AECO SMC-12 NO R1 AGD1 User manual

www.aecosensors.com

YSM NNNNNN

SMC-12 NO R1 AGD1

YSM000020

SMC-12 NO R1 LC5 AGD1

YSM000021

SMC-12 NO R1 LC10 AGD1

YSM000022

SMC-12 NO R1 AGD1■

mm

mm

V

A

W/VA

Hz

°C

IP

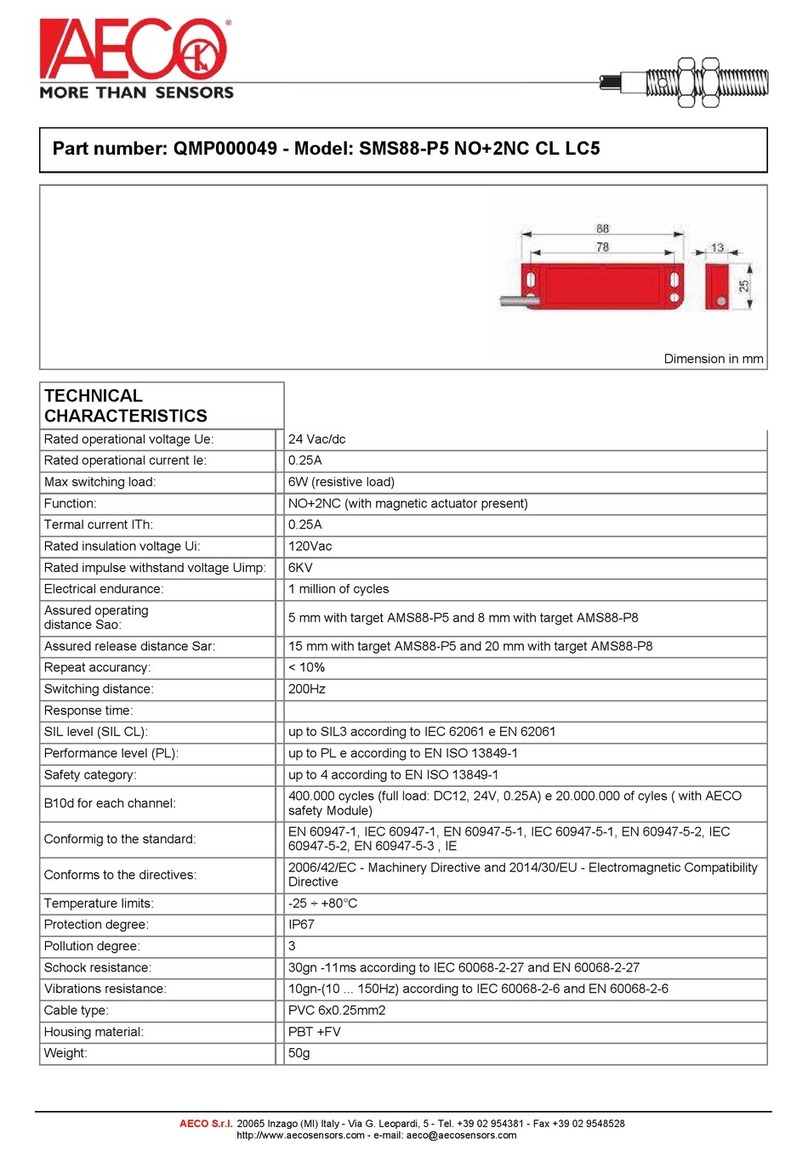

> 4

NO

230

0.5

50

230

-25 ÷ +70

67

2 x 0.25mm² PVC

FM010Ex Rev. A

50

CH17

M12x1

NO

SMC-12 NO AGD

LC10

1R1

LC5

ETC000466

BLUE

BROWN

Sensing distance (Sn)

Hysteresis (’’H’’)

