

E

NANC

E

O

p

era

t

i

ng

P

o

si

t

i

on

Si

ng

le s

t

a

g

e

Oil

C

a

p

aci

t

y

Doub

le s

t

a

g

e

T

ri

p

le s

t

a

g

e

Oil

L

evel

H

o

riz

onta

l

Shaft

--

18 qt

s

/ 17 L

i

te

rs T

o ho

riz

onta

l

c

ente

rli

ne of

gea

r

d

riv

e

Ve

r

t

ic

a

l

Shaft

(

P

i

n

i

on

U

p

)- -

27 qt

s

/ 25 L

i

te

rs T

o

si

de po

r

t on gea

r

d

riv

e

ba

s

e

Ve

r

t

ic

a

l

Shaft

(

P

i

n

i

on

D

o

w

n

)-

31 qt

s

/ 29 L

i

te

rs T

o

mi

d

w

a

y

on uppe

r

/

p

rim

a

ry

gea

r

s

et

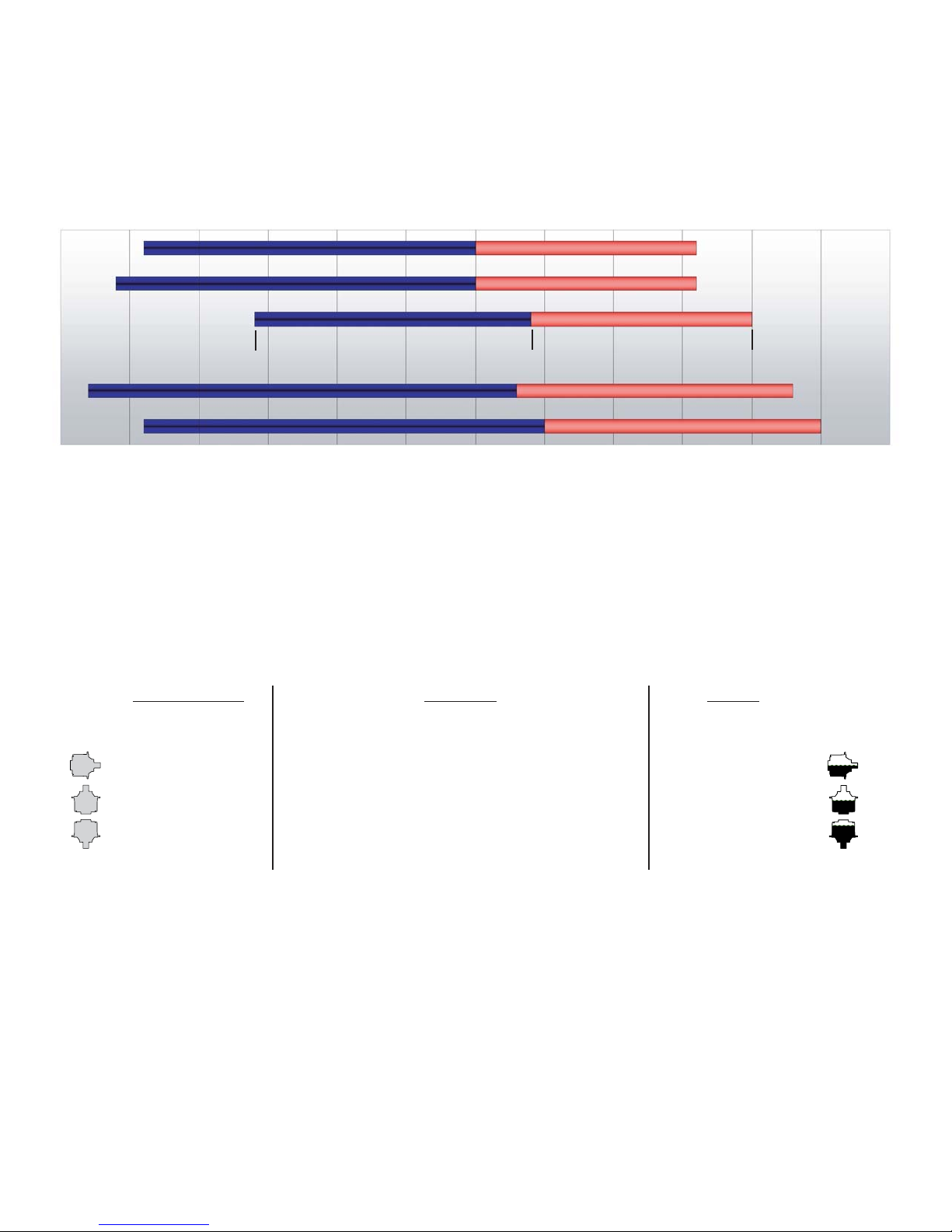

Usi

ng the

c

ha

r

t be

l

o

w

, dete

rmi

ne an app

r

op

ri

ate

l

ub

ric

ant

visc

o

si

t

y

.

