AE SVLD1 User manual

SVLD1 Valve Leakage Detector(AE)

User Manual

QingCheng AE Institute (Guangzhou) Co.,Ltd

www.acousticemission.cn

Quick operation manual

Once used for the first time, firstly connect the sensor with the detector, press

"start" for a long time to enter the main interface of the test, ensure that

the sensor and valve are well coupled during the test。

2.Press “Test” button to do valve leakage detection;

3. Press ”FFT” to view the FFT spectrum of the measured signal;

4. Press ”Back” to switch to current displayed acoustic emission parameters;

5. Press ”Save” to save the current testing datum;

6. Press ”Valve” to switch to the saved valves;

7. Press “Filter” to switch the currently selected filter to the sampling rate;

When no leakage calibration is carried out, press “Test” to get parameters like

RMS、 ASL 、P of the valve , and the current display parameters can be switched

by pressing “PARA”, the reference value of corresponding leakage amount

below is 0

Leakage calibration:

Press “Menu”, firstly add new valve to be calibrated in “valve” option, select

the corresponding valve from the “calibration” options; select the

corresponding filter and sampling rate in the “add” option, add the calibration

curve, and select the corresponding curve in the calibration curve list.

After entering the standard leakage amount, move the cursor to the RMS option,

press the "test" key to generate the current calibration value.

Remarks: The more points there are, the more accurate the reference value of

leakage is.

Announcement

Our company is irresponsible for any results caused by mistaken operation, pls

obey the operation manual strictly; if any abnormal conditions take places during

usage, pls don’t disassemble the machine without permission for maintenance,

and timely contact our company for processing.

For more detailed info, please visit our website: https://www.acousticemission.cn,

or please call at: 86-20-32290092

Catalogue

CHAPTER ONE: INTRODUCTION ...................................................................................................... 1

1.1 TECHNICAL PARAMETERS ....................................................................................................................................... 2

1.2 MAIN CHARACTERISTICS ....................................................................................................................................... 3

1.3 CONFIGURATION LIST ............................................................................................................................................. 4

1.4 CAUTIONS ............................................................................................................................................................... 5

CHAPTER TWO: BRIEF INTRODUCTION OF HOST MACHINE、KEYBOARD AND DISPLAY .... 6

2.1 INTRODUCTION OF THE HOST MACHINE ............................................................................................................... 6

2.2 KEYBOARD INTRODUCTION ................................................................................................................................... 7

2.3 DISPLAY INTRODUCTION ........................................................................................................................................ 9

CHAPTER THREE: MENU AND DISPLAY ........................................................................................ 10

3.1 VALVE ................................................................................................................................................................... 10

3.2 CALIBRATION ....................................................................................................................................................... 11

3.3 SAVE ..................................................................................................................................................................... 12

3.4 SETTING ............................................................................................................................................................... 13

3.4.1 Basic Setting: ....................................................................................................................................... 13

3.4.2 Alarming Setting ................................................................................................................................... 15

CHAPTER FOUR: BRIEF OPERATION INTRODUCTION ................................................................. 16

4.1 VALUE SETTING .................................................................................................................................................... 16

4.2 TEST ...................................................................................................................................................................... 17

4.3 FFT SPECTRUM ANALYSIS .................................................................................................................................. 18

4.4 CALIBRATION ....................................................................................................................................................... 19

CHAPTER FIVE: MAINTENANCE ..................................................................................................... 21

5.1 APPLICATION NOTICE .......................................................................................................................................... 21

5.2 DAILY MAINTENANCE AND SERVICING .............................................................................................................. 21

CHAPTER SIX: FAULT ANALYSIS AND TROUBLESHOOTING ....................................................... 22

CHAPTER SEVEN: PC SOFTWARE ................................................................................................... 23

