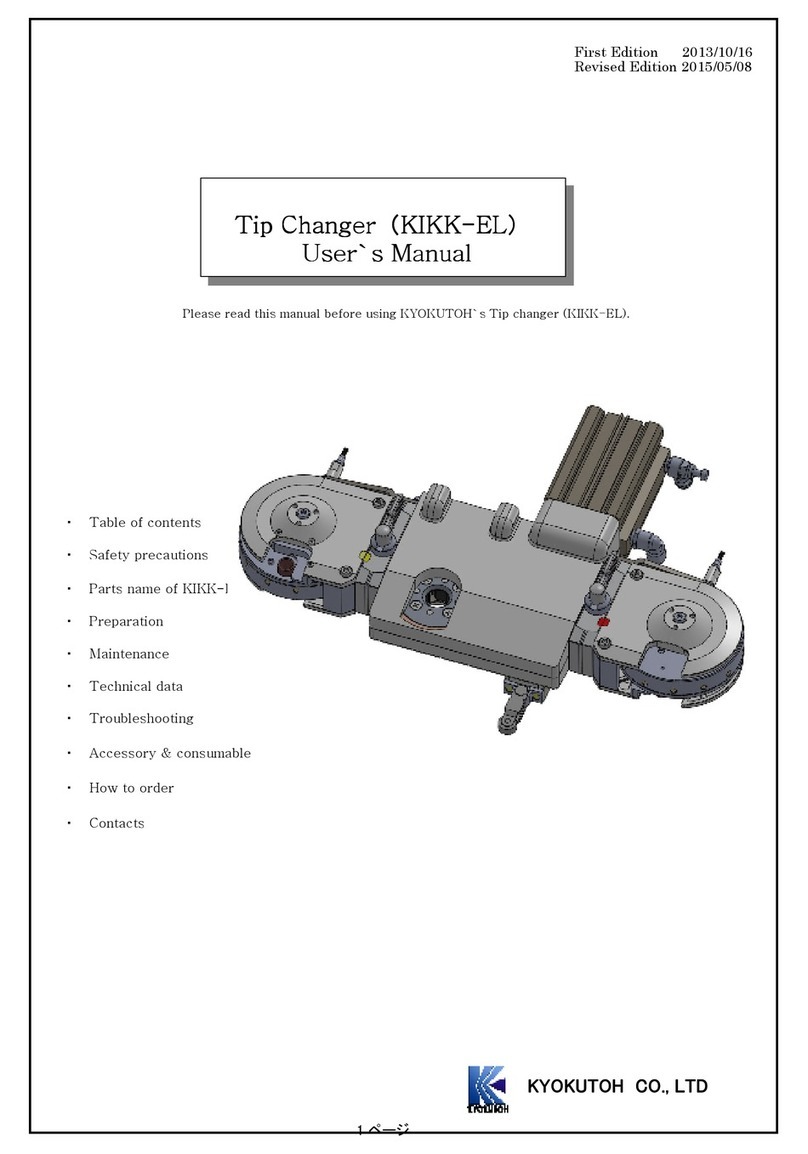

Adveco TOTEM 10 User manual

PRODUCT MANUAL

TR400057

TOTEM

Cogeneration (CHP) Range

PRACTICAL, EFFICIENT & SUSTAINABLE

BUILDING SERVICES SOLUTIONS

TOTEM 10 -TOTEM 20 -TOTEM 25 MICROCOGENERATORS

Service Manual

Important Notes

No tampering and/or changes of any kind to the product are permitted, including

replacement of components with non-genuine spare parts and/or any alternation

to original product conformity unless expressly approved by O EM ENERGY.

Any changes to the casing or components inside the product will cause suspension

and/or exclusion of the product warranty.

By way of non-exhaustive example, the following are not permitted in any manner

before or after commissioning the product:

•Piercing the casing, the structure or the components inside the product.

•Welding or gluing system parts or components to the casing or to the devices

inside the product.

•Changes to the electrical system and to the devices inside the product.

•ransporting and positioning the product in manner different from the

transportation instructions illustrated in this manual.

•Non-conforming grounding.

•Non-conforming product storage.

•Alteration or tampering with the software or control parameters.

•Electrical powering of the product not conforming with the specifications

illustrated in this manual.