Us

e on

ly

EP

(

e

x

t

r

e

m

e p

r

e

ss

u

r

e

)

o

r

API

GL

-

5 de

si

gnated

l

ub

ric

ant

s

.

C

hange the

l

ub

ric

ant afte

r

the f

irs

t 50 hou

rs

of ope

r

at

i

on and at 500 hou

r

i

nte

rv

a

ls

the

r

eafte

r

.

T

he gea

r

d

riv

e

s

hou

l

d be pa

r

t

i

a

lly

d

is

a

s-

s

e

m

b

l

ed to

i

n

s

pe

c

t gea

rs

and bea

ri

ng

s

at 1000 hou

r

i

nte

rv

a

ls

.

80

W

90

con

v

en

ti

ona

l

75

W

90

con

v

en

ti

ona

l

85

W

140

con

v

en

ti

ona

l

75

W

90

sy

n

t

he

ti

c

80

W

140

sy

n

t

he

ti

c

Not

e

:

A

m

b

ie

nt

t

em

p

era

tu

re is

th

e air

t

em

p

era

tu

re meas

u

re

d

i

n

th

e imme

d

ia

t

e vici

n

i

t

y

of

th

e

g

ear

bo

x.

A

Gear

bo

x ex

po

se

d

to

th

e

d

irec

t

rays

of

th

e s

un

o

r

oth

er ra

d

ia

nt

h

ea

t

s

ou

rces will

op

era

t

e a

t

h

i

gh

er

t

em

p

era

tu

res a

nd

th

ere

fo

re m

u

s

t

b

e

g

ive

n

s

p

ecial c

on

si

d

era

t

i

on

.

Th

e max

op

era

t

i

ng

t

em

p

m

u

s

t

not

b

e excee

d

e

d

und

er a

n

y circ

u

ms

t

a

n

ces, re

g

ar

d

less

of

am

b

ie

nt

t

em

p

era

tu

re.

R

ec

o

mme

nd

e

d

am

b

ie

nt

a

nd

op

e

ra

t

i

ng

t

em

p

era

tu

res

fo

r c

on

ve

nt

i

on

al a

nd

sy

nth

e

t

ic

g

ear l

ub

rica

nt

s

-

50

-

25 0 25 50 75 100 125 150 175 200 225 250

F

-

45

-

32

-

18

-

4 10 24 38 52 66 79 93 107 121

C

M

i

n

A

m

b

ie

nt

/

op

e

ra

t

i

ng

t

em

pM

ax O

p

era

t

i

ng

t

em

p

M

ax

A

m

b

ie

nt

t

em

p

ES

KR

I

D

GE

M

O

D

E

L

1400 OI

L

CA

P

AC

I

T

IES

ES

KR

I

D

GE P

ART

NUMB

E

R

I

NT

E

R

P

R

E

TAT

IO

N

Not

e

:

A

ll s

t

a

nd

ar

d

Eskri

dg

e Gear

d

rives are iss

u

e

d

a

d

escri

pt

ive

p

ar

t

nu

m

b

er w

h

ic

h

i

n

cl

ud

es i

nfo

rma

t

i

on

re

g

ar

d

i

ng

th

e

Mod

el, mea

n

s

of

s

h

a

ft

re

t

e

nt

i

on

,

b

ase s

t

yle, s

h

a

ft

s

t

yle, i

nput

m

ount

i

ng

, i

nput

s

h

a

ft

si

z

e,

o

verall ra

t

i

o

a

nd

vari

-

ou

s availa

b

le

opt

i

on

s.

