AEG Powertools PSD18B-254X User manual

2

2

Important!

It is essential that you read the instructions in this manual

before assembling, operating and maintaining the product.

Subject to technical modifications.

33

The following tools (not included) are needed for making adjustments:

COMBINATION SQUARECOMBINATION WRENCHFRAMING SQUARE

Ø 254 mm

n

max.

7000

Ø 30 mm

48HW 2.2mm

42

43

41

1

7

8

9

11

13

14

15

16

17

18

19

20

21

23

25

26

33

35

34

10

12

12

36

40

12

24

12

32

28

29

31

30

27

4

22

37 3938

23

6

5

1. “D” Handle

2. Laser button

3. LED button

4. Saw blade

5. LED light

6. Spindle lock button

7. Switch trigger

8. Lower guard lock out lever

9. Upper blade guard

10. Laser guide

11. Lower blade guard

12. Mouting hole

13. Right sliding fence

14. Extension bar

15. “No hands zone” boundary line

16. “No hands zone” label

17. Mitre lock knob

18. Detent release lever

19. Balancing foot

20. Throat plates

21. Mitre scale

22. Turning table

23. Saw base

24. Blade wrench

25. Fixed fence

26. Left sliding fence

27. Work clamp

28. Bevel scale

29. Depth stop

30. Head lock pin

31. Depth control knob

32. Sliding lock knob

33. Slide bar

34. Dust bag

35. Carrying handle

36. Battery pack

37. Sliding fence adjustment knob

38. Bevel lock knob

39. Single/dual bevel selector

40. Screws for fixing fence

41. 0° bevel stop screw

42. Right bevel angle adjusting screw

43. Left bevel angle adjusting screw

4

4

1- Mounting holes

2 - Mounting surface

3 - Base

Fig. 1

Fig. 2

2

11

3

2

1

3

Fig. 3

1

3

2

4

1 - Right sliding fence

2 - Slot

3 - Sliding fence adjustment knob

1 - Work clamp

2 - Base

3 - Single/dual bevel selector

4 - Work clamp knob

Fig. 4

Fig. 5

2

1

1 - Exhaust port

2 - Dust bag

1 - Extension bar

2 - Blade wrench

1

2

55

Fig. 6

1 - Mitre indicator screw

2 - Mitre scale indicator

3 - Detent release lever

4 - Mitre lock knob

5 - Miter scale

4

5

3

1

2

Fig. 8

1 - Fixed fence

2 - Mitre lock knob

3 - Detent release lever

4 - Turning table

5 - Framing square

6 - Saw blade

Fig. 7

1 - Indicator screw

2 - Scale indicator

3 - Bevel scale

1

3

4

1

6

2

3

5

Fig. 9

2

6

6

1

Fig. 10

1 - Saw blade

2 - Framing square

3 - Turning table

4 - Fixed fence

3

4

1

2

Fig. 12

Fig. 11

Fig. 13

View of blade not square with

fence, adjustments are required.

1 - Mitre scale indicator

2 - Mitre scale

3 - Mitre detent

1 - Screws for fixing fence

2 - Fence

1 - Mitre lock knob

2 - Detent release lever

3 - Detent override

23

1

2

1

4

2

3

2

1

77

Fig. 15

Fig. 14

Fig. 16

Fig. 17

1 - Saw blade

2 - Combination square

3 - Turning table

1 - Dust-proof cover

View of blade not square with

turning table, adjustments are required.

1

2

3

1

2

1

Ø 254 mm

n

max.

7000

Ø 30 mm

48HW 2.2mm

Note: Before use, replace

blade bolt cover screw and

tighten securely to prevent

blade bolt cover movement

6

17

4

3

2

8

To tighten

To loosen

1

1 - Blade bolt cover screw

2 - Outer flange

3 - Blade bolt

4 - Saw blade

5 - Inner flange

6 - Blade bolt cover

7 - Lower blade guard

8 - Blade wrench

9 - Spindle lock button

2

3

4

5

9

8

8

1 - Laser button

2 - Red line

Fig. 18 Fig. 20

Fig. 19

1 - “D” handle

2 - Head lock pin

1 - Depth stop

2 - Depth control knob

1

2

1

2

1

2

99

Cross cut

1 - Work clamp

2 - Mitre detent release button

3 - Mitre lock knob

Fig. 21

Fig. 22

1 - LED button

Fig. 23

Fig. 24

1 - Push back

1

3

2

Shadow of

blade teeth

projected

onto workpiece

1 - Sliding lock knob

2 - Slide cut

3 - Pull lower guard lock lever

4 - Slide saw arm forward, pull lower guard lock out lever

to unlock lower guard, then push down.

4

3

2

1

1

1

10

10

Bevel cut

1 - Bevel lock knob

2 - Single/dual bevel selector

Fig. 25

Fig. 26

Mitre cut

1 - Work clamp

1

1

Bevel cut

1 - Work clamp

Fig. 28

Compound mitre cut

1 - C-clamp (not included)

Fig. 27

1

2

2

11 11

Fig. 30

Fig. 32

Fig. 31

1 - Wide board

1

23

Ceiling

Wall

38°

52°

2

Top edge against fence:

Left side, inside corner

Right side, outside corner

1

Ceiling

Wall

45°

45°

1

4

3

Top edge against fence:

Left side, inside corner

Right side, outside corner

2

1 - Cut these grooves with saw

2 - Use a chisel to cut out the middle

3 - Workpiece

1 - Inside corner

2 - Sliding fence

3 - Outside corner

4 - Turning table

1 - Sliding fence

2 - Turning table

1 - Long workpiece

2 - Workpiece supports

2

1

1

Fig. 29

12

12

Fig. 33

Fig. 34

Fig. 35

Right

Fig. 36

Fig. 37

Wrong

1 - Spring clamp (not included)

2 - Molding

3 - Sliding fence

3

1 - 0º Bevel stop screw

1 - Left bevel angle adjusting screw

2 - Right bevel angle adjusting screw

Fig. 38

2

1Bottom edge against fence:

Left side, inside corner

Right side, outside corner

1 - Sliding fence

2 - Spring clamp (not included)

3 - Turning table

Crown molding nested against front facing mitre fence

2

13

1

2

1

13 13

Fig. 41

Fig. 42

1 - Throat plates

1 - Throat plates

2 - Mitre lock knob

2

1

Fig. 40

1

2

1

Fig. 39

1 - Rivets

2 - Guard block

1 - Laser adjustment screw #1

2 - Laser adjustment screw #2

3 - Laser adjustment screw #3

2

Unlock

Lock

1

1

3

2

14

14

TECHNICAL DATA SLIDE COMPOUND MITRE SAW PSD18B-254X

Voltage DC 18 V

Maximum cutting depth 91 mm

No-load speed 3900 min-1

Weight - excluding battery pack 15.6 kg

Saw blade diameter x hole diameter 254 x 30 mm

Saw blade thickness / kerf 1.6 mm / 2.2 mm

Maximum cutting capacity

Mitre 0°/ Bevel 0° 90 mm × 305 mm

Mitre 0°/ Bevel 45° (R) 39 mm × 305 mm

Mitre 0°/ Bevel 45° (L) 43 mm × 305 mm

Mitre Left 45°/ Bevel 0° 90 mm × 215 mm

Mitre Right 45°/ Bevel 0° 50 mm × 215 mm

Mitre 45°/ Bevel 45° (R) 39 mm × 215 mm

Mitre 45°/ Bevel 45° (L) 43 mm × 215 mm

Vertical Base

Mitre Left 45°/ Bevel 0° 19.1 mm × 105 mm

Mitre Right 45°/ Bevel 0° 19.1 mm × 88.9 mm

Nested Crown

Mitre 45°/ Bevel 0° 88.9 mm

Minimum workpiece dimensions 215 mm × 35 mm × 2.5 mm

Laser class Class 1

Laser wavelength λ 650 nm

Laser maximum power 1 mW

Measured values determined according to EN61029

A-weighted sound pressure level LP= 89.0 dB(A)

Uncertainty K K = 3 dB(A)

Measured values determined according to EN61029

A-weighted sound power level LW= 98.5 dB(A)

Uncertainty K K = 3 dB(A)

The vibration total values (triaxial vector sum) determined according to EN61029

Vibration emission value ah= 1.1 m/s2

Uncertainty K K = 1.5 m/s2

REPLACEMENT PARTS

Saw blade 089292001099

Combination wrench 089292001078

Dust chute rubber 089292001111

Work clamp 089292001800

Dust bag 089292001705

BATTERY AND CHARGER

Compatible battery pack

(not included)

Compatible charger

(not included)

L1815R

L1820R

L1825R

L1830R

L1840R

L1850R

L1860R

AL1218G

BL1218

BLK1218

Use AEG 18V battery and charger only.