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

2

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

Index

01. Safety nstructions ......................................................................................................6

02. Safety ...................................................................................................................... 12

03. Safety Line Checking Procedures ................................................................................. 14

04. nspections and Checks ............................................................................................. 17

05. Panel and Upright dentification .................................................................................. 19

06. Side Panel Removal- nstallation (Removal)................................................................... 21

07. Upper Panel Removal- nstallation (Removal) ................................................................ 22

08. Casing Upright Removal- nstallation (Removal) ............................................................ 24

09. Automatic Engine Oil Change (Removal) ...................................................................... 34

10. Manual Engine Oil Change (Removal) .......................................................................... 37

11. Level Switch Holder Replacement (Removal) ................................................................ 42

12. Coolant Check and Top-Up ......................................................................................... 46

13. Coolant Change (Removal) ......................................................................................... 47

14. TOTEM Module Battery Check ..................................................................................... 51

15. TOTEM Module Battery Replacement ........................................................................... 52

16. Electronic Control Unit Replacement (Removal) ............................................................ 53

17. Gateway Replacement (Removal) ................................................................................ 56

18. Electrical Panel Component Replacement (Removal) ..................................................... 58

19. Electrical Panel Replacement (Removal) ....................................................................... 70

20. Lambda Sensor Replacement (Removal) ...................................................................... 76

21. PT200 Sensor Replacement (Removal) ........................................................................ 80

22. Flow Switch Replacement (Removal) ........................................................................... 82

23. Engine Water Sensor Replacement (Removal) .............................................................. 84

24. Solenoid Valve Replacement, Electrical Part (Removal) .................................................. 86

25. Solenoid Valve Replacement, Mechanical Part (Removal) ............................................... 88

26. NTC Sensor Replacement (Removal) ........................................................................... 95

27. Deaerator Replacement (Removal) .............................................................................. 97

28. DUNGS Valve Replacement (Removal) ......................................................................... 99

29. Primary Air Cleaner Replacement (Removal) ............................................................... 103

3

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

30. Secondary Air Cleaner Replacement ( nstallation) ....................................................... 105

31. Secondary Air Cleaner Assembly Replacement (Removal) ............................................ 107

32. Engine Oil Filter Replacement (Removal) ................................................................... 111

33. Plate Heat Exchanger Replacement (Removal)............................................................ 113

34. Coaxial Replacement (Removal) ................................................................................ 117

35. Tube Bundle Heat Exchanger Replacement (Removal) ................................................. 121

36. gnition Coil Replacement (Removal) ......................................................................... 125

37. Spark Plug Wire Replacement (Removal) ................................................................... 127

38. Spark Plug Replacement (Removal) ........................................................................... 129

39. Timing Upper Cover Replacement (Removal) .............................................................. 131

40. Timing Lower Cover Replacement (Removal) .............................................................. 133

41. Timing Belt Replacement (Removal) .......................................................................... 135

42. Tappet Cover Replacement (Removal) ....................................................................... 139

43. Valve Clearance Check/Restore ................................................................................. 143

44. Front Support Replacement (Removal) ...................................................................... 145

45. Exhaust Manifold Replacement (Removal) .................................................................. 147

46. Catalytic Converter Replacement (Removal) ............................................................... 151

47. Cylinder Head Replacement (Removal) ...................................................................... 153

48. Camshaft Replacement (Removal)............................................................................. 157

49. Cylinder Compression Pressure Check ........................................................................ 161

50. Engine Unit Replacement (Removal) .......................................................................... 163

51. Starter Motor Replacement (Removal) ....................................................................... 171

52. Generator Unit Replacement (Removal) ..................................................................... 175

53. Electrical Engine Water Pump Replacement (Removal) ................................................ 185

54. Mechanical Engine Water Pump Replacement (Removal) ............................................. 188

55. Engine Wiring Replacement (Removal) ...................................................................... 190

56. Vibration Damping Replacement (Removal) ................................................................ 192

57. Fan Replacement (Removal) ..................................................................................... 195

58. Blow-by Line ........................................................................................................... 199

59. nsulation ............................................................................................................... 200

60. ndications for Cleaning ........................................................................................... 205

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

4

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

61. Tube Bundle Cleaning ( nstallation) ........................................................................... 206

62. Gas Detector Cleaning ( nstallation) .......................................................................... 210

63. nstruments ............................................................................................................ 212

5

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

01. Safety nstructions

Secure the TOTEM module as described in CHAPTER 02 before starting any maintenance

operations.

Some internal components of the TOTEM, such as the endothermic engine, the heat recovery

devices (heat exchangers), the pumps, the engine water and service water pipes, the exhaust pipes

and the exhaust muffler, become very hot during normal use (some even hotter than 700°C). Some

components remain hot for many hours after having switched the TOTEM off.

