FORM NO. L-20066-B-0402

2

OPERATION

MAINTENANCE AND REPAIR

3. Release the hold-off pressure to engage the spring

actuated Brake Caliper.

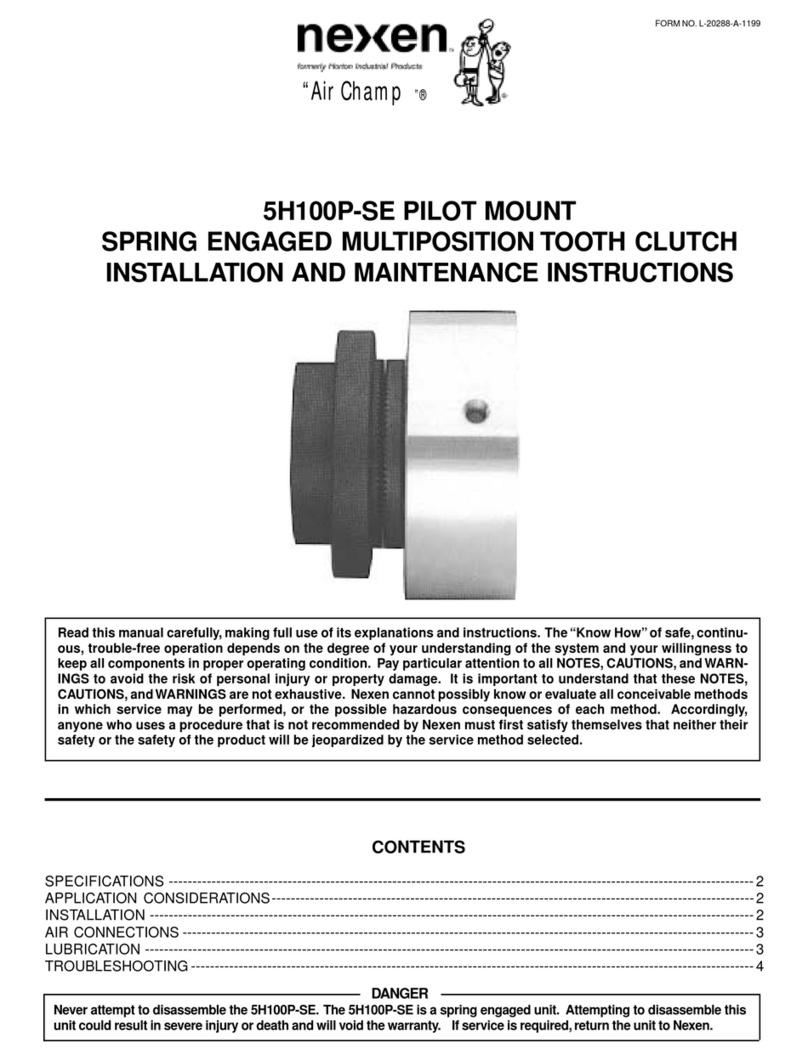

Friction Facing Wear Adjustment:

1. To maintain new facing torque levels, periodic

adjustments for facing wear is necessary. Optimum

torque is derived with a 1/32 inch gap on each side

of the disc.

2. Apply 90 PSI hold-off air pressure at the air inlet

and inspect the gap between the friction facing and

the disc.

3. Loosen the set screw hex nut (item #17) and turn

the set screw CW until a 1/32 inch spacer can be

slid between the facing and the disc.

4. Remove the spacer and retighten the hex nut.

NOTE: Periodically inspect all airline connections

for leaks. Inspect all fasteners to make sure they are

tightened to the torques recommended in Table 1.

NOTE: Depending upon the Brake Caliper

accessibility, friction facing replacement and piston

seal maintenance can be performed without

removing the brake from it’s mounting.

2. Replace the Friction Facings (Item 5) when they are

approximately 3/16 inch thick:

a. Spring Actuated Unit: Apply 90 PSI hold-off

pressure at the air inlet or manually release the

brake as described in paragraph B.1 of the

OPERATIONsection.

b. All models: Remove the Shoulder Screws (Item 11).

Remove the facing/shoe assembly (Items 4 & 5)

and Spacer (Item 6). Remove the Machine Screws

(Item 9) and replace the Friction Facings.

c. All models: Reassemble the Spacer, Shoe/Facing

assembly, Springs and Shoulder screws. Tighten the

Shoulder Screws to the torque recommended in

Table 1.

d. Spring Actuated Unit: Reset as described in

paragraph B.2 of the OPERATION section.