Fo

r a

d

e

t

aile

d

b

reak

do

w

n

of

th

is i

nfo

rma

t

i

on

,

p

lease re

f

er

to

Eskri

dg

e

p

r

odu

c

t

s

p

eci

f

ica

t

i

on

s

h

ee

t

s

found

a

t:

http:

//www.eskri

dg

ei

n

c.c

o

m/

g

ear

d

rives/

g

ear

p

r

od

s

p

ecs.

ht

ml

Mod

el 1400 S

h

a

ft

D

rive service ma

nu

al, S

M

1400

KD

3

-AA

Pa

g

e 5

Eskri

dg

e, I

n

c. Ola

th

e,

K

s. 913

-

782

-

1238 www.eskri

dg

ei

n

c.c

o

m

Un

i

t

T

ear

do

w

n

1

)

S

cri

be a d

i

agona

l

li

ne a

cr

o

ss

the out

si

de of the un

i

t f

r

o

m

the top

c

o

v

e

r

(

53

)

to the adapte

r

c

o

v

e

r

(

3

)

, and to the ba

s

e

(

1

)

befo

r

e

d

is

a

ss

e

m

b

ly

to a

i

d

i

n the p

r

ope

r

po

si

t

i

on

i

ng of p

i

e

c

e

s

du

ri

ng

r

ea

ss

e

m

b

ly

.

2

)

R

e

m

o

v

e d

r

a

i

n p

l

ug

s

(

30

A)

and d

r

a

i

n o

il

f

r

o

m

un

i

t.

T

he o

il

will

d

r

a

i

n out

m

o

r

e qu

ickly

and

c

o

m

p

l

ete

ly

i

f

w

a

rm

.

3

)

R

e

m

o

v

e the t

w

ent

y

5/8

-

11

c

ap

scr

e

ws

(

75

B)

s

e

c

u

ri

ng the top

c

o

v

e

r

(

53

)

to the un

i

t.

4

)

R

e

m

o

v

e the top

c

o

v

e

r

(

53

)

,

i

nput th

r

u

s

t

w

a

s

he

r(s)

,

bea

ri

ng

(s)

(

64

A

, 64

B)

, and Stage I

i

nput gea

r

(

54

)

.

In

s

pe

c

t

c

o

v

e

r

o

-ri

ng

(

66

)

; d

isc

a

r

d

i

f da

m

aged o

r

defo

rm

ed.

5

)

L

i

ft the

s

tage I p

l

anet

c

a

rri

e

r

a

ss

e

m

b

ly

(

55

)

i

n

cl

ud

i

ng

s

haft

adapte

r

(

52

)

f

r

o

m

the un

i

t .

6

)

R

e

m

o

v

e Stage I

ri

ng gea

r

(

62

)

,

i

n

s

pe

c

t o

-ri

ng

(

66

)

and

r

ep

l

a

c

e

i

f da

m

aged o

r

defo

rm

ed.

7

)

R

e

m

o

v

e the t

w

ent

y

3/4

-

10

c

ap

scr

e

ws

(

25

C)

and

l

o

ckw

a

s

he

rs

(

25

D)

s

e

c

u

ri

ng the

ri

ng adapte

r

c

o

v

e

r

(

3

)

.

8

)

R

e

m

o

v

e the

ri

ng adapte

r

c

o

v

e

r

(

3

)

, th

r

u

s

t

r

a

c

e

(

14

C)

,

Stage II

s

un gea

r

(

54

)

and th

r

u

s

t

w

a

s

he

rs

(

14

A

, 14

B)

f

r

o

m

un

i

t. In

s

pe

c

t

c

o

v

e

r

o

-ri

ng

(

16

C)

; d

isc

a

r

d

i

f da

m

aged o

r

defo

rm

ed

9

)

L

i

ft the

s

tage II p

l

anet

c

a

rri

e

r

a

ss

e

m

b

ly

(

7

)

f

r

o

m

the un

i

t .

10

)

R

e

m

o

v

e the Stage III

s

un gea

r

(

6

)

.

11

)

R

e

m

o

v

e the th

r

ee 3/8

-

24 f

l

at head

c

ap

scr

e

ws

(

25

A)

s

e

c

u

ri

ng

the

c

a

rri

e

r

r

eta

i

n

i

ng p

l

ate

(

5

L)

to the output

s

haft

(

2

)

.

12

)

R

e

m

o

v

e

r

e

m

a

i

n

i

ng

ri

ng gea

rs

(

12

B

, 12

A)

and Stage III

c

a

r-

ri

e

r

a

ss

e

m

b

ly

(

5

)

. In

s

pe

c

t gea

r

to gea

r

and gea

r

to ba

s

e O

-

ri

ng

(s)

(

16

C)

, d

isc

a

r

d and

r

ep

l

a

c

e an

y

da

m

aged o

r

defo

rm

ed

O

-ri

ng

s

.

13

)

T

he un

i

t

is

no

w

d

is

a

ss

e

m

b

l

ed

i

nto g

r

oup

s

of pa

r

t

s

.