The entire machine must normally operate in safe conditions with the casing panels installed to

prevent direct access to hot parts. Where possible, the internal components are heat-insulated to

ensure protection for the operator if panels need to be removed for troubleshooting or servicing.

However, some zones remain accessible and may be freely touched.

These activities must be performed by technically qualified personnel trained for performing the

operations using appropriate PPE.

Remember that high temperatures may cause fires in presence of potentially flammable

substances.

The TOTEM module contains chemical substances which are essential for its operation.

n particular, it contains substances such as battery acid, new and used lubricating oil and water

and glycol mixture.

t is very important to avoid direct contact of these substances with the eyes and skin and to

respect safety regulations for their storage and disposal. Refer to the safety datasheets of the

lubricants.

After contact with the chemical substances, wash the concerned body parts with plenty of water. f

needed, call a doctor and take the product datasheet with you. These substances may be very hot

and cause burns.

Furthermore, the TOTEM module produces a constant flow of exhaust gas containing CO, CO2 and

NOX during operation.

Electrical damage may occur if the safety protections are removed from the system, the control

panel or the ignition system if required for troubleshooting, servicing or commissioning (e.g.

functional test).

These activities must be performed by technically qualified personnel trained for performing the

operations using appropriate PPE. Always cut off the master switch of the machine and the

interface device (DD ) before starting any servicing operation.

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

6

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

A. Symbols used

[Danger]

This indicates operative procedures which may cause injury or death if not performed correctly.

[Warning]

This indicates operative procedures which may cause severe damage to the device.

[Information]

This indicates important information related to use of the device.

B. Glossary and definitions

Operator: person without specific skills capable of performing only simple tasks, i.e. operating the

machine by means of the controls provided for the operator, checking operation and reporting any

faults to service.

Qualified technician: a professional with specific skills in the areas of heating and hot water

production systems, electrical systems and electricity generators, systems running on fuel gas and

devices equipped with Otto or Miller cycle endothermic engines. This person must be enabled

according to the law in force where the system is installed.

Service technician: a qualified technician having acknowledge professional systems trained and

authorized by TOTEM ENERGY to perform maintenance operations on the TOTEM® modules.

Personal protection equipment (PPE): including:

•ear protection (ear muffs or ear plugs) for protecting the hearing of workers operating with

the soundproofing panel removed and with the TOTEM® microcogenerator running (for

troubleshooting and servicing only);

•gloves and protective eyewear for working with battery acid, glycol and engine lubricant;

•safety footwear;

•dielectric insulating screen and gloves for operations on live components.

The PPE must be worn by service technicians during installation, starting and servicing operations

on the TOTEM®.

7

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

C. Safety instructions

If you smell gas:

•Close the gas valve.

•Ventilate the room.

•Evacuate the room.

•Do not operate any electrical devices, including the telephone.

•Promptly call a professionally qualified technician or the gas company from another room.

Call the fire department if this is not possible or if emergency intervention is needed.

•Report the active safety system fault if the room is provided with a gas leakage detection

system.

If you smell exhaust fumes:

•Switch the device off.

•Ventilate the room.

•Evacuate the room.

•Call a qualified technician.

•Report the active safety system fault if the room is provided with a fume and CO detection

system.

If you see leakages of water, glycol, oil or other fluids on the floor near the O EM®:

•Switch the device off.

•Call a professionally qualified technician.

•Cut off services, such as the water or gas line.

nstallation, calibration or changes to the gas feeding system must be performed by a qualified

technician according to national and local laws and to the instructions provided in the installation

manual.

nstallation, calibration or changes to the electrical power system must be performed by a qualified

technician according to national and local laws and to the instructions provided in the installation

manual.

nstallation, calibration or changes to the water supply system must be performed by a qualified

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

8

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

technician according to national and local laws and to the instructions provided in the installation

manual.

The exhaust gas evacuation line from the device must be connected to a fume evacuation pipe

compliant with the regulations in force at the place where the TOTEM® module is installed. Failure

to respect this instruction implies severe risks for the safety of humans and animals.

The user, in accordance with instructions for use, shall keep the installation in good conditions and

guarantee reliable and safe operation of the microcogenerator and of the systems connected to it

by entrusting the operations to qualified technical personnel.

The user shall have the device serviced according to the instructions contained in this manual in

compliance with national and local regulations by a qualified technician. ncorrect installation or

poor servicing may cause damage or injury to humans, animals or property for which TOTEM

ENERGY will not be liable.

Make sure all panels and screens are correct installed before starting. Risks for personnel safety

exist.

Do not obstruct the intake and exhaust pipe terminals, even partially.