15 15

WARNING!

Read all safety warnings and all instructions. Failure to follow

the warnings and instructions may result in electric shock, re and/

or serious injury.

Save all warnings and instructions for future reference.

GENERAL SAFETY WARNINGS

WARNING

When using electric tools, basic safety precautions should

always be followed to reduce the risk of re, electric shock and

personal injury. Read all these instructions before attempting to

operate this product and save these instructions.

Keep work area clear. Cluttered areas and benches invite injuries.

Consider work area environment. Do not expose tools to rain. Do

not use tools in damp or wet locations. Keep work area well lit. Do

not use tools in the presence of ammable liquids or gases.

Guard against electric shock. Avoid body contact with earthed

or grounded surfaces (e.g. pipes, radiators, ranges, refrigerators).

Keep other persons away. Do not let persons, especially children,

be involved in the work, touch the tool or the extension cord, and

keep them away from the work area.

Store idle tools. When not in use, tools should be stored in a dry

locked-up place, out of reach of children.

Do not force the tool. It will do the job better and safer at the rate

for which it was intended.

Use the right tool. Do not force small tools to do the job of a heavy

duty tool. Do not use tools for purposes not intended, for example,

do not use circular saws to cut tree limbs or logs.

Dress properly. Do not wear loose clothing or jewellery, they can

be caught in moving parts. Non-skid footwear is recommended

when working outdoors. Wear protective hair covering to contain

long hair.

Use protective equipment. Use safety glasses. Use face or dust

mask if working operations create dust.

Connect dust extraction equipment. If the tool is provided for

the connection of dust extraction and collecting equipment, ensure

these are connected and properly used.

Do not abuse the cord. Never yank the cord to disconnect it from

the socket. Keep the cord away from heat, oil and sharp edges.

Secure work. Where possible, use clamps or a vice to hold the

work. It is safer than using your hand.

Do not overreach. Keep proper footing and balance at all times.

Maintain tools with care. Keep cutting tools sharp and clean for

better and safer performance. Follow instruction for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have them repaired by an authorised service facility.

Inspect extension cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

Disconnect tools. When not in use, before servicing and when

changing accessories such as blades, bits and cutters, disconnect

tools from the power supply.

Remove adjusting keys and wrenches. Form the habit of

checking to see that keys and adjusting wrenches are removed

from the tool before turning it on.

Avoid unintentional starting. Ensure switch is in “off” position

when installing battery pack.

Use outdoor extension leads. When the tool is used outdoors,

use only extension cords intended for outdoor use and so marked.

Stay alert. Watch what you are doing, use common sense and do

not operate the tool when you are tired.

Check damaged parts. Before further use of tool, it should be

carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting and any other

conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced by an authorised

service centre unless otherwise indicated in this instruction manual.

Have defective switches replaced by an authorised service centre.

Do not use the tool if the switch does not turn it on and off.

Warning. The use of any accessory or attachment other than the

one recommended in this instruction manual may present a risk of

personal injury.

Have your tool repaired by a qualied person. This electric tool

complies with the relevant safety rules. Repairs should only be

carried out by qualied persons using original spare parts otherwise

this may result in considerable danger to the user.

MITRE SAW SAFETY WARNINGS

Always clamp the workpiece safely and securely.

Ensure that the machine is always stable and secure (e.g. xed to

a bench).

Always wear ear protectors. Exposure to noise can cause hearing

loss.

Always wear safety goggles when using the machine. It is

recommended to wear gloves for handling blades and rough

material, as well as sturdy non-slip shoes which also protect the

feet from workpieces that may fall from the cutting area.

Always remove the plug or battery pack before carrying out any

adjustment, maintenance or cleaning on the machine.

Ensure the machine is switched off before installing or removing

the battery pack.

Do not stand in a line with the saw blade in front of the machine.

Always stand aside of the saw blade.

Keep hands, ngers, and arms away from the rotating saw blade.

Never reach into the area near the blade, unless the blade has

completely stopped.

Before use, thoroughly check the tool for any damage or material

fatigue. Repairs should only be carried out by authorised service

agents.

Always use the guards on the machine. Do not use the machine if

the guards are not in place and working correctly.

Do not clamp the protective swing guard.

If the workpiece or blade becomes jammed, turn the mitre saw

“OFF”. Wait for all moving parts to stop and disconnect the plug

from the power source and/or remove the battery pack. Then work

to free the jammed material.

Never alter of modify the saw or its function. Your safety may be

compromised.

Do not use saw blades which are cracked, damaged, or deformed.

Do not use saw blades made of high-speed steel.

Only use saw blades which are sharp. Replace blunt blades with a

new replacement.

Use a blade holder or wear gloves when handling a saw blade.

Always use blades with the correct size and shape of arbour holes.

Blades that do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

Use only woodworking blades specied in this manual, which

comply with EN 847-1.

Do not use any anges, washers, and nuts to secure the saw blade

other than those supplied or indicated in the instruction manual.

It is essential to adhere to the maximum speed specied on the

saw blade.

It is necessary to select a saw blade which is suitable for the

material being cut.

Never use the mitre saw to cut materials other than those specied

16

16

in the intended use section in this manual.

Replace the table insert when worn or damaged.

Before work, make a dummy cut without the motor turned on so the

position of the blade, operation of the guards with respect to other

machine parts, and workpiece may be checked.

Refrain from removing any cut-offs or other parts of the workpiece

from the cutting area while the machine is running and the saw head

is not in the rest position.

When transporting the machine, use only transportation devices

and never use guards for handling or transportation.

The handle lock must always be engaged when transporting the

mitre saw.

Keep the oor area free of loose material e.g. chips and cut-offs.

Long workpieces must be adequately supported.

Stock having a round or irregular cross section (such as rewood)

which cannot be clamped securely by the provided clamp must

not be cut. When sawing into the edge of thin or layered stock, a

suitable auxiliary fence must be used to provide support.

The dust produced when using this tool may be harmful to health.

Use a dust suction system and wear a suitable dust protection

mask. Remove deposited dust thoroughly, e.g. with a vacuum

cleaner.

Connect the saw to a dust-collecting device when sawing wood.

Do not replace the LED or laser with a different type. Any repairs

must only be carried out by the manufacturer or authorised service

agent.

SAFETY INSTRUCTIONS FOR WOOD CUTTING BLADE

Please read the manual and instructions carefully before using the

saw blade and the machine.

The machine must be in good condition, the spindle without

deformation and vibration.

Do not use the saw without the guards in position, keep guards in

good working order and properly maintained.

Ensure the operator is adequately trained in safety precautions,

adjustment, and operation of the machine.

Always wear goggles and ear protection when using the machine. It

is recommended to wear gloves, sturdy non-slip shoes and apron.

Before using any accessory, consult the instruction manual. The

improper use of an accessory can cause damage and increase the

potential for injury.

Use only blades specied in this manual, complying with EN 847-1.

Observe the maximum speed marked on the saw blade. Ensure

the speed marked on the saw blade is at least equal to the speed

marked on the saw.

Always use blades with correct size and shape of arbour holes.

Blades that do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

Do not use blades of larger or smaller diameter other than

recommended. Do not use any spacers to make the blade t onto

the spindle.

Check the tips of the saw blade for damage or abnormal appearance

before each use. Tips that are damaged or loose can become ying

objects in use and increase the chance of personal injury.

Do not use cracked or distorted saw blades. Do not use saw blades

that are damaged or deformed.

Scrap the saw blade if damaged, deformed, distorted or cracked,

repairing is not permitted.

Do not use HSS blades.

Ensure the saw blade is mounted correctly, tighten the arbor nut

securely before use (tightening torque approx. 12 Nm).

Fastening screw and nuts shall be tightened using the appropriate

spanner, etc.