T

he a

r

ea

(s)

r

equ

iri

ng

r

epa

ir

s

hou

l

d be

i

dent

i

f

i

ed b

y

tho

r

ough

i

n

s

pe

c

t

i

on of the

i

nd

ivi

dua

l

c

o

m

ponent

s

afte

r

the

y

ha

v

e been

cl

eaned and d

ri

ed.

C

arrier

A

ssem

b

ly

T

ear

do

w

n

Rot

a

t

e

p

la

n

e

t

g

ears

(

55

B

S

tg

I,7

B

S

tg

II, 5

B

, S

tg

III

)

to

c

h

eck

fo

r

a

bno

r

mal

no

ise

o

r r

oughn

ess i

n

b

eari

ng

s. I

f

fu

r

th

er i

n

s

p

ec

t

i

on

o

r re

p

laceme

nt

is re

qu

ire

d

,

p

r

o

cee

d

as

fo

ll

o

ws.

1

)

Driv

e

r

o

ll

p

i

n

s

(

55G S

tg

I, 7

C

S

tg

II

)

c

o

m

p

l

ete

ly

i

nto the p

l

anet

s

haft

s

o

r

r

e

m

o

v

e p

l

anet

s

haft

r

eta

i

n

i

ng

ri

ng

s

(

5

F

S

tg

III

)

2

)

S

li

de p

l

anet

s

haft

s

(

55

C

S

tg

I, 7

C

S

tg

II, 5

C

S

tg

III

)

out of

c

a

r-

ri

e

r

(

55

A

S

tg

I, 7

A

S

tg

II, 5

A

S

tg

III

)

.

3

)

R

e

m

o

v

e p

l

anet gea

rs

,

w

a

s

he

rs

(

55

D

S

tg

I, 7

D

S

tg

II

)

and bea

r-

i

ng

s

(

55E S

tg

I, 7

F

S

tg

II, 5

D

&

5E S

tg

III

)

f

r

o

m

c

a

rri

e

r

.

4

)

In

s

pe

c

t the p

l

anet gea

r

,

bea

ri

ng bo

r

e and p

l

anet

s

haft

(

55

C

S

tg

I, 7

C

S

tg

II, 5

C

S

tg

III

)

and bea

ri

ng

s

.

C

he

ck

fo

r

s

pa

lli

ng, b

r

u

is-

i

ng o

r

othe

r

da

m

age and

r

ep

l

a

c

e

c

o

m

ponent

s

a

s

ne

c

e

ss

a

ry

.

N

ote:

W

hen u

si

ng

l

oo

s

e

(

un

c

aged

)

r

o

ll

e

r

bea

ri

ng

s

, a

ll

r

o

ll

e

rs

i

n

the

c

o

rr

e

s

pond

i

ng p

l

anet gea

r

s

hou

l

d be

r

ep

l

a

c

ed

i

f an

y

i

n the

s

et a

r

e found to be defe

c

t

iv

e

5

)

R

e

m

o

v

e

r

o

ll

p

i

n

s

(

55

C

S

tg

I, 7

C

S

tg

II

)

f

r

o

m

p

l

anet

s

haft

s

(

55

C

S

tg

I, 7

C

S

tg

II

)

u

si

ng a 3/16

”

(

Stg I

)

o

r

1/4

”

(

Stg II, Stg III

)

p

i

n pun

c

h.

C

arrier

R

eassem

b

ly

1

)

Loo

s

e

r

o

ll

e

r

i

n

s

ta

ll

at

i

on;

i

f u

si

ng bea

ri

ng a

ss

e

m

b

li

e

s

,

r

e

-

p

l

a

c

e bea

ri

ng

s

a

s

needed and p

r

o

c

eed to

s

tep 2:

a

)

Set p

l

anet

w

a

s

he

r

(

55

D

S

tg

I, 7

D

S

tg

II

)

on

w

o

rk

tab

l

e

wi

th p

l

anet gea

r

(

55

B

S

tg

I, 7

B

S

tg

II

)

on top of

i

t.

C

ente

r

p

l

anet

w

a

s

he

r

to p

l

anet gea

r

a

s

cl

o

s

e

ly

a

s

po

ssi

b

l

e.

b

)

C

ente

r

p

l

anet

s

haft

(

55

C

S

tg

I, 7

C

S

tg

II

)

i

n p

l

anet

gea

r

bea

ri

ng bo

r

e.

c)

If u

s

ed, p

l

a

c

e

s

pa

c

e

r

w

a

s

he

r

(

55E S

tg

I, 7E S

tg

II

)

onto p

l

anet

s

haft

(r

efe

r

to e

x

p

l

oded

vi

e

w

to

c

onf

irm

s

pa

c

e

r

po

si

t

i

on

s)

.

d

)

Beg

i

n p

l

a

ci

ng

r

o

ll

e

rs

(

55

F

S

tg

I, 7

F

S

tg

II

)

a

r

ound

s

haft

(

5

C

S

tg

I, 7

C

S

tg

II

)

.

