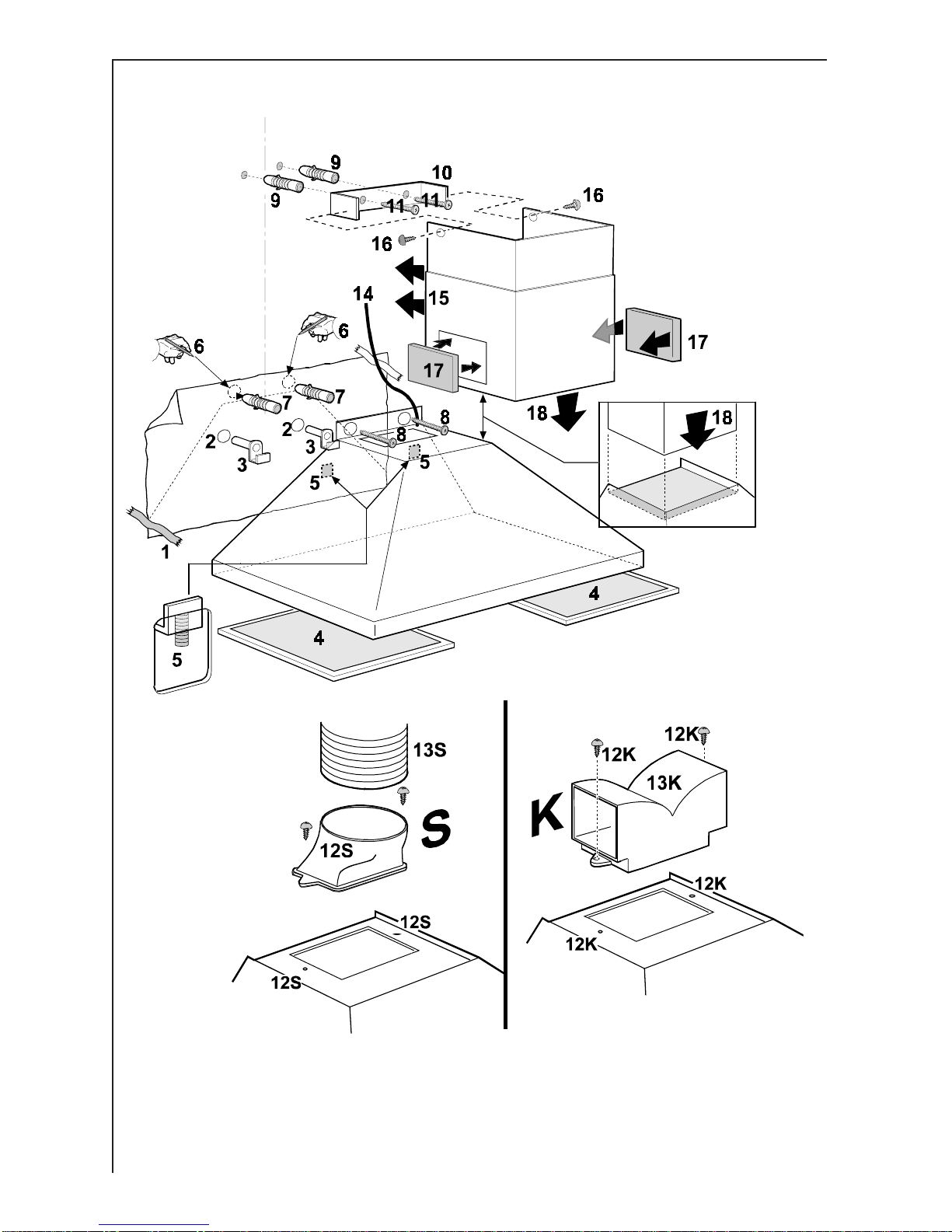

8

●Regulations on fuel-burning systems specify a maximum

depression of 0.04 bar in such rooms.

●Hoodscanonlybeusedsafelywithappliancesconnectedtoa

chimneyiftheroomand/orflat(air/environmentcombination)is

ventilatedfromoutsideusingasuitableventilationholeapproxi-

mately500-600cm2 toavoidthepossibilityofadepressionbeing

createdduringoperationofthehood.

Ifyouhaveanydoubts,contacttherelevantcontrollingauthority

orbuildinginspector’soffice.

●Sincetheruleforroomswithfuelburningappliancesis“outlethole

ofthesamesizeastheventilationhole”,aholeof500-600cm2,

whichistosayalargerhole,couldreducetheperformanceofthe

extractorhood.

●Ifthehoodisusedinitsfilteringfunction,itwilloperatesimplyand

safelyintheaboveconditionswithouttheneedforanyofthe

aforementionedmeasures.

●Whenthehoodisusedinitsextractorfunction,thefollowingrules

mustbefollowedtoobtainoptimaloperation:

—shortandstraightoutlethose

—keepbendsinoutlethosetoaminimum

—neverinstallthehoseswithanacuteangle,theymust

alwaysfollowagentlecurveonly

—keepthehoseaslargeaspossible(120mmØmin.).

●Failuretoobservethesebasicruleswilldrasticallyreducethe

performance and increase the noise levels of the extractor

hood.

●Where flexible ducting is fitted the length should be no more

than:

— 3 metres with one 90° bend

— 2 metres with two 90° bends.

Bends of more than 90° will reduce the efficiency of the hood

and reduce the air flow.