Extension of the spanner or tightening using hammer blows is not

permitted.

Make sure the blade and anges are clean and the recessed sides

of the collar are against the blade.

Make sure the blade rotates in the correct direction.

Before work, make a dummy cut without the motor turned on so the

position of the blade, operation of the guards with respect to other

machine parts and workpiece may be checked.

Never leave the machine unattended.

Do not apply lubricants on the blade when it is running.

Never perform any cleaning or maintenance work when the machine

is still running and the head is not in the rest position.

Never attempt to stop a machine in motion rapidly by jamming a tool

or other means against the blade, serious accidents can be caused

unintentionally in this way.

Disconnect the saw from the mains supply or remove battery pack

before changing blades or carrying out maintenance.

Pay attention to blade packing and unpacking, it is easy to be

injured by the sharp blade tips.

Use a blade holder or wear gloves when handling a saw blade.

Keep and store the blade in original packaging or other suitable

packaging, keep in dry conditions and away from chemicals which

may damage the blade.

LASER SAFETY RULES

■The laser radiation used in this saw is Class 1 with maximum

<1mW and 650nm wavelengths. Do not view directly with

optical instruments. Failure to comply with the rules could result

in serious personal injury.

■Do not stare into beam during operation.

■Do not project the laser beam directly into the eyes of others.

Serious eye injury could result.

■Do not place the laser in a position that may cause anyone to

stare into the laser beam intentionally or unintentionally.

■Do not use optical tools to view the laser beam.

■Do not operate the laser around children or allow children to

operate the laser.

■Do not attempt to repair the laser device by yourself.

■Do not attempt to change any parts of the laser device by

yourself.

■Any repairs must only be carried out by the laser manufacturer

or authorized service agent.

■Do not replace the laser with a different type.

SPECIFIED CONDITIONS OF USE

The slide compound mitre saw is intended for sawing solid and

bonded wood with or without glued veneer, plastics, and materials

similar to wood.

The slide compound mitre saw is intended to be used only by adult

operators who have read the instruction manual and understand the

risks and hazards.

The slide compound mitre saw is designed to be xed at the base

to a solid bench top. If the base is not securely xed, the whole

machine may move during cutting operations, which increases the

possibility of serious personal injury.

The slide compound mitre saw is designed make bevel and mitre

cuts. The capacities for the various cuts are provided in the product

specications in this manual.

The slide compound mitre saw is to be used in dry conditions, with

excellent ambient lighting and adequate ventilation.

The slide compound mitre saw is intended for consumer use and

should only be used as described above and is not intended for

any other purpose.

17 17

RESIDUAL RISKS

Even when the slide compound mitre saw is used as prescribed,

it is still impossible to completely eliminate certain residual risk

factors. The following hazards may arise and the operator should

pay special attention to avoid the following:

■Risk of contact with uncovered parts of the rotating saw blade.

■Kick-back of work pieces or parts of work pieces due to improper

adjustment or handling.

■Catapulting of faulty carbide tips from the saw blade. Wear Eye

protection at all times.

■Damage to the respiratory system. Wear respiratory protection

masks containing filters appropriate to the materials being

worked. Ensure adequate workplace ventilation. Do not eat,

drink or smoke in the work area.

■Damage to hearing if effective hearing protection is not worn.

WARNING

Dust from certain paints, coatings, and materials may cause

irritation or allergic reactions. Dust from wood such as oak,

beech, MDF, and others are carcinogenic. Materials containing

asbestos should only be worked on or processed by qualied

specialist operators.

WARNING

Injuries may be caused or aggravated by prolonged use of a

tool. When using any tool for prolonged periods, ensure you take

regular breaks.

ASSEMBLY

UNPACKING

Packing list

■Dust bag x 1

■Work clamp x 1

■Left sliding fence x 1

■Right sliding fence x 1

■Extension bar x 2

■Dust chute rubber x 1

■L1860R battery pack x 2 (PSD18B-254-062 only)

■Charger x 1 (PSD18B-254-062 only)

■Operator’s manual x 1

■Battery manual x 1 (PSD18B-254-062 only)

■Charger manual x 1 (PSD18B-254-062 only)

The product requires assembly.

Carefully lift saw from the carton by the carrying handle and the saw

base, and place it on a level work surface.

The product has been shipped with the saw arm secured in the

down position. To release the saw arm, push down on the top of the

saw arm, cut the tie-wrap, and pull out the head lock pin.

WARNING

The saw arm is spring loaded. Hold the handle down to prevent

saw arm from snapping up when cutting the tie-wrap. Failure to

do so could result in possible serious injury.

■Lift the saw arm by the handle. Hand pressure should remain on

the saw arm to prevent sudden rise upon release of the tie wrap.

■Inspect the product carefully to make sure no breakage or

damage occurred during shipping.

■Do not discard the packing material until you have carefully

inspected and satisfactorily operated the product.

■The product is factory set for accurate cutting. After assembling

it, check for accuracy. If shipping has influenced the settings,

refer to specific procedures explained in the manual.

WARNING

If any parts are damaged or missing, do not operate the product

until the parts are replaced. Use of the product with damaged or

missing parts could result in serious personal injury.

WARNING

Do not attempt to modify the product or create accessories not

recommended for use with the product. Any such alteration or

modication is misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING

To prevent accidental starting that could cause serious personal

injury, always remove the battery packs from the product when

assembling parts.

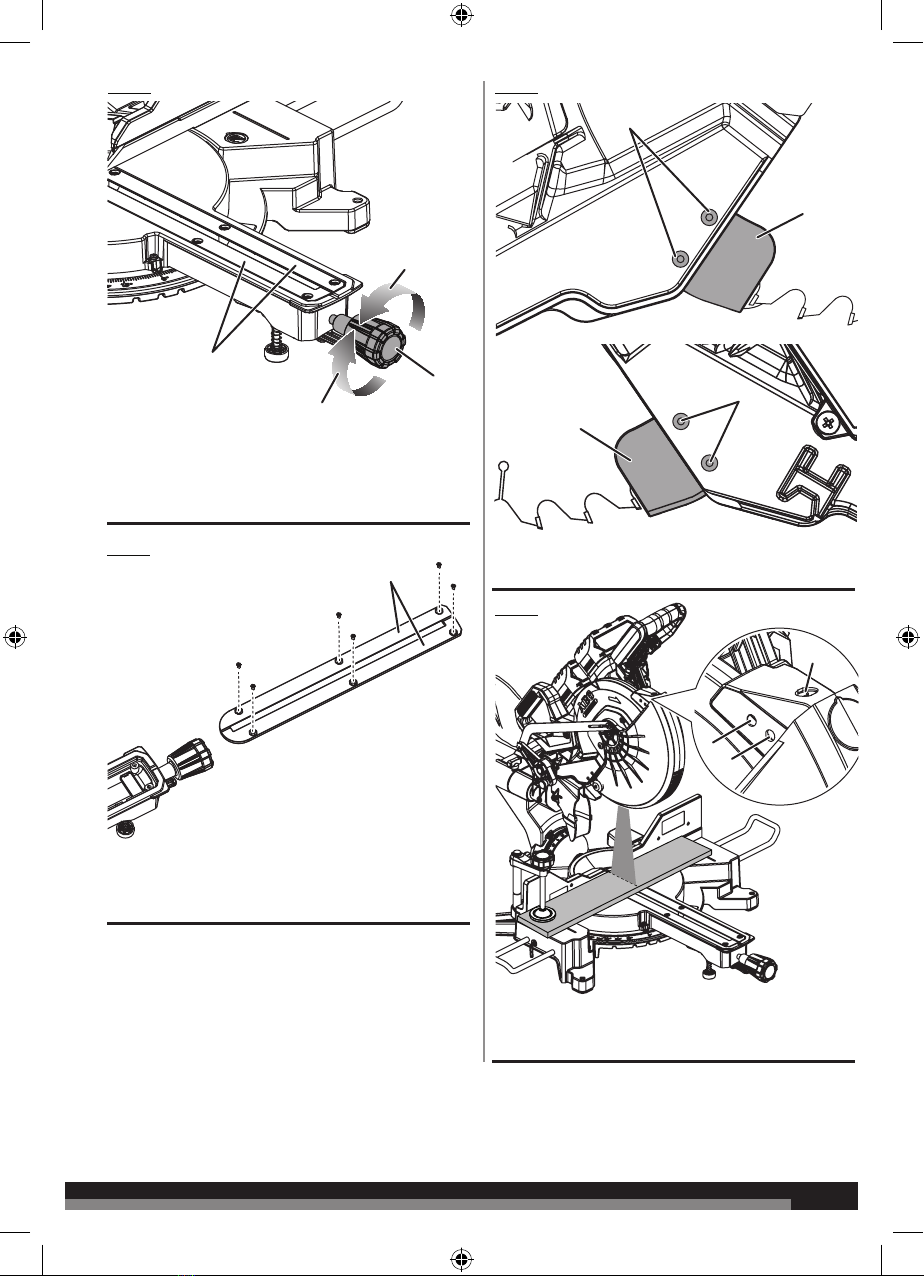

INSTALLING EXTENSION BARS

See gure 1.