1

Chapter one: Introduction

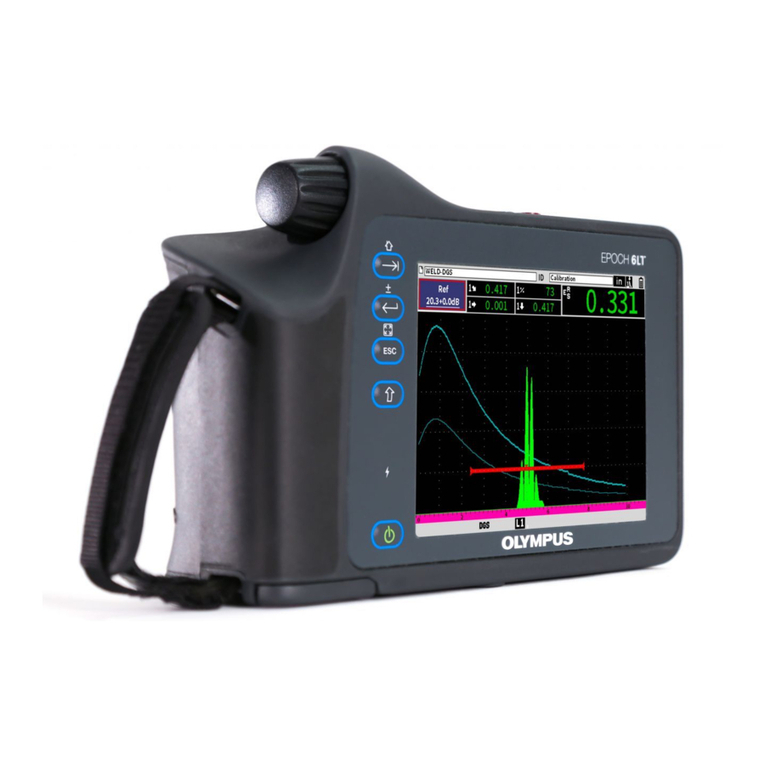

Firstly, thank for purchasing our Handheld Valve Leakage Detector (AE). Set up

reference number of the leakage rate through gathering fixed length AE signals,

processing and calculating effective parameters like RMS、ASL、P; at the same

time can demarcate the leakage rate of the detecting device in advance, through

internal calculation to output parameter- the demarcated curve of leakage rate,

thus can output reference values of current leakage rate of the valve while testing。

This instrument applies the principle of acoustic emission technology, easy to

operate、small volume、long working time. Before using it, pls read the operation

carefully. This manual mainly describes its function、technical parameters、

settings、operation、calibration, etc, in order to make customer to know how to

operate it in short time.

2

1.1 Technical parameters

Model No

Parameter SVLD1

Sampling frequency optional 4MHz/2MHz/1MHz/500KHz/200KHz/

100KHz/50KHz/20KHz

Sampling precision 16bit

Response frequency 1kHz-1MHz (±1.5dB)

Protection level Host machine:IP64;sensor:IP66

Channel quantity 1

Working temperature -10℃~50℃

Working humidity 20%~90%RH

Built-in preamplifier 26dB (Sensor)

Analog filter

Six kinds of filters can choose(1KHz-1MHz,

1KHz-600KHz, 20KHz-1MHz, 20KHz-600KHz,

100KHz-1MHz, 100KHz-600KHz)

Power 3VDC(two pieces of AA alkaline battery )

Working time 280 hours(Auto backlight ),100 hours(Backlit

open)

Screen 128×64 lattice LCD

Outside size 136(L)×72(W)×20(H)mm

Weight 176g(including batteries)

Working temperature

-10℃~﹢50℃(high temperature probe,working

temperature:<300℃)

Working humidity 20%~90%RH

Storage room 50,000 groups testing datum

Valve quantity 200

Generageted parameter RMS,ASL,P

3

1.2 Main Characteristics

Applying the principles of acoustic emission technology, it is simplified

operation process and easy to be operated. Multiple shortcut keys are set to

complete leak detection with one key;

Choosing AE time indicators(RMS,ASL,P) as leakage testing parameters,

thus can calibrate the valve leakage rate. Once leakage rate is calibrated, the

detector can display the referential values while testing;

Obtaining FFT frequency spectrum analysis function, can check FFT

frequency spectrum signals of current testing data at any time;

Up to 200 kinds of different valves are available, each kind of valve can store

up to 8 calibration curves;

16 digital sampling precision, sampling frequency can be adjusted based on

the frequency range of leakage signal;

6 kinds of analog filters can be selected , and can filter the noise signal

according to test condition

Two pieces of AA dry batteries to supply power, normal endurance time can

achieve 100 hours, it is easy to replace the battery, and is applicable for

long-time working outside, small volume,low weight, easy to carry;

Two kinds of alarming modes: beeping and flashing alarm, can set up two

kinds of alarm limits: first level and second level, alarming data can be saved

automatically;

Datum storage:Storage shortcuts are set up, can finish datum storage by

one button, can track and record time、date simultaneously,datum storage

volume can achieve 50,000 groups;

Communication interface: high speed of USB interface which can export

the datum, also can processes datum on the master computer.

Working way: can offer testing of valve AE parameters and valve AE leakage

rate( which are under demarcated condition);

Daily AE valve leakage detecting can be done through operating the

functional button, easy to see and to learn, no need to operate it by entering

menu.

4

1.3 Configuration list

NO Model Name Unit Quantity

1 SVLD1 Machine set 1

2 Plastic box piece 1

3

AE Sensor LS35

5VDC, with coaxial

cable

piece 1

4 Mini-USB cable piece 1

5 PC software Set 1

6 User Manual piece 1

7 Warranty Card piece 1

8 Conformity Card piece 1

5

1.4 Cautions

◇ In order to make sure safe operation, the person who use this instrument

should know related NDT Knowledge firstly;

◇ This instrument should be used under permissive condition, especially

cannot be used in strong magnetic field and under strong corrosive

environment;

◇ During the operating process, please obey the instruction to use correctly,

make sure safe operation, thus to avoid unnecessary loss;

◇ During testing process, if the instrument indicates that the power is too low,

please replace the battery in time to avoid the measurement error caused by

the voltage is too low;

◇ If the device is not used for a long time, the battery should be taken out and

placed separately, in order to prevent battery leakage damage to the device;

◇ Please contact us if there is any fault, do not disassemble and repair by

yourself.