Do not store materials which could be dangerous, such as explosive, combustible or flammable

material, in the same room as the microcogenerator. Do not stay in the utility room while the

microcogenerator is operating.

Do not tamper with, modify or alter the microcogenerator, its accessory components, the systems

needed for its operation (gas, water, electricity, cut-off devices, fire-fighting devices, detectors,

panels, electrical panels, parts of the utility room where the TOTEM® is installed, etc.) for any

reason to prevent even very severe accidents to humans, animals or property.

This manual is an integral and essential part of the microcogenerator and must be kept with care

by the user. Always make sure that this manual is given to the new owner if the microcogenerator

is transferred or if the property of the building in which it is installed changes hands.

The information contained in this manual is up-to-date and referred to the date of

publishing except for changes and technical updates. Minor differences may be present in images,

process descriptions and technical data as the result of continual product updates. Please contact

us to receive the most recent version of the documentation or in case of suggestions for

improvement or if inaccuracies are found.

The microcogenerator must be used only for the purpose for which it was expressly designed, e.g.

for the contextual production of:

•hot water for closed circuits for residential or industrial purposes

•low voltage electricity (400 Volts) for use on site, supplying to the grid or for self-

consumption.

TOTEM ENERGY shall not be liable in contractual or extra-contractual terms for damage caused by

9

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

errors in installation or use and in all case for failure to respect the instructions provided by the

manufacturers or to respect applicable national and local laws.

D. Potential safety risks

Mechanical risks

Mechanical injury or damage may occur when safety protections are removed (panels or casing

protecting moving parts of the microcogenerator). These activities must be performed exclusively

by maintenance technicians trained for performing the operations using appropriate PPE.

Electrical risks

Electrical injury or damage may occur when safety protections are removed in the system or in the

control panel or the ignition system. Furthermore, changes to the existing electrical system may

cause even severe dangers if performed by personnel who is not enabled. These activities must be

performed exclusively by maintenance technicians trained for performing the operations using

appropriate PPE.

Heat risks

Some components inside the TOTEM® may become very hot during normal operation. The entire

machine must normally operate in safe conditions with the casing panels installed to prevent direct

access to hot parts. The panels may be opened by maintenance technicians only.

Noise risks

The entire TOTEM® module must normally operate in safe conditions with the casing panels

installed to abate the sound emission of the module.

Vibration risks

The TOTEM® unit is provided with appropriately dimensioned vibration damping feet to contain

vibrations to structures and the system connected to them. The vibration damping joints on the

connections to the gas line, fume exhaust line and heat system must not be removed.

Radiation/electromagnetic risks

The TOTEM® complies with Directive 2004/108/EC in the matter of electromagnetic compatibility.

n all cases, the magnetic fields generated by the asynchronous generator may cause temporary

malfunctioning of electro-medical devices (pacemakers, hearing aids, etc.) in the immediate

proximity.

Risk of injury due to contact with dangerous materials and substances

The TOTEM® module contains chemical substances essential for its operation. n particular, it

contains substances such as battery acid, new and used lubricating oil and water and glycol

mixture. Direct contact with these substances in case of spillage outside the TOTEM® module must

be absolutely avoided. After contact with the chemical substances, wash the concerned body parts

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

10

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

with plenty of water. f needed, call a doctor and take the product datasheet with you. These

substances may be very hot and cause burns. Furthermore, the TOTEM® module during operation

produces a constant flow of exhaust gas. n case of release or stagnation of exhaust gas from the

fume evacuation system leave the area immediately and stop operation of the module, if possible.

nstallation of a CO/CH4 sensor in the room may be required by the regulations of the place where

the product is installed. The TOTEM® module is equipped with a CH4 leakage detection sensor.

Contact the Technical Service to have the device periodically checked and calibrated.

Risk of slipping, tripping and falling

Leakages of lubricant oil, glycol water or battery acids may occur following a fault or

malfunction of the module making surfaces slippery and causing the risk of falling.

Spillage must be promptly contained and disposed of according to the regulation in

force if possible.

Emergency stopping/shutdown risk

The TOTEM® is set to stop immediate if one or more safety device outside the TOTEM® and

connected to it trip.

Blackout risk

The TOTEM® is set to be shutdown immediately in safe conditions in case of electrical grid

blackout. The presence of an interface protection device (not supplied by TOTEM ENERGY) suited

and approved by the laws in force in the place of installation, guarantees interruption of the

connection to the electrical mains if the requirements stated in standards are not satisfied.