T

he

r

e

s

hou

l

d be

cl

ea

r

an

c

e

fo

r

l

a

s

t

r

o

ll

e

r

to

sli

de

i

n. Be

s

u

r

e to

i

n

s

ta

ll

six

teen

(

Stg

I

)

o

r

t

w

ent

y

(

Stg II

)

r

o

ll

e

rs

i

n ea

c

h bea

ri

ng

r

o

w

.

(

If u

si

ng

m

u

l

t

i

p

l

e

r

o

ws

of

r

o

ll

e

rs

,

r

epeat

s

tep

s

C

and

D

a

s

ne

c

e

ss

a

ry

. On

c

e

c

o

m

p

l

ete,

r

efe

r

to e

x

p

l

oded

vi

e

w

to

c

onf

irm

that an

y

s

pa

c

e

r

w

a

s

he

rs

(

55E S

tg

I,

7E S

tg

II

)

a

r

e app

r

op

ri

ate

ly

po

si

t

i

oned.

)

e

)

P

l

a

c

e a

w

a

s

he

r

(

55

D

S

tg

I, 7

D

S

tg

II

)

o

v

e

r

gea

r

and

onto

s

haft.

f

)

C

a

r

efu

lly

sli

de a

ss

e

m

b

ly

off of tab

l

e, ho

l

d

i

ng p

l

anet

w

a

s

he

rs

aga

i

n

s

t p

l

anet gea

r

.

g

)

S

li

de p

l

anet

s

haft out of the a

ss

e

m

b

ly

and

sli

p a

s-

s

e

m

b

ly

i

nto

c

a

rri

e

r

.

h

)

A

li

gn p

l

anet gea

r

& bea

ri

ng a

ss

e

m

b

ly

i

n

si

de

c

a

rri

e

r

and

i

n

s

ta

ll

p

l

anet

s

haft th

r

ough ent

ir

e

a

ss

e

m

b

ly

.

2

)

P

l

anet

s

haft

s

(

55

C

S

tg

I, 7

C

S

tg

II, 5

C

S

tg

III

)

s

hou

l

d

be

i

n

s

ta

ll

ed

wi

th

c

ha

m

fe

r

ed end of

r

o

ll

p

i

n ho

l

e

(

Stg

I, II

)

o

r

sl

ot

(

Stg III

)

to

w

a

r

d

s

out

si

de d

i

a

m

ete

r

of

c

a

rri

e

r

.

3

)

Driv

e

r

o

ll

p

i

n

i

nto the

c

a

rri

e

r

ho

l

e

(

Stg I & II

)

and

i

nto p

l

anet

s

haft o

r

r

ep

l

a

c

e p

l

anet

s

haft

r

eta

i

n

i

ng

ri

ng

s

(

Stg III

)

to

r

e

-

ta

i

n pa

r

t

s

.

R

epeat fo

r

r

e

m

a

i

n

i

ng p

l

anet gea

rs

.

B

ase

S

ub

assem

b

ly

T

ear

do

w

n

1

)

R

e

m

o

v

e the

s

ea

l

c

a

rri

e

r

r

eta

i

n

i

ng

scr

e

ws

(

25

B)

and

s

ea

l

c

a

rri

e

r

(

13

)

f

r

o

m

un

i

t. In

s

pe

c

t

s

ea

l

(

16

A)

fo

r

si

gn

s

of

w

ea

r

o

r

da

m

age and

r

ep

l

a

c

e a

s

ne

c

e

ss

a

ry

.

2

)

R

e

m

o

v

e the output

s

haft

l

o

ck

ri

ng

(

35

C)

u

si

ng a hee

l

ba

r

o

r

pu

ll

e

r

;

i

f u

si

ng a hee

l

ba

r

, be

s

u

r

e not to p

ry

aga

i

n

s

t the

c

age of the

i

nne

r

output

s

haft bea

ri

ng

(

20

C)

.

R

e

m

o

v

e the

s

p

li

t

ri

ng

s

eg

m

ent

s

(

35

B)

and

s

h

ims

(

35

A)

.

C

a

ut

i

on:

Si

n

ce

th

e s

h

a

ft

is

no

l

ong

er

po

si

t

ively re

t

ai

n

e

d

,

care s

hou

l

d

b

e

t

ake

n

to

av

o

i

d

i

n

j

u

ry.