3. Air Actuated U-cup and O-ring replacement (Items

10 & 14):

a. Disconnect the air supply to both cylinders.

b. Remove the clamps (Item 8) and end caps (Item 2).

c. Pull the Pistons (Item 3) out of the Cylinders (Item

1) and remove the U-cups (Item 10). Inspect the

Sleeve Bushings (Item 15) for wear and replace if

necessary.

d. Lubricate the new u-cups with O-ring lube and

place them, with the seal lip upward, over the small

diameters of the pistons and into the grooves. Slide

the pistons into the cylinders.

e. Lubricate the new O-rings (Item 14) with 0-ring

lube, place them into the end cap grooves and

reinstall the end caps and clamps. Tighten the

clamp bolts to the torque recommended in Table 1.

4. Spring Actuated u-cup and O-ring replacement

(Items 10 & 21):

a. Disconnect the air supply from the air inlet.

b. Manually release the Brake Caliper as described in

Section IV, paragraph 2.

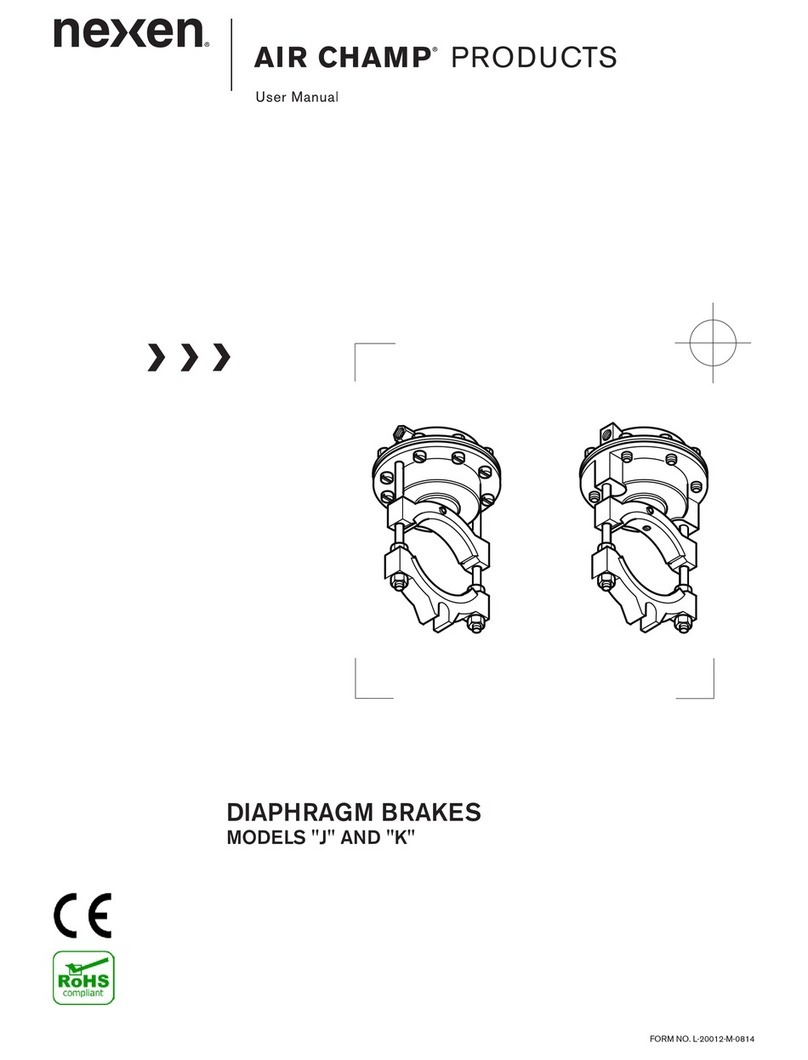

AIR ACTUATED UNIT

This unit engages when air is applied to both calipers.

Return Springs (Item 12) disengage the calipers when air

exhausts from the cylinders.

SPRING ACTUATED UNIT

Manual Release:

1. Loosen the Hex Nut (Item 17) attached to the Set

Screw (Item 20). Use an Allen wrench to turn the

Set Screw CCW until the Return Springs (item

#12) pull the Shoe/Facing assembly back against

the cylinder (Item 1).

2. Adjust the caliper halves for the space requirements

as described in the INSTALLATION section.

Reset:

1. Apply 90 PSI hold-off air pressure at the air inlet.

2. Turn the Set Screws CW until the Shoe/Facing

assembly just starts to move towards the disc;

tighten the Hex Nuts.

®

DIST. AUTORIZADO

MEX (55) 53 63 23 31

QRO (442) 1 95 72 60

MTY (81) 83 54 10 18