Insert each of the extension bars in the holes at the side of the saw

base. Align the holes on the bars and under the saw base. Tighten

with screws.

MOUNTING HOLES

See gure 2.

WARNING

Before starting any cutting operation, mount the product to a

solid workbench. Never operate the product on the oor or in

a crouched position. Failure to heed this warning can result in

serious personal injury.

The product should be mounted to a rm supporting surface such

as a workbench, mounting board. Four bolt holes have been

provided in the saw base for this purpose. Each of the four mounting

holes should be bolted securely using 7.9 mm (5/16 in.) machine

bolts, lock washers, and hex nuts (not included). Bolts should be

of sufcient length to accommodate the saw base, lock washers,

hex nuts, and the thickness of the workbench. Tighten all four bolts

securely.

The hole pattern for mounting to a workbench is shown in gure 1.

Carefully check the workbench after mounting to make sure that no

movement can occur during use. If any tipping, sliding, or walking is

noted, secure the workbench to the oor before operating.

18

18

CARRYING HANDLE

WARNING

Only use the lift handles on the table and/or the carrying handle

on top to move or carry the product. Never use the “D” handle and

always remove the battery before moving. Carrying the product

with the “D” handle may cause inadvertent switch actuation and

may result in serious personal injury.

BLADE WRENCH

A blade wrench is packed with the product. One end of the wrench

is a Phillips screwdriver and the other end is a hex key. Use the

hex key end when installing or removing blade and the Phillips end

when removing or loosening screws. A storage area for the blade

wrench is located at the left side of the saw base.

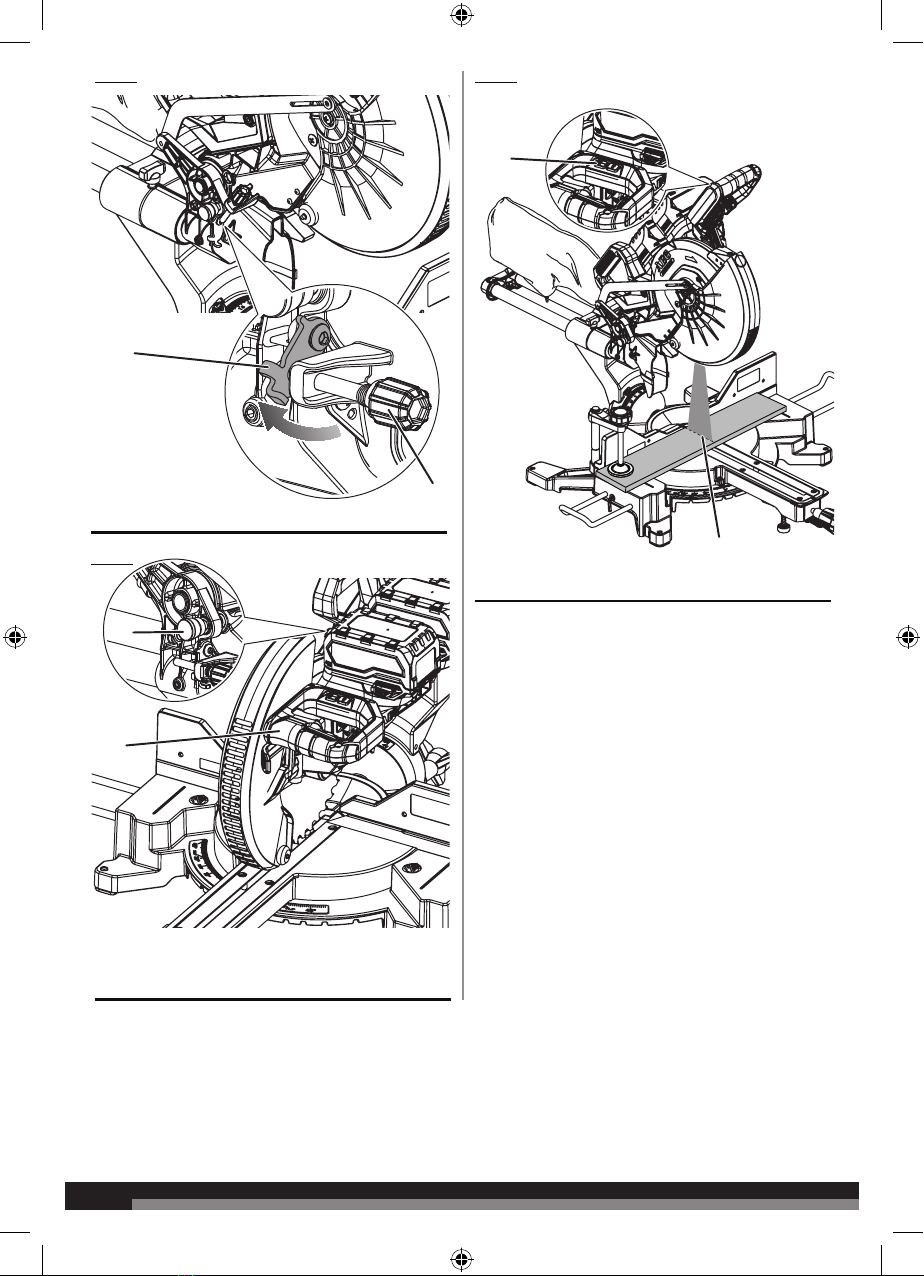

INSTALLING SLIDING FENCE

See gure 3.

■Turn the sliding fence adjustment knob counterclockwise, to

clear fence slots.

■Install the sliding fence. Lower fence into fence slot. Be sure

side of fence lines up flush with side of fixed fence.

■Tighten sliding fence adjustment knob securely.

NOTE: To remove the sliding fence, loosen the sliding fence

adjustment knob. Then, slide the fence towards the blade to take

out.