Max switching voltage

Ambient temperature range

IP rating

Housing material

Cable

Output type

Max switching current

Max switching power

Max switching frequency

> 20 with M20 magnet

Nickel-plated Brass

2mt, 5mt or 10mt

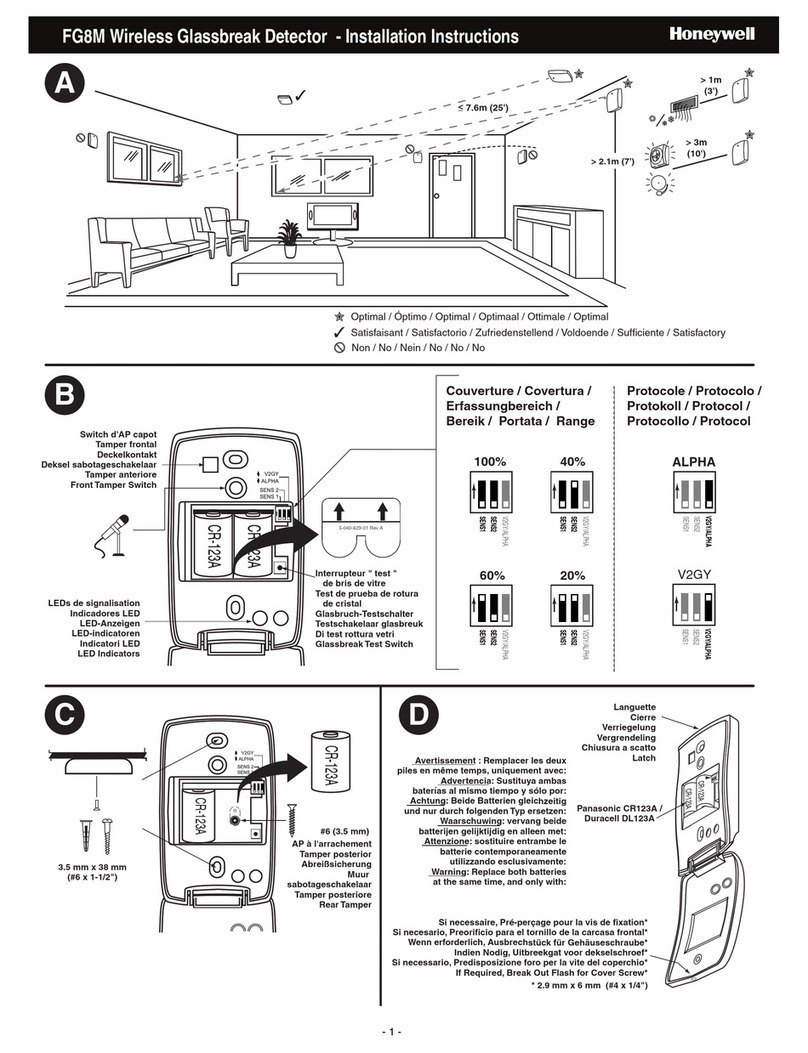

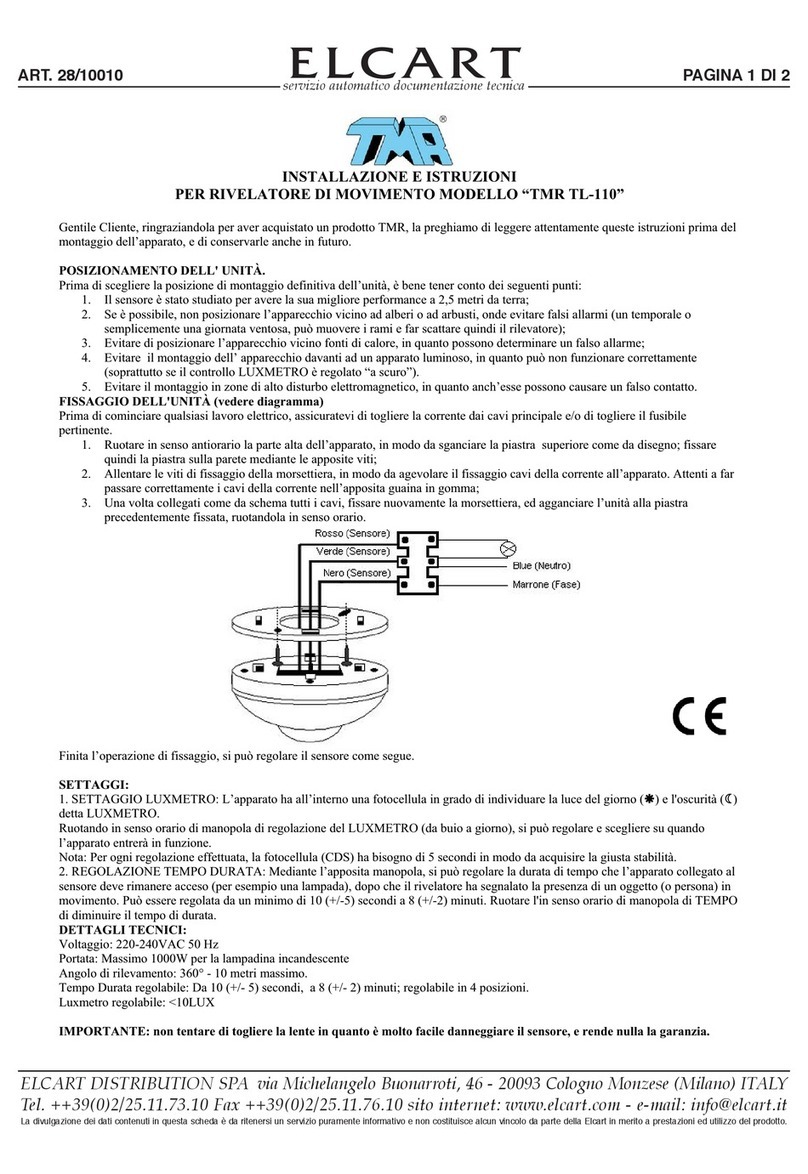

WIRING DIAGRAM

Characteristics

Models

Dimensions ‘’mm’’

4. Electrical and Mechanical Characteristics

( Description )( Code )

3.3 Product series

The magnetic sensors series includes the

models listed below :

SMC-12 NO R1 AGD1■

Potentially explosive atmosphere

with GAS and/or DUST.

Reed Contact model: Vmax = 230Vac/dc

Imax = 0.5A

Pmax= 50W/VA

Cable length "2mt".

Cable length "5mt".

Cable length "10mt".

Equipment category "1"

Magnetic Sensor with cylindrical housing

"M12x1" and "NORMALLY OPEN" output

3.2 Description diagram

3.1 Code diagram

Magnetic sensor intended for use in the explosive atmospheres

according to EU Directive ATEX 94/9 EC.

Progressive number

3. Sensor identification

The series is only identified by the '' ''

and '' ''. The diagrams for the decoding are shown below.

Code

Description

SMC-12 NO R1 AGD1■

1. Introduction

This manual should be read and understood in all its parts before proceeding

with installation of the sensor.

The Magnetic Sensors series, are intended to be

used in a potentially explosive atmospheres with presence of GAS and/or

DUST. They are designed and produced according to the requirements of the

following european standards:

* EN60079-0 - Explosive atmospheres - Part 0 : Equipment - General requi-

rements.

* EN60079-18 - Explosive atmospheres - Part 18 : Equipment protection by

encapsulation ‘’m’’.

* EN60079-26-Explosive atmospheres - Part 26 : Equipment with protection

level (EPL) Ga.

All sensors of this series are covered by the EC-type Examination Certificate

n ° issued by Notified Body IMQ spa.IMQ 12 ATEX 016X

SMC-12 NO R1 AGD1

■

2. Installation and Startup

The sensor must be installed, connected and activated only by specialized

personnel. Personnel must be familiar with the types of protection anti-ignition,

the production rules and regulations in the potentially explosive area. The user

is solely responsible for the choice and the use of sensor suitable to the final

application. When installing the sensor observe the following requirements:

Check whether the classification of the sensor is suitable for the application

(see‘’ATEX Marking’’ to paragraph 5 and marking on the equipment).

Make sure that the connection cable of the sensor does not have the

endings too tight. Moreover it must not prevent the movement of people

and/or things.

Do not touch uninsulated parts of the connecting cable of the sensor before

having it disconnected from the supply voltage. Do not install the sensor

during a thunderstorm with lightning.

If the cable is subject to movement, do not place the sheath with bending

radius too short; Pay attention to the mounting of the parties subject to

movement and to the fixed ones.