Control panel failure risk

The TOTEM® is set to be shutdown immediately in safe conditions in case of control panel failure.

Fault-related risks during normal operation

The TOTEM® is ready to operate in manner which is safe for operators, users and connected

systems providing it is intact, employed according to the expected destination of use and technical

parameters envisaged by TOTEM ENERGY and correctly serviced.

Risk deriving from use in environments with risk of explosion/fire (Ex)

The TOTEM® is not designed to work in environments with risk of explosion/fire (Ex). Do not keep

materials which may increase the risk of explosion or fire in the rooms where the TOTEM® is

installed.

11

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

02. Safety

Note: Read CHAP ER 01 carefully before securing the O EM module.

Description:

Close the system gas cut-off valve (external to

the TOTEM module).

Turn the main switch on the panel of the module

to the "OFF" position.

Switch the battery disconnector off as described in CHAPTER 15.

Deactivate the service water circulation pump and cut off the circuit, where possible, by closing the

valves. (External to the module).

Select the interface device (DD ) (external to the TOTEM device).

Emergency Stop

Main Switch

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

12

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

Safety

Safety instruction: Perform this operation in safe conditions with all casing panels

installed. If the panels need to be removed during troubleshooting or for specific

service activities, these activities may be performed exclusively by technically qualified

personnel trained for performing the operations using the specific PPE.

Description:

Reset the interface device (DD ) (external to the TOTEM device).

Turn the main switch on the panel of the module

to the "ON" position

Release the emergency stop button on the

module panel.

Switch the battery disconnector on as described in CHAPTER 15.

Restore service water circulation in the circuit by opening the valves and reactivating the service

water circulation pump. (External to the module).

Open the system gas cut-off valve (external to the TOTEM module)

Main Switch

Emergency Stop

13

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

03. Safety Line Checking Procedures

Note: Read CHAPTER 01 carefully before securing the TOTEM module.The safety line of the

machine is designed to trip and secure the machine if the temperature inside the box is over 65°C

and in case of leakage of natural gas in the box. The parameters are detected by two sensors fitted

inside the box in zones suited to detect the faults.

Methane sensor check

The gas sensor is provided with a specific kit for calibrating and testing it. The kit consists of a

canister containing a mixture of methane equal to 50%LEL (2.2%CH4 in air), an adapted for the

detector head and a pre-calibrated flow adjustment valve.

Description:

Open the side panel P6 as described in CHAPTER 06.

Disconnect the connector of the 20%LEL signal directed to the PLC and jump it.

Apply the adapter to the sensor head.

Fit the flow adjuster to the calibr

ation canister.

Connect the flexible pipe with quick connector to the head and to the cylinder.

Slowly open the valve to obtain a constant gas flow slower than 0.5 l/min. The valve is pre-

calibrated to obtain the required flow when opened.

Check that the safety functions are actuated:

•The machine switches off (if it was running).

•The two LEDs on the safety relay switch off.

•The “Emergency line alarm” signal appears on the operator panel.

•Machine restart is inhibited (after switch-off or if the machine was not running).

•Fan is activated (if the machine is off).

•Sending of a signal to the system fan which can be verified with a tester.

n order to restart the machine it is necessary to eliminate the presence of methane so that the

sensor can resume normal operating conditions. f sensor is automatically rearmed when the

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

14

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

presence of methane is no longer detected and LED 1 appears again on the safety relay. Press the

manual rearm button on the panel flat safety line (LED 2 on the safety relay will light up) and reset

the alarm on the operator panel.

Safety thermostat check

The temperature safety function may be checked by increasing the air temperature near the

thermostat and checking that the safety functions are actuated. The sensor is set by the

manufacturer to 65°C. Another temperature sensor connected to the PLC is present in the machine.

The PLC is set to switch the machine off over 60°C. n this way the safety line will only trip in case

of fault to the machine control system.

Temperature increase may be simulated using an industrial heat gun. The heat gun may be

adjusted by setting the air temperature to the required value.

1. Open the panel at the thermostat.

1. Set the gun to a temperature of 65°C.

1. Send the hot air flow onto the thermostat bulb,

2. Check that the safety functions are actuated:

•The machine is switched off.

•The two LEDs on the safety relay switch off.

•The “Emergency line alarm” signal appears on the operator panel.

•Machine restart is inhibited (after switch-off).

To be able to restart the machine, it is necessary to manually rearm the thermostat, the LED 1 on

the safety relay lights up, press the manual rearming button for the safety line on the panel door

(LED 2 on the safety relay will light up) and reset the alarm on the operator panel.