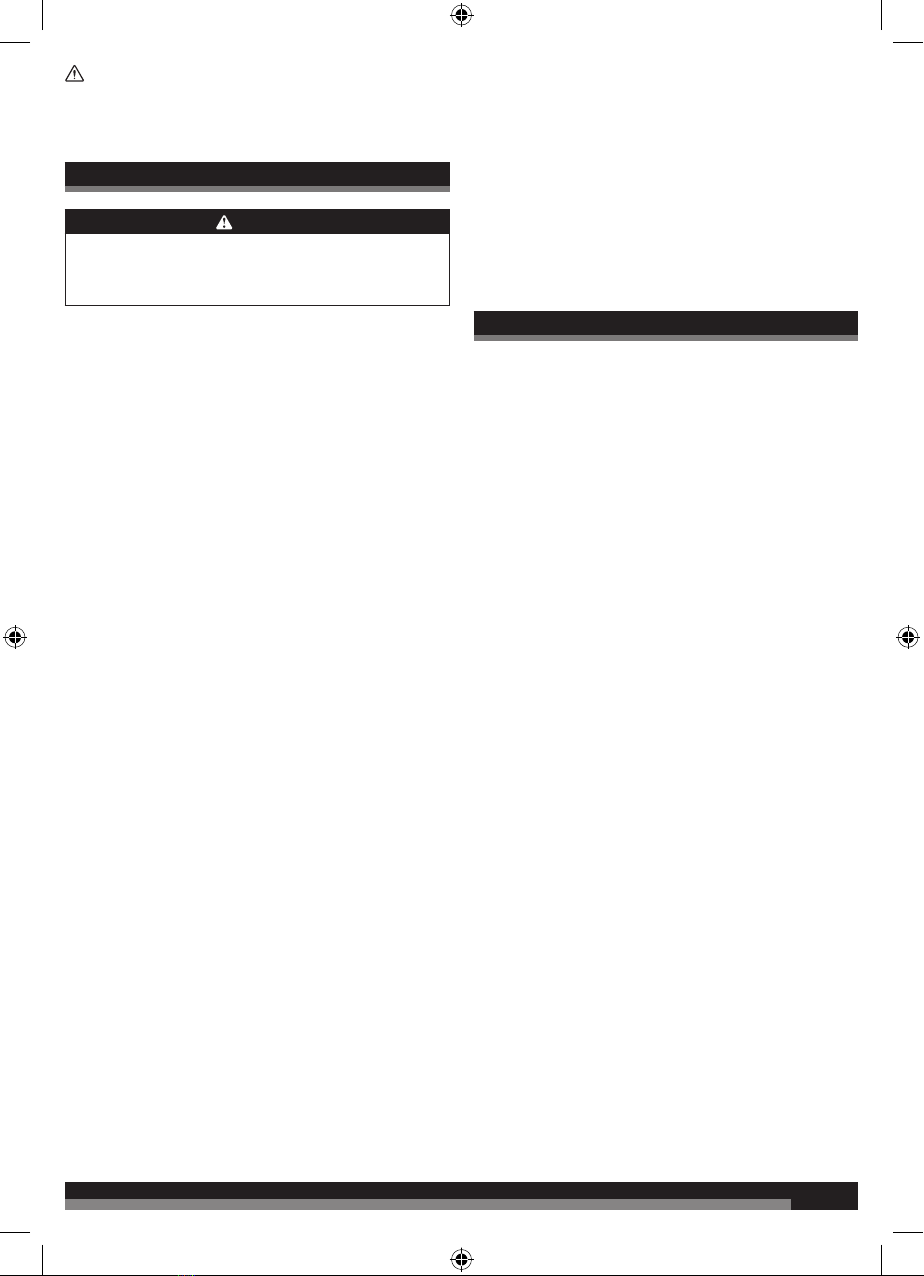

INSTALLING THE WORK CLAMP

See gure 4.

WARNING

In some operations, the work clamp assembly may interfere with

the operation of the blade guard assembly. Always make sure

there is no interference with the blade guard prior to beginning

any cutting operation to reduce the risk of serious personal injury.

The work clamp provides greater control by clamping the workpiece

to the table. It also prevents the workpiece from creeping towards

the saw blade.

Depending on the cutting operation and the size of the workpiece,

it may be necessary to use a C-clamp (not included) instead of the

work clamp to secure the workpiece prior to making the cut.

To install the work clamp:

■Place the shaft of the work clamp in either hole on the turning

table base.

■Rotate the work clamp knob on the work clamp to move it in or

out as needed.

NOTE: Many of the illustrations in this manual show only portions

of the product. This is intentional so that we can clearly show points

being made in the illustrations. Never operate the product without all

guards securely in place and in good operating condition.

DUST BAG

See gure 5.

■To install the dust bag and frame assembly, slide the open end

of the frame onto the exhaust port.

■For efficient operation, empty the dust bag before it is half full.

This will permit better air flow through the bag.

INSTALLING THE DUST CHUTE RUBBER

See gure 6.

The rubber part of the dust chute requires user assembly.

■Insert the tab on the dust chute rubber in the indent of the main

dust chute, so that the tab faces inward of the dust chute.

■Wrap the dust chute rubber around the main dust chute. Pass

the hole on the rubber through the tab on the main dust chute.