Separate the power cables from the connecting cable of the sensor.

Make sure that the sensor housing is always ground wired.

Operating Instructions

According to EU Directive 94/9 EC ( ATEX )

Annex II P1.0.6 group II, equipment category 1G/1D

GB

Sig. M. Scaramuzza

Fig. 1

BROWN

BLUE

SMC-12 NO R1 AGD1■

V= 230V I= 0.5A P= 50W/VA

Tamb: -25 ÷ +70°C

IMQ 12 ATEX 016X

88888

0722

II 1G Ex ma IIC T6 Ga

II 1D Ex ma IIIC T85°C Da IP67

AECO Inzago-MI-Italy

Fig. 2

DIC14014EX REV. 01

II 1D Ex ma IIIC T85°C Da IP67

II 1G Ex ma IIC T6 Ga Ta= -25 ÷ +70°C

0722

YSM000020

YSM000021

YSM000022

SMC-12 NO R1 AGD1

SMC-12 NO R1 LC5 AGD1

SMC-12 NO R1 LC10 AGD1

NO

Fp Fp

Via G. Leopardi 5 - 20065 Inzago ( MI ) Italia

Inzago: 2014/10/31

( Place and Date )

( Name and Signature )

( Description )( Code )

2006/95/CE - Low Voltage Directive

94/9/EC - ATEX Directive - GROUP CATEGORY EXPLOSIVE ATMOSPHERES

WITH PRESENCE OF GAS AND/OR THE

PRESENCE OF DUST

“II”

“G” ( )

“D” ( )

’’1”

ZONE 0

ZONE 20

MARKING :

( Title and / or number and date of issue of the standard )

according to the provisions of the European Directives:

EN 60079-0

August 2009

EN 60947-1

July 2007

EN 60947-5-1

June 2004

EN 60079-26

March 2007

EN 60079-18

December 2009

to which this declaration relates are in conformity with the following standards:

declare under our sole responsibility that the products:

(Product’s name )

MAGNETIC SENSORS

DECLARATION OF CONFORMITY

9. Declaration of Conformity

We, AECO s.r.l.

( Supplier’s name )

( Supplier’s address )

8. Maintenance

The sensor has no serviceable components and can not be changed and / or

repaired. In case of failure, please contact AECO srl customer service.

If necessary, you can ask AECO srl for a copy of the following documents :

Sensor Data Sheet

Declaration of Conformity

EC-Type Examination Certificate

You can also download the same documents from AECO web site

( ).

www.aecosensors.com

Production batch

ATEX Marking

EC-Type Examination

Certificate number

Ambient temperature range

‘’Model’’ description

Electrical parameters

Wiring diagram

7. Labelling

On every sensor of the '' ''

is applied as shown in Fig. 2 :

SMC-12 NO R1 AGD1■series a label

BROWN

BLUE

Signal

Signal

Sensor Field

If the non resettable fuse complies with IEC 60127 series or

IEC 60691 or ANSI/UL 248-1 only one fuse is necessary.

Protection Fuse

Fp =

Inf (A)= 1A

(Fuse nominal current)

Vnf (V)=230Vac

(Fuse nominal voltage)

Rupture capacity

1500A

Temperature class for GAS

Indicates the maximum surface temperature that can reach the sensor

at the maximum ambient temperature according to EN60079-0.

T6 Maximum surface temperature : 85 ° C

Maximum Surface Temperature for DUST

Indicates the maximum surface temperature that can reach the sensor

at the maximum ambient temperature according to EN60079-0.