C

are s

hou

l

d

als

o

b

e

t

ake

n

not

to

d

ama

g

e i

t

w

h

ile

p

ressi

ng

th

r

ough

b

ase.

3

)

P

l

a

c

e ba

s

e

(

1

)

e

x

te

ri

o

r

si

de do

w

n, on a p

l

ate o

r

tab

l

e.

P

r

e

ss

output

s

haft out botto

m

of ba

s

e b

y

app

lyi

ng a

l

oad

to

i

nte

r

na

l

end of

s

haft unt

il

i

t pa

ss

e

s

th

r

ough

i

nne

r

s

haft

bea

ri

ng

c

one

(

20

C)

.

Mod

el 1400 S

h

a

ft

D

rive service ma

nu

al, S

M

1400

KD

3

-AA

Pa

g

e 6

Eskri

dg

e, I

n

c. Ola

th

e,

K

s. 913

-

782

-

1238 www.eskri

dg

ei

n

c.c

o

m

4

)

A gea

r

pu

ll

e

r

m

a

y

be u

s

ed to

r

e

m

o

v

e the oute

r

bea

ri

ng

c

one

(

20

A)

f

r

o

m

the

s

haft

(

2

)

. If

r

eu

si

ng o

l

d bea

ri

ng

c

one, do not pu

ll

on o

r

da

m

age

r

o

ll

e

r

c

age.

Not

e

:

Press

b

eari

ng

c

on

e

onto

output

s

h

a

ft

b

y

p

ressi

ng

on

i

n-

n

er race

on

ly.

D

O

N

O

T

p

ress

on

r

o

ller ca

g

e, as i

t

may

d

ama

g

e

th

e

b

eari

ng

assem

b

ly.

5

)

In

s

pe

c

t

i

nne

r

and oute

r

bea

ri

ng

c

up

s

(

20

D

&

20

B)

. If

c

up

s

a

r

e

da

m

aged the

y

m

u

s

t be

r

ep

l

a

c

ed, d

riv

e the

m

out u

si

ng a b

r

a

ss

d

ri

ft and ut

ilizi

ng the bea

ri

ng

k

no

ck-

out not

c

he

s

i

n the ba

s

e

(

1

)

B

ase

R

eassem

b

ly

1

)

Cl

ean a

ll

fo

r

e

i

gn

m

ate

ri

a

l

f

r

o

m

m

agnet

ic

o

il

p

l

ug

s

l

o

c

ated In

ba

s

e

(

1

)

.

2

)

P

l

a

c

e ba

s

e e

x

te

ri

o

r

si

de up on

w

o

rk

tab

l

e.

3

)

App

ly

a

l

a

y

e

r

of

li

th

i

u

m

o

r

gene

r

a

l

pu

r

po

s

e bea

ri

ng g

r

ea

s

e to

the

r

o

ll

e

r

c

onta

c

t

s

u

r

fa

c

e of oute

r

bea

ri

ng

c

up

(

20

B)

.

4

)

P

r

e

ss

oute

r

bea

ri

ng

c

one

(

20

A)

onto the

s

haft unt

il

i

t

s

eat

s

aga

i

n

s

t the

s

hou

l

de

r

.

5

)

P

l

a

c

e the

s

haft

(

2

)

wi

th the oute

r

bea

ri

ng

c

one

i

nto the ba

s

e.

6

)

Fli

p

s

haft/ba

s

e a

ss

e

m

b

ly

, and app

ly

li

th

i

u

m

o

r

gene

r

a

l

pu

r

po

s

e bea

ri

ng g

r

ea

s

e to

r

o

ll

e

r

c

on

-

ta

c

t

s

u

r

fa

c

e of the

i

nne

r

c

up

(

20

D)

, then p

r

e

ss

i

nne

r

bea

ri

ng

c

one

(

20

C)

onto

s

haft unt

il

i

t

s

eat

s

aga

i

n

s

t

i

nne

r

bea

ri

ng

c

up.

7

)

P

ri

o

r

to

i

n

s

ta

ll

at

i

on of the

s

haft

s

ea

l

the p

r

e

-

l

oad

m

a

y

r

e

s

u

l

t

i

n a

r

o

lli

ng to

r

que

w

h

ic

h

v

a

ri

e

s

be

-

t

w

een 200 to 300

i

n

-l

b.