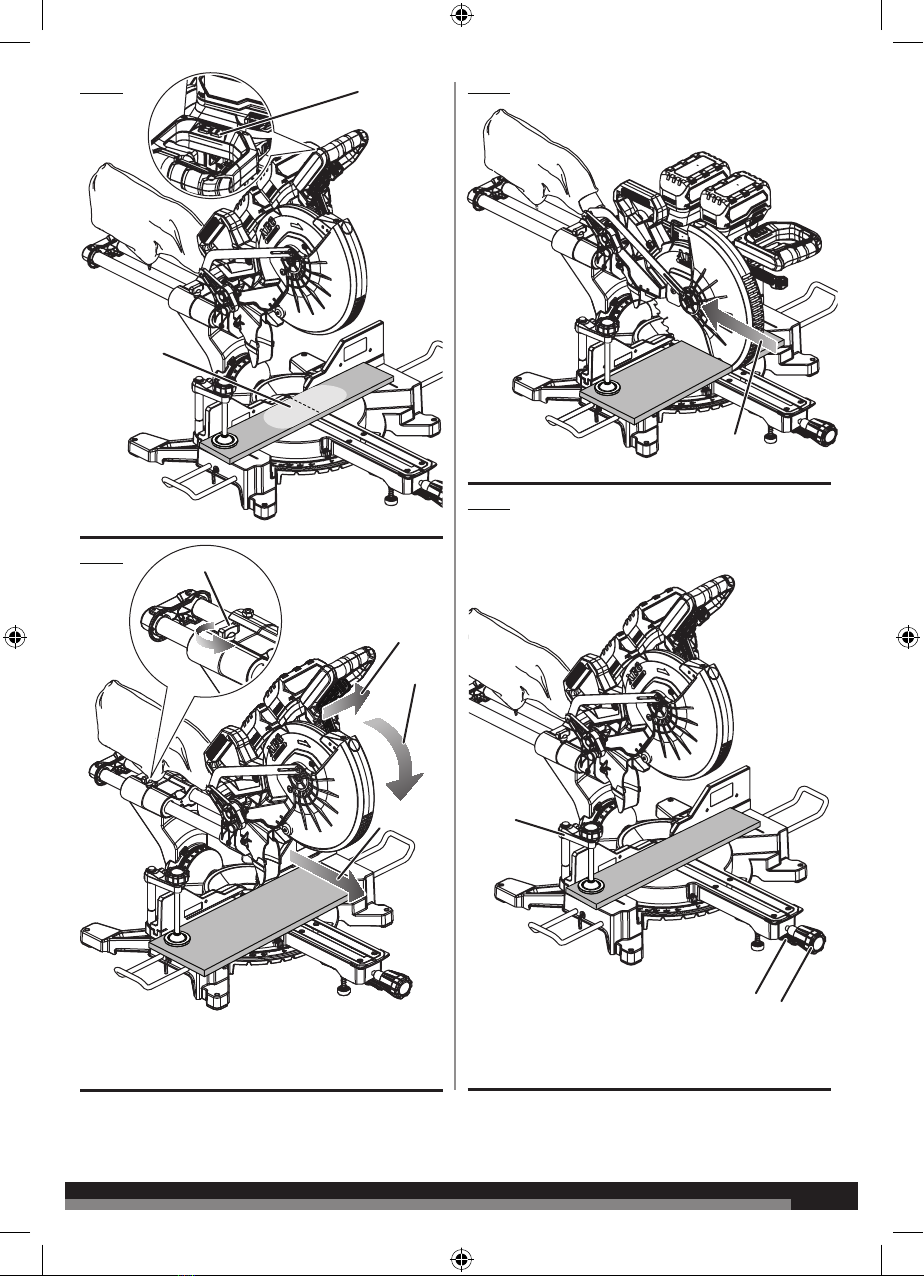

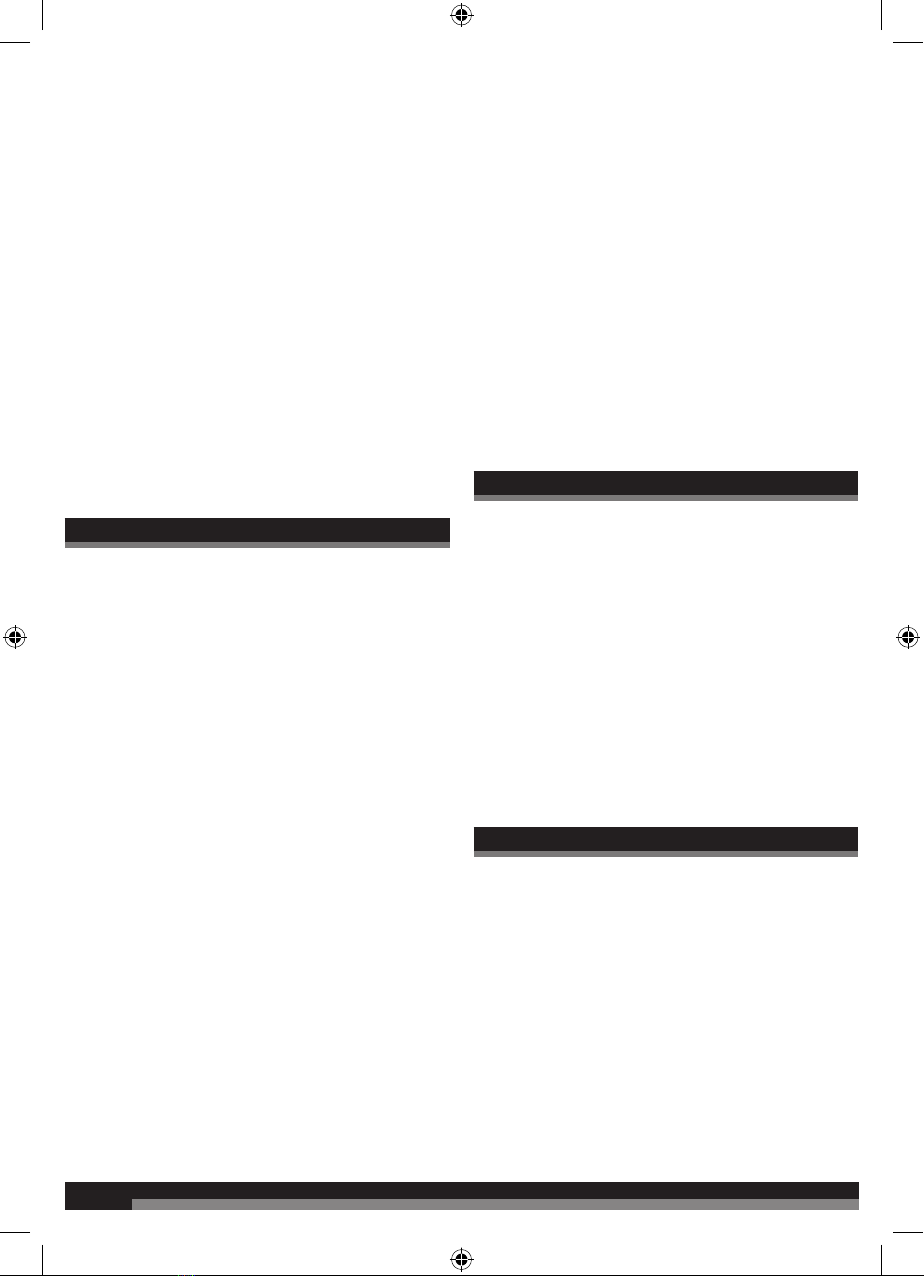

SQUARING THE SAW BLADE TO THE FENCE

See gures 7 - 13.

■Remove the battery packs from the product.

■Pull the saw arm all the way down and lock in transport position.

■Loosen the mitre lock knob to unlock the turning table.

■ Squeeze the detent release lever. Rotate the turning table until

the scale indicator is positioned at 0°.

■Release the detent release lever, and ensure the control arm is

seated in the positive notch.

■Tighten the mitre lock knob to secure the turning table.

■Loosen bevel lock knob and set saw arm at 0° bevel (blade set

90° to turning table). Tighten bevel lock knob.

■ Lay a framing square flat on the turning table. Place one leg of

the square against the fence. Slide the other leg of the square

against the flat part of saw blade.

NOTE: Make sure that the square contacts the flat part of the

saw blade, not the blade teeth.

■ The edge of the square and the saw blade should be parallel.

■If the front or back edge of the saw blade angles away from the

square, adjustments are needed. See figure 11.

■Refer to To adjust the mitre angle in the Adjustments section for

mitre angle adjustment.

SQUARING THE BLADE TO THE TURNING TABLE

See gures 14.

To square the blade at 0°:

■Remove the battery packs from the product.

■Pull the saw arm all the way down and engage the head lock pin

to hold the saw arm in transport position.

■Loosen the mitre lock knob, then depress and hold the detent

release lever to release the turning table.

■Rotate the turning table until the scale indicator is positioned

at 0°.

■Release the detent release lever and allow the turning table to

engage the 0° detent position. Tighten the mitre lock knob to

secure the turning table.

■Push the single/ dual bevel selector inward. See figure 4.

■Loosen bevel lock knob and tilt saw arm until it is seated in the

positive 0° bevel stop (blade set 90° to turning table). Tighten

bevel lock knob.

■ Place a combination square against the turning table and the

flat part of saw blade.

NOTE: Make sure that the square contacts the flat part of the

saw blade, not the blade teeth.

■Rotate the blade by hand and check the blade-to-table

alignment at several points.

■ The edge of the square and the saw blade should be parallel.

■If the top or bottom of the saw blade angles away from the

square as shown in figure 14, adjustments are needed.

■Loosen the bevel lock knob.

■Adjust 0° bevel stop screw to bring saw blade into alignment

with the square. See 0° Bevel Adjustment in the Adjustments

section.

■Retighten bevel lock knob. Recheck blade-to-table alignment.

To square the blade at 45°:

■Loosen the bevel lock knob and set the saw arm at 45° bevel.

19 19

Tighten bevel lock knob.

NOTE: To obtain right bevel angles, pull the single/ dual bevel

selector out and tilt the saw to the desired angle.

■ Using a combination square, check the blade-to-table alignment

as described earlier.

■If adjustments are needed, refer to 45° Bevel Adjustment in the

Adjustments section.

■ The product has several scale indicators. After squaring

adjustments have been made, it may be necessary to loosen

the indicator screws and reset them to zero. See figures 7-8.

OPERATION

WARNING

Do not allow familiarity with products to make you careless.

Remember that a careless fraction of a second is sufcient to

inict severe injury.

WARNING

Always wear eye protection with side shields. Failure to do so

could result in objects being thrown into your eyes, resulting in

possible serious injury.

WARNING

Do not use any attachments or accessories not recommended

by the manufacturer of the product. The use of attachments or

accessories not recommended can result in serious personal

injury.

WARNING

To avoid serious personal injury, always tighten the mitre lock

knob and tighten the bevel lock knob securely before making a

cut. Failure to do so could result in movement of the control arm

or turning table while making a cut.

WARNING

Do not start the product without checking for interference

between the blade and the mitre fence. Damage could result

to the blade if it strikes the mitre fence during operation of the

product. Failure to heed this warning can also result in serious

personal injury.