Emergency stop button check

The emergency stop button can be checked by pressing it during machine operation and checking

that the safety functions are actuated.

•The machine is switched off.

15

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

•The two LEDs on the safety relay switch off.

•The fan and the water circulating pump is also switched off.

•Machine restart is inhibited (after switch-off).

To be able to restart the machine, it is necessary to rearm the button, press the manual rearming

button for the safety line on the panel door and reset the alarm on the operator panel.

Refit the side panel P6 as described in CHAPTER 06.

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

16

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

04. nspections and Checks

Safety instruction: Carry out the " O EM module securing" operation or make sure that

it was previously performed in correct manner as described in CHAP ER 02.

Safety instruction: Do not perform the "Restoring otem for normal operation"

procedure and do not attempt to operate or start the otem module before having

completed the "Inspections and checks" operation and in all cases before refitting all

the components, including the panels.

Safety instruction: Carry out the machine inspection and checking operation with the

interior parts closed.

Safety instruction: Risk of contact with engine oil or coolant.

Description:

Secure the TOTEM module as described in CHAPTER 02.

Remove all the panels from the TOTEM module as described in CHAPTER 06.

Visually check all the internal parts of the TOTEM module. Check that:

•All components are intact and operative.

•There are no residues of liquid, such as engine oil or mixture of water and glycol on the

module base.

•All electrical connections and contacts are well positioned and well connected.

•The wirings inside the module are intact and not tripped or broken along the path.

•All plastic or metal pipe connections are tight on the respective connections.

•There are no interferences between wiring and rotating parts.

Open the front panel of the electrical panel of the TOTEM module and visually check that:

•All electrical connections are well positioned and correctly connected in the respective

housings.

•The wire insulation is not stripped in any points.

•There are no burns near the terminal.

•All terminal boards are correctly closed on the respective terminals (with a suitable

screwdriver).

•There are no traces of humidity or liquid residues in the electrical panel.

•All fuses are still intact.

17

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

Using a specific torque wrench check the

tightening torques of all tube bundle interfaces

(see example in photo).

IGH ENING ORQUE: 50 ± 2.5 Nm

Check the tightening of the electrical components

in the module (see example in photo).

nstall all the panels from the TOTEM module as described in CHAPTER 06.

Restart the TOTEM module as described in CHAPTER 02.