T85 Maximum surface temperature : 85 ° C

Equipment Protection Level (EPL) for GAS

Indicates the level of protection of the equipment according to

:EN60079-18

Ga Equipment with protection level ' 'ma

Equipment Protection Level (EPL) for DUST

Indicates the level of protection of the equipment according to

:EN60079-18

Da Equipment with protection level ' 'ma

6. Conditions of use in potentially explosive area.

During the use of the sensor in potentially explosive atmosphere observing

the following instructions is important for safety :

The maximum permissible ambient temperature is Ta = +70 °C

To protect the sensor from damage due to shock and vibration

It is necessary to protect the circuit by connecting in series to the sensor

2 non resettable fast-acting fuses with the following ratings :

5. ATEX marking

II 1D Ex ma IIIC T85°C Da IP67

II 1G Ex ma IIC T6 Ga

ZONE 0, ZONE 1 and ZONE 2 (Atmosphere with GAS)

ZONE 20, ZONE 21 and ZONE 22 ( DUST)Atmosphere with

for use in

For all models '' '' refere to the ATEX

marking below indicated :

SMC-12 NO R1 AGD1■

The meaning of the symbols that make the marking is as follows:

Specific mark. Protection against explosion

II

Equipment group.

Category group.

1Equipment designed for use in places where

(ZONE 0 or ZONE 20).

an explosive atmosphere

is constantly present

Equipment suitable for use in all other places other than mines and

their surface installations.

GAtmosphere due to the presence of , and .gases vapors mists

DAtmosphere due to the presence of dust

Ex Equipment designed for use in potentially explosive atmospheres

Type of explosive atmosphere

ma

Type of protection

Encapsulation protection level according to .EN60079-18''ma''

Explosion group GAS

Specifies the explosion group wich the type of GAS belongs to,

according to EN 60079-20.

IIC The typical GAS of this group is the hydrogen

Explosion group DUST

IIIC Conductive dust

Specifies the explosion group wich the type of DUST belongs to,

according to EN 60079-0.