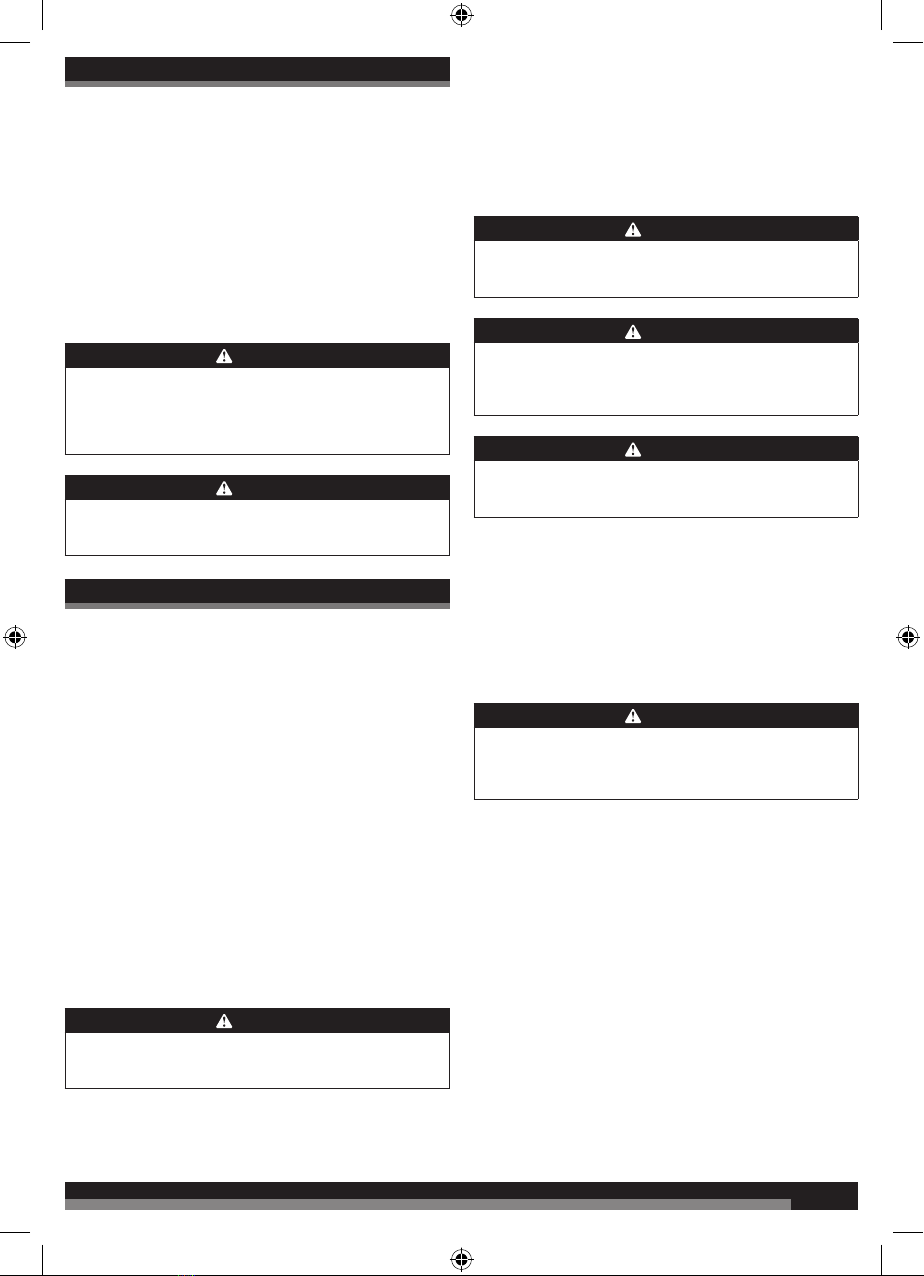

INSTALLING/REMOVING THE BATTERY PACKS

See gure 15.

■Place the battery packs in the product. Align the raised rib on

each battery pack with the groove inside the saw, then slide

each battery pack into the product.

■Make sure the latches on each side of the battery pack snap

into place and the battery pack is secured in the saw before

beginning operation.

■Depress the latches to remove the battery pack.

■For complete charging instructions, see the operator’s manuals

for your battery pack and charger.

WARNING

Always remove battery packs from the product when you are

assembling parts, making adjustments, cleaning, or when not in

use. Removing battery packs will prevent accidental starting that

could cause serious personal injury.

BATTERY PORT DUST COVER

See gure 16.

The battery port dust cover prevents dust from entering the battery

port. Cover the battery ports when battery packs are not in place.

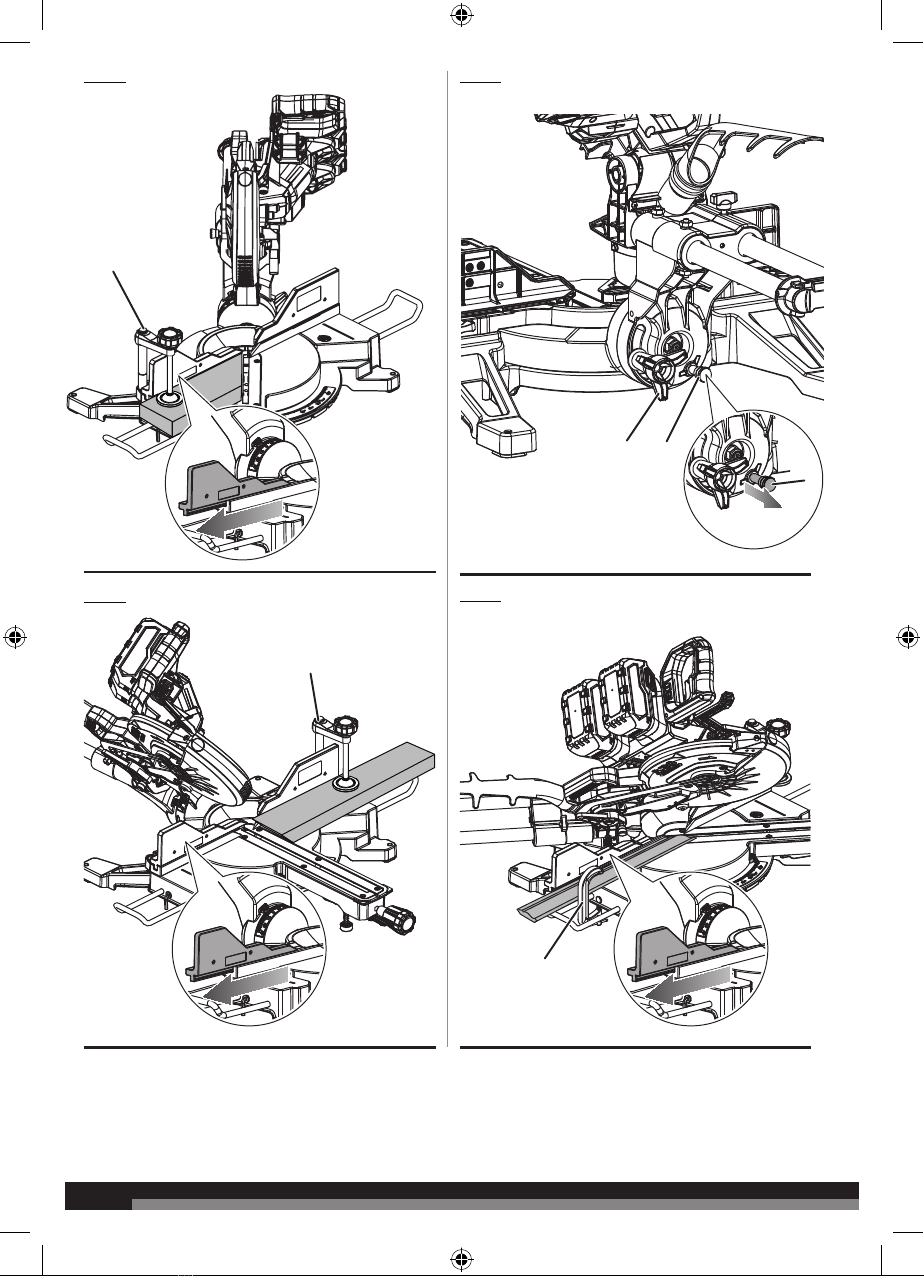

REPLACING THE BLADE

See gure 17.

WARNING

Before removing and tting the blade, make sure to wear safety

gloves.

WARNING

A 254 mm (10 in.) blade is the maximum blade capacity of the

product. Never use a blade that is too thick to allow outer ange

to engage with the ats on the spindle. Larger blades will come

in contact with the blade guards, while thicker blades will prevent

the blade bolt from securing the blade on the spindle. Either of

these situations could result in a serious accident and can cause

serious personal injury.

WARNING

Only use the blade specied in this manual and its speed is at

least equal to the speed marked on the product.

■Remove the battery packs from the product.

■Raise saw arm.

■Rotate lower blade guard up and loosen blade bolt cover screw.

Slide blade bolt cover towards upper blade guard to expose the

blade bolt.

■Depress the spindle lock button and rotate the blade bolt until

the spindle locks.

■Using the blade wrench provided, loosen and remove the blade

bolt.

NOTE: The blade bolt has left hand threads. Turn blade bolt

clockwise to loosen.

■Remove the outer flange. Wear gloves. Remove the blade.

Wear gloves when handling the saw blade.

■Wipe a drop of oil onto the inner flange and the outer flange

where they contact the blade.

WARNING

If inner ange has been removed, replace it before placing blade

on spindle. Failure to do so could cause an accident since blade

will not tighten properly.

■Wear gloves. Fit saw blade inside upper blade guard and onto

spindle. The blade teeth point downward at the front of saw as

shown in figure 17.

■Replace the outer flange. The double “D” flats on the blade

washers align with the flats on the spindle.

■Depress spindle lock button and replace blade bolt.