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

18

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

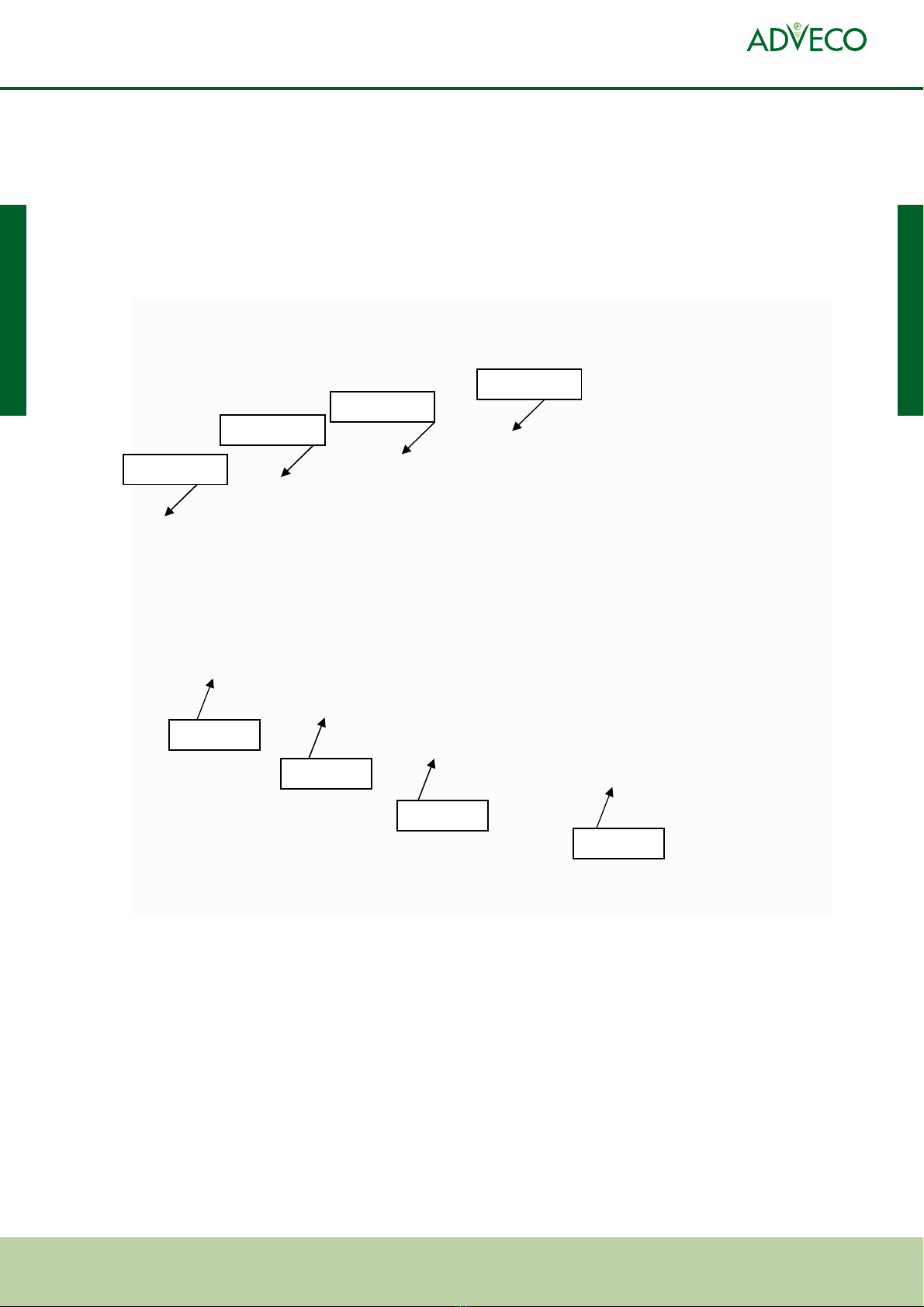

05. Panel and Upright dentification

UPRIGHT A

UPRIGHT

B

UPRIGHT

C

UPRIGHT

D

PANEL 3

PANEL 4

PANEL

2

PANEL 1

19

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

UPRIGHT G

UPRIGHT F

UPRIGHT E

UPRIGHT D

UPRIGHT H

PANEL 8

PANEL 7

PANEL

6

PANEL

5

PRACTICAL, EFFICIENT & SUSTAINABLE BUILDING SERVICES SOLUTIONS

20

TOTEM 10 - TOTEM 20 - TOTEM 25 - Service manual

This manual suits for next models

2

Table of contents

Other Adveco Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ELBO CONTROLLI