T

he bea

ri

ng p

r

e

l

oad

s

hou

l

d be

ta

il

o

r

ed to

y

ou

r

app

lic

at

i

on; a

l

o

w-s

peed app

lic

at

i

on

m

a

y

r

e

-

qu

ir

e a h

i

gh p

r

e

-l

oad,

w

h

il

e h

i

gh

-s

peed app

lic

at

i

on

s

u

s

ua

lly

benef

i

t f

r

o

m

l

o

w

p

r

e

-l

oad. Add

i

ng

s

h

ims

(

35

A)

will

i

n

cr

ea

s

e the

p

r

e

-l

oad on the bea

ri

ng

s

et.

D

ete

rmi

ne

y

ou

r

p

r

e

-l

oad

r

equ

ir

e

-

m

ent and

i

n

s

ta

ll

s

h

ims

to obta

i

n th

is

p

r

e

-l

oad.

In

s

ta

ll

the

s

uppo

r

t

ri

ng

(

35

B)

o

v

e

r

the

s

h

ims

.

N

e

x

t,

i

n

s

ta

ll

the

r

eta

i

n

i

ng

ri

ng

(

35

C)

i

nto the

s

haft g

r

oo

v

e.

8

)

Lub

ric

ate

s

haft

s

ea

l

and

r

e

i

n

s

ta

ll

s

ea

l

c

a

rri

e

r

.

A

ll s

ub

assem

b

ly service

o

r re

p

airs s

hou

l

d

b

e c

o

m

p

le

t

e a

t

th

is

t

ime.

Cont

i

nu

e

to

Un

i

t

A

ssem

b

ly

to

c

o

m

p

le

t

e

bu

il

dup

of

un

i

t

.

Un

i

t

R

easse

m

b

ly

1

)

In

s

ta

ll

the Stage III

c

a

rri

e

r

a

ss

e

m

b

ly

onto the output

s

haft; a

li

gn

the

s

p

li

ne

s

of the

c

a

rri

e

r

(

5

A)

wi

th the output

s

haft

s

p

li

ne

s

and

sli

de the

c

a

rri

e

r

onto the output

s

haft

(

2

)

.

2

)

In

s

ta

ll

c

a

rri

e

r

r

eta

i

n

i

ng p

l

ate

(

5

L)

&

s

e

c

u

r

e u

si

ng p

r

o

vi

ded 3/8

-

24

Fl

athead

c

ap

scr

e

ws

(

25

A)

.

If u

si

ng

r

eta

i

n

i

ng

c

o

m

pound to

a

ssis

t

i

n

scr

e

w

r

etent

i

on, app

ly

on

ly

a

sm

a

ll

a

m

ount to

i

nte

r

na

l

th

r

ead

s

.

Us

e of e

xc

e

ss

th

r

ead

r

eta

i

n

i

ng

c

o

m

pound

m

a

y

c

au

s

e

scr

e

ws

to be

irr

e

m

o

v

ab

l

e on

c

e the

c

o

m

pound ha

s

c

u

r

ed.

3

)

Lub

ric

ate o

-ri

ng

s

(

16

C)

and

i

n

s

ta

ll

on the

ri

ng gea

r

(

12

B

S

tg

II/,

12

A

S

tg

III

)

p

il

ot

s

.

C

a

ut

i

on:

U

se li

ft

i

ng

d

evice

to

p

reve

nt

i

n

j

u

ry w

h

e

n

h

a

nd

li

ng

ri

ng

g

ears a

nd

oth

er

h

eavy c

o

m

pon

e

nt

s.

4

)

A

li

gn gea

r

teeth of Stage III

ri

ng gea

r

(

12

A)

wi

th p

l

anet

gea

rs

(

5

B)

and p

l

a

c

e on ba

s

e, then a

li

gn

m

ount

i

ng ho

l

e

s

of

ri

ng gea

r

wi

th ho

l

e

s

i

n ba

s

e.

Us

e the

scri

bed

li

ne

m

ade

du

ri

ng d

is

a

ss

e

m

b

ly

fo

r

r

efe

r

en

c

e.

5

)

In

s

ta

ll

Stage II

ri

ng gea

r

(

12

B)

wi

th

l

ub

ric

ated o

-

ri

ng

i

n p

l

a

c

e. A

li

gn

m

ount

i

ng ho

l

e

s

of

ri

ng gea

r

wi

th ho

l

e

s

i

n ba

s

e, u

si

ng the

scri

bed

li

ne

m

ade

du

ri

ng d

is

a

ss

e

m

b

ly

fo

r

r

efe

r

en

c

e.