This manual suits for next models

5

Other AECO Security Sensor manuals

Popular Security Sensor manuals by other brands

olympia electronics

olympia electronics BSR-6060/A/MAR instruction manual

Powerfix Profi

Powerfix Profi PMDL 5 B1 operating instructions

Meec tools

Meec tools 010986 operating instructions

Ortus

Ortus PIR-R Operation manual

SImx

SImx LHT0142 installation manual

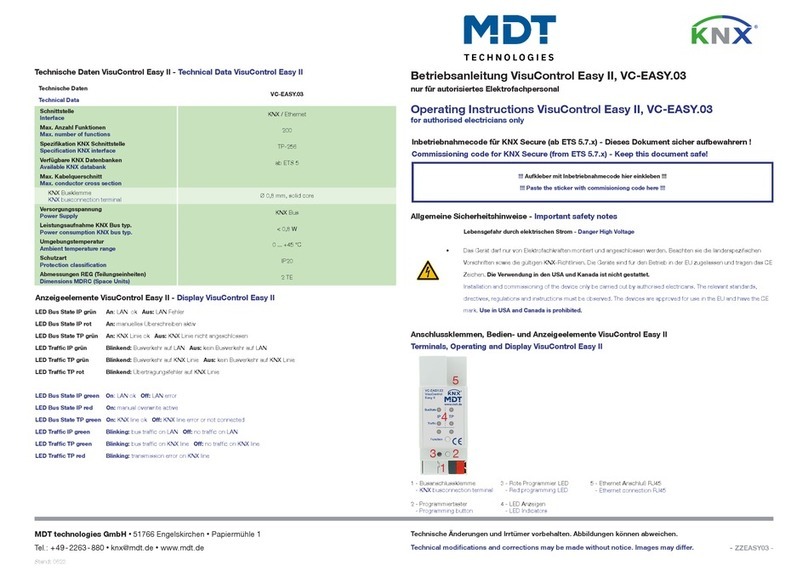

MDT Technologies

MDT Technologies VisuControl Easy II operating instructions

AccuTools

AccuTools eL-320 user guide

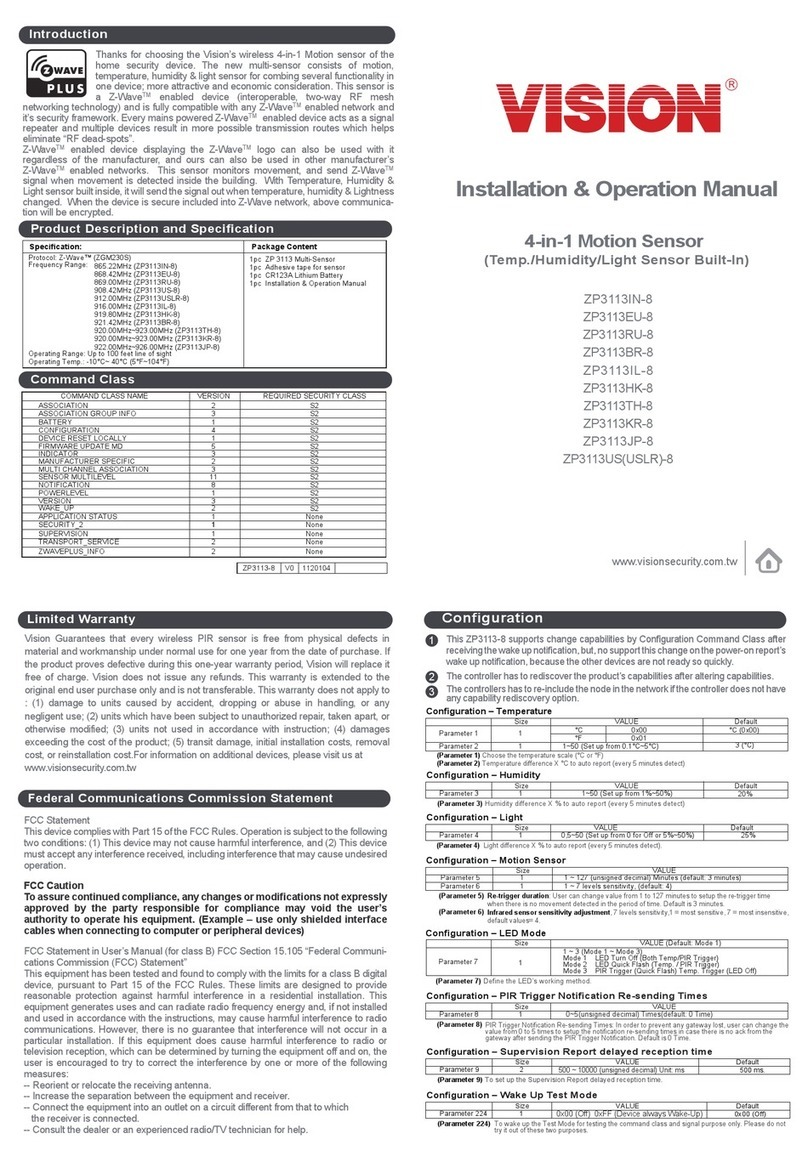

Vision

Vision ZP3113IN-8 Installation & operation manual

Leuze

Leuze MLD 300 operating instructions

Sonel

Sonel VT-2 instruction manual

ELCART

ELCART TMR TL-110 Installation and operating instructions

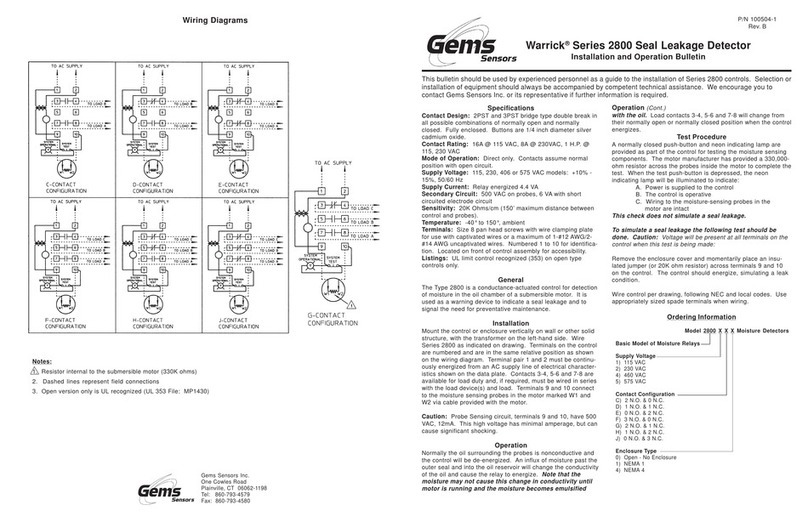

Gems Sensors

Gems Sensors Warrick 2800 Series Installation and Operation Bulletin