6

Chapter Two: Brief Introduction of Host Machine、Keyboard and Display

2.1 Introduction of the host machine

Picture 2-1: SVLD 1 Valve Leakage Detector (AE) host machine

Picture 2-2: Sensor Sketch Map

7

2.2 Keyboard introduction

The keyboard of the leak detector is shown in picture 2-3。

Picture 2-3:Keyboard Sketch Map

Keyboard Introduction:

:”On and off”, press it for 2 seconds to turn the instrument on, at the same

time it performs the self-inspection; once under the testing condition, press it for

2 seconds to turn off the instrument. Press this button only for short time, turn on

or off the screen backlight

:Under the test interface, press this key to quickly switch and select the

gate. Press this key in the menu interface to select or change values up。

:press the key to enter the menu list, in the menu list can do setting、

8

calibration or view operations。

:In the test interface, press the key to analyze the current test data FFT,

display the FFT spectrogram, and press the key again to exit. Press this key in the

menu interface to perform the left selection operation。

:In the test interface, press the key to test, and the results are displayed

on the screen. Press this key in the menu interface to perform the confirmation

operation。

:In the test interface, press the key to save the current test results, and the

data is stored according to the valve number with time mark. Press this key in the

menu interface to perform the operation of right selection。

:In the test interface, press this key to switch the currently displayed

parameters; Press this key in the menu interface to perform the back operation。

:Under the test interface, press this key to quickly switch and select the

filter and sampling frequency of the current gate. Press this key in the menu

interface to select or change values down。

9

2.3 Display introduction

Picture 2-4:Test interface diagram

10

Chapter three: Menu and display

This chapter will introduce the menu functions and Settings,Press to enter

the menu interface, including four options :valve、 calibration、save and set, as

shown in picture 3-1.

Picture 3-1:Menu display

3.1 Valve

Enter the valve option to view the valves that have been set for the current

instrument, and to add or duplicate the valve number as needed (change valve

number), and to delete specified valve number.

Picture 3-2:Valve options related to operation

11

3.2 Calibration

Enter the valve calibration option to select the specified valve sampling rate and

filter, and at the same time, perform the calibration operation (detailed in chapter

4). According to the same valve, up to eight calibration curves can be set (namely,

a total of eight sampling rates and filters be matched). And the calibration curve

can be added or deleted

Picture 3-3:Calibration related operation

12

3.3 Save

Once enter the save, user can check and see the measured data and alarm data,

and check the total memory space and available space.

Picture: Saving related operation

13

3.4 Setting

The setting options include basic setting 、alarm setting and factory setting, in

which the factory setting is used by the manufacturer for debugging, and the

operator does not need to change it.

Picture 3-5: Setting option

3.4.1 Basic Setting:

Enter the basic Settings option and change the following Settings:

Date and time, once the data is stored, the current time is also stored for

easy looking up;

The key sound and backlight can be turned on or off

Unit can be set as the display unit of leakage amount:mL/min 或 L/min;

Language options can be switched between Chinese and English; The

power-saving mode can be turned on or off. The power consumption of the

instrument will be reduced when the power saving mode is turned on and

the battery life will be prolonged

Automatic shut down time can be set in min. All the series no of Hardware

version、 software version and logical version is systematically displayed,

and cannot be changed.

Click on factory Settings and it will prompt you to restore factory Settings.

Click confirm to restore factory Settings and the data will be cleared.

14

Picture 3-6:Basic setting related operation

15

3.4.2 Alarming Setting

When entering the alarm setting options, one or two alarm limits can be set; the

alarm output can turn off the alarm, or the alarm can be prompted by buzzing or

flickering mode; the alarm parameters can be selected as the reference standard

for the alarm (RMS/ASL/P) or leakage.

Picture 3-7: Alarming setting related operation

16

Chapter Four: Brief Operation Introduction

4.1 Value Setting

When setting valve number, input calibration leakage, setting time and date,

setting alarm line and so on, value will be needed. Take increasing valve number

as an example, press to select the position to be changed, press

buttons of to change the related numerical value, press to

complete the value.

Picture 4-1:Valve no setting

17

4.2 Test

No matter whether the instrument has been calibrated in advance or not, the

valve can be tested. The difference is that only the acoustic emission parameters

(RMS/ASL/P) are obtained when the instrument is not calibrated, and the

corresponding leakage is shown to be 0. After calibration, acoustic emission

parameters and corresponding leakage reference values can be displayed

simultaneously. Firstly, the sensor is well coupled to the valve to be tested and

pressed under the test interface. After the instrument completes the test, the

results are automatically displayed and the current display parameters are

switched by keys.

Picture 4-2: The display result of no-calibration and after- calibration

Note: After calibration, the instrument will make three independent curves

according to different parameters, and then get the reference value of leakage,

according to different parameters , the value of leakage will be different.

Table of contents