ELBO CONTROLLI E236+ Installation, operation and maintenance manual

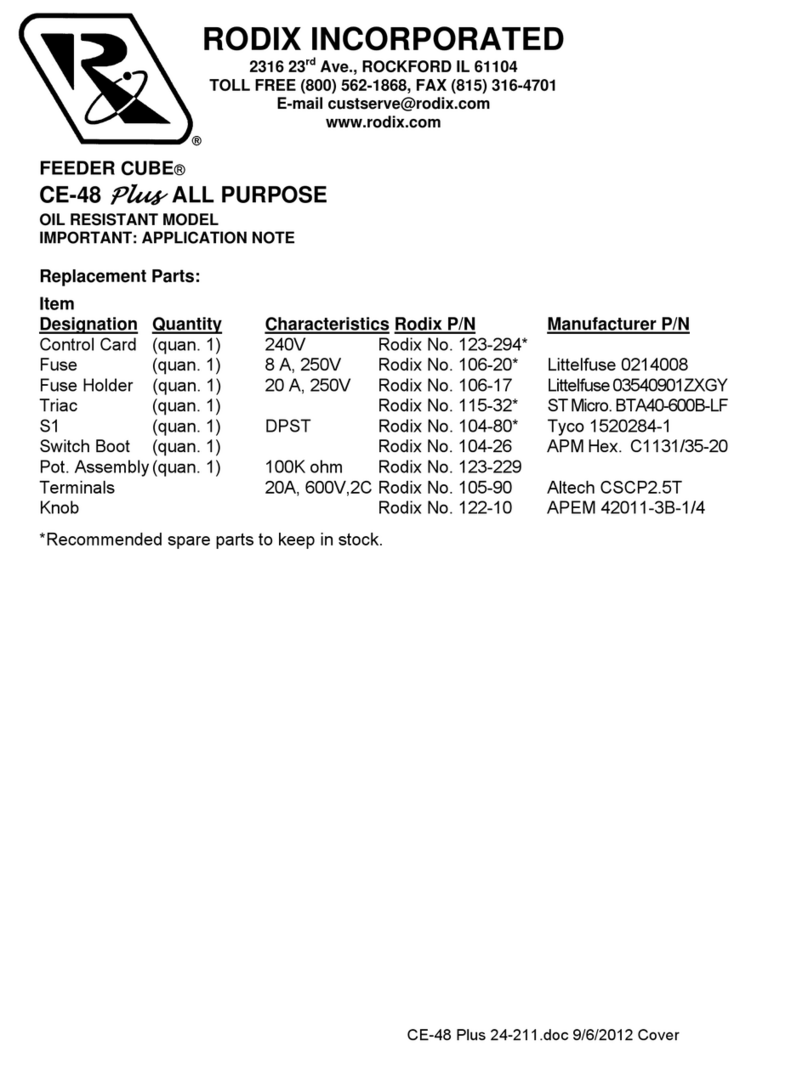

Rodix

Rodix FEEDER CUBE CE-40 Plus Series Adjustments and Set Up

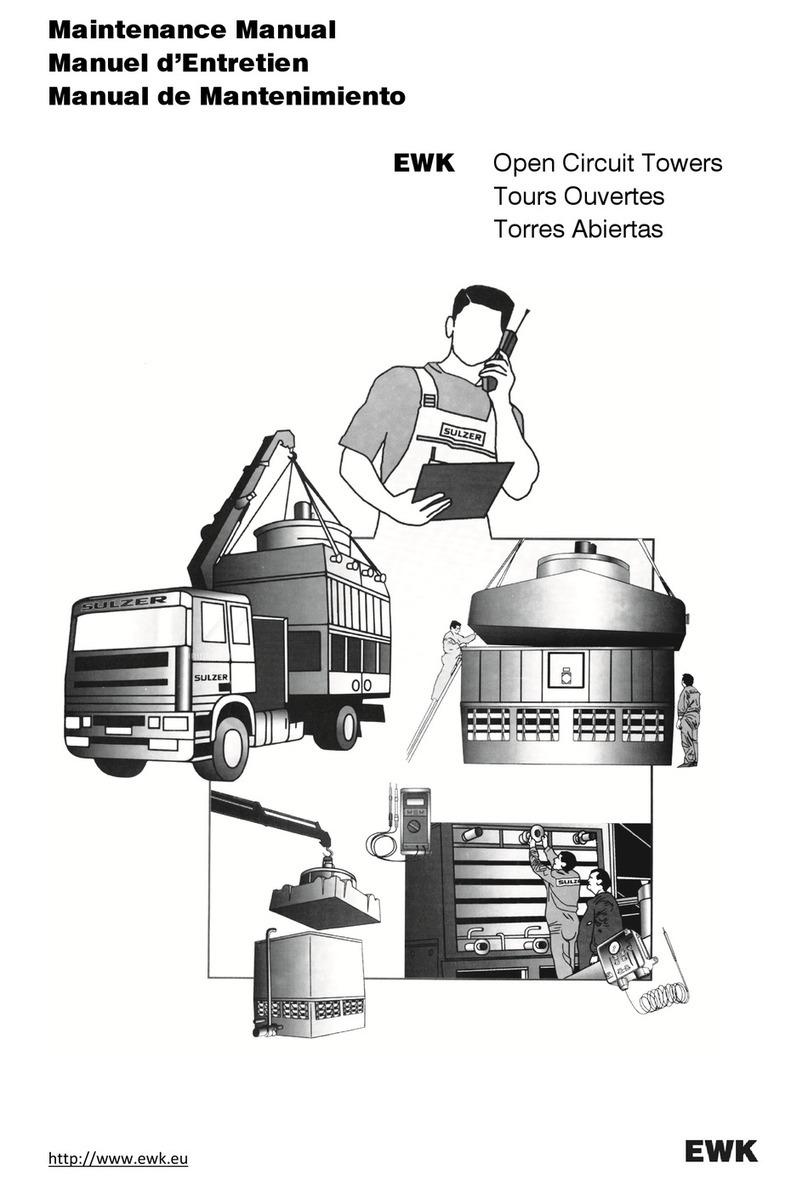

EWK

EWK 064 Maintenance manual

Concoa

Concoa 547 Series Installation and operation instructions

FIBRO

FIBRO 2480.00.35.04 instructions

Festo

Festo EPCE-TB operating instructions

ABB

ABB A140-M56 original operation manual

SUHNER MACHINING

SUHNER MACHINING MAX40R Technical document

Emerson

Emerson CC200 quick start guide

NTI

NTI T 151-200 Series installation instructions

Siemens

Siemens SIRIUS 3RV2926-3 Series Original operating instructions

ermengineering

ermengineering LRW-130 Use and maintenance manual