NOTE: The blade bolt has left hand threads. Turn blade bolt

20

20

counterclockwise to tighten.

WARNING

Always install the blade with the blade teeth and the arrow

printed on the side of the blade pointing down at the front of

the saw. The direction of blade rotation is also stamped with an

arrow on the upper blade guard.

■Tighten blade bolt securely.

■Replace blade bolt cover and tighten blade bolt cover screw

securely.

■Lower the blade guard.

■Raise and lower the saw arm to ensure lower blade guard

functions correctly.

USING THE DEPTH GUIDE

See gure 18.

When used, the depth guide limits the downward travel of the blade

when cutting dadoes and other non-through cuts.

To use the depth guide:

■Remove the battery pack from the product.

■Rotate the depth stop outward.

■With the depth control knob touching the depth stop, adjust the

depth control knob by turning the knob until the desired depth

of cut is attained.

■Rotate the depth stop inward for normal through cuts.

NOTE: The depth stop must be pushed in before locking/unlocking

the saw arm.

LOCKING / UNLOCKING THE SAW ARM

See gure 19.

When locking and unlocking the saw arm, it is not necessary to

loosen the depth control knob, however the depth stop must be

pushed in.

To unlock and raise the saw arm:

■Firmly grasp the “D” handle and apply downward pressure while

at the same time pulling the head lock pin out and away from

the saw housing.

■Raise the saw arm.

To lock the saw arm:

■Pull the lower guard lock out lever to right side to unlock the

lower guard.

■Firmly grasp the “D” handle and apply downward pressure until

head stops. Push in the head lock pin towards the saw allowing

it to lock the saw into place.

CUTTING WITH THE PRODUCT

WARNING

Secure the workpiece to the mitre saw base. Use the clamp

provided and, where necessary, use additional clamps or

holding mechanisms to prevent unintentional movement of the

workpiece while cutting.

WARNING

Never move the workpiece or make adjustment to any cutting

angle while the saw is running and the blade is rotating. Any

slip can result in contact with the blade causing serious personal

injury.

WARNING

Do not try to cut narrow pieces using the sliding feature. Failure

to heed this warning could result in serious personal injury.

LASER GUIDE

See gure 20.

For more accurate cuts, a laser guide is included with the mitre saw.

When used properly, the laser guide makes accurate, precision

cutting simple and easy.

■To use the laser guide, press the laser switch. The laser guide

will automatically turn off after 10 seconds.

NOTE: The laser guide will automatically turn on when the

switch trigger is depressed.

LED LIGHTING SYSTEM

See gure 21.

The LED lighting system casts the shadow of the blade onto the

workpiece. This results in greater accuracy of cuts and requires no

adjustments.

■To use this feature, press the LED button. The LED light will

automatically turn off after 15 seconds.

NOTE: The LED light will automatically turn on when the switch

trigger is depressed.

■Bring the saw arm down so that the blade is approximately 6.3

mm (1/4 in.) from the workpiece. The shadow of the blade will

be projected onto the workpiece, indicating where the blade

teeth will make contact as the cut is made.

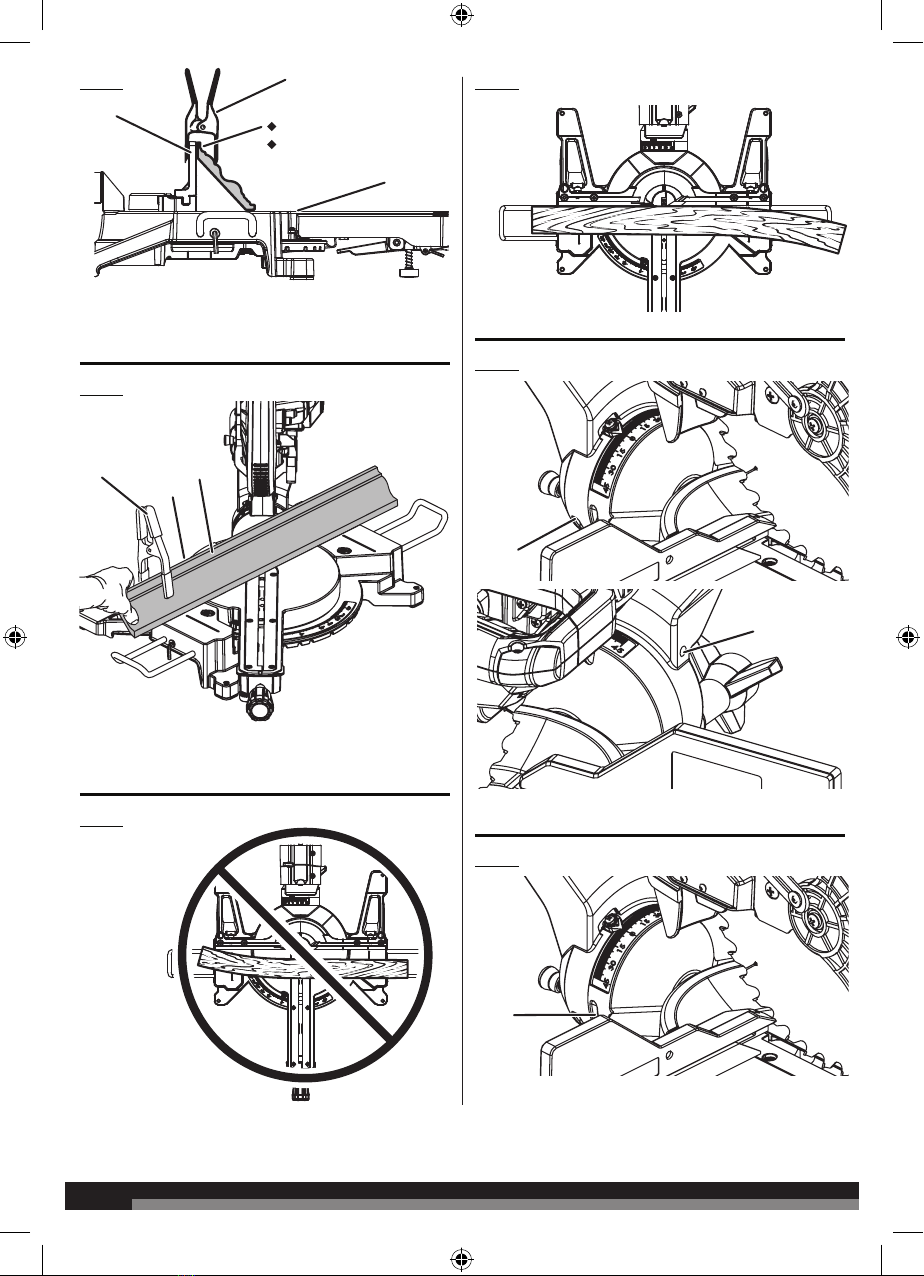

TO SLIDE CUT

See gures 22-23.

WARNING

Never make a cut by pulling the saw towards you as the blade

can climb on top of the workpiece and come towards you. Failure

to heed this warning could result in serious personal injury.

■The sliding feature will cut workpieces up to 305 mm (12 in.)

wide x 90 mm (3-1/2 in.) thick.

■ With the saw off, pull the saw arm forward. Squeeze the switch

trigger (let blade reach maximum speed), then push the blade

down on top of the workpiece then back towards the rear of the

saw to make a cut. Cuts are made by: pushing the saw blade

away from you and towards the bevel scale at the back of the

saw, stopping when the full rear position has been reached after

each cut. When the saw is running (turned on), never pull the

saw blade towards you or towards the front of the saw.

■Raise saw arm to its full height.

■Tighten the mitre lock knob to secure the turning table.

■Place the workpiece flat on the turning table securely against

the fence. If the board is warped, place the convex side against

the fence. If the concave edge of a board is placed against the

fence, the board could collapse on the blade at the end of the

cut, jamming the blade. See figures 35 - 36.

■When cutting long pieces of lumber or molding, support the

opposite end of the stock with a roller stand or with a work

surface level with the saw table. See figure 29.

■Align the cutting line on the workpiece with the edge of saw

blade.

■Loosen the sliding lock knob by turning the knob

counterclockwise.

■Press the LED button to project the blade’s shadow onto the

workpiece.

Table of contents

Other AEG Powertools Saw manuals