6

)

In

s

ta

ll

Stage III

s

un gea

r

(

6

)

,

then Stage II

c

a

rri

e

r

a

ss

e

m

b

ly

(

7

)

,a

li

gn

i

ng gea

r

teeth of

ri

ng gea

r

wi

th tho

s

e of the p

l

anet

gea

rs

and

c

a

rri

e

r

s

p

li

ne

s

a

li

gned

wi

th tho

s

e on the Stage

III

s

un gea

r

(

6

)

.

7

)

In

s

ta

ll

Stage II

s

un gea

r

(

4

)

, and

s

tage II

c

a

rri

e

r

th

r

u

s

t

-

w

a

s

he

rs

(

14

A

, 14

B)

.

8

)

In

s

ta

ll

o

-ri

ng

(

16

C)

to

ri

ng adapte

r

c

o

v

e

r

(

3

)

and

i

n

s

ta

ll

adapte

r

c

o

v

e

r

to Stage II

ri

ng gea

r

, a

li

gn

i

ng

m

ount

i

ng ho

l

e

s

of

c

o

v

e

r

wi

th tho

s

e

i

n

ri

ng gea

rs

.

Us

e the

scri

bed

li

ne

m

ade

du

ri

ng d

is

a

ss

e

m

b

ly

fo

r

r

efe

r

en

c

e.

9

)

In

s

ta

ll

, and to

r

que the t

w

ent

y

3/4

-

10

c

ap

scr

e

ws

(

25

C)

to

r

eta

i

n adapte

r

c

o

v

e

r

.

10

)

In

s

ta

ll

o

-ri

ng on Stage I

ri

ng gea

r

(

62

)

and

i

n

s

ta

ll

ri

ng gea

r

to adapte

r

c

o

v

e

r

, a

li

gn

i

ng

m

ount

i

ng ho

l

e

s

of

ri

ng

wi

th

tho

s

e

i

n the adapte

r

c

o

v

e

r

.

Us

e the

scri

bed

li

ne

m

ade

du

ri

ng d

is

a

ss

e

m

b

ly

fo

r

r

efe

r

en

c

e.

11

)

In

s

ta

ll

the Stage I

c

a

rri

e

r

a

ss

e

m

b

ly

wi

th adapte

r

s

haft

(

52

)

i

nto the Stage I

ri

ng gea

r

(

62

)

.

12

)

In

s

ta

ll

the

i

nput gea

r

(

54

)

.and th

r

u

s

t bea

ri

ng

s

et

(

64

A

,

64

B)

R

efe

r

to e

x

p

l

oded

vi

e

w

fo

r

deta

ils

..

13

)

N

ot

i

ng the

scri

bed

li

ne

m

ade du

ri

ng d

is

a

ss

e

m

b

ly

,

(wi

th

l

ub

ric

ated o

-ri

ng

i

n p

l

a

c

e

)

a

li

gn and

i

n

s

ta

ll

the top

c

o

v

e

r

(

53

)

.

14

)

In

s

ta

ll

and to

r

que the t

w

ent

y

5/8

-

11 he

x-

head

c

ap

-scr

e

ws

(

75

B)

wi

th

l

o

ckw

a

s

h

-

e

rs

,

r

eta

i

n

i

ng the top

c

o

v

e

r

.

T

he to

r

que fo

r

the

c

ap

-scr

e

ws

: 220 ft

-l

b d

ry

, 170 ft

-l

b

i

f the fa

s

tene

rs

a

r

e

l

u

-

b

ric

ated.

15

)

In

s

ta

ll

and to

r

que the t

w

ent

y

3/4

-

10

c

ap

scr

e

ws

(

25

C)

w

/

l

o

ckw

a

s

he

rs

(

26

D)

.

T

he to

r

que fo

r

the

c

ap

scr

e

ws

is

380

ft.

-l

b

s

. d

ry

o

r

280 ft.

-l

b

s

.

l

ub

ric

ated

16

)

Usi

ng a

s

p

li

ned

s

haft to d

riv

e the

i

nput gea

r

(

54

)

en

s

u

r

e

that the un

i

t

s

p

i

n

s

f

r

ee

ly

.

17

)

Fill

the un

i

t to the p

r

ope

r

l

e

v

e

l

, a

s

s

pe

ci

f

i

ed,

wi

th

r

e

c

o

m-

m

ended gea

r

o

il

(r

efe

r

to

c

ha

r

t, page 3

)

afte

r

un

i

t

is

s

ea

l

ed

wi

th b

r

a

k

e and/o

r

m

oto

r

.

Th

e

g

ear

d

rive is

no

w rea

d

y

to

u

se.

Table of contents

Other Eskridge DC Drive manuals